Quick Answer: For B2B decision-makers, the key to staying competitive in the booming pickleball market is to leverage advanced manufacturing techniques—such as Hot Pressing1, Cold Pressing2, and Thermoforming3—while integrating premium materials like Carbon Fiber4 and Fiberglass5 to deliver high-performance, customizable paddles that meet diverse customer needs.

The rapid growth in the pickleball market has driven manufacturers and sports equipment suppliers to adopt innovative production techniques to keep up with increasing demand. With consumers ranging from casual players to competitive professionals, offering a competitive product means not only utilizing cutting-edge materials but also optimizing production processes. In today’s article, we compare different advanced production methods and material technologies that are pivotal in manufacturing high-performance pickleball paddles. This analysis enables B2B procurement professionals and sports equipment decision-makers to make an informed choice that aligns with their business strategy.

At NEX Pickleball, we have harnessed the power of modern production techniques to create paddles that stand out in durability, performance, and customization. Our processes are tailored to meet both large-scale manufacturing needs and bespoke product requirements. In this article, we will take you through a detailed comparison of our key production approaches, the benefits and challenges of each method, and how these factors shape product performance and cost efficiency.

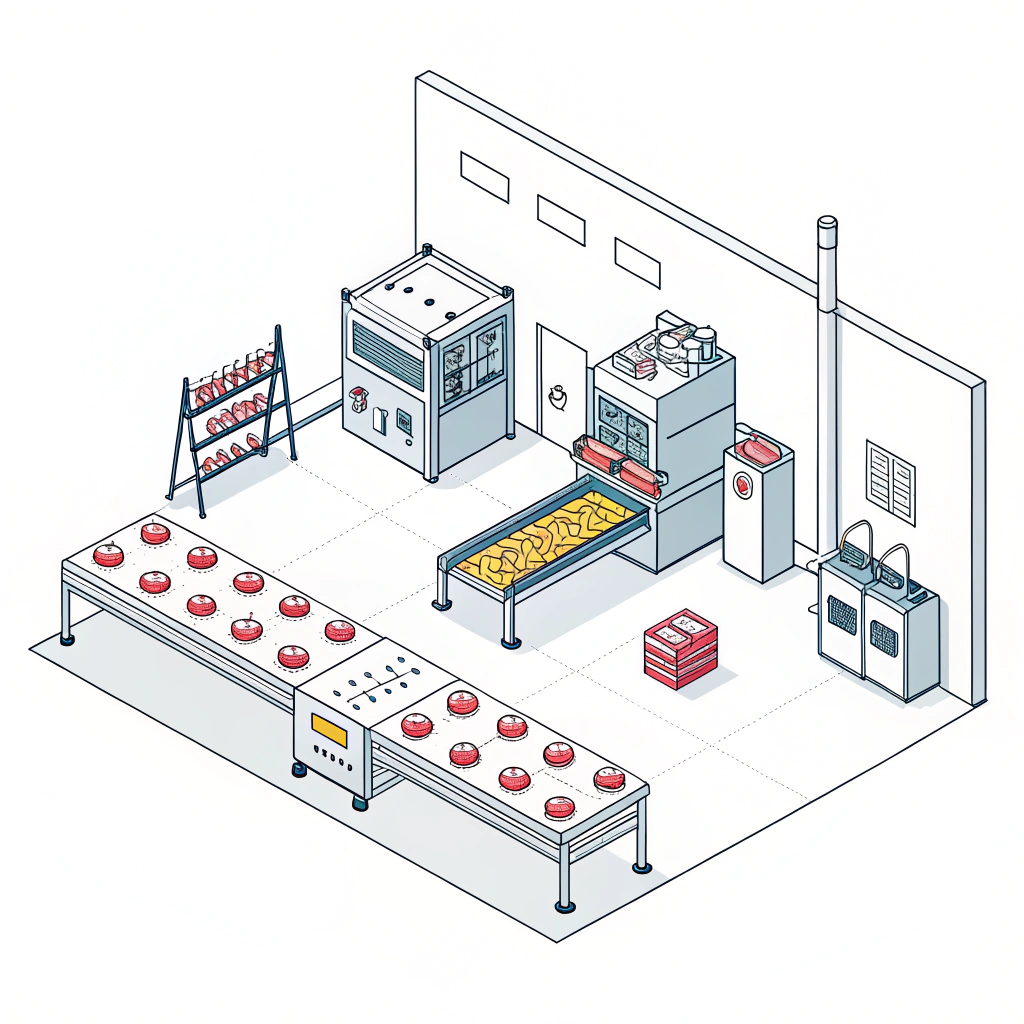

In the realm of pickleball paddle production, the following three manufacturing processes are at the forefront:

-

Hot Pressing

Hot pressing involves applying heat and pressure to form the paddle structure. This technique is favored for producing high-strength and durable paddles that can sustain heavy impact.- Advantages:

• High production efficiency suitable for mass manufacturing.

• Creates a strong paddle with excellent impact resistance.

• Integrity of the structure remains robust under repetitive use. - Disadvantages:

• High investment costs for specialized equipment.

• Potential alteration of some material properties, which may affect the paddle's feel.

- Advantages:

-

Cold Pressing

This method uses mechanical pressure applied at room temperature. It allows for greater precision in controlling the paddle’s thickness and structure, maintaining the original material properties.- Advantages:

• High level of precision in design control.

