In short, NEX Pickleball’s advanced manufacturing techniques and diverse material options ensure that our OEM/ODM1 solutions deliver high-performance pickleball paddles at competitive factory prices. By comparing materials, production processes, and customization capabilities, procurement managers can confidently select a partner that meets both quality and cost-efficiency requirements.

In today’s rapidly evolving sporting goods market, partnering with the right manufacturer is essential. For procurement managers and business owners seeking OEM/ODM partners, production reliability, technical precision, and cost efficiency are key considerations. NEX Pickleball leverages state-of-the-art technologies and premium materials to produce pickleball paddles engineered for performance and durability.

Understanding the full scope of our production capabilities—from advanced carbon fiber2 options to distinct production techniques—can help you make an informed decision. This article presents a detailed comparison of material choices, production processes, and customization features, enabling you to scale your product offering with a reliable partner.

Choosing the right material is crucial for maximizing paddle performance. At NEX Pickleball, we offer a variety of materials designed to meet the needs of competitive and recreational players alike.

Our paddle designs incorporate several types of carbon fiber, each offering unique performance benefits:

-

3K Carbon Fiber: Known for its excellent strength and flexibility, this variant delivers high rebound force while significantly reducing paddle vibration. It is ideal for players seeking durability and enhanced playability.

-

12K Carbon Fiber: With a higher thread density, 12K carbon fiber provides a smoother surface and superior hardness. Its enhanced impact resistance makes it the first choice for competition-grade paddles.

-

T300 Carbon Fiber: T300 balances exceptional tensile strength with light weight, offering players a paddle that is both strong and easy to maneuver.

These carbon fiber options are critical for achieving the right balance between power and control.

Beyond carbon fiber, we also utilize fiberglass and composite materials in our paddle production:

-

Fiberglass Paddles: These paddles provide a generous sweet spot, greater flexibility, and refined ball control. Our E-Glass fiberglass is engineered for elasticity and durability.

-

Composite Materials: By combining carbon fiber with fiberglass, our composites achieve a balance of strength, weight, and flexibility. Additionally, options like Bamboo Core Composite offer a lightweight yet highly impact-resistant design, while Honeycomb Core Composite focuses on superior shock absorption.

This extensive material portfolio means you can meet the varying performance requirements of different player segments.

