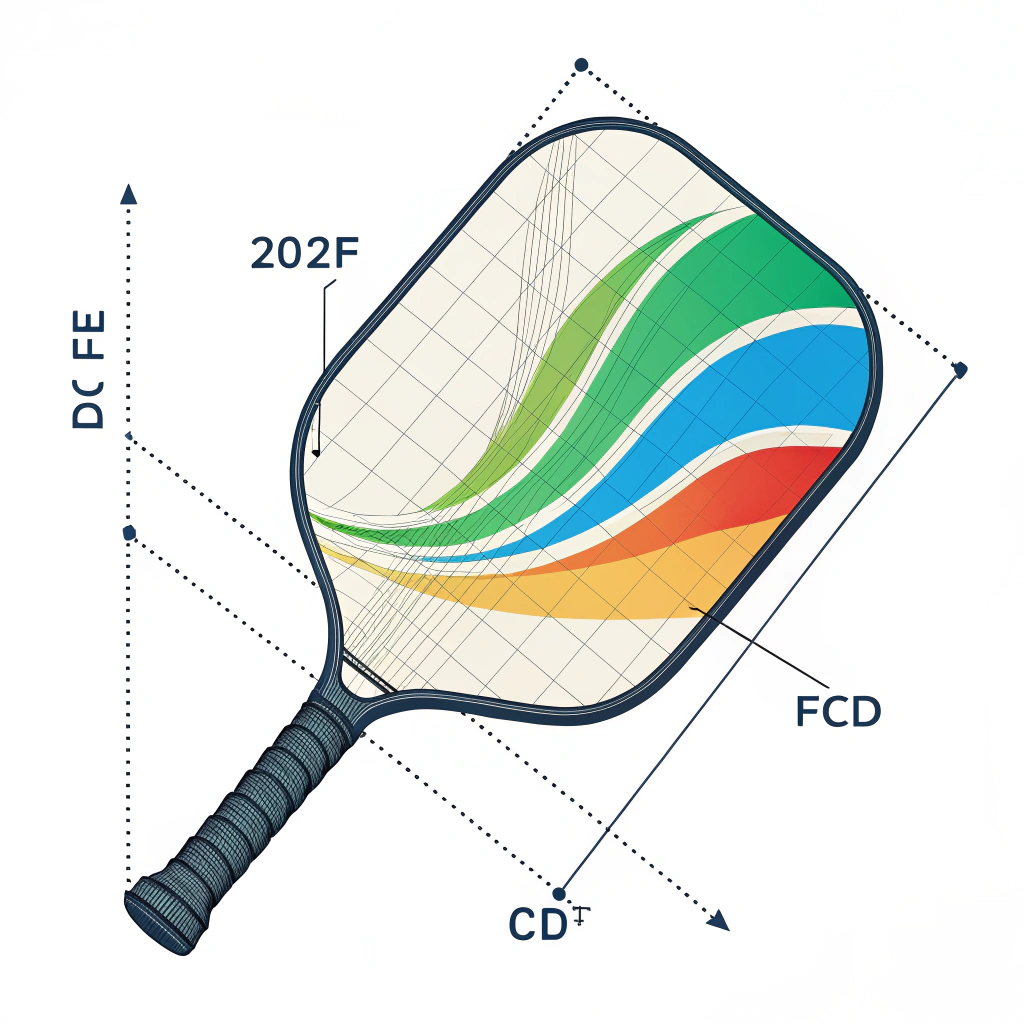

CFD simulation offers manufacturers a powerful tool to optimize pickleball paddle design by accurately modeling airflow and material behavior, ultimately improving performance and reducing costs.

The world of high-performance sports equipment is rapidly evolving, driven by technological advancements that enable manufacturers to enhance product quality and performance. In this context, Computational Fluid Dynamics (CFD)1 simulation emerges as a game-changing solution for optimizing the aerodynamic properties of pickleball paddles. CFD simulation allows design engineers to predict how air and fluid flows interact with paddle surfaces, ultimately guiding decisions that balance power, control, and durability. This article explores how CFD simulation compares with traditional design methods, outlines its benefits, and explains why it is becoming an essential tool in sports equipment manufacturing.

