High-performance ODM1 pickleball paddles can significantly enhance your product portfolio by offering superior materials, precise manufacturing processes, and complete customization options that meet both competitive and recreational demands.

In today’s competitive sports equipment industry, sourcing reliable, high-performance ODM partners for pickleball paddles is essential. Procurement managers and product development specialists are increasingly seeking suppliers who not only deliver durability and playability but also the ability to customize products according to market trends. At NEX Pickleball, our advanced techniques including hot pressing2, cold pressing3, and thermoforming4 ensure that every paddle is built to deliver optimal performance and longevity.

Many industry buyers face challenges when selecting a manufacturing partner due to concerns about quality control, production scalability, and overall performance. Common issues include:

- Inconsistent product quality due to varied manufacturing processes.

- Limited material options that restrict performance enhancements.

- Lack of flexibility in product customization that hinders market competitiveness.

These challenges can lead to compromised performance, increased warranty claims, and ultimately, customer dissatisfaction. The right ODM partner must provide robust quality control, innovative production techniques, and a wide array of customization options.

At NEX Pickleball, we understand that the choice of raw materials is critical. Our focus on advanced materials ensures that our products deliver the power, control, and durability required by today’s competitive players. Here are some of our premium material options:

-

Carbon Fiber Variants:

- 3K Carbon Fiber: Offers high rebound force and excellent durability with reduced vibrations.

- 12K Carbon Fiber: Provides enhanced hardness, smoother surfaces, and superior impact resistance, ideal for competitive play.

- T300 Carbon Fiber: Known for its outstanding tensile strength while maintaining a lightweight balance.

-

Fiberglass:

- E-Glass Fiberglass: Delivers an optimal balance between power and control with a wider sweet spot and excellent elasticity.

-

- Carbon Fiber and Fiberglass Composite: Merges the benefits of both worlds to provide a harmonious balance of strength and flexibility.

- Bamboo Core Composite: Provides a lightweight feel with high impact resistance for consistent play.

- Honeycomb Core: Incorporates high-density polymers to enhance shock absorption and minimize paddle vibrations.

-

Core Materials:

- Nomex Honeycomb Core: Ensures stability and longevity with excellent shock absorption.

- Aluminum Honeycomb Core: Balances weight and power, delivering precise control.

- Polymer Honeycomb Core: Reduces vibrations and offers a softer hit, making it user-friendly for beginners.

The use of these premium materials contributes directly to the performance and durability of the pickleball paddles, thereby boosting competitive advantage in the marketplace.

