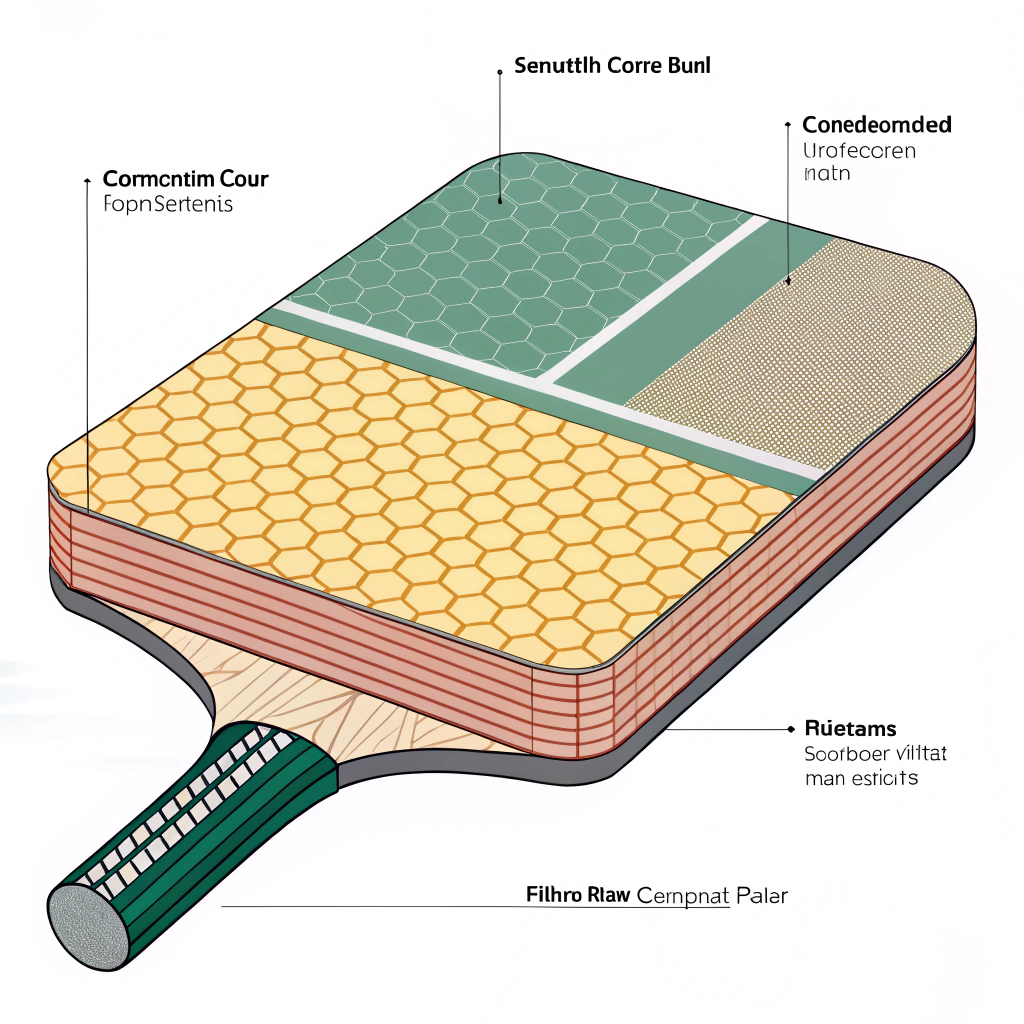

In high-performance pickleball paddle manufacturing, the construction revolves around a layered composite structure that combines a robust honeycomb core with advanced surface materials such as carbon fiber1 and fiberglass2. This structure delivers the optimal balance of power, control, and durability that both recreational and competitive players seek.

Pickleball paddles are engineered with multiple layers designed to maximize performance attributes. At the heart of these paddles is the core, typically made from honeycomb materials (such as Nomex3, aluminum, or polymer). This core is then laminated with surface layers for enhanced strength and rebound characteristics.

The most common construction method combines a honeycomb core with at least one layer of composite or carbon fiber material. Today's paddles rely on a sandwich structure that provides both rigidity for powerful hits and the necessary softness to reduce vibrations for better control and comfort.

