Advanced manufacturing techniques such as hot pressing, cold pressing, and thermoforming1 enable the production of high-performance pickleball paddles that balance durability, control, and power – critical factors for distributors and B2B purchasers.

The pursuit of superior pickleball paddle performance drives the need for state-of-the-art production methods and premium materials. For procurement managers evaluating options, understanding how each manufacturing process impacts product quality is essential. In this article, we explore the technical aspects behind high-performance paddles, compare various production techniques, and provide actionable recommendations for bulk purchasing decisions.

High-performance paddles must meet rigorous standards for durability, control, and responsiveness. Several challenges arise during manufacturing:

- Material Consistency: Achieving uniformity in carbon fiber, fiberglass, or composite materials to ensure consistent performance.

- Process Precision: Balancing production efficiency with the need to preserve the inherent properties of premium materials.

- Customization Needs: Providing tailored options to meet varying ergonomic and design requirements demanded by professionals and recreational players alike.

- Quality Control: Maintaining rigidity and optimal weight distribution during large-scale production while ensuring every paddle undergoes rigorous testing.

Manufacturers like NEX Pickleball have addressed these challenges by adopting specialized production processes that offer distinct advantages in achieving the desired balance of performance characteristics.

A key differentiator in high-performance paddles is the careful selection of raw materials. Here are the main types frequently used:

-

Carbon Fiber:

Advanced carbon fibers come in varieties such as 3K, 12K, and T300.- 3K Carbon Fiber offers strength and flexibility with excellent rebound force, reducing vibration.

- 12K Carbon Fiber provides a smoother surface and enhanced durability, vital for competitive play.

- T300 Carbon Fiber strikes a balance between strength and lightness, ideal for players seeking both control and speed.

-

Fiberglass:

The use of E-Glass Fiberglass2 contributes to a broader sweet spot and improved ball control. Its flexibility ensures an optimal feel during play. -

Composite Materials3:

Combining carbon fiber with fiberglass or using bamboo core composites allows manufacturers to fine-tune paddle weight, strength, and vibration absorption. Such composites balance the benefits of multiple materials, catering to diverse playing styles. -

Core Materials:

The core material determines the paddle’s overall hitting feel and performance. Options include:- Nomex Honeycomb Core4: Renowned for shock absorption and durability.

- Aluminum Honeycomb Core: Offers balanced power and precision by maintaining even weight distribution.

- Polymer Honeycomb Core: Enhances elasticity and reduces vibration, tailoring to players who prefer a softer feel.

These materials are selected to meet the high standards required for competitive play and reliable long-term use, helping distributors cater to a wide market segment.