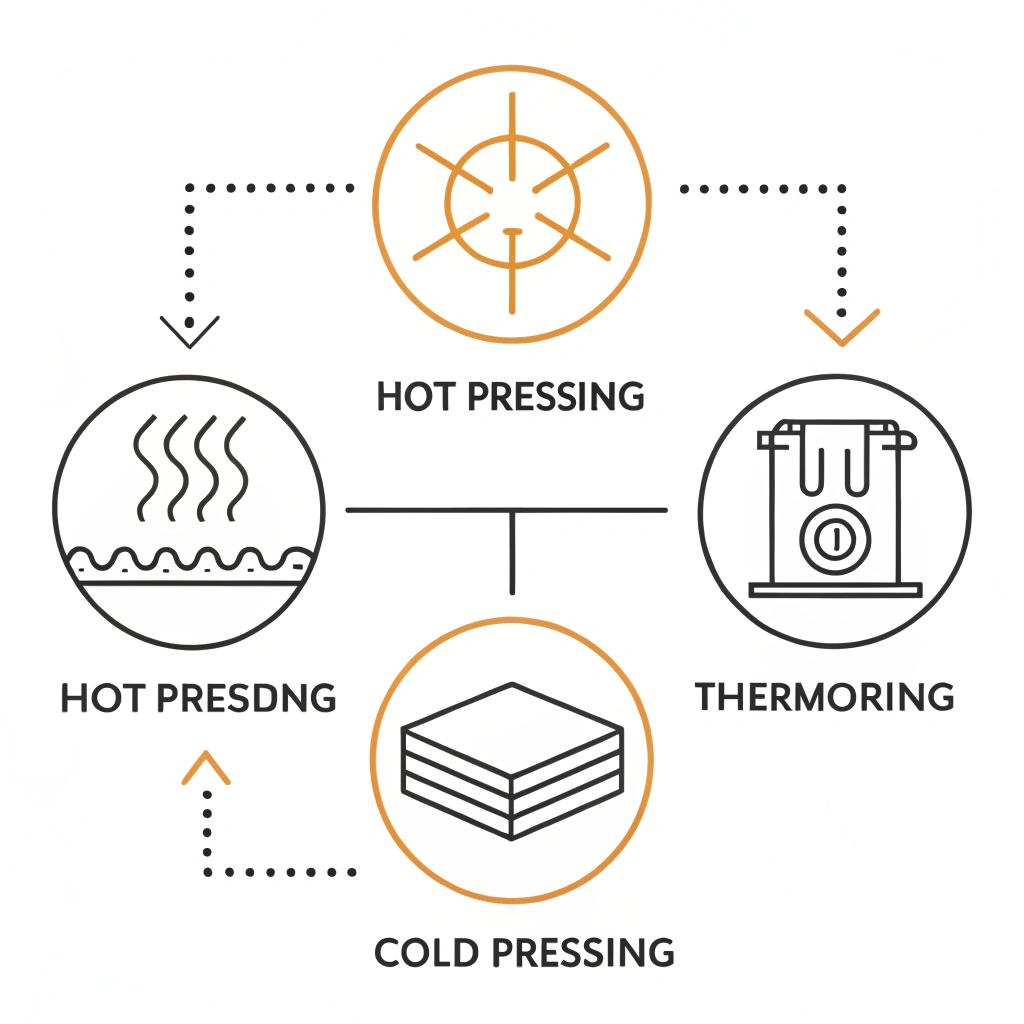

Production Processes: Hot Pressing, Cold Pressing, and Thermoforming3

The production process is a key element that impacts the performance and quality of pickleball paddles. At NEX Pickleball, our production techniques are designed to optimize both quality and cost efficiency. Below is a detailed comparison of our three main production processes:

| Production Process | Advantages | Disadvantages | Suitable For |

|---|---|---|---|

| Hot Pressing | • High production efficiency • Increased impact resistance • Strong structural integrity | • May alter some material properties • Requires high investment in equipment | High-performance paddles, large-scale manufacturing |

| Cold Pressing | • Precise control over paddle thickness • Maintains material properties • Excellent ball feel and responsiveness | • Longer production cycles • Needs precise pressure control equipment | Custom-designed paddles, detailed control for specialized play |

| Thermoforming3 | • Ability to create intricate designs • Ensures balanced material distribution • High stability in final product | • Higher equipment cost • Longer production time | Premium products or custom-made paddles with complex shapes |

The above table clearly outlines the benefits and limitations of each process, enabling you to choose the best method that aligns with your product requirements and market strategy.

Customization plays a central role in today’s competitive market. NEX Pickleball offers a wide range of custom options that allow you to tailor paddle features to specific player needs or brand requirements. Key customization options include:

- Design and Weight Adjustments: Clients can specify paddle design, optimal weight distribution, and balance to meet precise playability goals.

- Grip Size and Ergonomics: We offer multiple grip sizes to ensure comfort and a secure hold, critical for both power and control.

- Surface Texture Enhancements: Our paddle surfaces undergo special treatments, delivering improved ball grip, increased spin, and boosted accuracy during play.

Quality control is integral to our production process. Every paddle undergoes rigorous testing to ensure it meets strict market standards. By implementing advanced inspection techniques, we maintain the highest levels of product consistency in strength, flexibility, and performance. This commitment to excellence reduces return rates and builds long-term trust with our B2B partners.

In addition to technical excellence, competitive pricing is paramount for any procurement decision. NEX Pickleball’s manufacturing process is optimized for cost efficiency without compromising on quality. Our factory price paddles are the result of streamlined production methodologies and a focus on bulk OEM/ODM arrangements.

Key factors contributing to our cost efficiency include:

- Bulk Production Scaling4: By utilizing high-efficiency production processes like hot pressing, we can achieve significant economies of scale.

- Advanced Material Sourcing: Strategic sourcing of premium materials (e.g., carbon fiber variants and fiberglass) helps keep production costs competitive while ensuring top-tier quality.

- Customization with Minimal Overhead: Our flexible manufacturing setup allows for tailored products with minimal additional costs, making customization accessible even on large orders.