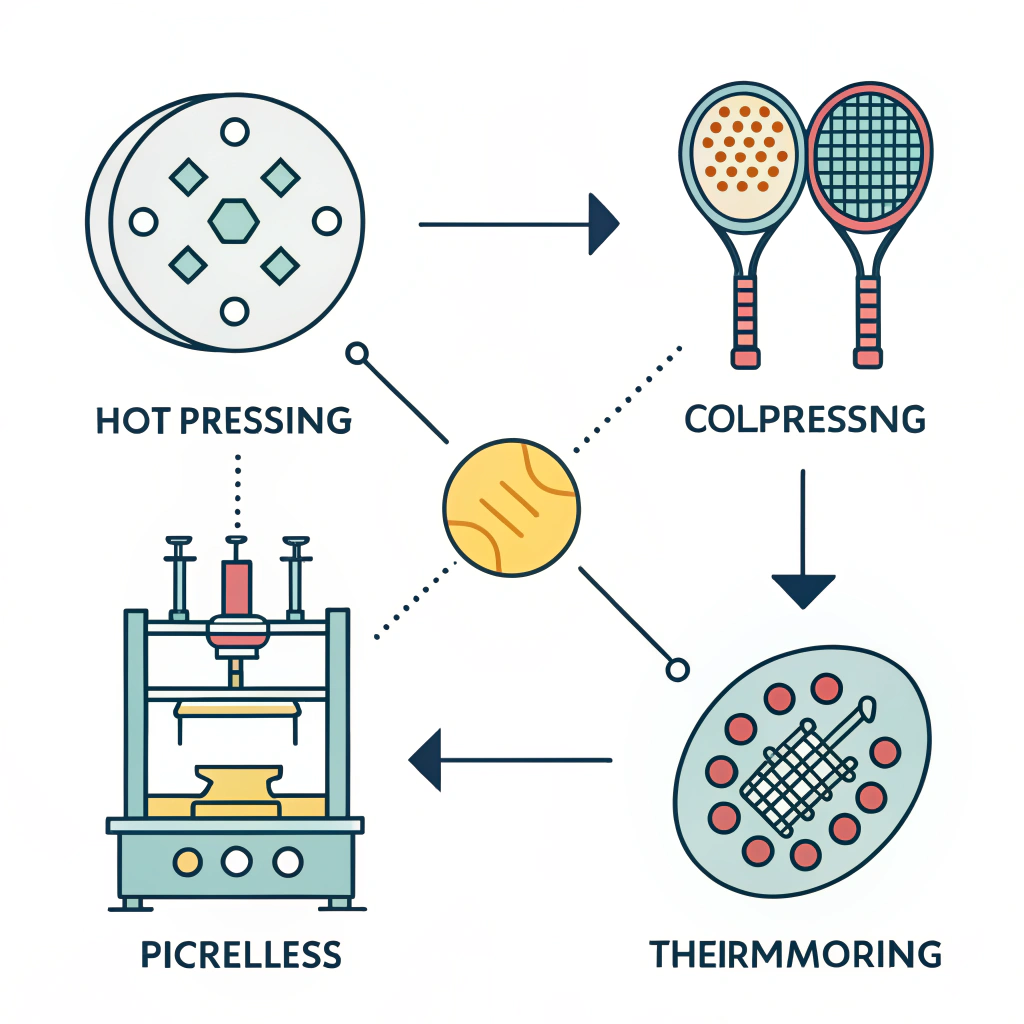

Production Processes: Hot Pressing, Cold Pressing, and Thermoforming4

Manufacturing high-performance pickleball paddles involves three predominant processes. Each technique influences the final paddle attributes such as weight, balance, and durability.

Hot pressing is a manufacturing process in which the materials are heated and pressed together to form a strong bond.

Advantages:

- High production efficiency suitable for large-scale manufacturing.

- Enables strong paddles with excellent impact resistance.

- Improves structural integrity through evenly applied heat and pressure.

Disadvantages:

- The high temperature may alter some material properties, possibly affecting the tactile feel.

- Requires significant investment in high-quality equipment to maintain consistency.