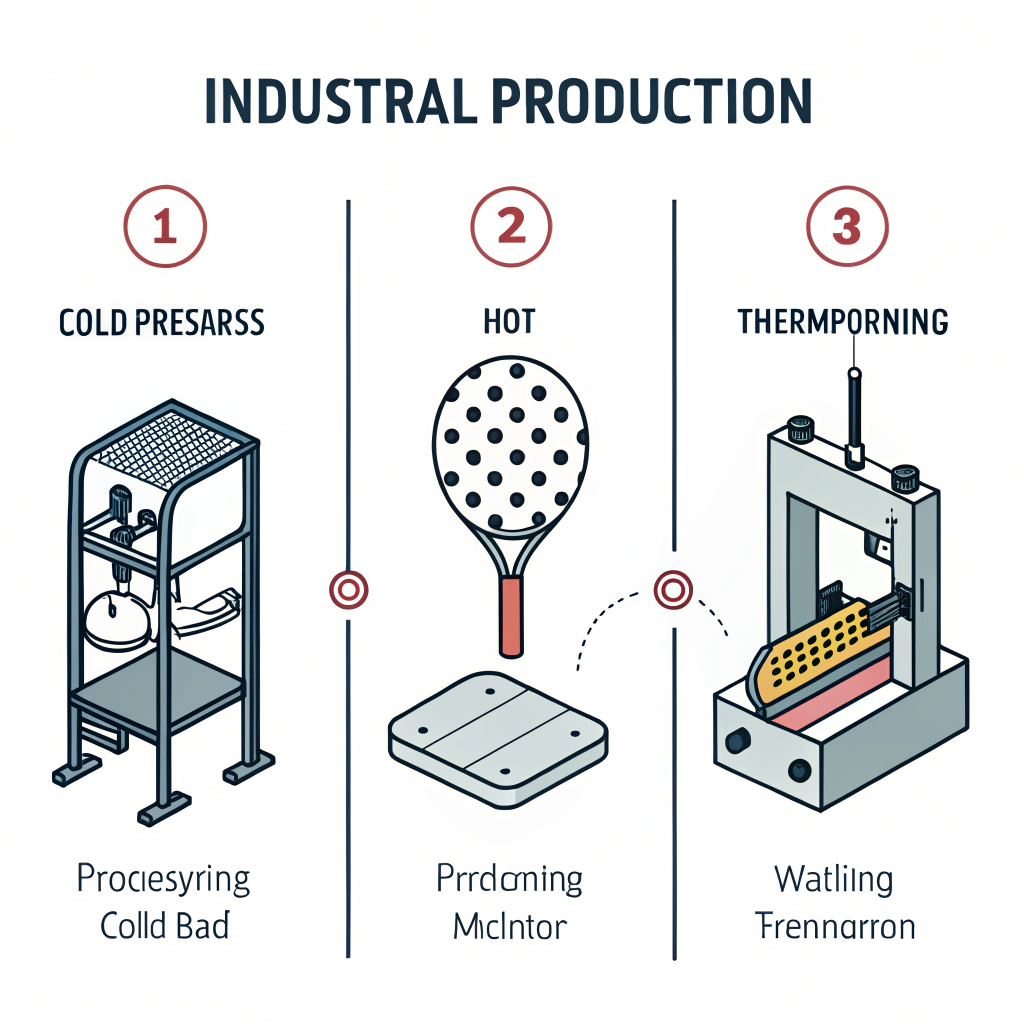

The choice of production process directly influences paddle performance. Manufacturers typically choose between three main methods:

| Process | Advantages | Disadvantages | Best for |

|---|---|---|---|

| Hot Pressing | High efficiency; produces strong paddles with excellent impact resistance; maintains structural integrity. | May alter certain material properties; high equipment investment. | Large-scale production; durable paddles. |

| Cold Pressing | Provides precise control over paddle thickness; maintains intrinsic material properties; enhances ball feel. | Longer production cycles; requires precise pressure control. | Designs prioritizing control and flexibility. |

| Thermoforming | Allows for intricate design features; maintains uniform material distribution; improves overall paddle stability. | Longer processing time; higher equipment cost. | Premium or custom-designed paddles. |

Each method offers trade-offs between production speed, cost-efficiency, and end-product performance. Businesses aiming to import or distribute high-performance paddles must weigh these factors along with material choices to ensure they select the right product that meets their market demands.

Strict quality control is indispensable in ensuring that every paddle produced meets the expected standards. At NEX Pickleball, every paddle is subjected to a series of tests:

- Rigorous Testing: Each paddle undergoes impact resistance, flexibility, and durability tests to simulate real-game scenarios.

- Ergonomic Assessment: The paddles are evaluated for weight distribution and grip comfort, ensuring compliance with performance metrics.

- Customization Assurance: Clients can opt for custom paddle features such as grip size, weight, and balance. This ensures that every product delivery aligns perfectly with the buyer’s specific needs.

By focusing on these critical quality metrics, manufacturers can guarantee that the paddles are ready for high-intensity use, thereby boosting the confidence of B2B purchasers.

