Optimizing lead times for large orders of high-performance pickleball paddles means streamlining production processes, ensuring capacity planning1 is robust, and maintaining rigorous quality control. This article explains common production challenges, analyzes the factors impacting delivery times, and provides proven solutions to ensure timely fulfillment of bulk orders.

For procurement managers, managing bulk orders of high-performance pickleball paddles requires a keen understanding of production scheduling2 and supply chain reliability3. Delays in manufacturing directly affect delivery times, which can compromise customer satisfaction and market competitiveness. With increasing demand and complex production processes, ensuring that every order is delivered on schedule is a critical challenge.

Several factors contribute to lead time delays in paddle manufacturing:

-

Production Process Complexity: Manufacturing paddles involves multiple stages, including material selection, shaping processes (hot pressing, cold pressing, or thermoforming4), and surface finishing. Each process has its own cycle time, and inefficiencies at any stage can extend overall lead times.

-

Capacity Planning: Misjudging production capacity or failing to account for high-volume orders can lead to bottlenecks. This can occur if equipment, labor, or raw material supplies are not scaled appropriately for larger orders.

-

Quality Control and Testing: While rigorous quality testing ensures product reliability, it may also add time to each production cycle if not properly integrated into the schedule.

-

Supply Chain Reliability: Timely delivery of raw materials is vital. Any disruptions in the supply chain—whether due to transportation issues or supplier delays—can cascade into longer production times.

-

Equipment and Process Variations: Different production methods (hot pressing, cold pressing, thermoforming) have unique advantages and disadvantages that affect production speed and consistency.

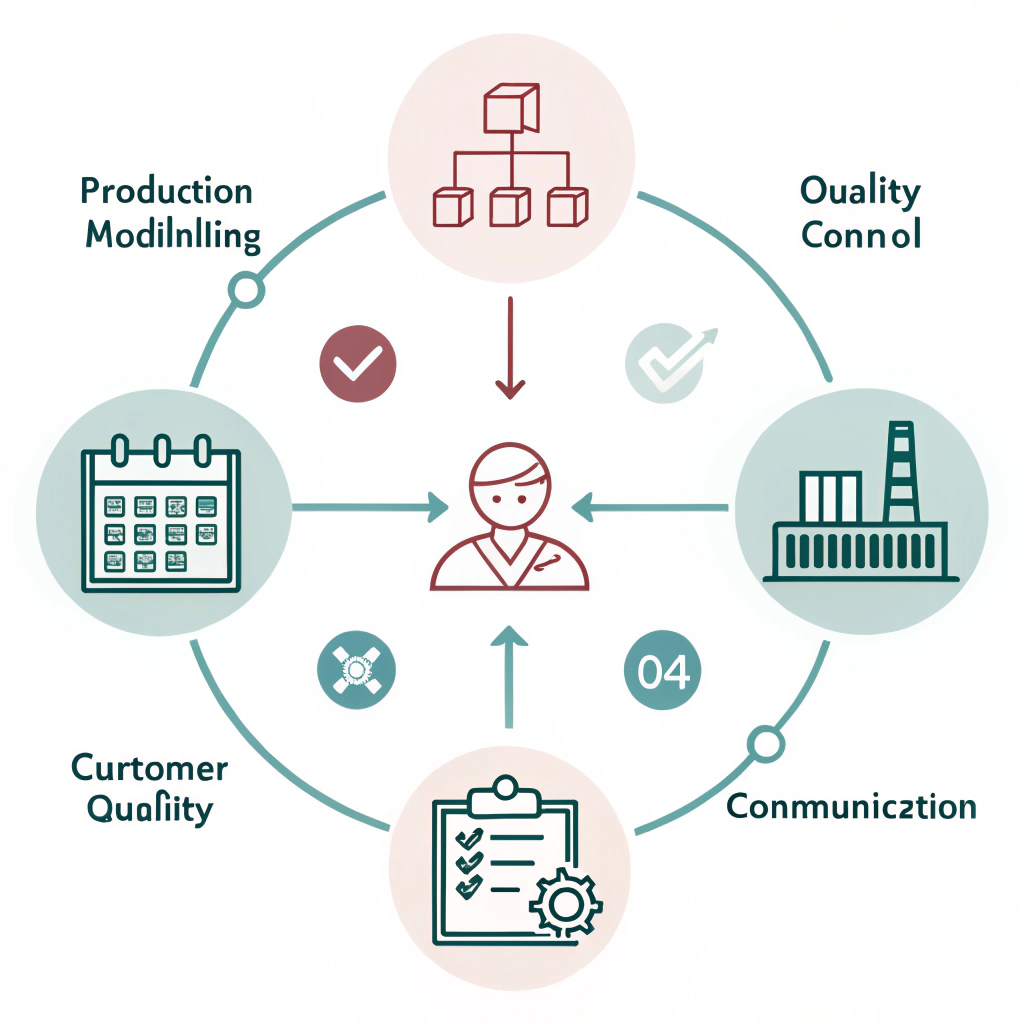

To effectively manage and reduce lead times, consider the following strategies:

- Integrated Planning: Use advanced production scheduling systems that integrate customer orders with manufacturing capacity. Automated scheduling tools can reduce transition times between production phases.

- Clear Milestones: Establish clear production milestones for each process step—from material preparation to final quality checks.

- Buffer Management: Maintain a strategic inventory of critical raw materials to account for unexpected delays.

