Pickleball OEM1 partners can elevate their product line by selecting manufacturers who combine advanced production technologies with premium materials and robust quality control. In this article, we compare production processes, material options, and customization capabilities that distinguish leading OEM pickleball paddle manufacturers, helping you make an informed decision.

In today’s competitive sports equipment market, finding the right OEM partner for your pickleball paddle production is critical. High-performance paddles require the right balance of power, control, durability, and customization. As a procurement manager or product development specialist, you need detailed insights about production processes and material innovations to ensure your products excel on the court. In this article, we will review key manufacturing techniques, compare material choices, and offer actionable recommendations for selecting an OEM partner that meets your high-volume, high-performance demands.

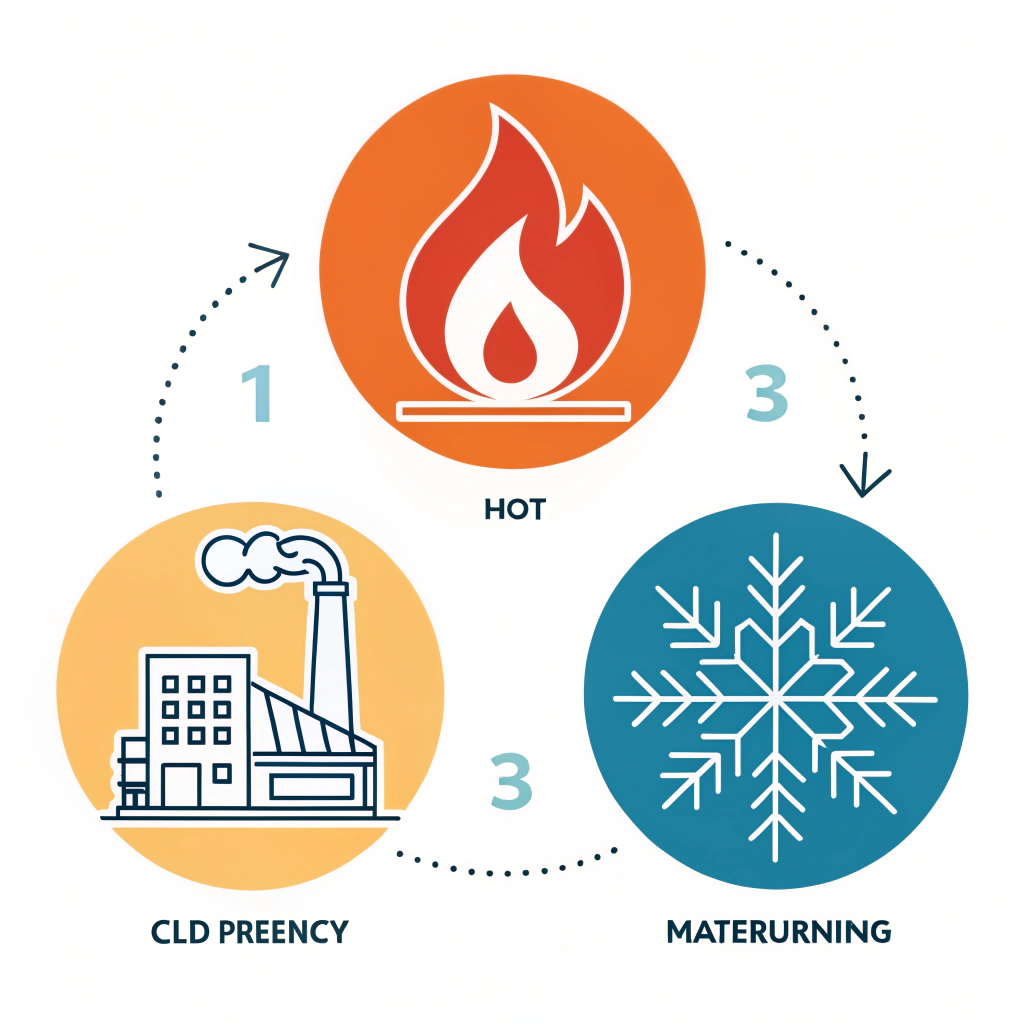

Selecting a manufacturing process is a cornerstone in paddle production. The three primary techniques—Hot Pressing, Cold Pressing, and Thermoforming2—each offer distinct advantages and trade-offs. Below is a detailed comparison that highlights the critical aspects your supply chain must consider.