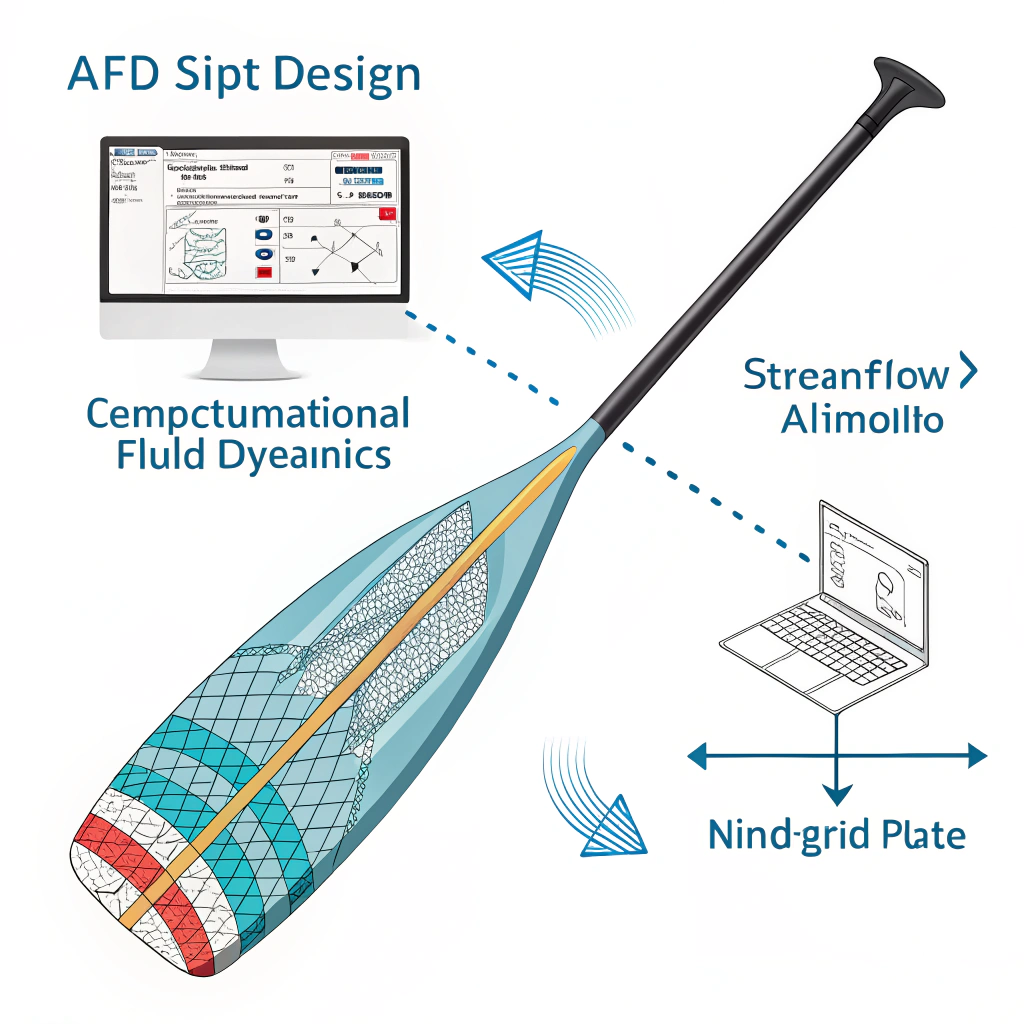

CFD stands for Computational Fluid Dynamics. This numerical approach is used to study both steady and unsteady fluid motion, making it invaluable in many industries. In paddle design, CFD simulation is used to:

• Model airflow around the paddle’s surface to predict lift and drag characteristics.

• Evaluate potential vibrations which can affect ball control and player comfort.

• Analyze the impact of material choices on aerodynamic performance.

