Quick Answer: To optimize pickleball paddle production, startups must balance MOQ1 requirements, production efficiency, and quality control by carefully selecting processes like hot pressing, cold pressing, and thermoforming2, while negotiating with reliable suppliers such as NEX Pickleball. This integrated approach can reduce risks, lower costs, and ensure high-performance equipment for the competitive pickleball market.

Managing Minimum Order Quantities (MOQ) is one of the biggest challenges for startup founders and procurement managers in the fast-growing pickleball industry. The key lies in understanding how different manufacturing processes, material choices, and supplier negotiations impact overall production costs and quality.

At companies like NEX Pickleball, we have refined our production strategies to strike a balance between optimal production scales and cost-effective purchasing. Leveraging advanced production techniques — including hot pressing, cold pressing, and thermoforming — not only guarantees a premium product but also allows us to offer competitive MOQs to support supply chain flexibility.

A major issue for startups is the pressure to meet suppliers’ MOQs, which can force you to commit to bulk orders, potentially increasing storage costs and upfront investment. This challenge is compounded by the need for quality standards expected from professional-level equipment.

- Production Process Efficiency:

Manufacturers invest in high-volume production to recoup costs on expensive machinery. This means that small-batch orders might be raised significantly or carry a premium. - Material Costs and Quality:

Using advanced materials such as 3K Carbon Fiber3, 12K Carbon Fiber, T300 Carbon Fiber, and various composite options can increase per unit cost, pushing suppliers to enforce higher MOQs. - Customization and Precision Requirements:

Custom paddle options, which include specific weight, balance, and grip sizes, require special tooling and quality control. This, in turn, can drive minimum order sizes upward as a way for manufacturers to ensure the process remains economically viable. - Supply Chain Agreements:

Long-term supply and contractual agreements are often based on volume guarantees. These conditions require careful negotiation, especially for startups seeking flexibility with lower risks.

These factors demand that startups assess production strategies holistically, linking manufacturing details with business financial planning to make informed sourcing decisions.

Different production processes have inherent advantages and limitations that influence MOQ requirements. Below is a comparison table reflecting the key attributes of each manufacturing method:

| Production Process | Advantages | Disadvantages | MOQ Impact |

|---|---|---|---|

| Hot Pressing | - High efficiency and fast production - Produces durable, high-resilience paddles | - High equipment investment - Possible alteration of material properties | Lower flexibility; often higher MOQ |

| Cold Pressing | - Greater precision and control in paddle thickness - Retains material properties | - Longer production cycles - Requires high-quality pressure control | Moderate MOQs with flexibility |

| Thermoforming | - Allows for intricate designs and optimal weight distribution - Suitable for premium orders | - Longer production times - Higher cost due to specialized equipment | Customizable, but generally higher |

Selecting a production process should not be based solely on MOQ but also on the balance between efficiency, cost, and product performance. For startups with limited budgets, negotiation on MOQ requirements can focus on adapting processes that allow lean manufacturing without compromising on the paddles' structural integrity.

In the dynamic landscape of sports equipment manufacturing, establishing smart sourcing strategies is essential. Here are several strategies to manage and negotiate MOQs effectively:

Startups can benefit from a diversified production approach, which might include:

- Hybrid manufacturing models: Use cold pressing for limited batch orders and hot pressing for scaling up when you expect higher demand.

- Custom Production Runs: Collaborate with manufacturers who offer on-demand printing and custom paddle production to meet specific client needs without excessively high MOQs.

Joining forces with other small orders or partnering with local distributors can help meet MOQ requirements while minimizing costs. In some cases, shared production runs can lead to better pricing and reduced risk.

Discuss with suppliers the possibility of:

- Lowering MOQs for initial trial orders, particularly if there is a potential for long-term business.

- Structuring agreements that allow for incremental increases in MOQs as your business grows or as market demand stabilizes.

- Incorporating build-to-order models that optimize inventory management and reduce waste.

Implementing effective supply chain management practices is key:

- Demand Forecasting: Use sales forecasting to predict optimal order quantities, reducing the risk of overproduction.

- Inventory Management: Adopting a lean inventory approach can minimize storage costs while ensuring you always have sufficient stock to meet market demands.

A well-structured supply chain not only helps lower the cost per unit but also ensures that production is closely aligned with customer demands and market trends.

