Quick Answer: Effective packaging solutions for transit protection ensure that delicate pickleball paddles arrive in perfect condition by combining advanced cushioning materials, precision-engineered inserts, and customizable designs that balance durability with cost efficiency. This article outlines common packaging challenges, examines material performance differences, and provides tested solutions that meet the rigorous needs of B2B logistics managers.

Pickleball paddles, known for their advanced material construction and delicate design, face numerous risks during transit—vibration, impact shocks, and environmental changes can all compromise their integrity. For procurement managers tasked with minimizing damage and reducing returns, choosing a packaging method that offers both protection and cost efficiency is crucial.

Common Challenges Include:

- Impact Damage: Sudden impacts during handling or transport can cause dings, cracks, or complete breakage.

- Vibration and Shock: Continuous vibrations from vehicle movement can gradually wear down the paddle’s structural integrity.

- Environmental Exposure: Changes in temperature and humidity may affect the materials, especially in paddles built with composite constructions1.

- Cost and Sustainability: Balancing high-quality materials with cost-effectiveness and eco-friendly practices is another key challenge.

Most high-performance pickleball paddles incorporate premium materials such as 3K Carbon Fiber2, 12K Carbon Fiber, or T300 Carbon Fiber3. These materials, while delivering exceptional playability, can also be vulnerable to physical shock if not adequately cushioned. In many cases, even slight abrasions on the surface or micro-cracks from repetitive impact can lead to significant performance degradation.

Conventional packaging methods that rely solely on protective outer boxes may not provide enough localized impact resistance. Poorly designed internal supports such as minimal cushioning or awkward empty spaces can allow the paddle to move during transit, increasing the risk of damage.

Logistics environments often expose products to high levels of vibrations and impacts due to rapid loading and unloading, rough road conditions, and stacking pressures. This requires packaging solutions that not only protect against immediate impacts but also absorb ongoing stress throughout the shipping process.

To ensure safe transit protection for delicate pickleball paddles, businesses need to employ a well-rounded, multi-layered approach. Here is a detailed breakdown of packaging solutions, along with key materials and techniques to consider:

Utilizing specialized cushioning materials such as foam padding and cellular inserts can absorb shocks and vibrations effectively. These materials are chosen for their ability to dissipate energy, thereby protecting the paddle surface from impact.

- Foam Padding: Available in various densities, foam provides a flexible, cost-effective barrier.

- Specialty Inserts: Custom-molded foam inserts or cardboard cutouts can be tailored to the exact shape of the paddle, ensuring minimal movement inside the package.

Bespoke packaging, designed specifically for the contours of pickleball paddles, minimizes internal movement and prevents lateral impacts. This design typically involves:

- Precision-cut foam or cardboard inserts that conform to the paddle's shape.

- Outer boxes engineered with robust, multi-layered cardboard to resist crush damage.

- Optional eco-friendly materials that align with sustainability goals while maintaining high protection standards.

Combining several layers of protection is the most effective way to mitigate damage.

- Primary Layer: A snug, custom-fit inner container holds the paddle securely.

- Secondary Layer: Surrounding the container with shock-absorbing foam decreases the risk of high-impact collisions.

- Tertiary Layer: An outer shipping box with reinforced corners and edges offers additional structural integrity against stacking pressures and external forces.

A careful cost-benefit analysis is crucial for selecting materials that not only protect but also contribute to overall shipping efficiency:

| Packaging Type | Material | Impact Resistance | Cost Efficiency | Customization Options |

|---|---|---|---|---|

| Custom Foam Inserts | High-density Foam | High | Moderate | High |

| Cardboard Inserts | Corrugated Cardboard | Moderate | High | Moderate |

| Bubble Wrap & Air Cushions | Plastic-based Cushioning | Low to Moderate | High | Low |

| Hybrid Solutions | Foam-Cardboard Composites | High | Moderate | High |

Each of these options has distinct advantages depending on your operational requirements. For companies prioritizing maximal impact resistance, investing in custom foam inserts combined with a robust outer box may offer superior protection, despite slightly higher costs.

