USAP testing process is a comprehensive quality assurance framework designed to evaluate a product’s durability, performance, and safety standards through a series of rigorous testing protocols. It ensures that sports equipment meets exacting industry standards and provides manufacturers with critical insights to refine product development and quality control.

The USAP testing process1 provides a systematic approach to evaluate sports equipment, particularly paddles, using standardized protocols to ensure their performance under various conditions. Developed with input from industry standards and extensive field testing, this process helps manufacturers maintain consistent quality and safety across their product lines.

In the competitive sports equipment manufacturing industry, quality control managers, product development engineers, and procurement specialists rely on robust testing procedures to validate product durability and performance. The USAP testing process is particularly valuable because it breaks down complex performance metrics into understandable results, making it easier for companies to benchmark their products and identify areas for improvement.

Many manufacturers encounter challenges such as variability in product performance and discrepancies between laboratory test results and real-world applications. These issues can lead to costly recalls, brand reputation damage, and even safety hazards for end users. The key problems that the USAP testing process addresses include:

• Ensuring consistent product performance across diverse conditions.

• Verifying that materials like 3K Carbon Fiber2, 12K Carbon Fiber3 and composite cores maintain their structural integrity.

• Identifying potential weak points in the manufacturing process before products are shipped.

Without a thorough testing protocol, even high-performance paddles can fail under stress, reducing their durability and overall customer satisfaction.

The root causes behind product inconsistency often include variability in material properties, limitations in current manufacturing processes, and a lack of standardized testing methodologies. Understanding these causes is crucial for quality control managers and engineers as they compare the USAP testing process with their internal protocols:

-

Material Variability:

Different materials used in paddle construction—such as various types of carbon fiber and fiberglass—exhibit unique properties that influence performance. Variations in material quality can lead to differences in rebound force, vibration absorption, and overall durability. -

Process Limitations:

The production methods such as hot pressing, cold pressing, and thermoforming each have inherent limitations. For example, while hot pressing is highly efficient, it may alter certain material properties, which could affect the paddle’s feel and performance characteristics. -

Testing Inconsistencies:

Absence of a unified testing protocol can result in inconsistent analysis results. Variations in testing equipment calibration, environmental conditions, and operator expertise contribute to discrepancies in quality control outcomes.