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | • High production efficiency • Strong paddles with excellent impact resistance • Ensures structural integrity for high-performance use | • Potential alteration of material properties affecting paddle feel • High investment in specialized equipment |

| Cold Pressing | • Precise control over paddle thickness and structure • Maintains material properties for enhanced control and flexibility • Offers excellent ball feel and responsiveness | • Longer production cycles reduce efficiency • Requires high-quality equipment for precise pressure control |

| Thermoforming | • Ideal for intricate designs and precise material distribution • Enhances paddle stability and performance • Suitable for high-performance, custom-made paddles | • Longer production time and higher equipment costs • Best for premium products where cost is justifiable |

Each method plays a pivotal role depending on the paddle’s design and performance goals. For instance, if you aim for a product with exceptional impact resistance for competitive play, hot pressing is a strong candidate. Conversely, for more nuanced playability and refined player feedback, cold pressing or thermoforming can be advantageous.

The material composition of your pickleball paddle is as essential as the production process. Leading OEM manufacturers use several premium materials to achieve the perfect balance between durability, control, and performance.

Carbon Fiber3 Variants

Carbon Fiber is renowned for its strength and lightweight properties. The different types offer distinct benefits:

• 3K Carbon Fiber

– Known for high strength and flexibility

– Provides excellent durability and reduced vibration during play

– Perfect for paddles needing high rebound and impact resistance

• 12K Carbon Fiber

– Higher thread density ensures a smoother paddle surface

– Increased hardness for competitive play

– Ideal for paddles that must withstand intense impacts

• T300 Carbon Fiber

– Offers a balanced performance with robust tensile strength and lightweight features

– Ensures paddles provide both power and agility

Fiberglass and Composite Materials4

Fiberglass offers a blend of power and control with a wider sweet spot, making it ideal for players prioritizing ball control. Additionally, composite materials combine the beneficial properties of carbon fiber and fiberglass, resulting in a paddle that strikes a balance between strength and playability.

• E-Glass Fiberglass

– Known for its excellent elasticity and tensile strength

– Enhances the paddle’s ball feel and control

• Carbon Fiber and Fiberglass Composite

– Combines the strength of carbon fiber with the flexibility of fiberglass

– Offers a harmonious balance that caters to both aggressive and controlled playing styles

The core of the pickleball paddle determines how a paddle performs on impact:

• Nomex Honeycomb Core

– Provides outstanding shock absorption

– Delivers long-lasting durability and stability during intense play

• Aluminum Honeycomb Core

– Balanced weight ensuring excellent power and control

– Ideal for paddles requiring precise impact response

• Polymer Honeycomb Core

– Offers enhanced elasticity and reduced vibration

– Preferred by recreational players aiming for a comfortable hitting experience

Manufacturers, such as NEX Pickleball, excel in combining these advanced materials with state-of-the-art production processes. This integration not only improves paddle performance but also ensures that every unit meets rigorous quality and durability standards.

Modern OEM partners recognize the importance of catering to diverse customer requirements. Customization has become a critical differentiator in the sports equipment market. Leading manufacturers provide options for custom paddle designs that include adjustments to weight distribution, grip size, and surface texture.

On-Demand Printing5 and Custom Design

One of the significant innovations in paddle manufacturing is on-demand printing. This service allows companies to imprint specific designs or branding elements on their paddles. Customized paddles not only serve personal or team branding needs but also provide a competitive edge in niche markets. On-demand printing ensures that the final product aligns with consumer expectations and marketing strategies.

Quality control is a non-negotiable aspect of paddle production. Manufacturers like NEX Pickleball implement strict quality assurance protocols, which include:

• Detailed material inspection before production

• In-line process monitoring during manufacturing

• Post-production testing for impact resistance, tensile strength, and vibration reduction

These measures ensure that the paddles are consistent in quality and meet the high-performance benchmarks necessary for both recreational and competitive play.

For businesses looking to establish a reliable and scalable supply chain, understanding these quality controls is essential. It not only minimizes risk but also ensures customer satisfaction in the long term. Additionally, when evaluating OEM partners, consider their capability to provide technical support and after-sales services—factors that are indicative of a truly customer-centric approach.