A quick overview table comparing hot pressing with other methods is provided below:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | Fast production, strong impact resistance | Altered material properties, high equipment cost |

| Cold Pressing | Precise control, preserves intrinsic material qualities | Longer production cycle, requires precision equipment |

| Thermoforming | Allows complex shapes, precise material distribution | Longer production time, higher initial costs |

Cold pressing involves shaping materials at room temperature under mechanical pressure. This technique is particularly favorable when precise thickness and material integrity are required.

Advantages:

- Provides enhanced control over the paddle’s structure.

- Maintains the original properties of the base materials, resulting in improved feel.

- Ensures excellent ball response and paddle control.

Disadvantages:

- Slower production cycles compared to hot pressing, which may influence throughput.

- Demands rigorous precision in pressure application, thus requiring robust quality control systems.

In thermoforming, materials are heated until soft and then molded into shape using precision molds. This process is ideal for designs that require intricate shapes and a uniform material distribution.

Advantages:

- Enables the creation of paddles with complex designs and enhanced stability.

- Maintains optimal paddle performance by ensuring precise control over the material distribution.

- Suitable for premium and custom paddle production.

Disadvantages:

- Necessitates longer production times.

- Higher equipment costs which can increase the unit cost for small production runs.

These production techniques allow us to cater to a diverse market, ensuring that both bulk OEM5 orders and custom, on-demand production meet the highest quality standards.

Carbon Fiber is a critical component in enhancing the paddle's performance. NEX Pickleball uses several types to achieve targeted outcomes:

- 3K Carbon Fiber: Known for its balance of strength and flexibility. It is ideal for paddles that require high rebound and vibration reduction.

- 12K Carbon Fiber: Provides a smoother feel and increased durability. The higher thread density makes it perfect for extreme strength and impact resistance in competitive play.

- T300 Carbon Fiber: Valued for outstanding tensile strength, ideal for players seeking a combination of light weight and durability.

Each variant contributes differently to paddle performance. For example, while 3K is excellent for beginners due to its forgiving nature, 12K serves competitive players who demand precision and endurance.

Fiberglass paddles are designed to offer a wider sweet spot and enhanced flexibility, making them suitable for players who prioritize ball control.

- E-Glass Fiberglass: With its outstanding elasticity, this type offers an excellent ball feel and enhanced control.

Meanwhile, composite materials combine the benefits of different materials to achieve a balance of power and control. For instance:

- Carbon Fiber and Fiberglass Composite: Merges the high strength of carbon fiber with the flexibility of fiberglass.

- Bamboo Core Composite: Offers lightweight characteristics and high impact resistance, producing a tactile feel during play.

- Honeycomb Core: Manufactured from polymers or pulp, this core type absorbs shock effectively, reducing vibrations and potentially extending the paddle’s lifespan.

The core is integral to determining the paddle’s overall feel and performance. Some of the core options include:

- Nomex Honeycomb Core: Excellent for shock absorption and durability, ideal for those who seek long-lasting performance.

- Aluminum Honeycomb Core: Offers a balanced weight ideal for players seeking both power and precision.

- Polymer Honeycomb Core: Known for its elasticity, this core provides a softer hit, reducing vibration and increasing comfort—ideal for beginners and recreational play.

This wide range of material options allows OEM5 partners to tailor paddles to specific performance criteria, ensuring a product that is perfectly aligned with market needs.

Robust quality control is non-negotiable in OEM manufacturing, especially when producing high-performance sports equipment. At NEX Pickleball, every paddle undergoes stringent testing processes designed to assess:

- Structural Integrity: Testing the bond between layers to ensure durability.

- Weight Distribution: Ensuring the paddle is balanced for optimal swing performance.

- Vibration Damping: Measuring the paddle’s shock absorption ability to minimize hand fatigue.

We also deliver on-demand printing services, enabling bulk orders as well as custom, tailored solutions. The ability to customize paddle design, weight, balance, and grip size is indispensable for businesses that need packaging for team branding or personalized marketing campaigns.

With consistent testing protocols and adherence to quality standards, clients can be confident that every paddle leaving the production line meets the highest industry benchmarks.

