Pickleball is one of the fastest-growing sports globally, with over 50 million participants anticipated by 2025. This surge creates enormous opportunities for companies involved in sports equipment manufacturing, distribution, and strategic planning. In this article, we explore the factors fueling this growth, analyze the manufacturing processes driving high-performance pickleball paddles1, and provide actionable insights for B2B decision-makers looking to capitalize on the booming market.

The rapid rise of pickleball can be attributed not only to its popularity among all age groups but also to its minimal learning curve and wide social appeal. According to recent data, the sport has witnessed exponential growth in participation, with numbers increasing by nearly 45% in a single year. This trend is not limited to the United States; international markets, particularly in Asia and Europe, are embracing pickleball as a mainstream recreational activity.

Several factors contribute to this surge:

- Low barrier to entry: Pickleball requires minimal equipment and space, making it accessible in community parks, corporate wellness programs, and urban centers.

- Social and health benefits: The sport promotes physical fitness, mental well-being, and social interaction, increasingly valued by modern consumers.

- Media exposure and sporting events: Increased media coverage, tournaments, and social media engagement are simultaneously boosting participation and awareness.

The growth in consumer demand is driving both manufacturers and distributors to rethink their strategies, invest in product innovation, and re-evaluate their market positioning, especially as the sport evolves from a recreational pastime to a competitive arena.

The pickleball market is being influenced by several interrelated factors that create a robust environment for growth:

-

Demographic Shifts:

The aging population in many developed countries is seeking low-impact sports that provide excellent cardiovascular benefits. Pickleball fits this niche perfectly with its simple rules and effective workout regimen. -

Competitive and Recreational Demand:

As interest grows at both competitive and casual levels, there is increased demand for high-performance equipment. Decision-makers in sports equipment companies are urged to invest in cutting-edge materials and production processes to meet diverse consumer needs. -

Economic Considerations:

The sports equipment industry is witnessing a shift where quality and performance are equally prioritized by consumers, leading to an upward trend in investment for premium materials and innovative manufacturing techniques. -

Global Market Penetration:

While the US continues to be a robust market, Asia and Europe are emerging as reliable growth corridors. This shift encourages companies to rethink product customization and diversification to appeal to local tastes and regulatory standards.

