We maintain consistency in every pickleball paddle order by implementing rigorous quality control1, standardized production processes, and precision engineering steps that ensure every paddle meets the highest performance and durability standards.

In today’s competitive sports equipment market, consistency is a key factor in maintaining strong supplier relationships and meeting end-user expectations. Consistent pickleball paddle quality is especially crucial for businesses looking to offer reliable and high-performance products. At NEX Pickleball, we achieve this through a series of carefully designed manufacturing processes, quality control1 procedures, and continuous process improvement methodologies to ensure every order meets our high standards.

Maintaining uniform quality in every paddle is not merely a goal but a necessity for B2B procurement managers responsible for brand reputation and customer satisfaction. Variability in materials, production methods, and environmental conditions can lead to differences in paddle performance. These differences can affect balance, durability, and ball control. Our industry’s demanding requirements drive us to optimize every production step from raw material selection to final quality testing.

Key Challenges Include:

- Variations in base materials such as carbon fiber2, fiberglass, or composite materials.

- Differences arising from manual handling versus automated processes.

- Environmental factors during production processes (e.g., temperature fluctuations during thermoforming).

- Need for scalability while preserving the quality of individual paddle components.

At NEX Pickleball, our manufacturing processes are engineered to balance efficiency with precision. We use three core methods—hot pressing, cold pressing, and Thermoforming3—each contributing unique advantages to our overall consistency strategy.

