Quick Answer: NEX Pickleball offers advanced ODM1 solutions for custom carbon fiber surface pickleball paddles by combining innovative material science with precise production processes like hot pressing2, cold pressing3 and thermoforming4. This integrated approach ensures high-performance, durability, and tailored paddle design to meet the rigorous demands of today’s competitive sports equipment market.

In today’s competitive sports equipment market, it is essential for B2B partners to choose an ODM with not only reliable production capabilities but also the technical expertise to produce high-performance pickleball paddles. NEX Pickleball uses advanced production techniques and engineering-driven design to create custom carbon fiber5 surface paddles that meet exact specifications. Our commitment to innovation, quality control, and customization makes us a trusted partner for professionals in product development and procurement.

The sports equipment industry requires pickleball paddles that blend performance with durability. However, most buyers face several challenges when evaluating ODM partners:

• Achieving a consistent balance between weight distribution and paddle responsiveness.

• Ensuring that innovative materials, especially advanced carbon fiber composites, are correctly integrated into the paddle's design.

• Managing production processes to keep quality high while tailoring designs for specific market segments.

These challenges are compounded by the need to evaluate multiple production techniques while navigating the limitations inherent to each process.

Understanding the root causes of these challenges is crucial for making informed decisions:

-

Material Complexity:

- Carbon Fiber Variants: Different types such as 3K, 12K, and T300 carbon fibers have varying degrees of strength, flexibility, and durability. Misapplication of these materials can compromise performance.

- Composite Alternatives: Blends of carbon fiber with fiberglass or other composites need precise balance to maximize both control and power.