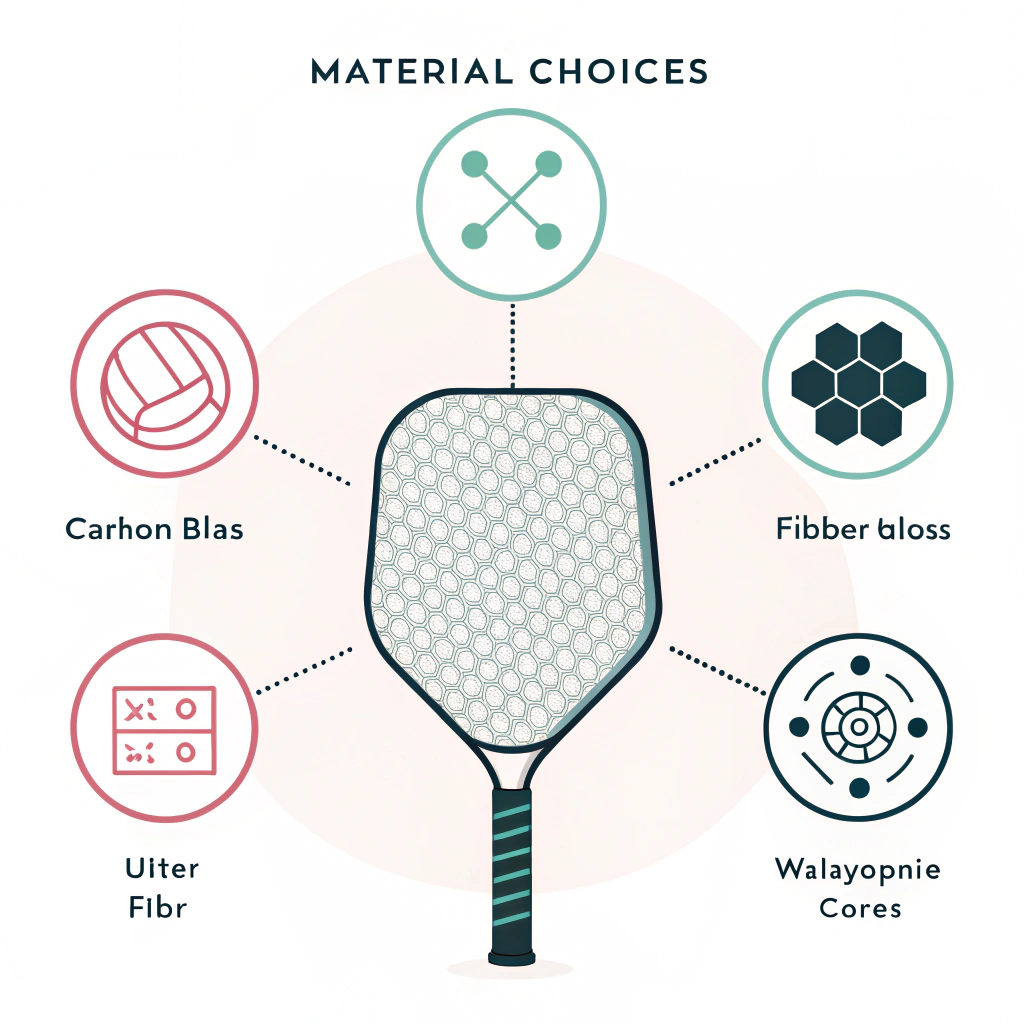

The choice of production material significantly affects MOQ structure:

- Carbon Fiber Options:

- 3K Carbon Fiber offers great flexibility and durability, making it ideal for paddles that require high rebound forces but might push MOQ higher due to its cost.

- 12K Carbon Fiber provides a smoother surface and is often used in competitive paddles, which may require even stricter MOQ thresholds for quality assurance.

- T300 Carbon Fiber strikes a balance between weight and strength, making it a popular choice in competitive markets.

- Fiberglass:

Provides a balance between control and power with a more cost-effective approach, which can help in lowering MOQs for entry-level production. - Composite Materials:

Combinations such as carbon fiber and fiberglass composites offer advantages that support both lower MOQ and enhanced performance, helping startups achieve a competitive edge. - Core Materials:

Using Nomex Honeycomb Core4, Aluminum Honeycomb Core, or Polymer Honeycomb Core affects the paddle’s performance. MOQs may vary based on the complexity and availability of these materials in the desired quality.

