NEX Pickleball delivers high-performance, customizable pickleball paddles by utilizing advanced production techniques to guarantee quality, brand consistency, and exceptional playability. In today’s competitive sports equipment market, partnering with a supplier that offers innovative production processes and reliable on-demand printing1 services is essential for distributors and retailers aiming to differentiate themselves.

Customizable pickleball paddle sets have become a crucial tool for sports equipment distributors looking to build a competitive edge. The procurement manager or product development specialist faces the challenge of sourcing products that meet high-performance standards while offering distinct branding opportunities. At NEX Pickleball, we understand the importance of combining modern production methods with customization capabilities. Our expertise in techniques such as hot pressing2, cold pressing3, and thermoforming4 enables us to deliver paddles that not only perform exceptionally on court but also align perfectly with the distributor’s brand identity.

The decision-making process for selecting a supplier is inherently complex. Distributors must evaluate several technical factors: material quality, production efficiency, customizable options (especially logo printing), durability, and cost effectiveness. NEX Pickleball stands out through our commitment to quality control and innovation. We manufacture our paddles using premium materials such as various types of carbon fiber5 (3K, 12K, T300), E-Glass Fiberglass, and superior composite materials. Each material is chosen to meet specific performance needs, ensuring that our paddles support both power and control for different levels of play.

Below is a summary table comparing the three primary production processes employed by NEX Pickleball:

| Production Process | Advantages | Disadvantages | Customization Potential |

|---|---|---|---|

| Hot Pressing | • High production efficiency • Strong paddles with excellent impact resistance • Ensured structural integrity | • May alter some material properties • Requires significant investment in equipment | Moderate – Suitable for large-scale orders with standard designs |

| Cold Pressing | • Precise control over paddle thickness and structure • Maintains material properties • Better ball feel and responsiveness | • Longer production cycles • Needs precision pressure control | High – Ideal for customized designs and precise branding |

| Thermoforming | • Enables intricate designs and precise material distribution • Enhances paddle stability • Perfect for complex shapes | • Longer production time • Higher equipment cost | High – Best for premium and custom-made paddles |

Our production methods are supported by detailed technical know-how. In our process:

- Hot Pressing2 integrates heat and pressure, forming a robust paddle structure ideal for high-impact competitive scenarios.

- Cold Pressing3 focuses on maintaining the original material properties, ensuring a consistent and responsive feel during play.

- Thermoforming4 allows for detailed customization, accommodating intricate designs and ensuring uniform material distribution.

Additionally, our paddle manufacturing involves using several high-performance materials:

- Carbon Fiber Types5:

• 3K Carbon Fiber forms a flexible yet strong surface, minimizing vibration.

• 12K Carbon Fiber provides an ultra-smooth, durable finish suitable for high-impact play.

• T300 Carbon Fiber strikes a balance between strength and light weight, enhancing maneuverability. - Fiberglass Options:

• E-Glass Fiberglass is known for its elasticity and excellent ball control, delivering a wider sweet spot. - Composite and Core Materials:

• Carbon Fiber & Fiberglass Composite marries the qualities of both materials for balanced performance.

• Bamboo Core Composite and Honeycomb Core strategies give paddles superior shock absorption and a distinct hitting feel.

• Core options like Nomex Honeycomb, Aluminum Honeycomb, and Polymer Honeycomb each provide unique advantages in durability, power, and comfort.

A recent case study illustrates our commitment to quality and customization. A leading sports distributor approached us with the challenge of replacing inconsistent vendor supplies that struggled to meet the high standards required for competitive play. By switching to NEX Pickleball, the distributor experienced a significant improvement in both the consistency of paddle performance and the vibrancy of their custom logo prints. With our scalable production methods and rigorous quality control, customer satisfaction increased dramatically, proving the value of partnering with a technically advanced manufacturing facility.