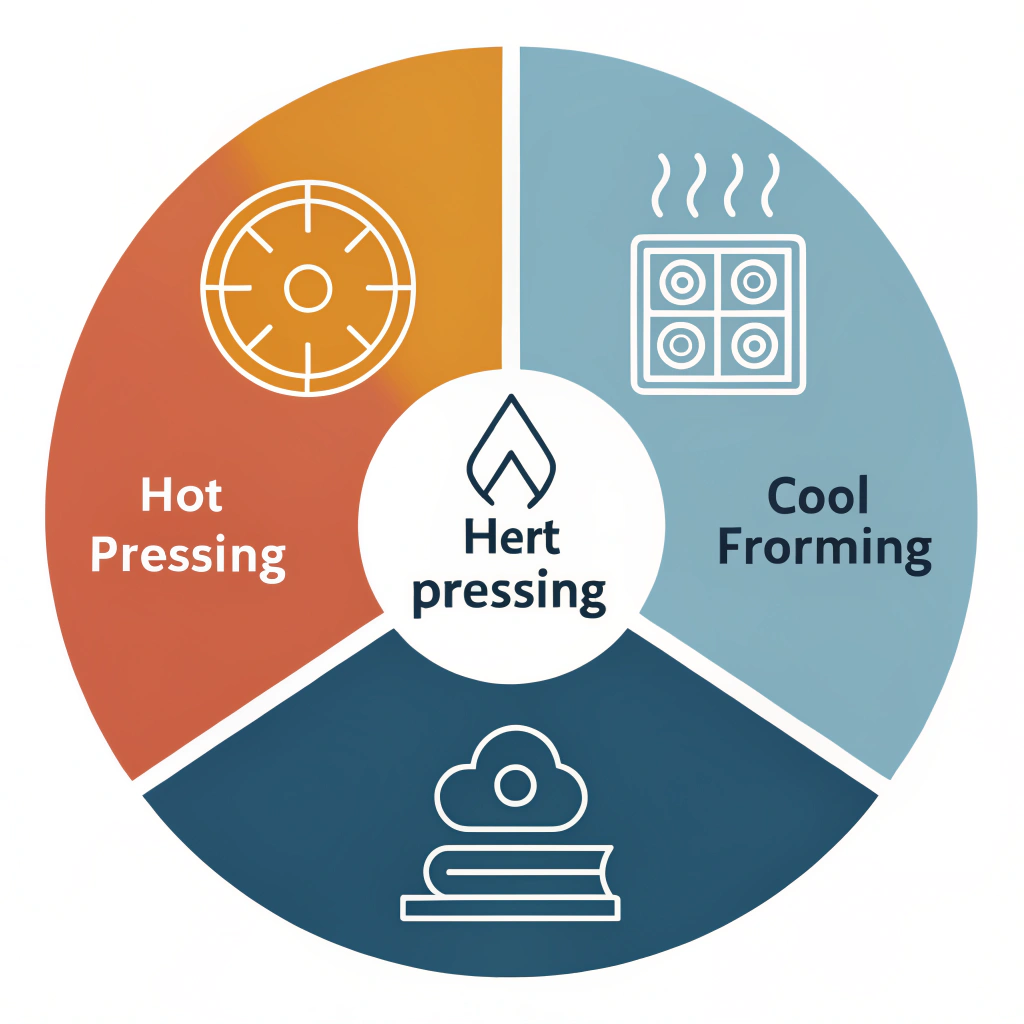

The manufacturing process is as vital as choosing the right materials. At NEX Pickleball, we deploy three core production techniques to achieve high-performance paddles tailored to different playing styles and needs.

Hot pressing involves heating and applying pressure to form the paddle’s composite structure. This method creates a strong bond between layers of material, resulting in paddles with excellent impact resistance.

Advantages:

- High production efficiency suitable for large-scale manufacturing.

- Superior impact resistance and structural integrity.

- Consistency in producing durable products.

Disadvantages:

- Potential alteration in material properties affecting feel.

- Higher initial investment for specialized equipment.

In contrast, cold pressing shapes paddle components at room temperature. This process preserves the inherent flexibility of the materials, which is ideal for producing paddles with enhanced control and ball feel.

Advantages:

- Greater control over paddle thickness and structural precision.

- Maintains material properties, ensuring a natural ball feel.

- Suitable for designs requiring delicate material handling.

Disadvantages:

- Production cycles are comparatively longer, reducing throughput.

- Requires high-precision equipment for effective pressure control.

Thermoforming allows for creating paddles with complex shapes and consistent material distribution by heating materials to their softening point and molding them into shape.

Advantages:

- Ability to produce intricate paddle designs with precise material layout.

- Guarantees stability and consistency in performance.

- Versatile for using a range of high-performance materials.

Disadvantages:

- Longer production times and higher equipment costs.

- Best suited for premium or custom-made paddle lines.

To better understand the trade-offs, refer to the table below:

| Production Method | Key Advantages | Limitations | Ideal Use Case |

|---|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance | Potential alteration of material feel | Large-scale production, competitive paddles |

| Cold Pressing | Precise control over thickness, excellent ball feel | Longer cycle times, high equipment precision | Customized paddles, designs requiring tactile sensitivity |

| Thermoforming | Complex design capability, uniform material distribution | Longer production times, premium cost | Premium products, custom designs |

Quality control and customization are core factors when procuring ODM pickleball paddles. Here are key strategies and considerations when evaluating a potential manufacturing partner:

Every paddle undergoes comprehensive testing to ensure compliance with stringent performance criteria. This includes:

- Vibration and shock absorption tests.

- Durability testing under various playing conditions.

- Inspection of material integrity, particularly in composite and core constructions.

Customization is essential for brands looking to stand out. NEX Pickleball offers:

- Custom design options including color schemes and graphics to match brand identity.

