In today’s fast-paced sports equipment market, OEM1 pickleball paddles must combine advanced production methods with premium raw materials to provide both performance and brand differentiation. NEX Pickleball delivers this solution—offering custom, high-performance paddles that meet the rigorous standards of professional play and ensure your brand stands out.

Manufacturers and sports equipment distributors face pressure to meet rising consumer expectations for high durability, precision engineering, and tailored design. Procurement managers2 must balance production efficiency with technical excellence, especially when dealing with OEM solutions for pickleball paddles. Issues such as material performance, process consistency, and customization flexibility become key factors in the decision-making process.

When selecting an OEM manufacturing partner, many brand and procurement managers encounter the following challenges:

- Inconsistent Quality: Variations in production can impact paddle performance, causing inconsistent playing experiences.

- Technical Precision: The need to integrate multiple advanced materials such as carbon fiber3, fiberglass, or composite structures without sacrificing overall paddle performance.

- Customization Limitations: Meeting diverse client specifications such as paddle weight, grip dimensions, and surface finish while keeping production costs competitive.

- Process Compatibility: Ensuring that the manufacturing process—from material selection to final assembly—meets both national and international sports equipment standards.

These issues require a reliable, technically proficient partner who can combine cutting-edge production processes with a strong commitment to quality.

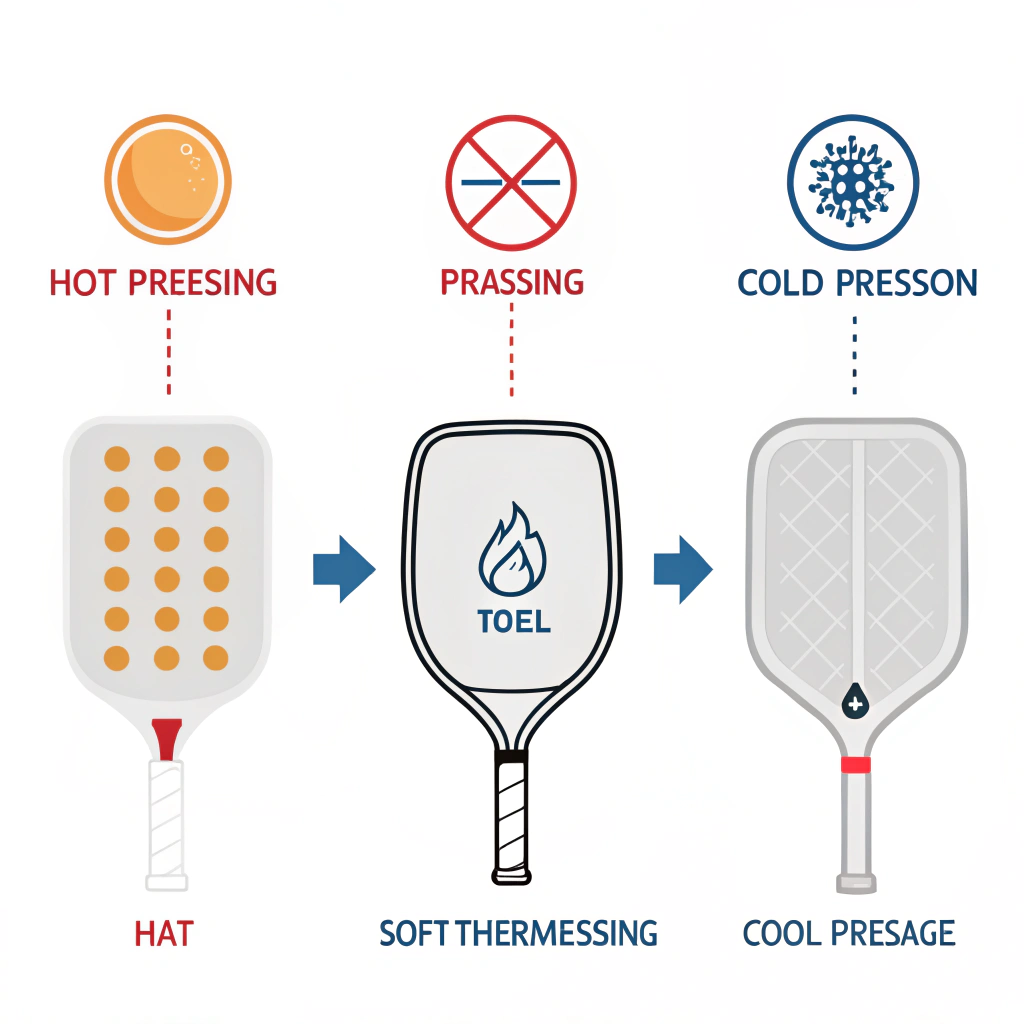

At NEX Pickleball, our manufacturing processes are engineered to balance efficiency, precision, and product integrity. We primarily use three advanced production methods:

Hot pressing involves applying both heat and pressure to mold the paddle components together. This method is widely used in mass production for its efficiency and the robust characteristics it imparts to the paddle.

- Advantages:

- High production efficiency, ideal for large-scale runs.

- Produces paddles with excellent impact resistance and structural strength.

- Ensures strong bonding between layers for enhanced durability.

- Disadvantages:

- Potential alteration of material properties, which might affect the feel of the paddle.

- Requires significant capital investment in high-grade equipment.

In contrast, cold pressing is executed at room temperature using mechanical pressure, allowing for precise control over the paddle’s structure.

- Advantages:

- Maintains the intrinsic properties of the materials, preserving the paddle’s flex and balance.

- Provides tighter control over paddle thickness, ensuring a more consistent product.

- Delivers superior ball feel and responsiveness.

- Disadvantages:

- Longer production cycles compared to hot pressing.

- Demands high-quality machinery and strict process control for optimal results.