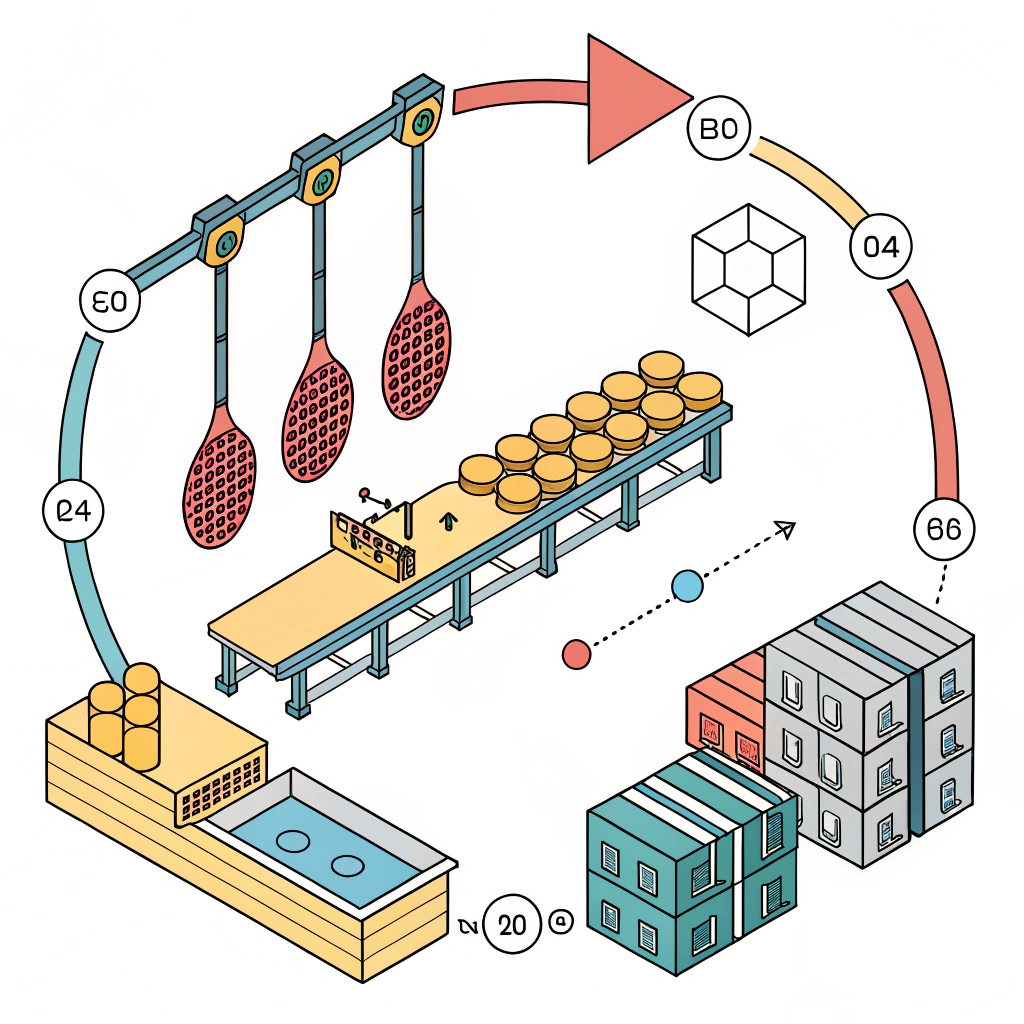

The USAP testing process introduces a series of standardized steps that manufacturers can adopt to ensure their products meet high-performance criteria. Below is a detailed breakdown of the process, highlighting its methodology and integration with production:

-

Initial Material Check:

Inspect the raw materials by comparing certifications, material properties, and previous performance data. For instance, verifying that T300 Carbon Fiber4 or E-Glass Fiberglass meets quality benchmarks essential for high-performance paddles. -

Baseline Performance Metrics:

Establish a baseline metric for impact resistance, rebound force, vibration damping, and friction coefficients. These metrics are crucial as they provide reference values against which post-production products can be tested.

-

Laboratory Conditions:

Conduct tests in controlled environments that simulate different real-world conditions. This involves subjecting the paddles to temperature variations, pressure scenarios, and repetitive impact forces. -

Consistency Checks:

Perform repeated tests to identify any anomalies in performance. This stage ensures that the product outcomes are reproducible and that any variation can be traced back to specific production batches.

-

Stress Testing:

Products are subjected to high-stress conditions to evaluate their limits. For instance, using specialized equipment to simulate repetitive high-impact scenarios helps in identifying potential failure points in the paddle’s core or surface materials. -

Comparative Analysis:

Compare the performance data from the USAP testing process with existing internal test results. This comparison is instrumental in uncovering discrepancies and allowing manufacturers to benchmark their quality against industry standards.

-

Regulatory Standards Evaluation:

Ensure that the paddle meets or exceeds established regulatory standards. Certification processes often require documentation of all testing procedures and results, which is an integral part of the USAP protocol. -

Final Quality Approval:

Only products that meet predefined thresholds for durability, impact resistance, and overall safety are approved for market release. This step minimizes the risk of product recalls and enhances consumer trust.

-

Ongoing Testing Feedback:

Use data from field performance and continuous quality monitoring to refine the testing process over time. Feedback loops are essential for evolving the manufacturing process and ensuring long-term product reliability. -

Updating Test Protocols:

As new materials or production processes are introduced, the USAP testing guidelines are updated to incorporate these changes, ensuring that even cutting-edge advancements maintain consistent quality.

Below is a comparative table highlighting key differences between the USAP testing process and more traditional quality testing methods:

| Criteria | USAP Testing Process | Traditional Testing Methods |

|---|---|---|

| Material Verification | Comprehensive baseline measurement using certified materials | Often focuses on limited material parameters |

| Environmental Simulation | Testing under controlled, varying conditions | Usually single-condition testing |

| Stress and Impact Analysis | Detailed stress testing to simulate real-world use | Standardized tests with less variability |

| Documentation & Certification | Rigorous documentation for compliance and certification | Variable documentation standards |

| Data Feedback Loop | Continuous improvement through iterative testing | Limited post-production feedback |

| Adaptability | Regular updates to test protocols with new materials | Infrequent updates, often static process |

This table helps illustrate why many quality control teams are moving towards adopting the USAP testing process in their operations. The enhanced focus on repeatability, data-driven feedback, and compliance with international standards makes it a compelling option for businesses looking to maintain a competitive edge.