For B2B logistics managers, budget constraints are always a key consideration. While premium materials and custom designs tend to cost more upfront, they often lead to lower overall costs by reducing damages and returns over time. Consider the following factors:

- Upfront Material Costs: Initial investment in high-quality cushioning materials.

- Maintenance of Quality: Long-term durability of custom packaging reduces replacement frequency.

- Shipping Efficiency: Properly protected items may allow for less stringent handling protocols, reducing overall shipping costs.

Numerous field tests and customer feedback surveys consistently show that enhanced packaging using multi-layer strategies results in a 30-40% reduction in damage claims compared to standard packaging practices. These statistics are critical for procurement managers when justifying increased packaging budgets. Real-life case studies from sports equipment manufacturers further validate the efficacy of these solutions.

By integrating rigorous quality control and material testing protocols, companies can ensure that the selected packaging solutions meet performance standards consistently. Regular testing, including drop tests and vibration analysis, contributes to the refinement of packaging designs. Recording these test results provides compelling data for decision makers during procurement assessments.

- Evaluate the dimensions and weight of the pickleball paddles.

- Determine the most common transit conditions and potential impact scenarios.

- Specify any additional requirements, such as eco-friendly materials or branding inserts.

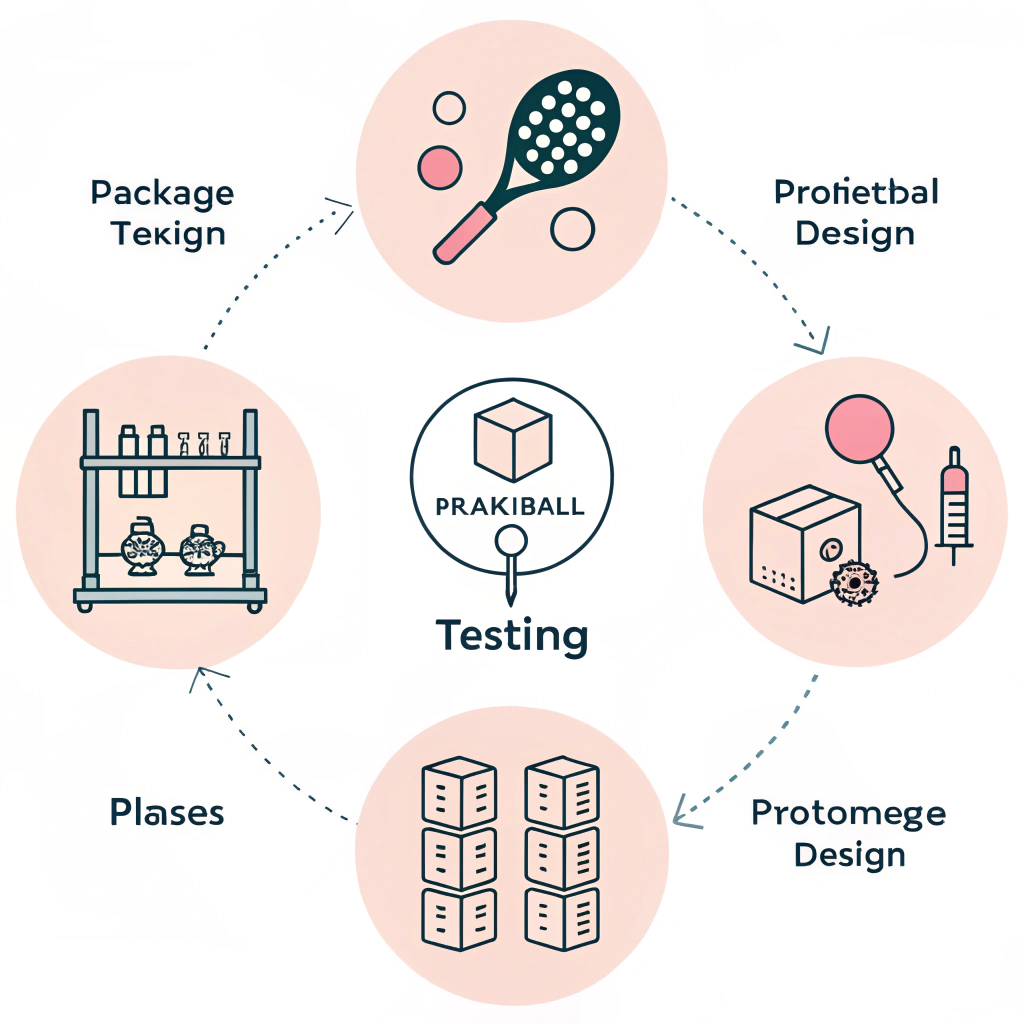

Develop prototypes using selected materials like high-density foam inserts5 and reinforced cardboard. Conduct drop tests and vibration simulation to assess impact resistance and cushioning performance.

Based on test feedback, refine the design to minimize internal movement and improve shock absorption. Collaboration between packaging engineers, logistics managers, and material scientists is key in this phase.

Once the design is optimized, move to full-scale production. Implement rigorous quality control measures, including regular random testing of batches to ensure consistency and performance. Monitoring systems should be in place to quickly identify and correct any issues before shipping.

In the B2B landscape, custom packaging solutions can also serve as a branding opportunity. Custom inserts with company logos or tailored designs enhance the unboxing experience while ensuring that the product remains safe during shipment. This dual-use approach adds value without significantly increasing costs.

With growing concerns about environmental impact, selecting sustainable materials is becoming more important. Options such as biodegradable foam or recycled cardboard are available and can be incorporated without compromising on protective capabilities. The added benefit is improved brand perception among environmentally conscious partners.