When selecting an OEM5 manufacturing partner, procurement managers should evaluate several factors:

-

Production Process Expertise:

Understanding the nuances of hot pressing, cold pressing, and thermoforming is essential. A company skilled in these processes can assure precision and high performance in the final product. -

Material Selection and Customization:

The choice of materials such as carbon fiber variants, fiberglass, and composite cores directly impacts the paddle’s performance. Leading manufacturers offer a suite of customization options, including varying carbon fiber grades and core materials to meet specific performance and budget criteria. -

Quality Control Measures:

A rigorous quality control system is a prerequisite for any reliable OEM partner. This ensures that each paddle consistently adheres to performance standards, and that any potential issues are identified and rectified early in the production process. -

Industry Experience and References:

Partnering with an OEM that boasts a strong track record, including relationships with globally recognized brands like Joola and Selkirk, adds a significant layer of trust and reliability. -

Cost vs. Performance Trade-Offs:

While premium materials and advanced manufacturing processes might drive up costs, the resultant paddle performance is paramount. It is crucial to strike the right balance between cost and the necessary performance metrics demanded by the end-user.

Below is a table summarizing key aspects to consider:

| Criteria | Considerations | Importance |

|---|---|---|

| Production Process Expertise | Hot pressing, cold pressing, thermoforming | Ensures product quality and consistency |

| Material Selection | Carbon fiber variants, fiberglass, composites, core materials | Dictates performance characteristics |

| Quality Control | Structural integrity, weight distribution, vibration testing | Guarantees reliability and durability |

| Customization Capabilities | On-demand printing, design customizations | Meets specific market and branding needs |

| Industry Experience | Partnerships with leading brands, performance track record | Builds trust with procurement managers |

Our partner companies can rely on our extensive capabilities in adopting advanced manufacturing techniques paired with comprehensive quality control protocols to deliver paddles that meet even the most rigorous standards.

For B2B procurement managers and engineering teams, the decision to partner with a reliable OEM manufacturer is critical. With advanced processes like hot pressing, cold pressing, and thermoforming combined with a selectable range of high-performance materials, manufacturers like NEX Pickleball provide a scalable, customizable, and quality-assured solution for the pickleball paddle market.

Key takeaways include:

- The layered composite construction of paddles ensures a balance of strength, control, and vibration reduction.

- Selecting the right manufacturing process directly influences the end product’s performance.

- Material choices, from various grades of carbon fiber to fiberglass and composite cores, provide customization to match competitive demands.

- Rigorous quality control processes are essential in delivering a consistent product that meets market demands.

- An experienced OEM5 partner, with a track record serving top global brands, ensures that your business receives both top-tier product quality and reliable service.

For further details or customized solutions that meet your specific production needs, we welcome you to contact our sales team and explore how NEX Pickleball can help elevate your product offering.

-

What is the construction of a pickleball paddle?

Pickleball paddles are built with a layered design, typically featuring a honeycomb core (using materials such as resin impregnated paper, aluminum, or polypropylene) laminated with composite surface materials like fiberglass or carbon fiber/graphite to provide the desired balance of power and control. -

How to judge a pickleball paddle?

A paddle is usually judged based on its weight classification: lightweight paddles (typically under 7.3 ounces) enhance control, midweight paddles (between 7.3 and 8.5 ounces) serve as a balanced option for beginners, and heavy paddles (over 8.5 ounces) offer more power. Other factors include balance, durability, and overall construction quality. -

How is a pickleball paddle made?

Pickleball paddles are manufactured using a layered sandwich technique. A honeycomb core is combined with surface layers that can be made from fiberglass, carbon fiber, or composite materials, with the choice of materials based on the desired performance characteristics and compatibility between layers.

-

Carbon Fiber: Click to read an in-depth article on how carbon fiber is produced and used to enhance the strength and lightness of high-performance products. ↩

-

Fiberglass: Click to learn about fiberglass, its manufacturing process, and its role in providing durability and vibration dampening in composite structures. ↩

-

Nomex: Click to explore Nomex, a high-temperature resistant material often used in honeycomb cores for its excellent strength-to-weight properties. ↩

-

Thermoforming: Click to understand the thermoforming process, a manufacturing technique that uses heat to mold materials into complex shapes while maintaining material uniformity. ↩

-

OEM: Click to read more about Original Equipment Manufacturer (OEM) partnerships, including benefits, common practices, and how to evaluate potential manufacturing partners. ↩ ↩2 ↩3 ↩4