-

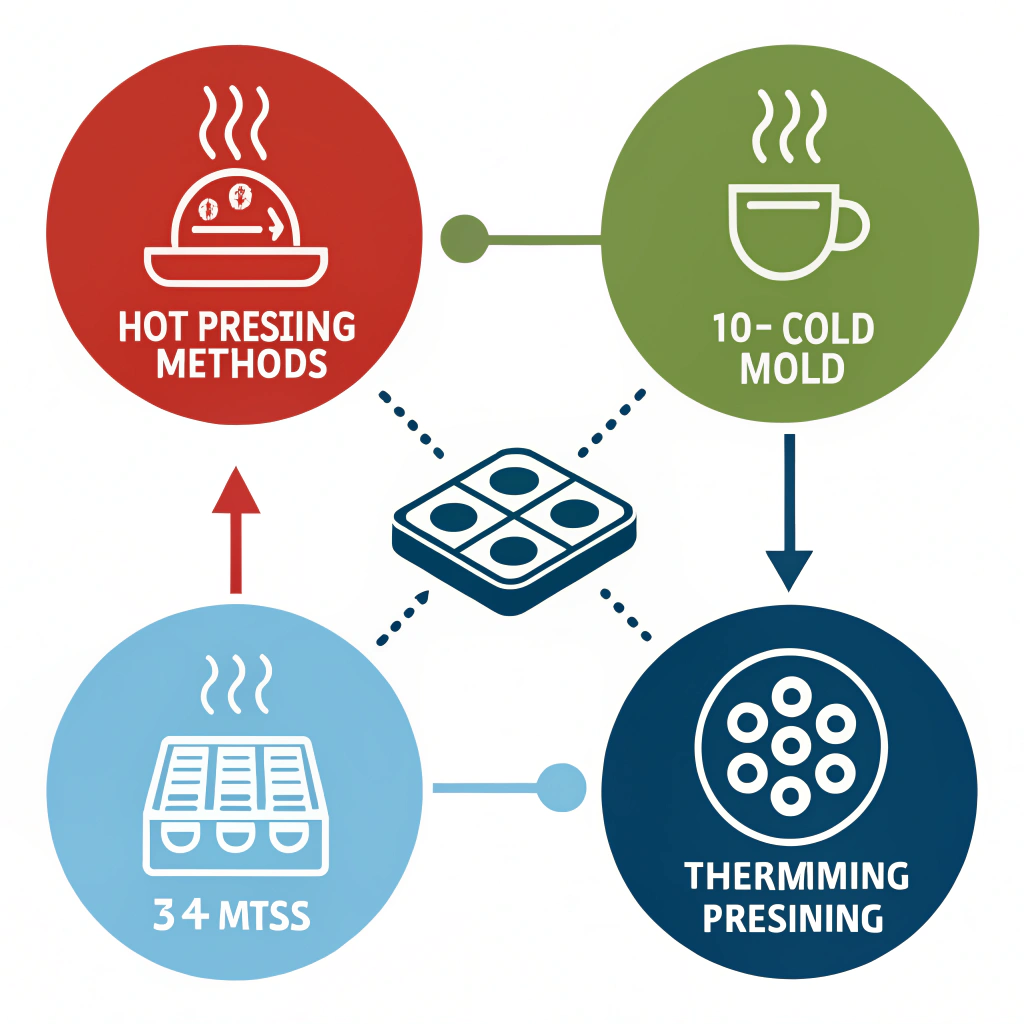

Production Techniques:

- Hot Pressing: Offers high efficiency and strong impact resistance but may alter material properties if not carefully controlled.

- Cold Pressing: Provides precise control over thickness and structural consistency, yet this slower method demands intensive quality assurance.

- Thermoforming: Allows for intricate paddle design; however, the longer production cycles increase costs and equipment needs.

-

Customization Demands:

- Modern players and teams require custom designs that reflect their brand or personal play style. This customization must not detract from the paddle’s performance characteristics.

NEX Pickleball’s ODM solutions address these challenges through a blend of advanced production methods, expert material selection, and stringent quality control. Below is an outline of our solution strategy.

| Production Technique | Advantages | Disadvantages | Best Use Cases |

|---|---|---|---|

| Hot Pressing | High production efficiency; excellent impact resistance; enhanced structural integrity | Requires significant upfront equipment investment; may slightly alter material feel | Mass production of high-performance paddles |

| Cold Pressing | Precise control over paddle thickness and structure; preserves original material properties | Slower production cycle; demands precise pressure control | Custom designs requiring meticulous control and premium ball feel |

| Thermoforming | Capable of producing intricate designs; maintains stability across paddle surfaces | Higher costs and longer production times due to mold complexity | Custom, premium paddles with complex shapes and specialized material distribution |

Each technique is paired with premium materials ensuring that the paddles remain lightweight yet robust. For instance, our use of 3K carbon fiber delivers strength and flexibility, whereas 12K provides the enhanced hardness required in competitive play. Additionally, we leverage T300 carbon fiber which offers an unparalleled balance of tensile strength and lightweight design.

Our approach to customization sets us apart. Clients can specify design elements such as:

• Paddle weight

• Balance distribution

• Grip size that conforms to ergonomic design principles

• Surface texture treatments for improved ball grip and spin control

By integrating custom options into the production process, we ensure that each paddle not only meets but exceeds industry performance standards.

Quality assurance is an important pillar of our ODM strategy. Each paddle undergoes rigorous testing, including:

- Structural Integrity Tests: Ensuring that all materials, especially delicate carbon fiber layers, combine to produce a paddle capable of withstanding high-impact play.

- Vibration Analysis: Reducing unwanted bounce and vibration to enhance the playing experience across all levels of play.

- Ergonomic Evaluation: Testing different grip sizes and designs to ensure optimal hand comfort and control during extended gameplay.

These testing protocols are vital to reducing defects and maintaining the high quality that NEX Pickleball is known for in the industry.

Carbon fiber is at the forefront of material technology in paddle manufacturing. Its use in pickleball paddles offers specific benefits:

• Strength and Durability: Carbon fiber ensures that the paddle withstands rigorous use without warping or degrading in performance over time.

• Lightweight Nature: This attribute contributes to the paddle’s agility, enabling faster response times and better maneuverability during play.

• Enhanced Rebound Properties: The stiffness inherent in carbon fiber translates to superior ball rebound and control, giving competitive players a performance edge.

By judiciously selecting and applying the appropriate carbon fiber type, NEX Pickleball ensures that each product provides the ideal mix of durability, power, and control.

A recent project with a sports equipment distributor demonstrates our capability to handle complex requirements. The client required paddles featuring a custom carbon fiber surface integrated with a bamboo core composite. The challenges included:

• Maintaining consistency across a large production batch

• Balancing the inherent flexibility of bamboo with the rigidity of carbon fiber

• Producing a paddle that satisfies both recreational and competitive play demands

Through the application of careful design and process engineering, our team successfully deployed a hybrid production approach, combining both thermoforming for the intricate surface design and cold pressing for precise control over the paddle's thickness. The outcome was a durable, high-performance paddle that received outstanding feedback from professional players and retailers alike.