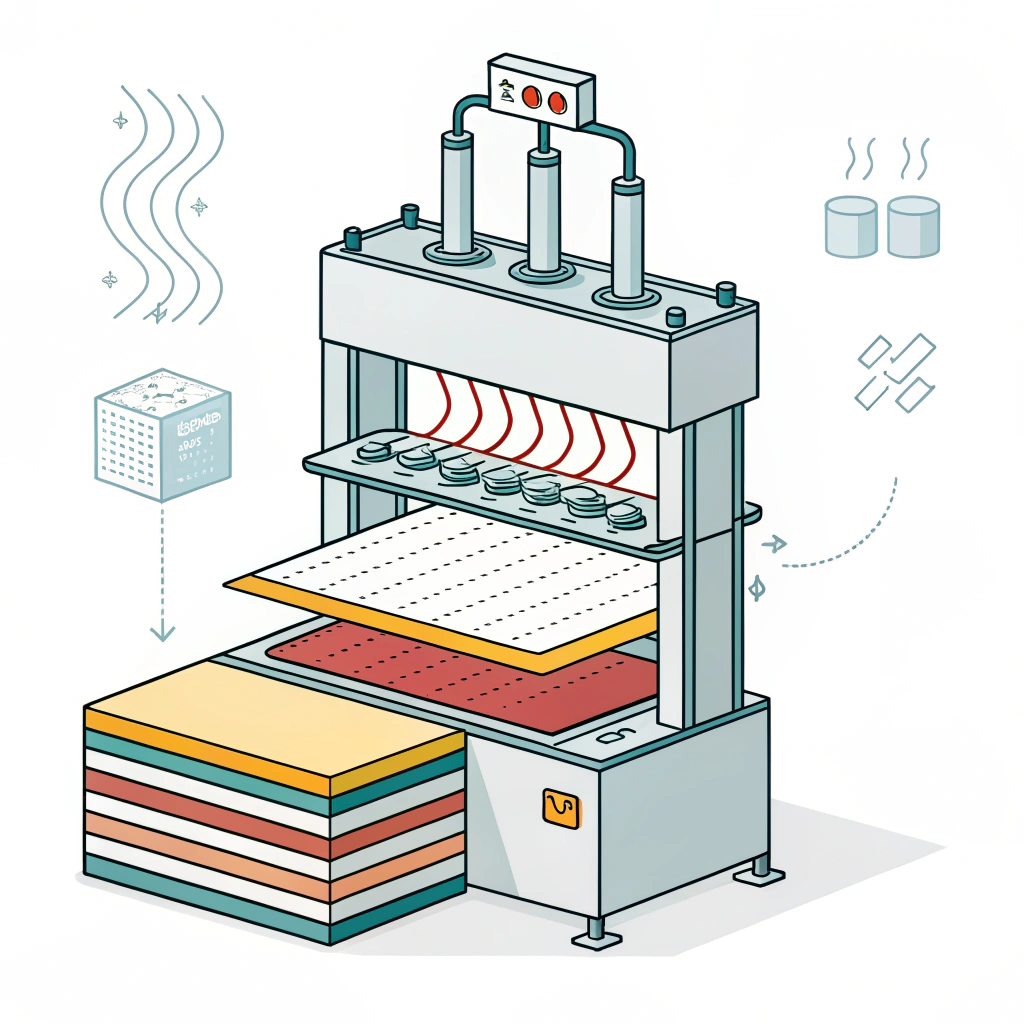

Hot pressing involves applying both heat and pressure to transform raw materials into a durable paddle structure. This method creates a robust bond among the materials and ensures structural integrity.

-

Advantages:

• High production efficiency suitable for large orders.

• Enhanced impact resistance thanks to the robust bond in the final product.

• Reliable structural integrity for high-performance play. -

Considerations:

• Requires substantial equipment investment and consistent temperature controls.

• May alter some material properties if not regulated precisely.

Cold pressing shapes the material at room temperature using controlled mechanical pressure, which preserves the natural properties of the base materials. This approach provides unparalleled control over thickness and texture.

-

Advantages:

• Superior control over paddle dimensions, enhancing ball feel and responsiveness.

• Maintains material properties intact, delivering the expected performance for every paddle. -

Considerations:

• Production cycles are longer due to the precision required.

• Demands precise pressure control equipment to maintain uniformity.

