Quick Answer: NEX Pickleball leverages cutting‐edge production techniques—hot pressing, cold pressing, and thermoforming—with advanced materials like carbon fiber1, fiberglass2, and composite cores to create pickleball paddles that optimize performance, durability, and user comfort. By comparing these methods and understanding material properties, sourcing managers can select paddles that precisely meet their high-performance criteria.

In today’s competitive sports equipment market, the demands on pickleball paddles have never been higher. Business professionals, sourcing managers, and product developers are searching for paddles that combine technical excellence with reliable performance. At NEX Pickleball, our commitment to precision manufacturing and innovation ensures that each paddle harnesses advanced production processes and premium materials. This article will dissect the manufacturing techniques, material characteristics, and performance considerations that underpin the high-quality paddles we produce—helping you make an informed sourcing decision.

Modern pickleball paddle performance hinges on choosing the right manufacturing process. Each technique offers unique strengths and challenges. By understanding these differences, you are better prepared to align performance objectives with production capabilities.

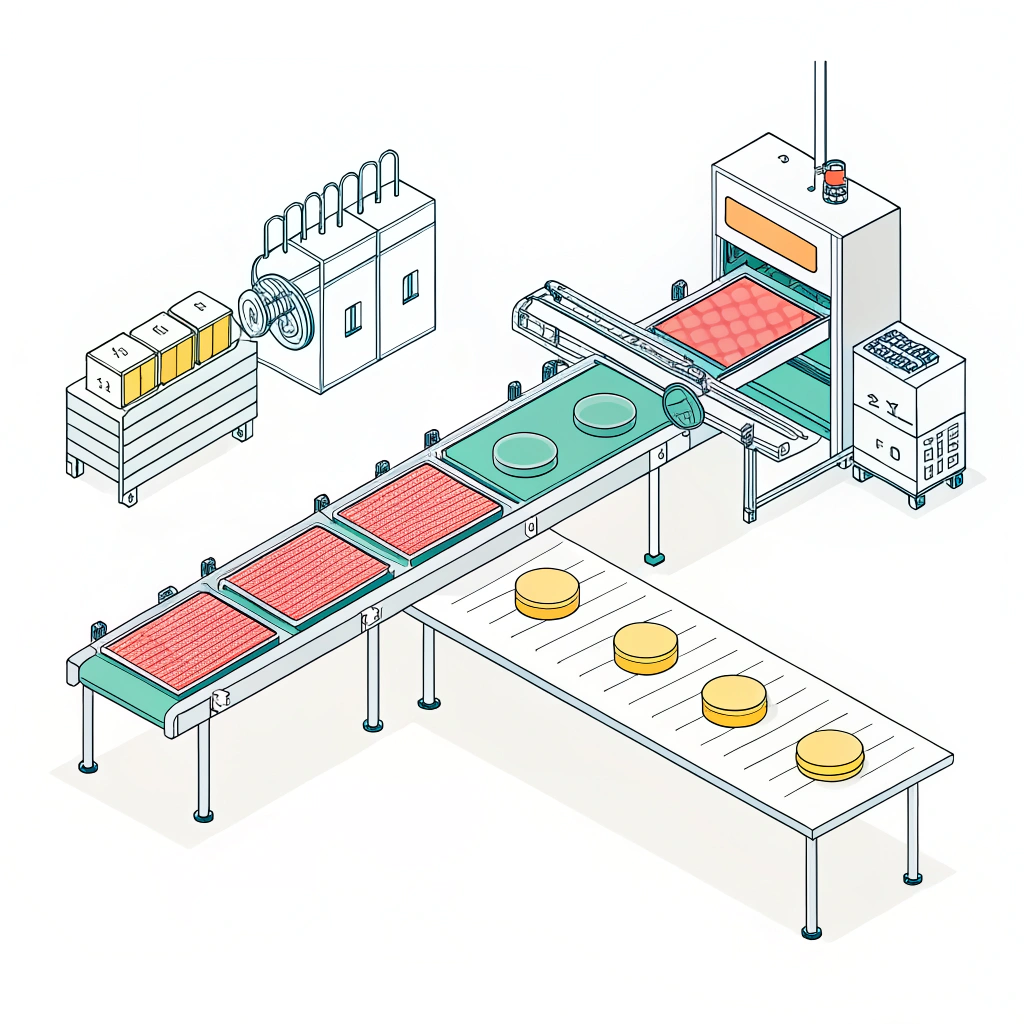

Hot pressing involves applying both heat and pressure to shape the paddle. This process is widely used for constructing high-strength, durable paddles.