For a clearer understanding, consider the following detailed product attribute comparison:

| Attribute | Production Process Impact | Benefits | Considerations for Customization |

|---|---|---|---|

| Material Strength | Hot Pressing preserves overall integrity | Enhanced durability and impact resistance | Ideal for mass production with robust performance |

| Precision and Control | Cold Pressing enables fine-tuned adjustments | Superior ball feel and responsive hitting | Supports intricate logo designs and custom strokes |

| Design Complexity | Thermoforming allows for unique, detailed shapes | Allows for elite performance with uniform consistency | Perfect for limited edition or high-priced custom paddles |

This table underscores the critical balance between production efficiency and customization needs—a central consideration for procurement managers.

The combination of advanced production methods and customizable painting or printing techniques provides immense value when selecting a supplier. Here are some strategic tips for evaluating potential suppliers:

- Ensure they offer detailed documentation of their production processes and quality controls.

- Request sample orders to assess the tactile, visual, and performance characteristics of the paddles.

- Compare the cost models in relation to production scalability, ensuring the supplier can manage your volume requirements without compromising quality.

- Look for certifications or testimonials that solidify their track record in producing high-performance, customizable paddle sets.

At NEX Pickleball, we pride ourselves on innovation and adaptability. Our prowess in both high-volume production and intricate customization makes us an ideal partner for sports distributors. The ability to print logos on-demand and adapt to evolving market trends provides a competitive edge that many suppliers cannot match.