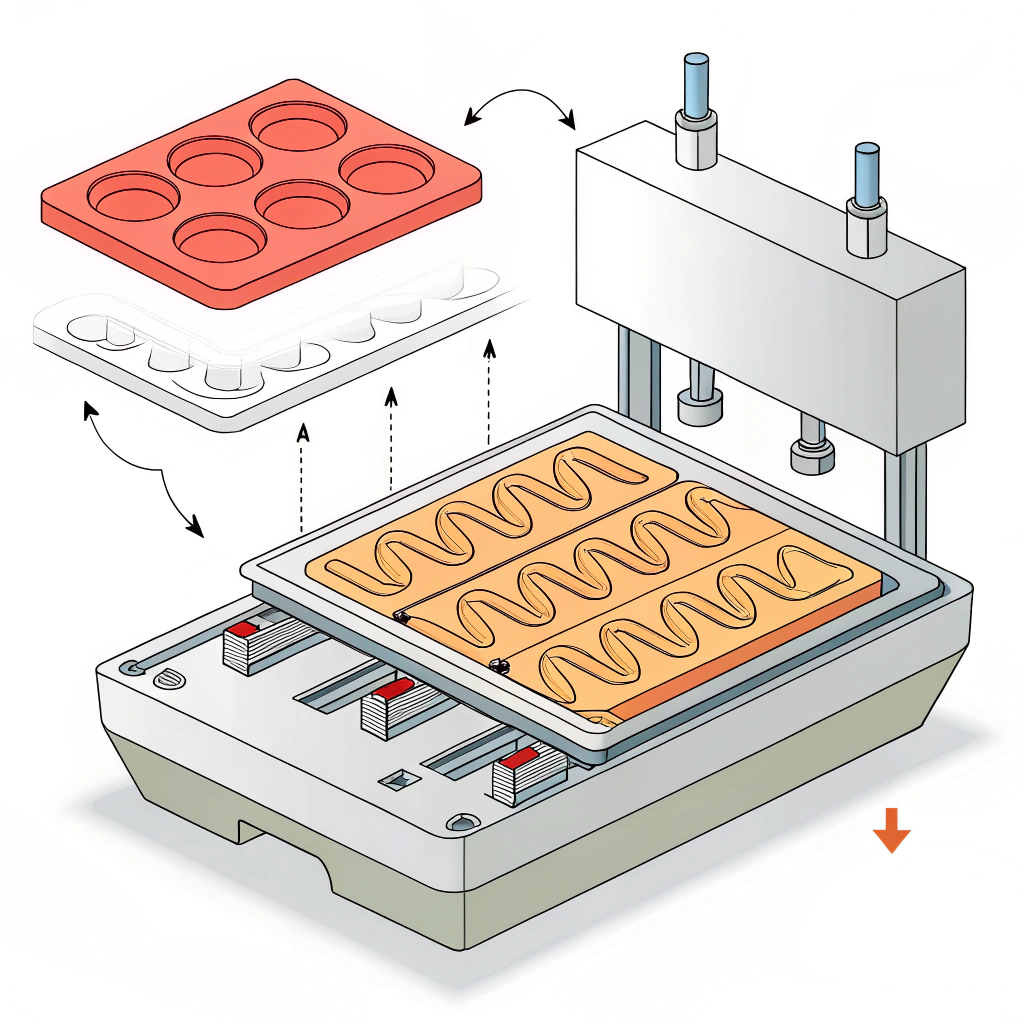

Thermoforming3 involves heating materials until they become pliable and then molding them into the desired shape using dedicated molds. This method is particularly useful for achieving intricate designs and precise material distribution.

-

Advantages:

• Produces paddles with complex, ergonomic shapes that contribute to consistent weight distribution and optimal performance.

• Maintains paddle stability and reinforces the quality of high-performance materials. -

Considerations:

• Longer production times and higher equipment costs mean thermoforming is best suited for premium or custom paddle orders.

Consistency starts with selecting the right materials. We source several premium materials including different grades of carbon fiber2 such as 3K, 12K, and T300. Each type plays a unique role:

- 3K Carbon Fiber: Favored for its strength and flexibility, ensuring high rebound force and reduced vibration.

- 12K Carbon Fiber: Offers a smoother surface and increased durability, essential for competitive play where impact resistance is critical.

- T300 Carbon Fiber: Provides a balance of strength and light weight, perfect for players seeking precision without sacrificing performance.

We also complement these materials with fiberglass and advanced composites like bamboo core, honeycomb core, and Nomex honeycomb cores. Each material undergoes strict testing to verify its performance characteristics under varying conditions.

To further solidify consistency across paddle orders, our production protocols include:

-

Automated Process Controls: Advanced machinery monitors temperature, pressure, and timing in each production phase. This reduces human error and ensures that each paddle is produced under identical conditions.

-

SOPs4: Detailed Standard Operating Procedures guide every production step, ensuring that every operator follows the same precise standards. This not only minimizes variability but also speeds up training and process audits.

-

In-Process Inspection: Each paddle goes through multiple checkpoints during production. Visual inspections, dimensional checks, and material strength tests are conducted at key stages to catch any inconsistencies early.

-

Post-Production Testing: Every paddle undergoes rigorous final testing to confirm that it meets the predefined criteria for weight distribution, ball touch, and durability. Only paddles that pass these tests are approved for shipment.

To help visualize our quality control workflow, the table below summarizes the key processes and their benefits:

| Process Stage | Method | Key Benefits | Primary Considerations |

|---|---|---|---|

| Material Selection | Premium Materials | Superior performance, uniform properties | Strict supplier vetting and testing |

| Formation | Hot Pressing | High impact resistance, quick production | Equipment investment, temperature control |

| Formation | Cold Pressing | Precise texture, better ball feel | Longer cycle times, precise pressure control |

| Formation | Thermoforming | Intricate design, stable structure | Longer production time, higher cost |

| In-Process Inspection | Automated & Manual | Early detection of inconsistencies | Requires coordinated production schedules |

| Final Testing | Comprehensive Tests | Ensures paddle performance and durability | Must meet strict performance criteria |

Even when handling custom orders with unique specifications—such as specialized design, weight, balance, or grip size—our commitment to consistency remains unwavering. By integrating client specifications into our standardized processes, we ensure that while the paddle design may vary, the quality and performance stay consistent.

Our custom paddle orders undergo the same rigorous quality control checks. Advanced technology tracks every order’s production batch to guarantee that each custom design adheres to the same high standards as our standard products. This ensures that regardless of the order volume or customization level, every paddle will deliver predictable performance every time.

Imagine a sports equipment distributor placing a bulk order for high-performance pickleball paddles. Their primary concern is product consistency—each paddle must perform identically to maintain brand reputation and customer satisfaction across various sporting events.

-

Pre-Production Consultation: We collaborate with the distributor to understand their specific requirements, including detailed performance metrics and custom design elements.

-

Production Batch Control: For bulk orders, paddles are produced in batches under identical conditions. Batch monitoring ensures that environmental factors such as temperature fluctuations do not affect the final product.