- In-House Production Oversight: With complete production control, quality and costs are managed seamlessly, resulting in a product that is both reliable and competitively priced.

This focus on cost efficiency ensures that you receive a high-performing paddle that aligns with your budget and competitive market pressures.

Consider a scenario where a retail chain wishes to introduce a premium line of pickleball paddles. The decision-making process involves a detailed comparison of material durability, production processes, and final product cost. By partnering with NEX Pickleball, the retailer benefits from:

- Material Diversity: The ability to mix and match choices such as 12K carbon fiber for high durability with a Nomex Honeycomb Core5 for shock absorption ensures a product range that caters to different player preferences.

- Manufacturing Flexibility: The option to choose between hot pressing for mass production efficiency and cold pressing for ultimate control over paddle shape mitigates risk when launching new products.

- Competitive Pricing: Our factory pricing model combined with the opportunity for on-demand custom printing keeps costs predictable while maximizing market differentiation.

Data from recent projects show that our OEM clients have experienced improved market responsiveness and customer satisfaction due to our flexible manufacturing processes and dedicated quality control measures.

When selecting an OEM/ODM partner for pickleball paddles, consider the following:

- Evaluate Material Options Carefully: Determine which material variant best suits your target consumer segment. For competitive play, high-density carbon fiber options such as 12K carbon fiber deliver superior performance and longevity.

- Understand Production Processes: Each production process offers unique benefits; use the comparison table provided to match your product requirements with the appropriate technique.

- Emphasize Customization: Look for a partner that offers extensive customization without compromising cost efficiency. The ability to adapt paddle design to market trends can provide a substantial competitive advantage.

- Assess Quality Control Measures: Robust quality control processes ensure that every paddle meets high performance standards—a critical factor for retaining customer trust.

- Factor in Cost Efficiency: A reliable partner should balance premium performance with competitive pricing, enabling you to scale your product offering without eroding profit margins.

With these considerations in mind, NEX Pickleball stands out as an OEM/ODM partner that comprehensively meets the technical, design, and budgetary demands of today’s competitive market.

Choosing the right manufacturing partner is a pivotal decision for any business in the sporting goods industry. NEX Pickleball combines advanced materials, precise production processes, and cost-effective strategies to deliver high-performance pickleball paddles that cater to both competitive and recreational play. By understanding and comparing material options, production techniques, and quality control measures, procurement managers can confidently select a partner that provides both technical excellence and competitive pricing. Taking the next step in your procurement process with NEX Pickleball is an investment in durability, performance, and market differentiation.

Q: What are the advantages of using carbon fiber in pickleball paddles?

A: Carbon fiber variants, such as 3K, 12K, and T300, offer a combination of strength, flexibility, and low vibration, which result in a paddle that delivers high rebound force, enhanced durability, and superior performance during fast-paced play.

Q: How does the production process impact paddle performance?

A: The production process—whether hot pressing, cold pressing, or thermoforming—affects paddle strength, thickness precision, and overall design. Each method offers different benefits regarding impact resistance, control, and stability, enabling customization based on performance requirements.

Q: What customization options does NEX Pickleball offer for its OEM/ODM paddles?

A: NEX Pickleball provides extensive customization options including design modifications, weight balancing, grip size variations, and surface texture enhancements. These options ensure that each paddle meets specific performance needs and branding requirements.

-

OEM/ODM: Click to learn more about Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) partnerships—their strategic benefits, differences, and how they can drive efficiency in your supply chain. ^↩ ↩

-

carbon fiber: Click to explore comprehensive insights into carbon fiber, including its properties, variants, and why it’s critical for high-performance sporting goods manufacturing. ^↩ ↩

-

Thermoforming: Click to understand the thermoforming process, its applications in manufacturing, and how it contributes to intricate product designs and high-quality finish. ^↩ ↩ ↩2

-

Bulk Production Scaling: Click to read more about bulk production scaling strategies, focusing on achieving economies of scale and maintaining cost efficiency in high-volume manufacturing. ^↩ ↩

-

Nomex Honeycomb Core: Click to delve into the advantages of Nomex Honeycomb Core technology, including its impact absorption properties and role in enhancing the durability of composite structures. ^↩ ↩