Direct-to-Film (DTF transfer technology1) is a modern, cost-effective customization solution that delivers high-definition, durable designs on pickleball equipment, enhancing brand value and product appeal in the competitive sports market.

DTF transfer enables manufacturers to apply vibrant, high-resolution graphics directly onto pickleball paddles and other sports gear. By combining digital precision with advanced material compatibility, DTF transfers offer unmatched flexibility in design and production efficiency. This technology is particularly suited for B2B buyers seeking customization options that do not compromise on performance or durability.

Traditional printing techniques—such as screen printing and digital inkjet—often face limitations when applied to the unique contours and materials of pickleball equipment.

- Limited Design Flexibility: Conventional methods sometimes struggle with intricate designs and fine details.

- Durability Issues: Repeated impacts, moisture, and environmental exposure can cause traditional prints to fade or peel, reducing product lifespan.

- Production Constraints: High upfront costs and slower production cycles can hinder the ability to quickly adapt to market trends.

These challenges create a demand for innovative solutions that not only improve aesthetic appeal but also integrate seamlessly into existing manufacturing processes.

DTF transfer technology addresses many of the limitations of traditional customization techniques. Here’s how it stands apart:

-

High-Precision Printing:

- DTF employs digital methods that allow for intricate designs with consistent color accuracy and fine details.

- This precision leads to a visually striking product that enhances brand identity.

-

Enhanced Durability:

- The interplay of specialized inks and film results in prints that are resistant to abrasion, impact, and moisture.

- Durability is key for pickleball paddles, which experience high levels of kinetic force during play.

-

Adaptability to Complex Shapes and Materials:

- Pickleball paddles often utilize advanced composites like carbon fiber2 and fiberglass3.

- DTF technology is compatible with these materials, ensuring that the customization does not interfere with the paddle’s performance characteristics.

-

Cost-Effective and Efficient Production:

- With reduced setup times and the capability for on-demand printing, DTF helps streamline production cycles.

- This efficiency is crucial for sports branding agencies and procurement managers aiming for high-volume customization without a proportional increase in costs.