-

Quality Feedback Loop: Each batch is tested rigorously, and any deviations trigger immediate adjustments in the production process. This continuous feedback loop allows for real-time quality enhancement.

-

Final Approval: Only after each batch meets our strict quality standards do we proceed to packaging and shipment.

By following these steps, our clients can be confident that every paddle delivered, whether in a batch of ten or thousands, represents the same high level of quality and consistency.

Embracing technology in quality assurance plays a critical role in our consistency measures. Tools and systems such as automated temperature sensors, pressure monitors, and digital quality checkpoint systems have revolutionized how we maintain product quality.

-

Real-Time Data Analytics: Data gathered from every production stage is analyzed to spot trends and preemptively resolve issues that could affect consistency.

-

Predictive Maintenance5: Equipment is maintained through predictive analytics, ensuring that production machinery operates at peak performance with minimal downtime.

Ensuring that our workforce is well-trained on the latest manufacturing techniques and quality protocols enhances consistency. Regular training sessions and updates on SOP changes ensure that every team member is aligned with our quality goals.

-

Skill Enhancement: Workshops and certifications for operators help bridge knowledge gaps and foster an environment of continuous improvement.

-

Employee Feedback: Operators regularly contribute insights from the production line, enabling us to refine processes and address potential inconsistencies proactively.

Transparency in our manufacturing and quality control processes builds trust in our B2B relationships. We provide regular updates through performance dashboards, detailed production reports, and periodic quality assessments. This transparent communication ensures that our partners are always informed and confident in the consistent quality of their orders.

At NEX Pickleball, maintaining consistency in pickleball paddle orders is achieved through an integrated approach combining advanced production processes, material standardization, and rigorous quality control. We leverage hot pressing, cold pressing, and thermoforming techniques—each carefully calibrated to ensure precision and durability while incorporating strict testing protocols at every stage.

Our customized production processes, backed by continuous process improvement and employee training, provide a competitive edge. This robust quality assurance system not only minimizes variability but also reinforces our commitment to delivering paddles that consistently meet the highest performance standards.

For businesses looking to partner with a reliable manufacturer, understanding our process and quality controls can provide the confidence needed to ensure successful bulk orders and ultimate customer satisfaction. Whether you require standard orders or specialized custom designs, our scalable and transparent processes are built to meet B2B sourcing challenges head-on.

We invite you to reach out and discuss how our consistency and precision in manufacturing can support your business goals and elevate your product offerings.

People Also Ask

Q: How to get more consistent in pickleball?

A: Consistency in pickleball can be improved by practicing coordination drills, maintaining a proper grip size, and focusing on controlled strokes. While these tips are more applicable for players, ensuring paddle uniformity during manufacturing follows similar principles of maintaining precise control and consistency throughout the production process.

Q: How to keep a pickleball paddle in good condition?

A: Keeping a pickleball paddle in good condition involves regular maintenance such as gently wiping the surface with a damp, lint-free cloth after play, avoiding harsh chemicals that can damage the material, and conducting periodic deep cleaning, especially for carbon fiber paddles. These practices help maintain the paddle's performance over time.

Q: How to maintain grit on a pickleball paddle?

A: To preserve the texture or grit on a pickleball paddle, avoid excessive friction and heat that can wear it down. Using abrasive materials like rubber erasers on the paddle surface can break down the grit prematurely. Instead, maintain proper cleaning methods to ensure the paddle retains its performance-enhancing texture.

-

Quality Control: Click to learn about the systematic processes and techniques that ensure products consistently meet quality standards, reducing variability and defects throughout manufacturing. ↩ ↩ ↩2

-

Carbon Fiber: Click to understand the material properties, manufacturing advances, and performance benefits of carbon fiber in high-performance products. ↩ ↩ ↩2

-

Thermoforming: Click to explore how thermoforming works, its applications in creating complex shapes, and its role in achieving consistent product quality. ↩ ↩ ↩2

-

SOPs: Click to learn about Standard Operating Procedures that standardize tasks, minimize deviations, and streamline production processes for improved quality. ↩ ↩

-

Predictive Maintenance: Click to discover how predictive maintenance uses data analytics to foresee equipment failures and optimize operational efficiency. ↩ ↩