Adopting the USAP testing process involves thoughtful integration into existing quality control systems. Here are some essential considerations for manufacturers:

-

Investment in Equipment:

The accuracy of USAP testing relies heavily on advanced testing equipment that can simulate multiple environmental and impact conditions. Investing in high-quality testing machinery ensures that results are both reliable and repeatable. -

Training and Expertise:

Operators and quality control managers must receive adequate training on the new protocols. A well-trained team can correctly interpret the data and understand the nuances between slight variations in material behavior. -

Data Management Systems:

Implement robust data management systems to log results and track performance metrics over time. This will help in identifying trends and making informed decisions about process improvements or product redesigns. -

Regulatory Compliance:

Ensure that the updated testing process aligns with local and international regulations. Compliance is not only a legal requirement but also builds confidence among procurement specialists and end customers. -

Scalability:

Consider the scalability of the testing process, especially if your operation involves mass production. The streamlined nature of the USAP testing process is designed to be efficient even in high-throughput environments, but initial integration may require adjustments. -

Cost-Benefit Analysis:

Conduct a cost-benefit analysis to weigh the initial capital expenditure against long-term quality gains and reduced risk of recalls. Higher upfront costs may lead to significant savings by minimizing product failures and warranty claims.

Consider the scenario of a sports equipment manufacturer facing recurrent issues with paddle durability. By integrating the USAP testing process, they were able to:

• Identify that slight variations in Nomex Honeycomb Core5 production were causing inconsistent impact absorption.

• Adjust their cold pressing parameters to achieve more uniform material properties.

• Use the continuous feedback loop to further refine their thermoforming process, resulting in paddles with a more balanced weight distribution and improved playability.

The manufacturer documented these process enhancements in a detailed report, which not only improved quality control but also aided in securing new contracts by demonstrating adherence to internationally recognized testing standards.

The USAP testing process represents a significant advancement over traditional quality testing methods. Its comprehensive, data-driven approach not only ensures compliance with rigorous international standards but also offers deeper insights for continuous process improvement. By adopting this methodology, companies can expect to see enhancements in product reliability, a reduction in production inconsistencies, and an overall boost in consumer confidence.

For professionals in the sports equipment manufacturing industry, particularly those involved in quality control and product development, integrating the USAP testing process can lead to measurable improvements in your product line. Begin by:

• Evaluating your current testing protocols and identifying gaps.

• Investing in necessary testing equipment and training your team.

• Establishing a data feedback loop for continuous improvement.

• Benchmarking your results against the industry standards provided by the USAP process.

Taking these actions will not only streamline manufacturing processes but also position your products to meet the ever-increasing demands of today's competitive sports market.

Q: What is the primary benefit of the USAP testing process?

A: The USAP testing process provides a standardized, data-driven approach to evaluate product durability and performance. This ensures that products meet strict quality and safety standards, reducing discrepancies and enhancing reliability in various operating conditions.

Q: How does the USAP testing process improve manufacturing consistency?

A: By using controlled environment simulations, detailed stress testing, and continuous data feedback loops, the USAP testing process helps identify material variability and production inefficiencies, enabling precise adjustments to ensure consistent quality control across production batches.

Q: Can the USAP testing process be integrated with existing manufacturing procedures?

A: Yes, the USAP testing process is designed to complement existing quality control methods. It offers scalable solutions equipped with advanced testing equipment and data management systems that manufacturers can integrate into their production lines for improved product certification and performance evaluation.

-

USAP testing process: Read this article to understand a comprehensive quality assurance framework that standardizes product evaluation, ensuring durability, performance, and safety across various operating conditions. Back ↩

-

3K Carbon Fiber: Explore this article to learn about 3K Carbon Fiber’s properties, its role in enhancing structural integrity, and its applications in high-performance sports equipment. Back ↩

-

12K Carbon Fiber: Click here to dive into the specifics of 12K Carbon Fiber, including its material characteristics and benefits for improving product strength and durability. Back ↩

-

T300 Carbon Fiber: Discover detailed insights about T300 Carbon Fiber, a material known for its balanced strength and lightweight properties used for high-performance products. Back ↩

-

Nomex Honeycomb Core: Learn how Nomex Honeycomb Core contributes to improved impact absorption and structural efficiency in sports equipment manufacturing. Back ↩