With an increasingly competitive sports equipment market, the performance and production quality of pickleball paddles play a significant role in differentiating brands. Key market observations include:

- Technological Advancements: The integration of digital quality control systems5 and precision manufacturing techniques is becoming standard.

- Customization Demand: Customers, especially professional teams and retailers, demand options that reflect unique branding or tailored performance needs.

- Materials Innovation: Ongoing research in carbon fiber technology and composite materials continues to drive forward innovations in durability and responsiveness.

- Competitive Positioning: When comparing brands such as Selkirk and JOOLA, differences emerge:

- Selkirk often leverages advanced materials and focuses on durability.

- JOOLA emphasizes ergonomic designs and aerodynamic performance.

These trends highlight the importance of a dual focus on technical manufacturing and customer-centric design. Businesses must evaluate various production approaches and material technologies to make informed decisions about bulk procurement.

For B2B purchasing managers, the following guidelines can help in decision-making:

- Evaluate Production Quality: Confirm that the manufacturer employs strict quality control measures and relies on proven production processes. Request specifications and quality certifications.

- Consider Material Benefits: Assess the type and grade of carbon fiber, fiberglass, or composite materials used. Ensure that these materials match the performance needs of your target market.

- Examine Customization Options: Look for flexibility in design, which is crucial for meeting the diverse demands of recreational players versus competitive sports teams.

- Review Industrial Advancements: Stay updated on emerging trends and technologies. Innovations in production techniques can signal improved product longevity and performance.

- Compare Market Leaders: Understand the value propositions of leading brands. While some manufacturers may offer a focus on durability, others might prioritize speed and spin dynamics.

- Consider Pricing and ROI: Ensure that the chosen paddle line offers a competitive price point relative to its performance. The initial investment should be justified by enhanced durability and customer satisfaction over time.

Using a detailed checklist tailored to your procurement strategy will not only streamline the decision process but also ensure that each purchasing order meets the stringent requirements of today's competitive market.

High-performance pickleball paddles are defined by their advanced material compositions and precise manufacturing processes. By adopting techniques like hot pressing, cold pressing, and thermoforming, manufacturers achieve a balance of strength, control, and durability tailored to meet rigorous performance demands.

For B2B purchasing managers and distributors:

- Verify technical specifications and quality control measures.

- Compare the production process details and material benefits.

- Ensure customization options are available to address diverse consumer requirements.

In summary, understanding the nuances of production processes and material characteristics allows you to make informed and strategic bulk procurement decisions. Embrace these insights to partner with reliable manufacturers like NEX Pickleball, ensuring the supply of superior, market-leading pickleball paddles.

What's better, SLK or JOOLA?

Both SLK and JOOLA produce high-quality paddles, but your choice depends on performance priorities. SLK focuses on durability and leveraging advanced materials, while JOOLA emphasizes ergonomic design and improved aerodynamics. Evaluating the specific performance metrics that matter to your target market will help in making the optimal selection.

What is the best cheap pickleball paddle?

For buyers seeking budget-friendly options, some brands offer paddles under $10 that can deliver satisfactory performance for casual play. However, for bulk procurement aimed at high-performance standards, balancing cost with material quality and production reliability is essential.

-

Thermoforming: Click to learn how thermoforming is used in manufacturing to shape materials through heat and pressure, enabling the creation of complex designs and enhancing product stability. ↩

-

E-Glass Fiberglass: Click to discover the characteristics of E-Glass Fiberglass and its role in enhancing ball control and the overall playability of sports equipment. ↩

-

Composite Materials: Click to explore how composite materials blend multiple substances to optimize strength, weight, and durability in high-performance products. ↩

-

Nomex Honeycomb Core: Click to understand the properties of Nomex honeycomb cores and how their shock absorption capabilities contribute to improved durability and performance. ↩

-

Digital Quality Control Systems: Click to read about digital quality control systems and their integration into modern manufacturing processes for maintaining consistent and reliable product quality. ↩