- Customization of paddle weight, balance, and grip size, ensuring the optimal fit for diverse player profiles.

- On-demand print services allowing for unique branding opportunities on each paddle.

Procurement managers must also consider the production scalability of their ODM partner. NEX Pickleball is well-equipped to handle both large volume orders and small-batch customized orders, ensuring:

- Timely delivery and production consistency.

- Flexibility in adapting production lines to new design specifications.

- An established track record of supporting major sports equipment brands globally.

By adopting these strategies, procurement managers can be confident in the superior performance, durability, and tailored features of the paddles delivered.

Consider a mid-sized sports equipment retailer looking to expand its product portfolio with competitive pickleball paddles. The retailer was initially faced with concerns over inconsistent quality and leading-edge technology in ODM manufacturing. After sourcing NEX Pickleball, the following improvements were noted:

- The use of 12K Carbon Fiber in paddle construction provided players with heightened durability and exceptional power, resulting in a marked improvement in game performance.

- The cold pressing process enhanced the tactile feel of the paddle, thereby increasing customer satisfaction through improved ball control and handling precision.

- Custom branding options allowed the retailer to tailor paddles to their market segment, creating a unique product line that resonated with local sports teams and enthusiasts.

This case study exemplifies how integrating advanced materials with precise manufacturing processes can directly translate into superior product performance and market differentiation.

For procurement managers evaluating ODM partners for pickleball paddles, consider the following action steps:

- Define specific quality requirements and performance criteria based on your target customer profiles.

- Evaluate the manufacturer’s range of materials and review their production processes—assessing the trade-offs among hot pressing, cold pressing, and thermoforming.

- Confirm that the ODM partner provides robust quality control measures that align with your product standards.

- Assess customization capabilities to ensure your products can reflect unique brand attributes.

- Consider scalability and lead times to ensure timely fulfillment, particularly during peak season demands.

By following these steps and partnering with a manufacturer like NEX Pickleball, you can be confident in delivering products that enhance your brand’s competitiveness and provide superior performance to end-users.

In conclusion, choosing a reliable ODM partner for pickleball paddles requires a deep understanding of both advanced production techniques and material science. The integration of premium carbon fiber options, durable composite materials, and state-of-the-art production methods such as hot pressing, cold pressing, and thermoforming plays a pivotal role in achieving the perfect balance of power, control, and durability. With a dedicated focus on quality control and customization, suppliers like NEX Pickleball deliver products that not only meet but exceed market expectations.

For procurement managers and product development specialists, the insights provided here serve as a guide to evaluate and choose an ODM partner capable of supporting your brand’s growth and competitive edge. Embrace these strategies, explore the detailed material benefits, and opt for a manufacturing partner that is as committed to quality as you are.

-

What are the benefits of using carbon fiber in pickleball paddles?

Carbon fiber delivers exceptional strength and stiffness while keeping the paddle lightweight. This material minimizes vibration and enhances rebound force, allowing for improved power and control during play. -

How do production processes like hot pressing ensure paddle durability?

Hot pressing applies heat and pressure to bind materials together tightly, resulting in a robust composite structure. This process enhances impact resistance and ensures that the paddle maintains its structural integrity even under high stress. -

What customization options are available when ordering ODM pickleball paddles?

ODM paddle partners typically offer a range of customization options, including tailored designs, color schemes, grip sizes, paddle weight, and balance modifications. This flexibility allows brands to develop products that closely meet the specific needs of their target market.

-

ODM: Reading this article will help you understand the role of Original Design Manufacturers in providing specialized, tailored production solutions that accelerate product development and market entry. ↩ ↩

-

hot pressing: This article explains how hot pressing uses heat and pressure to form strong composite structures, enhancing product durability and consistency. ↩ ↩

-

cold pressing: Learn about cold pressing, a technique that preserves material properties at room temperature, ideal for achieving precise control and optimized tactile responses. ↩ ↩

-

thermoforming: Discover how thermoforming enables the production of complex, custom-shaped products by heating materials to their softening point and molding them into specific designs. ↩ ↩

-

Composite Materials: This resource delves into composite materials, detailing how combining various substances results in enhanced strength, durability, and versatility in product design. ↩ ↩