While traditional design techniques often rely on physical prototyping and empirical testing, CFD simulation offers a virtual testing environment that can drastically reduce the time and costs associated with product development. By integrating CFD simulation into the design process, companies can iterate quickly, optimize designs for specific performance goals, and achieve a better return on their engineering investments.

When evaluating design techniques, it is important to compare CFD simulation with traditional empirical approaches. Below is a detailed comparison that highlights the key differences:

| Aspect | CFD Simulation | Traditional Design Technique |

|---|---|---|

| Design Iteration Speed | Rapid virtual iterations; changes can be tested quickly without physical prototypes | Iterations depend on physical manufacturing cycles, often slower |

| Cost Efficiency | Reduces material waste and prototyping costs | Requires multiple prototypes and extensive lab tests |

| Data Accuracy | Provides high-precision data on airflows, vibrations, and fluid interactions | Relies on physical testing which may provide limited scope data |

| Flexibility in Testing | Simultaneously evaluates multiple design parameters (aerodynamics, material properties, etc.) | Often limited to one parameter per test cycle |

| Risk Mitigation | Predicts potential design flaws early in the process | Issues may only be detected after costly prototypes are built |

This table makes it clear that CFD simulation empowers companies to improve design processes, reduce risks, and speed up time-to-market, thereby providing a competitive advantage in today's fast-paced manufacturing environment.