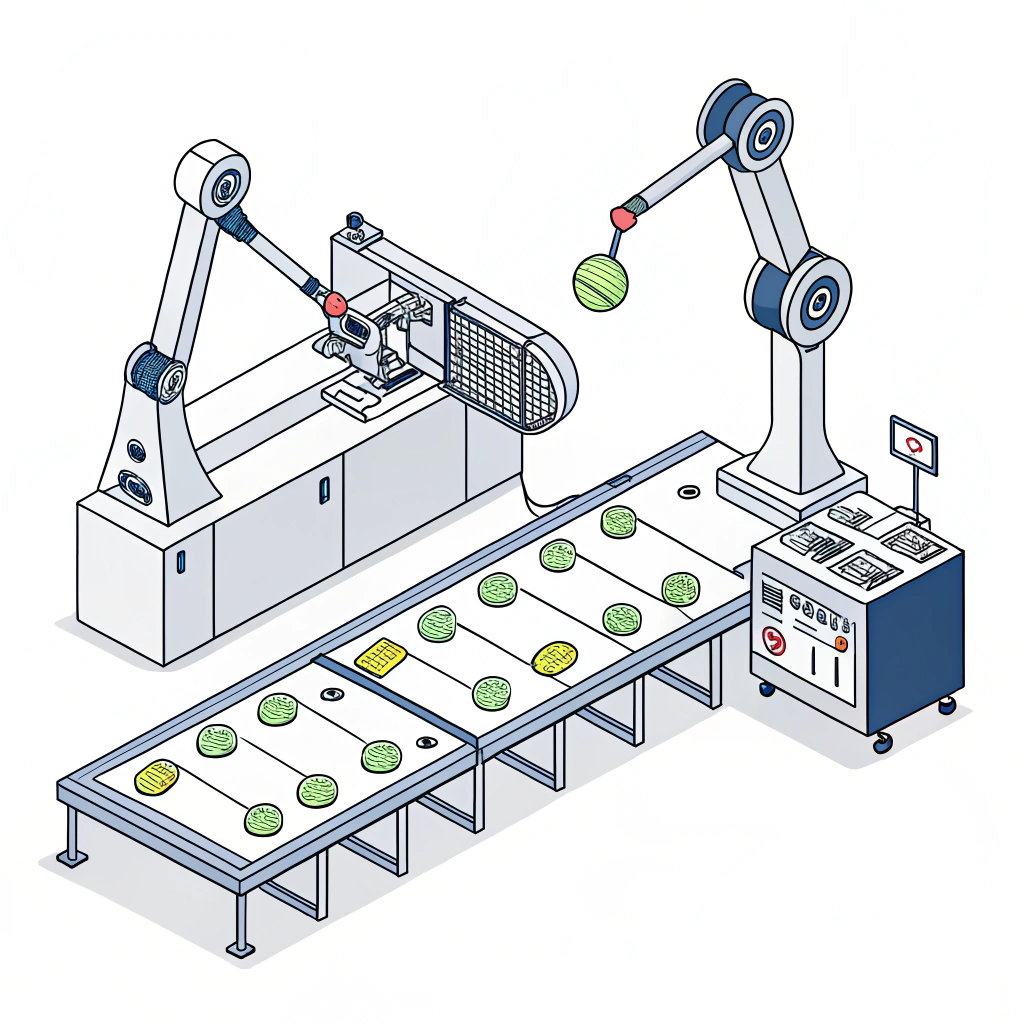

Another significant factor is the integration of our supply chain operations with modern technology. Automation in our production line ensures that each paddle is crafted with precision and consistency. Whether it is through our hot pressed paddles for extreme durability or cold pressed paddles that maintain material integrity, every process is optimized for high performance. We regularly upgrade our equipment and invest in research to continually enhance our production methods. This commitment not only supports large-scale production but also ensures that every customized detail, such as branded logos or specific design modifications, is delivered as requested.

Moreover, our on-demand printing1 service allows clients to personalize their orders quickly and accurately. This flexibility is crucial for companies that need to refresh seasonal designs or tailor product lines to specific events. The ability to combine rapid production with customization means that distributors can meet market demands efficiently without waiting for lengthy production cycles.

An additional operational highlight involves our stringent quality control measures. Each paddle undergoes a series of tests that simulate real-world play conditions to ensure they can withstand rigorous use. Our quality control process includes:

- Material integrity tests for each carbon fiber and composite layer.

- Vibration and impact absorption evaluations.

- Consistency checks on color, branding precision, and final finish.

These methodologies help us maintain a high standard across every batch, ensuring that our partners can rely on our products for competitive performance and brand reliability.

In summary, partnering with NEX Pickleball offers distributors a reliable and innovative solution for sourcing customizable pickleball paddle sets. Our advanced production techniques such as hot pressing, cold pressing, and thermoforming are designed to meet the diverse needs of competitive sports equipment markets. The use of premium materials combined with our custom printing services ensures that every paddle not only delivers exceptional performance but also reinforces your brand identity. We encourage procurement managers to consider factors such as production efficiency, material quality, and the ability to customize when choosing a supplier. With NEX Pickleball, you gain a dedicated partner committed to excellence, scalability, and continuous improvement—a truly competitive advantage.

We invite interested buyers to engage in further discussions with our technical and sales teams to explore how our solutions can meet and exceed your customized sports equipment needs.

People Also Ask

Q: How do advanced production methods like hot pressing, cold pressing, and thermoforming improve paddle performance?

A: These methods optimize material strength and design precision. Hot pressing boosts durability and impact resistance, cold pressing preserves material properties for enhanced control, and thermoforming enables intricate, customized designs that improve overall paddle performance.

Q: What benefits does customization offer in paddle manufacturing for sports equipment distributors?

A: Customization allows distributors to differentiate their product lines with branded logos, unique design features, and tailored performance characteristics. It supports better market positioning and meets specific consumer or team requirements.

Q: How does NEX Pickleball ensure consistent quality for high-volume orders?

A: NEX Pickleball employs rigorous quality control procedures throughout the production process, including standardized testing for material integrity, impact absorption, and branding precision. Combined with advanced manufacturing techniques, this ensures every batch meets stringent quality standards.

-

on-demand printing: Click the footnote 1 to learn how on-demand printing enables rapid customization and swift order turnaround, enhancing responsiveness in the competitive market. ^back ↩ ↩2 ↩3

-

hot pressing: Click the footnote 2 to understand how hot pressing leverages heat and pressure to create durable, high-impact resistant products for sports equipment. ^back ↩ ↩2 ↩3

-

cold pressing: Click the footnote 3 to see how cold pressing maintains material integrity through precise pressure control, which enhances the performance and responsiveness of the final product. ^back ↩ ↩2 ↩3

-

thermoforming: Click the footnote 4 to explore how thermoforming allows for intricate and detailed designs by shaping materials with controlled heat, ideal for custom projects. ^back ↩ ↩2 ↩3

-

carbon fiber: Click the footnote 5 to delve into the properties of carbon fiber, a high-performance material known for its exceptional strength-to-weight ratio and versatility in manufacturing. ^back ↩ ↩2 ↩3