Each manufacturing process has a distinct impact on lead times:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High production efficiency; strong and durable paddles; robust impact resistance | May alter material properties; requires high investment |

| Cold Pressing | Better control over paddle thickness; maintains material integrity and elasticity | Longer production cycles; demands precise equipment control |

| Thermoforming | Enables complex paddle designs; precise material distribution; excellent product stability | Longer production time; higher equipment cost |

-

Select the Right Process: Assess order requirements and choose the process that best balances speed and quality. For orders where durability and strength are prioritized, hot pressing could be ideal. However, for customization and precision control, cold pressing or thermoforming may be more appropriate.

-

Process Integration: When possible, integrate processes to reduce transition times. For example, linking quality control checkpoints directly with production milestones can shorten the feedback loop.

- Data-Driven Forecasting: Use historical production data to predict peak demand periods and adjust capacity accordingly.

- Scalable Equipment: Invest in scalable production equipment that can be quickly adapted to increasing order sizes.

- Flexible Labor Allocation: Cross-train workers to handle multiple stages of production. This flexibility can help address unforeseen bottlenecks in the manufacturing cycle.

- Inline Quality Checks: Incorporate quality checks at every stage of production to catch defects early without halting the entire process.

- Automated Inspection Tools: Leverage technology and automation to reduce the time taken for manual quality control while ensuring precision.

- Continuous Improvement: Analyze production data regularly to identify trends in defects or delays and adjust processes accordingly.

At NEX Pickleball, we have put these strategies into practice with consistent success. By integrating advanced production scheduling systems with data-driven capacity planning, we ensure that bulk orders are managed efficiently while meeting high-quality standards.

- Advanced Scheduling Software: Our production scheduling system integrates order data with real-time equipment capacity, ensuring a seamless workflow. This has reduced our production cycle times significantly.

- Process-Specific Optimization: Depending on the order requirements, we choose between hot pressing, cold pressing, or thermoforming. Each process is continuously monitored and optimized for performance.

- Integrated Quality Control: We use inline quality checks combined with post-production testing. This enables us to identify and correct issues early in the production cycle, minimizing rework delays.

- Capacity Flexibility: With scalable production equipment and a cross-trained workforce, we can ramp up production during peak times while maintaining efficiency throughout the year.

These initiatives have contributed to significant improvements in our turnaround times without sacrificing product quality. By maintaining rigorous standards and continuously analysing production metrics, NEX Pickleball has built a reputation for timely and reliable delivery—even for the largest orders.

When handling large orders, it’s vital to address the complexities of production cycles5 and lead time management. Here are some additional best practices:

-

Detailed Order Analysis: Before production begins, conduct a comprehensive analysis of the order. Identify key performance indicators (KPIs) such as expected turnaround time, quality benchmarks, and capacity constraints.

-

Customized Production Plans: Each order might have different requirements. Develop customized production plans that detail every stage of the manufacturing process. Include contingency plans in case of unexpected delays.

-

Clear Communication: Keep customers informed about production progress. Regular updates regarding order status, potential setbacks, and estimated delivery dates help maintain strong business relationships.

-

Continuous Feedback Loop: Establish a system for continuous improvement by gathering feedback from both production teams and customers. Use this data to refine processes and further optimize lead times.

-

Investment in Technology: Embrace modern manufacturing tools like AI-driven analytics and IoT sensors. These can provide real-time data on equipment performance and predict maintenance needs, reducing downtime.

By focusing on these areas, manufacturers can build a resilient production system capable of handling the pressures of bulk orders while maintaining on-time delivery.

In summary, optimizing lead times for large orders of high-performance pickleball paddles involves:

- Streamlining production scheduling with advanced systems.

- Selecting the appropriate manufacturing process (hot pressing, cold pressing, and thermoforming) based on order needs.

- Enhancing capacity planning through data-driven forecasting and scalable solutions.

- Integrating rigorous quality control practices throughout the production process.

- Maintaining clear communication with customers and using continuous feedback for improvement.

For procurement managers and supply chain professionals, partnering with a manufacturer that emphasizes these strategies is essential. NEX Pickleball’s commitment to process optimization and production efficiency makes us an ideal partner for ensuring timely delivery and superior performance of your pickleball paddle orders.

Take the next step by contacting us to discuss how we can support your bulk order requirements, optimize your lead times, and enhance your overall supply chain reliability.

Q1: How can production scheduling reduce lead time delays in manufacturing high-performance pickleball paddles?

A1: Effective production scheduling integrates order data with real-time capacity information to minimize gaps between production stages, thereby reducing overall lead times while maintaining quality control.

Q2: What are the benefits and drawbacks of using hot pressing, cold pressing, and thermoforming in paddle manufacturing?

A2: Hot pressing offers efficiency and strong impact resistance but may alter material properties. Cold pressing provides precise control and maintains material integrity, though it has longer cycle times. Thermoforming allows for complex designs and precise material distribution but generally requires more time and higher equipment costs.

Q3: How does capacity planning influence on-time order fulfillment for large pickleball orders?

A3: Capacity planning ensures that manufacturers scale their resources—such as equipment, raw materials, and labor—to match production demand. This proactive approach helps to avoid bottlenecks and ensures that orders are delivered on schedule, even during peak demand.

-

Capacity Planning: Click here to explore strategies for accurately forecasting production needs and scaling resources efficiently to support high-volume orders. ↩ ↩

-

Production Scheduling: Click here to learn how integrating orders with real-time manufacturing capabilities can optimize workflow and reduce downtime between production stages. ↩ ↩

-

Supply Chain Reliability: Click here for insights on building a resilient supply network that minimizes disruptions and enhances delivery performance. ↩ ↩

-

Thermoforming: Click here to understand the thermoforming process, its benefits for complex designs, and the technical considerations involved in its use for manufacturing. ↩ ↩

-

Production Cycles: Click here for a detailed explanation of production cycles, including how to manage and optimize each phase for improved efficiency and reduced lead times. ↩ ↩