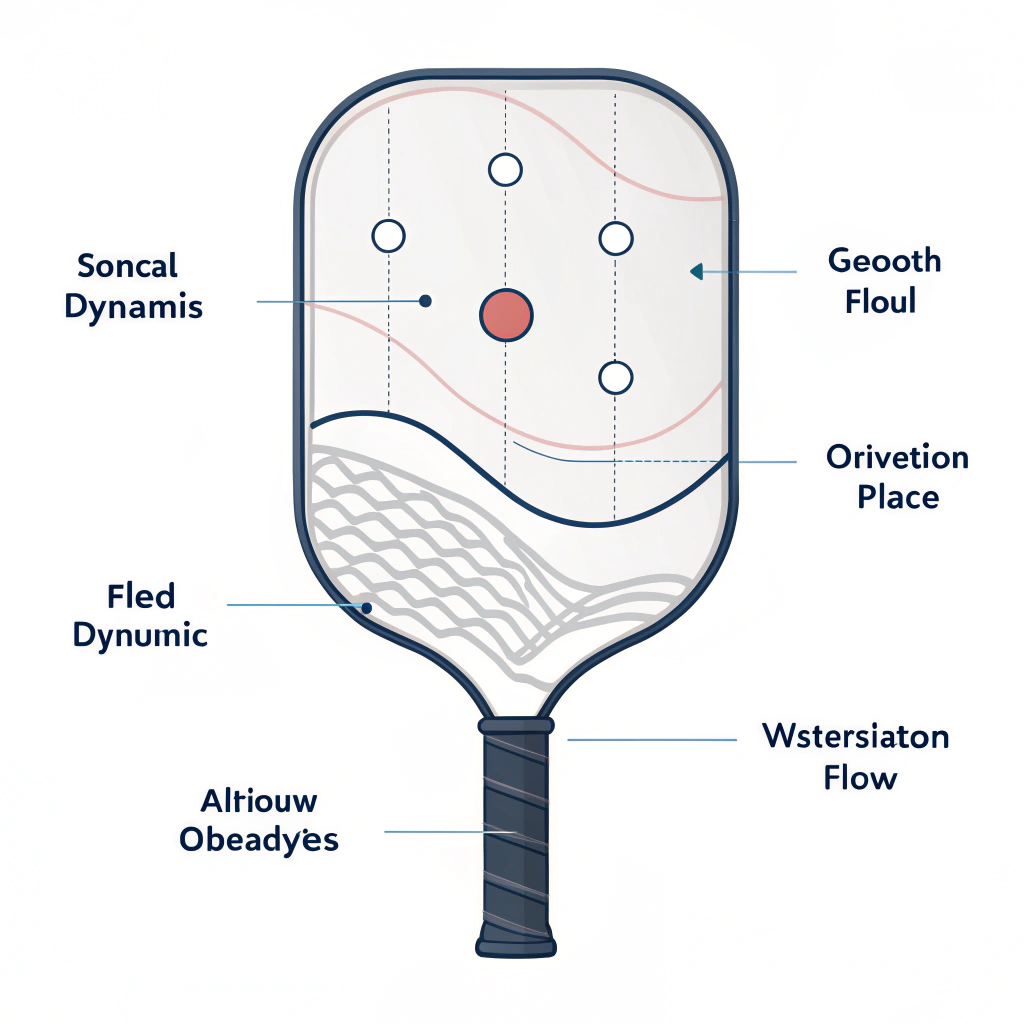

By simulating airflow, CFD helps in identifying critical areas where the paddle may experience turbulent flow or vibration. Engineers can then redesign these regions to ensure smoother airflow and reduced drag. This optimization leads to paddles that provide better control and more energy-efficient plays. For example, by adjusting the curvature and surface texture, designers can reduce vibration, resulting in a more comfortable playing experience.

Manufacturers like NEX Pickleball use advanced materials such as 3K Carbon Fiber2, 12K Carbon Fiber, and T300 Carbon Fiber. CFD simulation assists in predicting how these materials will behave under different physical stresses. When paired with traditional techniques like hot pressing, cold pressing, or thermoforming, CFD not only boosts performance but also ensures the durability and longevity of each paddle. This integrated approach allows engineers to fine-tune manufacturing parameters that lead to optimal material utilization and performance.

Traditional prototyping is not only time-consuming but also expensive. CFD simulation helps reduce the number of physical prototypes needed. This reduction in prototyping not only cuts development costs but also accelerates the product launch process, allowing companies to bring their high-performance products to market faster.

With CFD simulation, decisions are backed by quantitative data rather than assumptions. This ensures that every design change has a measurable impact on performance. For procurement managers and engineering leads, this data-driven approach means lower risk when adopting new design strategies, providing confidence in the long-term benefits of the product.

The performance of a pickleball paddle is deeply influenced by how it interacts with air during swing and impact. CFD simulation models the complex flow of air, enabling the calculation of forces such as lift and drag. Understanding these forces is crucial for ensuring that paddles not only hit the ball with precision but also maintain a comfortable balance and grip during rapid gameplay.

One common drawback in paddle design is excessive vibration, which can impact the feel and performance of the paddle. CFD simulation allows engineers to analyze the vibrational patterns that occur upon impact. With this insight, it is possible to tailor the paddle’s shape, core, and material distribution to minimize these unwanted effects. This process is particularly beneficial when using specialized materials like Nomex Honeycomb Core3 and Polymer Honeycomb Core4, which are chosen for their shock absorption properties.

A significant advantage of CFD simulation is its ability to create detailed virtual prototypes. These prototypes simulate both the aerodynamic environment and material responses under various conditions. Engineers can perform iterative testing under controlled virtual settings before committing to physical prototypes. This practice not only leads to a more refined product but also allows for the early detection of design weaknesses.

CFD simulation is often used in combination with other simulation tools such as Finite Element Analysis (FEA)5. Together, these simulations provide a complete picture of how a paddle will perform under real-world conditions. CFD focuses primarily on fluid and airflow aspects, while FEA addresses structural stresses and material deformations. This integrated approach helps in achieving a well-balanced design, ensuring both performance and reliability in competitive play.

Implementing CFD simulation requires robust computational resources and specialized software. While initial investment costs can be high, the long-term benefits in reduced development cycles and improved product quality justify the expense. Companies should consider scalable solutions that can handle extensive simulations, especially when designing products that integrate sophisticated materials.

To fully leverage CFD simulation, teams must possess the necessary technical expertise. Investing in training for engineers and designers ensures that simulation outputs are interpreted correctly and integrated effectively into the product development process. Cross-disciplinary collaboration between CFD experts, materials scientists, and manufacturing specialists can further enhance the overall design strategy.