By carefully selecting materials, businesses can control production costs and reorder requirements without sacrificing product performance.

At NEX Pickleball, our experience highlights the importance of a comprehensive approach to MOQ management:

- Integrated Production Processes: We utilize a mix of hot pressing and cold pressing to cater to different market needs. For instance, while hot pressing is ideal for large, cost-efficient runs, cold pressing is favored for precise designs in limited orders.

- Supplier Negotiation: Our longstanding relationships with suppliers like Joola and Selkirk have allowed us to negotiate flexible MOQ terms, ensuring that even small businesses have access to high-quality production capabilities.

- On-Demand Manufacturing: Offering on-demand-print services on our paddles further reduces the requirement for high MOQs while enabling customization. This flexibility is particularly valuable for retailers and sports clubs that require branded or unique paddle designs.

These strategies combine product innovation with operational efficiency, allowing startups to minimize the risks associated with bulk orders while still delivering high-quality pickleball paddles.

Aligning production strategies with your business goals is crucial for success in the competitive pickleball market. Here are the main takeaways:

-

Understand the Impact of Production Processes:

Analyze how hot pressing, cold pressing, and thermoforming each contribute to your MOQ requirements and overall production efficiency. -

Optimize Material Selection:

Choose materials that meet performance expectations while aligning with your budget and order volume requirements. The blend of carbon fiber, fiberglass, and composite cores should be tailored to your market niche. -

Adopt Flexible Sourcing Strategies:

Negotiate MOQs by leveraging collaborative orders, exploring build-to-order models, and employing demand forecasting. These tactics help in managing inventory and reducing upfront costs. -

Implement Robust Supply Chain Management:

Use lean manufacturing principles and inventory control strategies to better predict order needs and negotiate fair terms with suppliers. -

Leverage Cutting-Edge Production Techniques:

Advanced manufacturing methods can reduce production time and costs, offering a competitive edge in high-performance paddle production.

For startups and procurement managers, a thorough evaluation of these factors helps in making informed purchasing decisions, ensuring that production costs remain manageable while meeting quality expectations. By integrating these strategies, businesses can maximize efficiency, optimize order quantities, and create a sustainable competitive environment.

If you are looking to streamline your production process and negotiate better MOQs, consider partnering with experienced manufacturers like NEX Pickleball. Our commitment to quality, innovation, and customer satisfaction has helped many businesses achieve their operational goals while scaling production efficiently.

Q: How much money do you need to start a pickleball business?

A: The initial investment for starting a pickleball business can vary widely, often ranging from moderate to significant amounts. Startup costs generally include equipment, facility leasing or purchase, marketing, and staffing. For a franchise model, the initial fee can be substantial, but for an independent operation, careful planning and resource allocation can make the venture viable even with a smaller budget.

Q: Is a pickleball business profitable?

A: A pickleball business can be profitable if managed effectively. Profitability depends on operational efficiency, cost control, and additional revenue streams such as lessons, tournaments, and merchandise sales. Effective management of production costs and understanding MOQ strategies can also contribute to overall profitability in the competitive sports equipment market.

Q: How much to start playing pickleball?

A: The cost to start playing pickleball can be relatively low compared to other sports. Initial investments vary, ranging from a basic paddle and minimal gear at around $50 to several hundred dollars for premium equipment. Investing in quality gear enhances performance and ensures longevity, but the overall cost remains accessible for most beginners.

-

MOQ: Reading this article will help you understand Minimum Order Quantities—key parameters used in manufacturing that dictate the smallest quantity a supplier is willing to produce or sell, aiding in optimizing production scales and cost efficiency. ↩

-

thermoforming: Reading this article will introduce you to thermoforming, a manufacturing process that uses heat to shape plastics or composites, enabling intricate designs and tailored performance in equipment production. ↩

-

3K Carbon Fiber: Reading this article will provide insights into 3K Carbon Fiber, a specific grade known for its balance of strength and flexibility, often used in high-performance sporting equipment where material properties directly affect cost and MOQ. ↩

-

Nomex Honeycomb Core: Reading this article will explain Nomex Honeycomb Core, a lightweight yet robust material used to enhance structural integrity in composite products, offering advantages in performance while influencing production volume requirements. ↩