-

Advantages:

• High production efficiency; ideal for large batches.

• Produces paddles with outstanding impact resistance and structural integrity.

• Suitable for robust, high-performance designs. -

Disadvantages:

• The high temperatures may alter certain material properties, potentially influencing the paddle’s feel.

• Requires substantial investment in specialized equipment.

Cold pressing uses mechanical pressure at room temperature to form paddle structures. This technique is particularly effective when precision in material thickness and structural consistency is crucial.

-

Advantages:

• Maintains the original properties of the input materials.

• Offers superior control of thickness, resulting in a more responsive paddle.

• Provides an enhanced ball feel due to preserved material flexibility. -

Disadvantages:

• Longer production cycles can limit output efficiency.

• Demands precise pressure control and high-quality equipment to avoid defects.

Thermoforming involves heating the paddle material to a softening point and then molding it using precisely designed processes. This method is ideal for paddles requiring complex shapes and uniform material distribution.

-

Advantages:

• Enables intricate designs and strict control over material distribution.

• Delivers paddles with improved stability and performance consistency.

• Supports the integration of premium materials like raw and advanced carbon fiber. -

Disadvantages:

• The process usually takes longer than hot or cold pressing.

• Higher equipment costs might be a consideration for smaller production runs.

To summarize these manufacturing methods, consider the following table:

| Production Process | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Hot Pressing | High production efficiency; strong, durable paddles | Potential alteration of material feel; high equipment cost | Large-scale, high-performance use |

| Cold Pressing | Superior control; preserves material properties | Longer production cycles; precise pressure needed | Paddles requiring precise control |

| Thermoforming | Intricate design capability; uniform structure | Longer production time; higher equipment costs | Premium, custom designs |

NEX Pickleball’s diverse production strategies allow us to tailor our approach based on the intended paddle performance and design specifics.

The paddle materials are central to performance, and selecting the right one can dramatically affect key features such as control, rebound, and durability. Here, we review the benefits of various materials that NEX Pickleball employs:

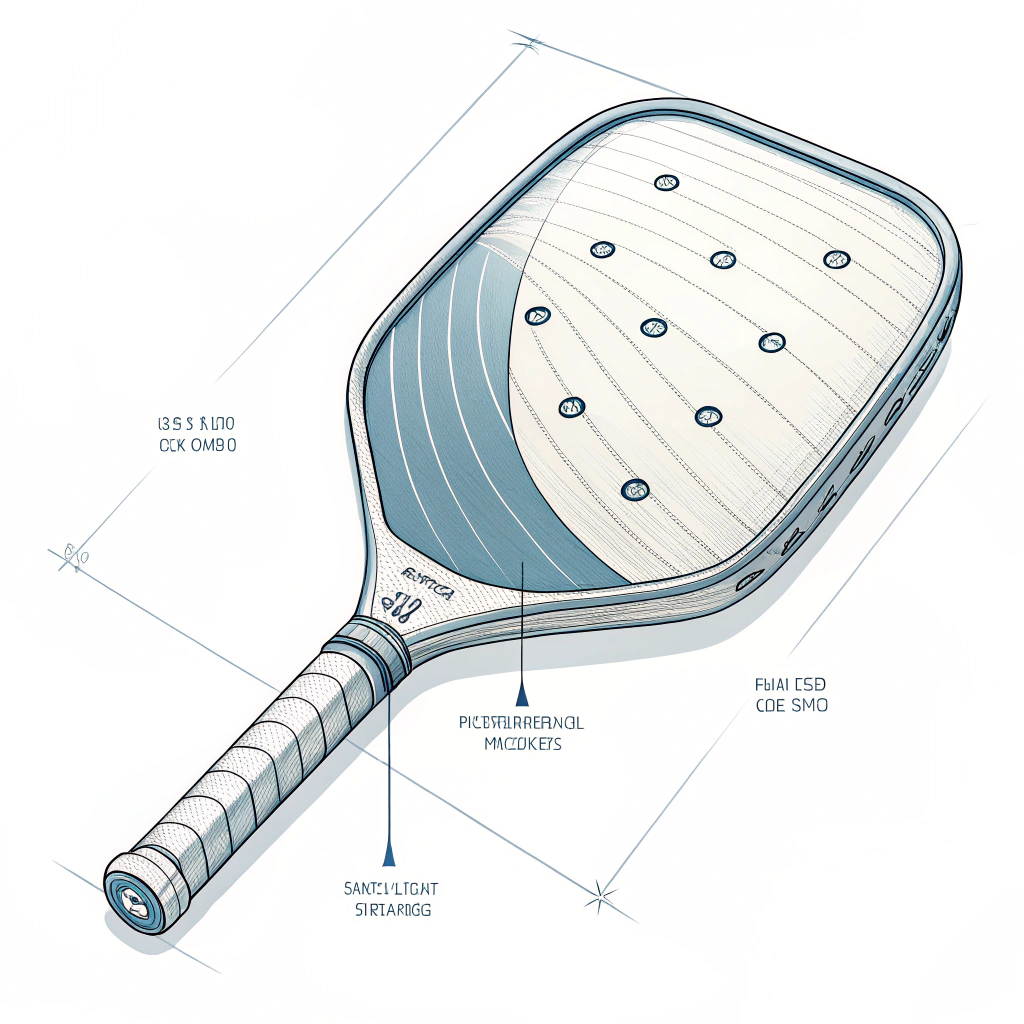

Carbon fiber is one of the premium materials that differentiates modern performance paddles. We utilize several types:

-

3K Carbon Fiber:

Known for its strength and flexibility, this carbon fiber variant offers a high rebound force with excellent durability, reducing vibration during play. -

12K Carbon Fiber:

With higher thread density, 12K offers a smoother surface, improved hardness, and superior impact resistance, making it well-suited for competitive play. -

T300 Carbon Fiber:

Valued for its outstanding tensile strength, T300 is used in paddles that require a balanced mix of strength and lightweight performance.

These carbon fibers enhance not only the rebound and control but also provide a robust platform for power play.

Fiberglass paddles create a harmonious balance between power and control. They are characterized by a larger sweet spot and enhanced durability:

- E-Glass Fiberglass:

This type is optimal for achieving high elasticity and tensile strength, providing a comfortable feel and meticulous ball control.

Combining multiple materials in composite paddles has become popular for achieving balanced performance qualities:

- Carbon Fiber and Fiberglass Composite:

This hybrid offers both the power of carbon fiber and the control provided by fiberglass—ideal for half professionals who need an adaptable paddle.

Beyond the surface, the core material plays a critical role in the paddle’s behavior:

-

Nomex Honeycomb Core:

Offering excellent shock absorption and structural stability, Nomex is perfect for prolonged high-intensity use. -

Aluminum Honeycomb Core:

This core provides a balanced weight with reliable power and precision, appealing to players needing both strength and maneuverability. -

Polymer Honeycomb Core:

Known for its elasticity and vibration reduction characteristics, polymer cores often are the choice for recreational players seeking comfort.

The interplay between these materials defines the paddle’s overall quality. Below is a comparative overview of core materials:

| Core Material | Key Benefits | Ideal For |

|---|---|---|

| Nomex Honeycomb | Superior shock absorption; structural stability | High-intensity, competitive play |

| Aluminum Honeycomb | Balanced weight and control | Players needing power and precision |

| Polymer Honeycomb | Enhanced elasticity; reduced vibration | Recreational players and beginners |

| Bamboo Core Composite | Lightweight; impact-resistant | Long-lasting play and clear hitting feel |

Optimizing a pickleball paddle is an intricate process that hinges on the synergy between manufacturing techniques and material selection. There are several key performance factors:

Players often discuss the concept of “swing weight.” Adjustments in the distribution of paddle weight can influence both swing speed and impact force. By tailoring material composition—such as integrating carbon fiber in strategic areas—manufacturers can improve overall swing momentum without sacrificing speed.

For instance, slight modifications in the core structure and the addition of swing weight can enhance power and spin. However, overcompensation may slow the paddle down, negatively impacting hand speed. Thus, engineers at NEX Pickleball carefully calibrate paddle weight to achieve a balance that suits both defensive and offensive play styles.

A well-designed paddle considers the ergonomic factors that affect play, such as grip size and handle shape. NEX Pickleball employs ergonomically designed grips that meet various hand sizes while optimizing vibration dampening through the use of high-quality composite materials. This focus on grip comfort and paddle balance contributes directly to player performance during extended play sessions.

Durability directly correlates with both the choice of materials and the specific manufacturing process employed. Hot pressing converts carbon fiber and composite materials into strong, impact-resistant structures, while cold pressing maintains a natural feel with excellent shock absorption qualities. Real-world testing under rigorous playing conditions validates that our production processes produce paddles which remain reliable even under the most strenuous play scenarios.