While CFD simulation provides high-accuracy data, it is crucial to validate simulation results with real-world testing. Establishing feedback mechanisms between simulation results and physical performance tests ensures that the models remain accurate and reflective of actual conditions. Continual improvement based on this feedback loop can lead to iterative design enhancements that significantly improve product performance over time.

Each sports equipment manufacturer has its unique design challenges and performance criteria. CFD simulation offers the flexibility to tailor models to meet these specific needs. For instance, companies focused on enhancing player comfort might prioritize reducing paddle vibration, while others may focus on maximizing power output. By adjusting simulation parameters, engineers can customize designs to align with market demands and competitive strategies.

Consider a scenario where a leading pickleball paddle manufacturer sought to reduce paddle weight while maintaining strength and durability. The design team integrated CFD simulation into their development process, focusing on aerodynamic performance and vibration reduction.

CFD simulation was used to model the airflow and determine areas of high turbulence around the paddle. This initial model identified specific regions that contributed to drag and unwanted vibration.

Based on the simulation results, the design team experimented with various materials such as 3K Carbon Fiber2 for improved flexibility and Bamboo Core Composite for enhanced impact resistance. Structural changes were simulated to determine the optimal combination that reduced vibration while maintaining a lightweight design.

Multiple iterations of virtual prototypes were generated and tested under simulated conditions. Each iteration focused on fine-tuning parameters such as curvature, core density, and surface texture. The resulting design showcased reduced drag, improved ergonomics, and enhanced ball control, all verified through simulation.

The most promising virtual design was then prototyped and tested in real-world conditions, confirming the accuracy of the simulation results. The final product not only met the performance targets but also demonstrated significant improvements over previous paddle models.

This case study highlights how CFD simulation can drive innovation, reduce development cycles, and result in competitive products in the market.

In an era where performance and precision are paramount, CFD simulation stands out as a vital tool for enhancing pickleball paddle design. By enabling detailed analysis of airflow, material behavior, and vibration, CFD simulation offers manufacturers a significant competitive advantage over traditional design methodologies. The ability to rapidly iterate and optimize designs not only reduces costs but also accelerates product development, ensuring that companies like NEX Pickleball remain at the forefront of innovation in sports equipment manufacturing.

For procurement managers, engineering leads, and product developers evaluating design technologies, integrating CFD simulation can result in substantial improvements in product performance and market readiness. It is not merely a trend but a necessary evolution in the method of designing high-performance equipment. As simulation technology continues to advance, the future of sports equipment design will undoubtedly be shaped by the insights generated through CFD and related simulation tools.

• Is CFD used for aerodynamics?

Yes, CFD is extensively used in various industries, including aerospace and sports equipment manufacturing, to model airflow and predict forces such as lift and drag. This simulation helps optimize aerodynamic performance and reduce fuel or energy usage.

• What does CFD stand for in aerodynamics?

CFD stands for Computational Fluid Dynamics, which is the numerical analysis of fluid flows. It is used to simulate how air and other fluids interact with surfaces, making it an essential tool for optimizing designs in aerodynamics.

-

Computational Fluid Dynamics (CFD): Reading the linked article will provide insights into how CFD models complex fluid flows and is applied to enhance performance in product design. ↩ ↩

-

3K Carbon Fiber: Reading the linked article will explain the properties of 3K Carbon Fiber and its role in improving product performance through enhanced material characteristics. ↩ ↩ ↩2

-

Nomex Honeycomb Core: Reading the linked article will explain why Nomex Honeycomb Core is valued for its superior shock absorption and structural benefits in design. ↩ ↩

-

Polymer Honeycomb Core: Reading the linked article will highlight how Polymer Honeycomb Core contributes to vibration damping and improved product durability. ↩ ↩

-

Finite Element Analysis (FEA): Reading the linked article will provide a deeper understanding of FEA, its integration with CFD, and how it helps optimize structural performance. ↩ ↩