Thermoforming involves heating the material to a pliable state and then molding it into intricate paddle shapes using custom-designed molds.

- Advantages:

- Allows production of paddles with complex design geometries and precise material distribution.

- Enhances paddle stability by maintaining form and function in challenging play scenarios.

- Ideal for premium or customized paddle designs.

- Disadvantages:

- Typically results in longer production times.

- Involves higher equipment and operational costs, making it suitable primarily for high-end products.

Below is a summary table comparing these processes:

| Process | Key Benefits | Considerations |

|---|---|---|

| Hot Pressing | High efficiency; strong, durable paddles | Potential material property changes |

| Cold Pressing | Enhanced control; superior ball feel | Longer production cycles |

| Thermoforming | Complex designs; precise material distribution | Higher costs; longer production time |

The performance of a pickleball paddle largely depends on the materials used. NEX Pickleball utilizes multiple premium materials to ensure each paddle meets high performance and longevity standards:

- 3K Carbon Fiber: Delivers strength and flexibility with reduced vibration, ideal for a high rebound force.

- 12K Carbon Fiber: Offers a smoother surface with increased hardness, meeting the demands of competitive play.

- T300 Carbon Fiber: Known for a superior balance of tensile strength and lightweight design.

Each carbon fiber type is chosen based on the paddle’s targeted use, ensuring that every model offers a tailored experience for power and control.

- E-Glass Fiberglass: Provides excellent elasticity and tensile strength. Paddles made with fiberglass offer a wider sweet spot and balanced playability, giving players excellent control over ball placement.

Combining the strengths of multiple materials leads to exceptional paddle performance. NEX Pickleball offers:

- Carbon Fiber and Fiberglass Composite: Merges the durability of carbon fiber with the flexibility of fiberglass, perfect for players seeking a balance of power and control.

- Bamboo Core Composite: Uses bamboo for a lightweight feel and high impact resistance.

- Honeycomb Core Structures: Made from high-density polymers or pulp, these cores reduce vibration, enhancing comfort during extended play.

A paddle’s core is crucial in defining its overall performance. Our core options include:

- Nomex Honeycomb Core: Known for its outstanding shock absorption and durability.

- Aluminum Honeycomb Core: Strikes a balance between power and precision.

- Polymer Honeycomb Core: Offers improved elasticity and reduced vibration, catering especially to recreational players seeking a comfortable hit.

A significant advantage of partnering with NEX Pickleball is our ability to deliver bespoke OEM solutions for any brand. We recognize that every market has unique needs and that customization is key in differentiating your brand in a competitive landscape. Our customization services include:

- Paddle Design: Choose from a variety of shape designs, edge techniques, and finishing touches to mirror your brand identity.