Engineers often integrate specialized treatment techniques on the paddle’s surface to improve texture and ensure exceptional grip on the ball. Additionally, the internal structure, including the core and composite layers, is meticulously designed to reduce vibrations and provide a consistent hit response.

At NEX Pickleball, our integrated approach combines advanced production techniques and material innovation to stay ahead of industry trends. Here is a brief case study that outlines our process and its benefits:

In the competitive world of pickleball, sourcing managers demand paddles that are not only high-performing but are also durable enough to withstand prolonged use. Many competitors present paddles with a focus on aesthetics rather than performance engineering, leading to inconsistencies in quality.

-

Material Selection:

We choose superior raw materials such as 3K, 12K, and T300 carbon fibers alongside advanced composites to sculpt paddles that deliver on strength, control, and longevity. -

Precision Production:

Our production pipeline employs a tailored mix of hot pressing, cold pressing, and thermoforming. Each method is selected based on the paddle design, intended performance parameters, and material compatibility. -

Quality Assurance:

Every paddle undergoes rigorous durability testing. Real-world impact tests and performance benchmarks ensure that our paddles meet the high standards expected by players and dealers. -

Tailored Customization:

We offer on-demand paddle customization. From design tweaks—such as grip size and weight distribution—to material adjustments, our technology allows us to meet specific retailer and team branding needs.

Through this process, we have seen measurable improvements in both the overall quality of our paddles and the satisfaction levels of our B2B partners. Consistent performance data and reliable production cycles have solidified our reputation as a trusted manufacturing partner in the pickleball industry.

Our approach not only enhances the specific performance benchmarks—such as power, control, and durability—but also provides a clear pathway for continuous innovation and product improvement.

For sourcing managers and procurement officers looking to invest in high-performance pickleball equipment, understanding the correlation between advanced manufacturing techniques and material choices is crucial. Key takeaways include:

• Evaluate the balance between production efficiency and final paddle feel when selecting between hot pressing, cold pressing, and thermoforming.

• Consider the role of innovative materials like various forms of carbon fiber, fiberglass, and composite cores in enhancing durability and performance.

• Recognize that weight distribution, grip ergonomics, and surface treatment are as critical as the structural integrity of the paddle.

• Rely on established quality testing protocols and proven performance data to ensure that your selected product meets both technical and practical benchmarks.

These steps not only guide you in making informed sourcing decisions but also help in fostering stronger, long-term partnerships with leading manufacturers like NEX Pickleball.

If your organization is committed to offering top-tier pickleball equipment and wants to incorporate the latest advances in paddle design science, now is the time to explore tailored solutions. Our expertise in both material innovation and advanced production processes sets a benchmark in the sports equipment industry.

-

What is the newest technology for pickleball paddles?

The newest technology in pickleball paddles incorporates thermoforming techniques that enable a stiff, unibody design. Using raw carbon fiber and innovative foam edge walls, these Gen 2 paddles offer enhanced spin, control, and power while improving overall durability. -

How can I make my pickleball paddle better?

Enhancing a pickleball paddle involves optimizing its swing weight and balance. Strategic addition of swing weight can increase power and spin, but it is important to maintain a balance so as not to hinder hand speed. Fine-tuning materials and design elements such as grip comfort and vibration reduction can significantly improve performance. -

What makes a good quality pickleball paddle?

A high-quality pickleball paddle typically features a light to medium weight, comfortable ergonomic grip, a large sweet spot, and a balanced mix of power and control. Key considerations include the material quality—often a blend of carbon fiber, fiberglass, or composite—and design specifics such as elongated shape, thinner core, and well-distributed weight for optimal response during play.

-

carbon fiber: Learn about the properties of carbon fiber and how its strength-to-weight ratio and durability contribute to enhanced performance in high-end manufacturing. ↩ ↩

-

fiberglass: Discover how fiberglass integrates with composite materials to offer a balanced mix of power and control, optimizing both elasticity and durability. ↩ ↩

-

Hot pressing: Explore the hot pressing process, which utilizes heat and pressure to mold materials into robust, high-performance components, ideal for mass production. ↩ ↩

-

Cold pressing: Understand cold pressing—a method that preserves material integrity at room temperature while providing precision and consistency in production. ↩ ↩

-

Thermoforming: Read about thermoforming, a technique that heats materials to create complex shapes and uniform distribution, perfect for custom, premium designs. ↩ ↩