To provide actionable insights for your procurement decisions, consider the following scenario: Your company needs to supply high-performance pickleball paddles for a new sports equipment line. You are comparing potential manufacturing partners based on their production technology and customization options.

| Factor | Key Questions | Impact on Decision |

|---|---|---|

| Production Process | Which process best balances speed and material integrity? | Hot pressing for high-volume needs; cold pressing/thermoforming for premium products |

| Material Quality | Are the materials offering optimal performance and durability? | Carbon fiber variants deliver high strength; composites balance power and control |

| Customization Options | Can the manufacturer meet custom design requirements? | On-demand printing and modular design enhance branding and market appeal |

| Quality Control | Do they adhere to strict quality assurance protocols? | Rigorous testing ensures products meet performance benchmarks |

This table is a helpful tool for evaluating different OEM partners. It simplifies the key factors and aligns your technical and business needs with the specific capabilities of each manufacturer.

The pickleball equipment market is evolving with increased awareness about health and fitness and rapid adoption of advanced manufacturing technologies. Industry trends show that manufacturers who invest in innovative production techniques and offer extensive customization options are better positioned to succeed. Some of the emerging trends include:

• Integration of digital design tools for custom paddle configurations

• Adoption of automated quality control mechanisms

• Expansion of on-demand production models to shorten lead times

These trends indicate that partnering with an OEM that is agile and forward-thinking can significantly enhance your competitive advantage. As market demands evolve, manufacturers like NEX Pickleball continue to invest in new technologies and processes to adapt to these changes and maintain high-quality outputs.

Your decision to align with an OEM partner that embraces these advancements will not only sustain product quality but also facilitate long-term innovation and brand growth. Additional factors such as environmental sustainability and supply chain resilience are also gaining prominence in supplier evaluations.

Based on the analysis above, here are some actionable recommendations for procurement and product development specialists:

- Evaluate OEM partners not only on cost but also on their capability to integrate advanced production methods with premium materials.

- Request detailed insights into their quality control processes to understand how each paddle meets performance and safety standards.

- Consider customization services, including on-demand printing and modular design options, as these will enable your brand to differentiate itself in a crowded market.

- Leverage detailed comparison tables when discussing potential partnerships with your team, ensuring you cover all key aspects from production efficiency to material performance.

- Stay informed about industry trends and ensure your chosen partner is forward-thinking and adaptable to future technological advancements.

By focusing on these factors, you can reduce risks in your supply chain and ensure that your product offering consistently meets the high expectations of competitive players and recreational enthusiasts alike.

What is the best pickleball paddle manufacturer?

The top pickleball paddle manufacturers, such as Joola, Selkirk, CRBN, and Gearbox, are known for offering high-performance products with various shapes, paddle lengths, and grip sizes. However, manufacturers like NEX Pickleball provide advanced materials and customizable production techniques that ensure precision, durability, and excellent playability through innovative production processes.

Do more expensive pickleball paddles make a difference?

While skill and technique remain key factors for success in pickleball, more expensive paddles often incorporate higher-quality materials and advanced manufacturing processes. These improvements can enhance durability, ball control, and overall performance, supporting competitive players in achieving their best game.

Are all pickleball paddles made in the same factory?

Many paddle brands manufacture their products in China due to robust production capabilities, but some brands do maintain operations domestically. The production facility is just one aspect; equally important are the manufacturing practices, quality control, and customization capabilities offered by the OEM partner.

-

OEM: Click to learn how partnering with an Original Equipment Manufacturer can streamline your production process, reduce costs, and enhance product quality. ↩ ↩

-

Thermoforming: Click to discover the thermoforming process, including its benefits for intricate designs and precise material distribution in high-performance manufacturing. ↩ ↩

-

Carbon Fiber: Click to explore the properties, types, and applications of carbon fiber which can significantly influence the strength and weight characteristics of your products. ↩ ↩

-

Composite Materials: Click to understand how composite materials combine different materials’ strengths to create superior, balanced products for enhanced performance. ↩ ↩

-

On-Demand Printing: Click to find out how on-demand printing provides customization and branding opportunities by allowing personalized, short-run production runs that meet modern market needs. ↩ ↩