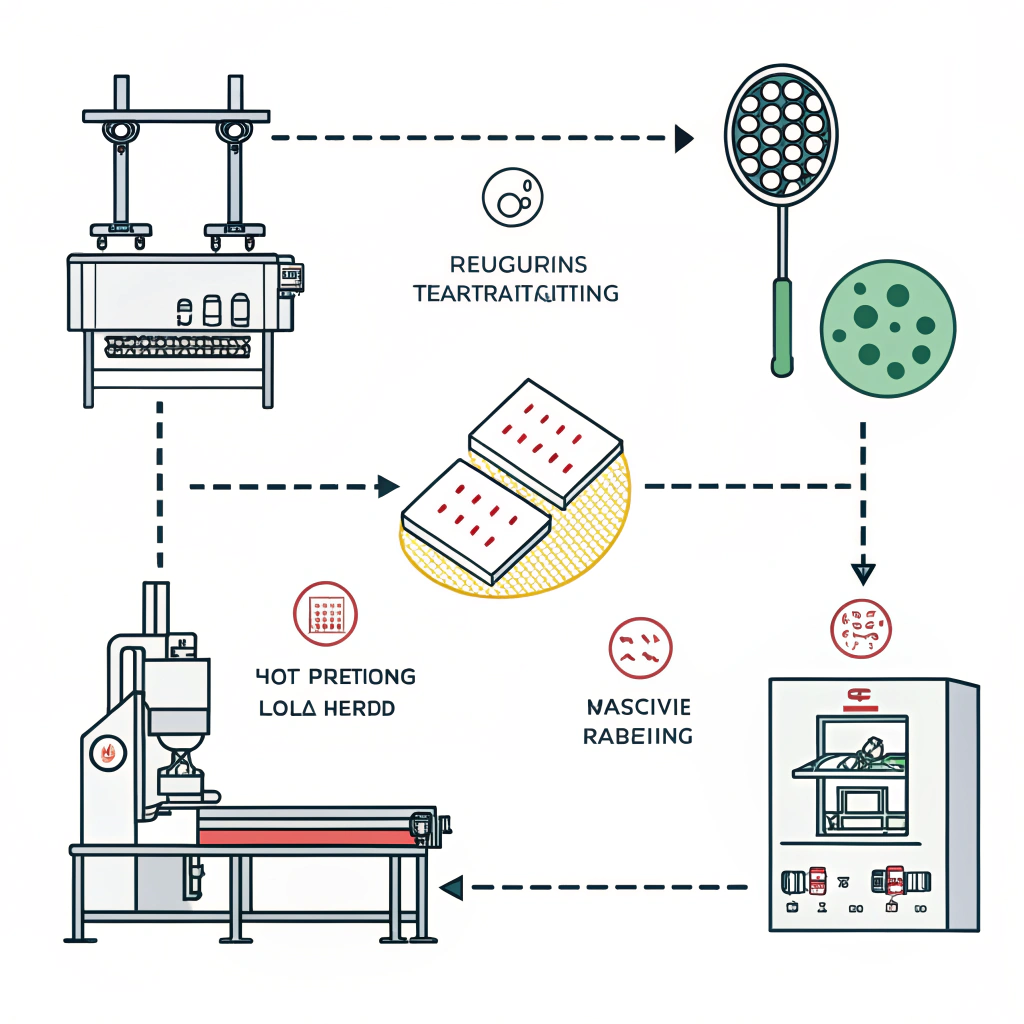

Central to capitalizing on the pickleball trend is the ability to deliver high-performance pickleball paddles1 using advanced manufacturing processes. At NEX Pickleball, we utilize cutting-edge techniques to meet the demands of both competitive and recreational players. Understanding these processes is crucial for B2B stakeholders who are evaluating potential investments in equipment technology and production capacity.

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | - High production efficiency - Produces strong, durable paddles with excellent impact resistance - Ensures structural integrity for high-performance play | - Risk of altering material properties, which can affect paddle feel - High initial equipment investment |

| **Cold Pressing2 | - Precise control over paddle thickness and structure - Maintains original material properties - Enhanced ball control and responsiveness | - Longer production cycles compared to hot pressing - Requires high-quality equipment for pressure precision |

| **Thermoforming3 | - Creates paddles with intricate designs and precise material distribution - Maintains paddle stability under varied conditions - Suitable for premium and custom-made paddles | - Requires longer production time - Higher equipment and operational costs |

At NEX Pickleball, these processes are optimized to deliver paddles that enhance performance, durability, and comfort. We offer options crafted from 3K Carbon Fiber4, 12K Carbon Fiber, and T300 Carbon Fiber, each selected for its unique balance of strength, flexibility, and lightweight properties. Additionally, our composite materials, such as the blend of carbon fiber with fiberglass and bamboo cores, provide players with products that meet specific performance benchmarks and market demands.

The selection of materials and manufacturing techniques is based on extensive testing and feedback from professional players, ensuring that every paddle not only meets but exceeds performance expectations. This approach is instrumental in driving brand loyalty and securing long-term partnerships in the competitive sports equipment market.

For decision-makers and strategic partners evaluating opportunities in the pickleball sector, several key considerations can help align investments with market demand:

-

Leverage Data for Market Positioning:

Investment strategies should be data-informed. Analyze participation trends, geographic growth patterns, and consumer behavior statistics to tailor product portfolios to emerging market needs. Brands that adopt this approach differentiate themselves through innovation and agile market responses. -

Invest in Advanced Manufacturing:

High-performance paddles require production techniques that balance efficiency, quality, and customization. Consider expanding production capabilities in processes like thermoforming and cold pressing, which offer precision and flexibility. These methods are particularly valuable for premium products and custom orders. -

Strengthen Supply Chain Partnerships:

Forming strategic alliances with leading manufacturers such as our company can provide access to superior technology and materials. Such partnerships can improve product quality, reduce lead times, and open new distribution channels. -

Capitalize on Emerging Markets:

With rapid growth in regions outside of the US, especially in Asia and Europe, companies should consider localized product adaptations. Understanding regional consumer insights and regulatory standards can create a competitive edge and facilitate successful market entries. -

Focus on Product Differentiation:

In a competitive landscape, product differentiation is key. Ensure that your paddle designs stand out by emphasizing features such as enhanced grip, optimal weight distribution, and innovative materials. Customization options that cater to specific player needs will further boost brand appeal.

Strategic investments in production technology and targeted market research can secure a competitive advantage in the evolving sports equipment industry. These steps not only align with current consumer trends but also set the stage for long-term growth as pickleball continues its global surge.

Looking ahead, brands must consider both immediate trends and potential future shifts in the sports landscape. While pickleball remains at the forefront, diversification into other emerging sports can provide additional revenue streams and mitigate market risks.

The current data indicates that pickleball is experiencing unprecedented growth. However, the competitive landscape may soon witness a shift towards other racket sports, such as padel5, which is already popular in Europe. The convergence of these trends necessitates that companies not only invest in pickleball but also remain agile enough to capture opportunities in adjacent markets.

Three strategic trends to watch include:

- Technological Innovation: Continued advancements in manufacturing techniques will further streamline production and enhance product quality. Innovations in materials like advanced carbon fibers and new composite blends will lead to lighter, stronger paddles.

- Consumer-Centric Customization: As players seek products tailored to their unique preferences, companies that offer customization—as with different core materials and grip sizes—will stand out.

- Sustainability and Eco-friendly Manufacturing: Increasingly, consumers and organizations are prioritizing sustainability. Investments in eco-friendly materials and efficient manufacturing processes can improve market reception and strengthen brand reputation.

For sports equipment brands and distributors, embracing these trends not only ensures relevance in the short term but also builds a foundation for innovation and leadership in the long haul.

In conclusion, the pickleball market represents a dynamic and rapidly expanding opportunity for stakeholders. By leveraging data insights, investing in advanced production technologies, and strategically expanding into adjacent markets, decision-makers can navigate the challenges and capitalize on the growth trends. Aligning production capabilities with market demand is essential for delivering products that enhance performance and build brand equity. Now is the time to evaluate your investment strategy, strengthen supply chain partnerships, and prepare for a future where pickleball and related sports continue to redefine the competitive landscape.

Q: How popular is pickleball in 2025?

A: As of 2025, pickleball is extremely popular with over 50 million players worldwide, making it the fastest-growing sport in regions like the US and gaining significant traction in Asia, including markets like Singapore.

Q: What is the future growth of pickleball?

A: Reports indicate that pickleball is set to remain the fastest-growing sport, with participation in the US reaching nearly 20 million in 2024—a 45.8% increase from the previous year—underscoring a strong growth trajectory.

Q: What is the next trend after pickleball?

A: While pickleball continues its rise, sports such as padel, already popular in Europe, are emerging as potential successors in the broader racket sports market, offering new opportunities for consumer engagement and investment.

-

pickleball paddles: Click to explore an in-depth discussion on design, performance criteria, and manufacturing best practices that drive high-performance paddle production in the sports equipment industry. ↩ ↩ ↩2

-

Cold Pressing: Click to learn about this manufacturing process that applies pressure without heat, preserving material properties to enhance paddle control and durability in competitive play. ↩ ↩

-

Thermoforming: Click to discover how this heat-based forming process creates precise, intricate designs for high-performance sports equipment, balancing production efficiency with quality. ↩ ↩

-

3K Carbon Fiber: Click to read about the characteristics and advantages of using 3K Carbon Fiber in sports equipment, highlighting its balance between lightweight construction and durability. ↩ ↩

-

padel: Click to understand more about padel, a fast-growing racket sport in Europe, and its impact on market trends and diversification strategies in the sports equipment sector. ↩ ↩