- Material Selection: Customize your paddle with your choice of carbon fiber, fiberglass, or composite materials tailored to performance and price points.

- Production Process Flexibility: Depending on your project, we can adjust the manufacturing process—whether hot pressing, cold pressing, or thermoforming—to optimize product quality and cost efficiency.

- Custom Sizing: We offer multiple grip sizes and paddle dimensions to suit various playing styles and player demographics.

- On-Demand Print Services: Personalize your paddles with logos, graphics, or even tailored back designs that resonate with your market demographic.

Our commitment to meeting client-specific requirements does not stop at design. Every production stage undergoes rigorous quality control. We employ advanced testing methods to ensure each custom OEM paddle performs to the highest standards in terms of strength, balance, and durability.

Over the years, NEX Pickleball has supplied OEM paddles to several leading sports brands and retailers. Our experience has equipped us to:

- Maintain consistent quality across large production batches.

- Adapt production processes based on iterative customer feedback.

- Leverage data-driven production adjustments that boost both performance and aesthetics.

For instance, in a recent collaboration with a major sports retailer, our production team optimized the cold pressing process to produce a paddle that not only met the exact weight and thickness specifications but also delivered a superior ball feel. This initiative resulted in a product that significantly boosted customer satisfaction and sales metrics.

Continued investments in our machinery and process upgrades have enabled high throughput while preserving craftsmanship. Our on-site quality control protocols ensure that every paddle receives detailed inspection at critical stages of production, guaranteeing that vendors receive products with minimal variability.

To summarize, NEX Pickleball offers a comprehensive OEM solution that addresses the technical and market-specific challenges of custom pickleball paddle production. Our advanced production methods—hot pressing, cold pressing, and thermoforming—combined with premium material selection, empower your brand to provide paddles that excel both in performance and in visual appeal.

Key takeaways include:

- A robust manufacturing process honed through years of industry experience.

- A wide array of material and core options that cater to various play styles.

- A commitment to customization that allows you to tailor every aspect of the paddle to your brand’s requirements.

- Consistent quality assurance that positions your brand as a leader in professional sports equipment.

For procurement and brand managers seeking a reliable OEM partner, NEX Pickleball represents a fusion of engineering precision and innovative production techniques. With our proven capabilities, you can confidently meet your clients’ demands for cutting-edge performance while building a lasting brand legacy.

What racquet do pro pickleball players use?

Professional pickleball players often opt for high-performance paddles, such as the Selkirk Vanguard Power or similar models. These paddles are engineered to balance power, control, and minimal vibration—qualities that are crucial at the pro level. The exact model can vary based on individual playing style and tournament requirements.

What is the best pickleball paddle for professionals?

The best pickleball paddle for professionals typically combines durable construction with precision-engineered materials. Leading brands like JOOLA, Selkirk, and others offer top-rated options such as the JOOLA Perseus Pro IV and JOOLA Hyperion Pro IV 16mm. These paddles are designed to provide optimal balance, power, and responsiveness required by competitive players.

What is the official pickleball paddle size?

Traditional pickleball paddles usually measure between 7 to 8.25 inches in width and 15 to 16 inches in length. For elongated paddles, the width tends to be around 6 to 8 inches with a length of 16 to 17 inches. These dimensions are established to ensure a balance between reach, control, and maneuverability during play.

-

OEM: Click to learn more about original equipment manufacturing and how OEM partnerships streamline product development and production for enhanced brand differentiation. ↩

-

Procurement managers: Click to read about the role of procurement managers in balancing cost-efficiency, quality control, and vendor relationships in the manufacturing supply chain. ↩

-

carbon fiber: Click to explore the properties of carbon fiber, including its strength-to-weight ratio and its applications in high-performance sports equipment. ↩

-

Thermoforming: Click to understand thermoforming processes, their benefits in manufacturing complex shapes, and their impact on production efficiency in the sports equipment industry. ↩

-

Composite Materials: Click to gain insights into composite materials, how combining different constituents results in improved performance, and why they are essential for modern paddle design. ↩