When B2B buyers compare ODM partners, they must consider several technical and production factors to ensure a successful partnership:

-

Material Expertise:

- Does the partner offer a diverse range of production materials including various grades of carbon fiber, fiberglass, and composite options?

- How well does the supplier understand the trade-offs between different materials in terms of performance and durability?

-

Production Capabilities:

- What are the partner’s expertise and production scale using hot pressing, cold pressing, and thermoforming?

- Is there a robust quality control system in place to handle both mass production and bespoke orders?

-

Customization and Flexibility:

- Can the ODM tailor products to meet different ergonomic and performance requirements?

- Does the supplier provide options for custom grip sizes, weight balancers, and surface treatments?

-

After-Sales Support:

- How does the supplier support post-production testing and quality assurance?

- Are there transparent production timelines and efficient logistics to meet market demand?

A thorough evaluation of these criteria will help decision-makers select an ODM partner who not only meets technical standards but also supports long-term growth and innovation.

For procurement specialists and product development managers seeking a reliable ODM partner for pickleball paddles:

-

Conduct a Multi-Faceted Evaluation:

- Review the supplier’s production techniques, portfolio of custom design options, and history of industry compliance.

- Ask for detailed case studies or data on material performance, particularly regarding advanced carbon fiber applications.

-

Engage in Direct Communication:

- Request technical consultations to clarify questions about production processes and material advantages.

- Discuss potential for custom modifications and volume adjustments that suit your market needs.

-

Leverage Data-Driven Insights:

- Use performance metrics and test data provided by the supplier to determine efficiency and product longevity.

- Compare these metrics with industry standards to ensure the chosen ODM partner offers the best return on investment.

-

Plan for Long-Term Collaboration:

- Verify the supplier’s capability to scale production in line with market demand.

- Establish clear quality control and product customization protocols to ensure continued excellence.

These actions will enable companies to build lasting relationships with ODM partners who are committed to quality and innovation, thereby ensuring that every product delivered truly enhances end-user performance.

NEX Pickleball’s advanced ODM solutions are designed to help businesses overcome the technical challenges of modern pickleball paddle production. By integrating cutting-edge material technologies like custom carbon fiber surfaces with meticulous production techniques such as hot pressing, cold pressing, and thermoforming, we deliver paddles that combine strength, precision, and tailored customization. Our rigorous quality control protocols and data-driven testing methods ensure that every paddle meets high-performance standards, enabling sports equipment manufacturers to confidently offer top-tier products in a competitive market.

By carefully evaluating material benefits, production methods, and customization potential, B2B decision-makers can select a partner that aligns with their performance and innovation goals. NEX Pickleball stands ready to deliver high-performance custom pickleball paddles that respond to the demanding needs of today’s market.

-

Is carbon fiber better for pickleball paddles?

Carbon fiber offers an exceptional combination of strength and lightweight properties. Its stiffness and durability provide superior ball rebound and control compared to traditional materials, making it an ideal choice for high-performance pickleball paddles. -

What is the best core material for pickleball paddles?

While some lower-end paddles may use full Nomex or aluminum cores, polymer cores have proven to be the most effective for balancing elasticity and vibration reduction, thereby delivering a better overall hitting experience, particularly in competitive settings. -

What is the best material for a pickleball paddle to be made of?

Based on extensive testing and industry experience, carbon fiber is widely regarded as the best material for pickleball paddles. It offers remarkable strength, durability, and performance, surpassing many alternatives such as composite materials or fiberglass.

-

ODM: Read more to understand how Original Design Manufacturers enable businesses to outsource product design and production, fostering innovation and efficiency in global supply chains. Back to ODM ↩

-

Hot pressing: Discover how hot pressing techniques optimize material bonding and structural integrity in advanced composite manufacturing. Back to hot pressing ↩

-

Cold pressing: Explore the benefits of cold pressing in controlling material thickness and preserving original properties for precision-engineered products. Back to cold pressing ↩

-

Thermoforming: Learn about thermoforming processes and their role in producing complex, custom shapes in modern manufacturing. Back to thermoforming ↩

-

Carbon fiber: Click to learn about the properties and applications of carbon fiber in enhancing product performance and durability in high-tech environments. Back to carbon fiber ↩