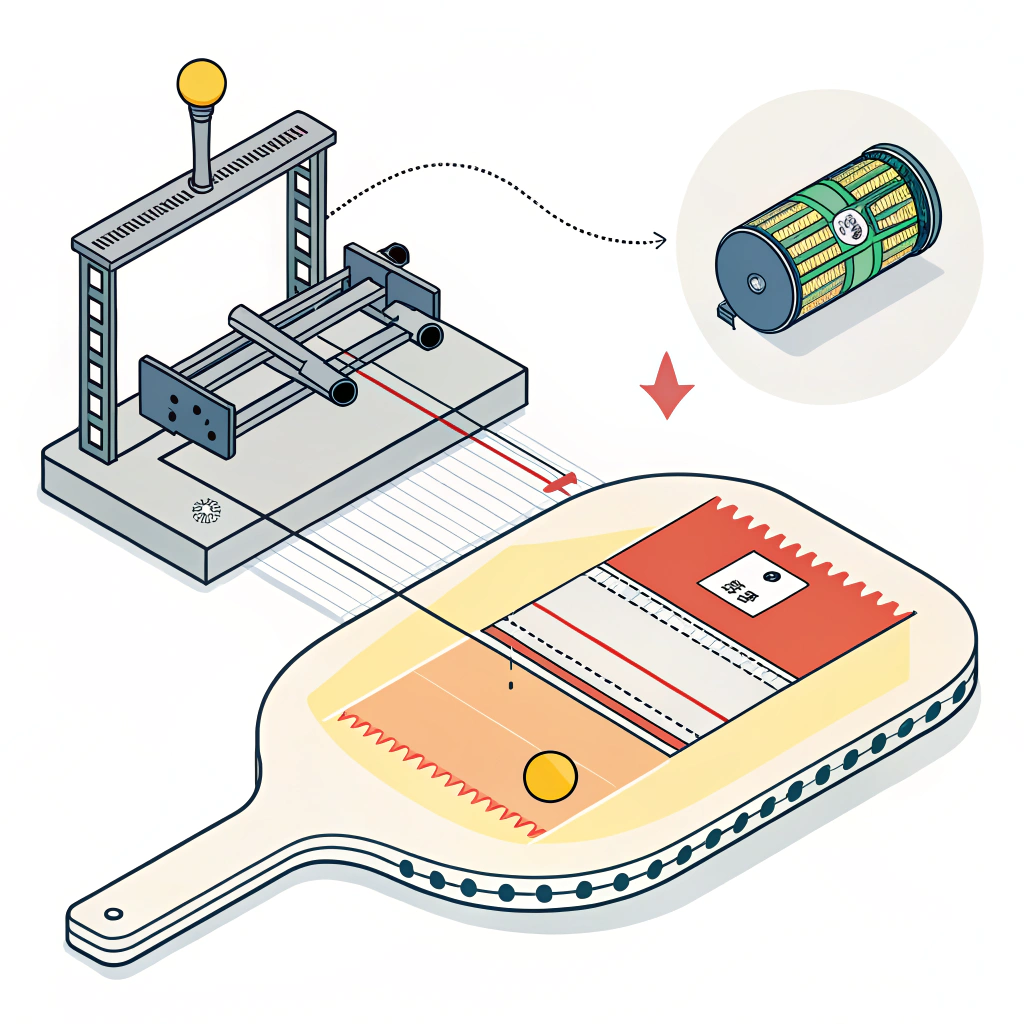

Implementing DTF transfer for pickleball equipment involves several key steps:

-

Design Creation:

- Designers create high-resolution graphics digitally.

- Special care is taken to ensure designs accommodate the contours and ergonomic features of pickleball paddles.

-

Film Preparation and Ink Application:

- High-performance films are used as the medium for transferring graphics.

- Advanced inks formulated for durability and vibrancy are applied through digital printing systems.

-

Transfer and Curing:

- The printed film is then aligned on the paddle surface.

- A controlled heat press process bonds the image to the paddle, ensuring long-lasting adhesion and resistance to external stresses.

-

Quality Assurance:

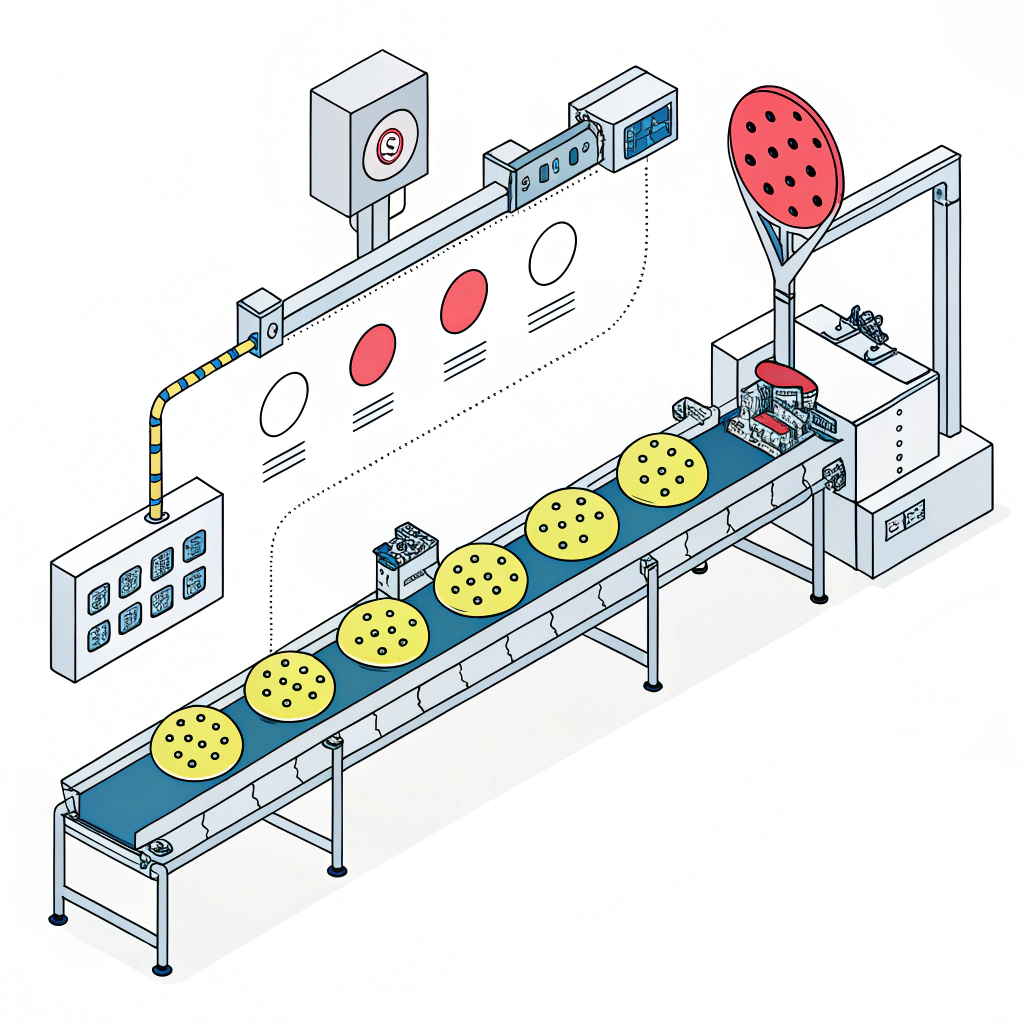

- Each customized unit undergoes rigorous testing to verify the quality and durability of the printed design.

- This includes accelerated wear tests to simulate long-term usage in competitive play.

This process can be integrated with existing production lines—such as hot pressing, cold pressing, and thermoforming4 processes widely used in paddle manufacturing—to ensure a seamless transition from production to final product.

To better understand the advantages of DTF transfer, consider the following comparison with other popular printing methods:

| Feature | DTF Transfer | Screen Printing | Digital Inkjet Printing |

|---|---|---|---|

| Design Precision | High detail, vibrant color reproduction | Limited detail; more manual adjustment | Moderate resolution; may require multiple passes |

| Production Speed | Fast, suitable for on-demand printing | Slower; requires setup for each job | Variable; faster than screen printing but slower than DTF |

| Material Compatibility | Works on various substrates (composite, fiberglass, carbon fiber) | Best for flat surfaces; limited on complex shapes | Generally good, but may be affected by surface texture |

| Durability | Excellent resistance to impact and moisture | Susceptible to wear over time | Good balance, but quality can vary based on ink and substrate |

| Cost Efficiency | Lower setup cost and high scalability | Higher labor and material costs | Moderate setup cost, less scalable for small runs |

This table clearly illustrates how DTF transfer offers a balanced trade-off between quality, speed, and cost—a crucial factor for B2B purchasers evaluating multiple customization technologies.

Consider a mid-sized sporting goods distributor looking to differentiate its product line by offering custom-branded pickleball paddles. The distributor faced challenges such as:

- Inconsistent print quality from traditional methods.

- Increased production lead times, leading to delayed market entry.

- Customer complaints about fading graphics after repeated play.

By integrating DTF transfer technology, the distributor achieved the following:

- Improved Visual Appeal: Custom paddles now feature crisp, detailed graphics that remain vibrant even after extensive usage.

- Shortened Production Time: On-demand printing reduced lead times significantly, enabling quick turnaround for seasonal promotions.

- Enhanced Durability: Quality tests confirmed that DTF prints maintained their integrity despite high-impact sports usage, boosting customer satisfaction and brand loyalty.

Manufacturers like NEX Pickleball are at the forefront of this innovation. As a leading manufacturer using advanced production techniques such as hot pressing, cold pressing, and thermoforming, NEX Pickleball leverages DTF transfers to provide customized solutions tailored to market demands.