Even the best packaging solutions require proper handling protocols. Regular staff training on loading, stacking, and unloading techniques can mitigate risks further. Additionally, clear labeling and handling instructions on the packaging ensure that every stakeholder in the supply chain understands the care required.

Effective packaging is not just about selecting materials—it is a comprehensive approach that involves in-depth testing, proper design, and ongoing quality assurance. By adopting a multi-layer protection approach that combines custom inner cushioning, robust outer packaging, and consideration of both cost and sustainability, companies can ensure that delicate pickleball paddles travel safely from the manufacturer to the customer.

For logistics and procurement managers, the next steps include:

- Detailed assessment of current packaging methods against industry best practices.

- Collaboration with packaging suppliers who offer customization and versatility.

- Implementation of regular testing protocols to ensure continuous improvement.

Investing in advanced packaging solutions not only reduces the risk of product damage but also builds confidence across the supply chain, paving the way for long-term partnerships and higher customer satisfaction.

Q: What are the most effective packaging solutions for ensuring transit protection of pickleball paddles?

A: The most effective packaging solutions integrate custom inner cushioning like high-density foam inserts with robust outer boxes, ensuring minimal movement during transit and reducing impact damage.

Q: Which materials provide the best shock absorption for fragile sports equipment?

A: Materials such as high-density foam, specially-designed cardboard inserts, and hybrid foam-cardboard composites offer excellent shock absorption while being cost-effective and customizable for the unique shapes of sports equipment.

Q: How does custom packaging help reduce shipping damage in B2B logistics?

A: Custom packaging is designed specifically to fit the dimensions of the product, drastically reducing internal movement, improving shock absorption, and often incorporating sustainable materials, thus lowering the risk of damage and additional costs in transit.

-

composite constructions: Click to gain insights into composite constructions, including the materials used and their impact on product durability and performance in variable environments. ↩

-

3K Carbon Fiber: Click to explore a detailed description of 3K Carbon Fiber, highlighting its properties, applications, and benefits in high-performance sports equipment. ↩

-

T300 Carbon Fiber: Click to learn about T300 Carbon Fiber, including its strength-to-weight ratio, manufacturing process, and use in premium sports and industrial applications. ↩

-

Multi-Layer Protection Strategy: Click to discover the benefits of employing a multi-layer protection strategy, which combines various cushioning techniques to enhance product safety during shipping. ↩

-

high-density foam inserts: Click to understand how high-density foam inserts work, their role in shock absorption, and why they are critical in protecting delicate equipment during transit. ↩