For procurement or marketing managers in sporting goods distribution, cost efficiency and product differentiation are essential metrics. Here’s why DTF transfers make sense from a financial perspective:

-

Lower Tooling and Setup Costs:

DTF transfers typically require less investment in setup compared to traditional methods. This is particularly important for small production runs or seasonal variations. -

Reduced Waste:

Digital precision minimizes errors and material waste, ensuring that each unit meets high-quality standards without incurring additional costs. -

Scalability:

The technology allows for rapid scaling up or down depending on market needs, ensuring that production volumes can be adjusted promptly in response to demand fluctuations. -

Brand Differentiation:

Customized, high-definition prints help build a strong brand identity in the marketplace. For sports equipment, where aesthetics can drive consumer preference, DTF transfers offer a clear competitive edge.

A simplified cost-benefit overview is presented below:

| Cost Factor | Traditional Methods | DTF Transfer Technology |

|---|---|---|

| Initial Setup Cost | High | Lower |

| Production Speed | Moderate | Fast |

| Material Waste and Errors | Higher | Minimal |

| Scalability | Limited | Highly scalable |

| Long-Term Brand Impact | Moderate | Significant due to superior aesthetics |

These factors collectively contribute to a robust return on investment for businesses that embrace DTF customization, making it an attractive option for enhancing product lines in a competitive sports market.

When integrating DTF transfer technology into pickleball equipment customization, several key factors ensure success:

-

Material Compatibility:

Ensure that the inks and films used are tested for compatibility with the paddle substrates. This is particularly important for materials like T300 carbon fiber, Nomex honeycomb cores5 and composite structures. -

Heat Press Calculation:

The parameters of the heat press—temperature, pressure, and duration—must be finely tuned to guarantee that the transfer adheres without altering the paddle’s material properties. -

Quality Control Measures:

A robust quality control process should include:- Visual inspections for print consistency and alignment.

- Durability tests (e.g., abrasion resistance and impact tests) to confirm long-term performance.

- Batch-to-batch consistency checks to maintain brand standards.

-

Environmental Considerations:

Given that pickleball equipment is used outdoors, DTF transfers must be resilient against UV exposure, moisture, and temperature fluctuations. Manufacturers must select inks and films that offer this robust resistance. -

Customization Flexibility:

Custom orders often require variable design specifications, ranging from full-color graphics to subtle branding elements. An effective DTF process should accommodate these diverse needs without significant modifications to production lines.

DTF transfer technology is revolutionizing the way pickleball equipment is customized. It provides striking visual quality, exceptional durability, and a flexible, cost-effective production process. For procurement or marketing managers in sports distribution and branding agencies, adopting DTF transfers can significantly enhance product differentiation and market responsiveness.

Our recommendation for businesses looking to upgrade their sports equipment portfolio is to evaluate DTF technology alongside traditional methods. Consider pilot projects or limited runs to test market response, followed by scaling up production once the benefits are clearly established. By leveraging DTF transfers, companies can stay ahead in a competitive market, ensuring that every product not only looks impressive but also withstands the rigorous demands of high-performance sports.

Taking action today means scheduling consultations with experienced manufacturers like NEX Pickleball. With a proven track record in advanced production techniques and on-demand customization, NEX Pickleball is well-positioned to help you achieve the next level of product excellence and market differentiation.

Q: What are 5 things you cannot do in pickleball?

A: Pickleball regulations specify that players may not volley the ball before it bounces, must avoid stepping into the non-volley zone (also known as the kitchen) while volleying, and should refrain from executing slam shots within this zone, among other rules. These guidelines ensure fair play and maintain the sport’s integrity, even though they are unrelated to DTF transfer technology for customization.

-

[DTF transfer technology]: Click to learn about the fundamentals of DTF transfer technology, including its process, material compatibility, and why it is revolutionizing custom printing in various industries. ↩

-

[carbon fiber]: Click to read about carbon fiber, a high-strength and lightweight composite material widely used in advanced manufacturing and sports equipment. ↩

-

[fiberglass]: Click to explore the properties of fiberglass, a durable and versatile material commonly incorporated into sporting goods and industrial applications. ↩

-

[thermoforming]: Click to understand thermoforming, a process used in manufacturing to shape plastic materials by applying heat, and its benefits in high-volume production. ↩

-

[Nomex honeycomb cores]: Click to discover the characteristics of Nomex honeycomb cores, a specialized material used in composite structures for improved strength and reduced weight. ↩