• Preserves material flexibility for superior ball feel.

• Minimizes changes in material characteristics, ensuring optimal performance. - Disadvantages:

• Production cycles take longer compared to hot pressing.

• Requires advanced machinery to ensure consistent high-quality output.

- Advantages:

-

Thermoforming

Thermoforming softens materials with heat before molding them into complex shapes. It is ideal for producing paddles with intricate designs that require precise material distribution.- Advantages:

• Enables the creation of paddles with complex designs.

• Enhances stability and weight distribution.

• Suitable for integrating diverse materials in a single product. - Disadvantages:

• Extended production time due to the heating and cooling cycles.

• Higher equipment costs reserved for premium or custom products.

- Advantages:

The comparison below summarizes these key aspects:

| Production Process | Advantages | Disadvantages | Best Use Scenario |

|---|---|---|---|

| Hot Pressing | High efficiency, strong structural integrity, excellent impact resistance | High equipment cost, potential material alteration | Mass production for high-performance competitive paddles |

| Cold Pressing | Precise control over thickness, preserves material properties, superior ball feel | Longer production cycles, high-quality machinery requirement | Premium lines where material performance and control are prioritized |

| Thermoforming | Enables intricate designs, excellent stability, broad material compatibility | Extended production time, higher costs | Custom or limited-edition products requiring advanced design features |

This table should assist B2B buyers in aligning production methods with specific product strategies, depending on whether efficiency, design complexity, or material integrity is a higher priority.

High-performance paddles require the thoughtful selection of materials. At NEX Pickleball, we use a strategic blend of premium materials that directly influence paddle performance. Understanding these materials is essential for B2B decision-makers as it impacts not only the playability but also the durability and overall market appeal of the product.

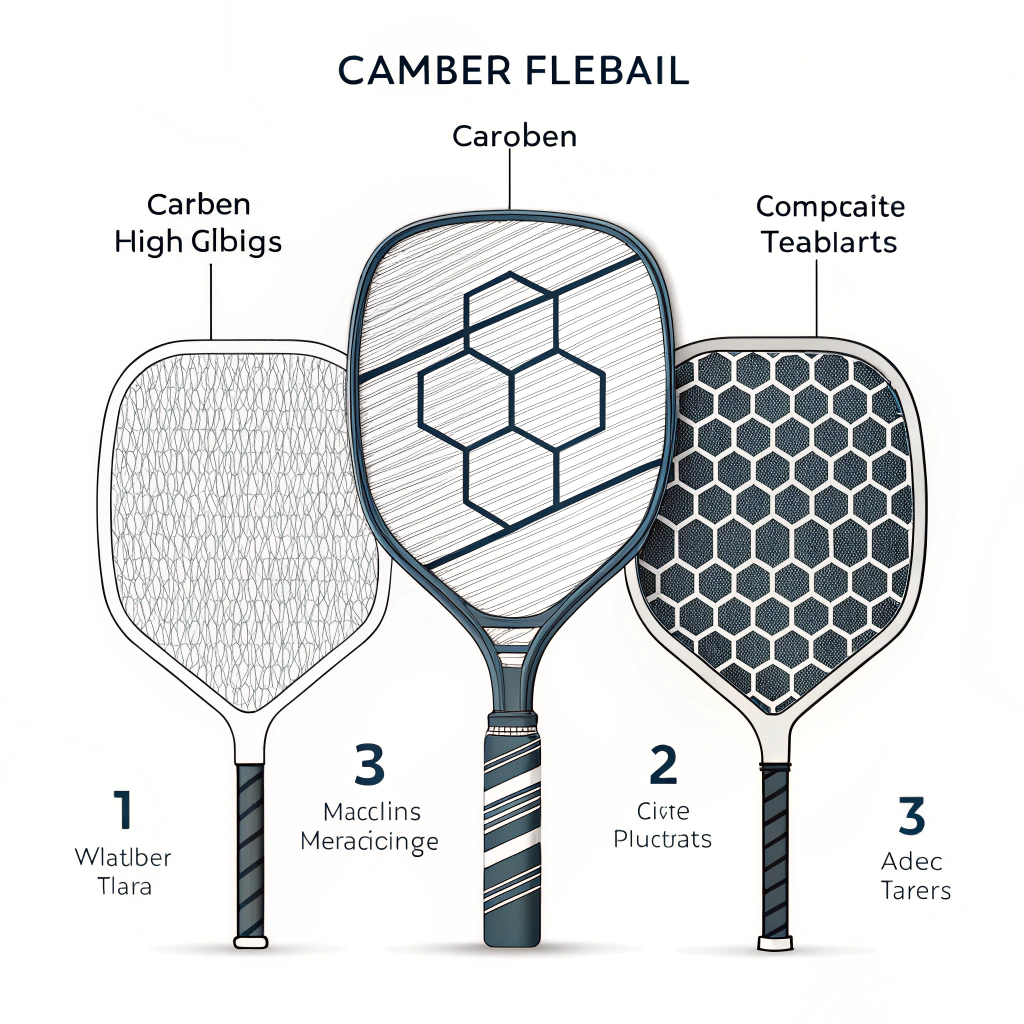

Carbon Fiber remains a favored choice due to its robust characteristics. We use several types:

- 3K Carbon Fiber: Known for its balance between strength and flexibility, making it ideal for paddles that need to deliver high rebound force.

- 12K Carbon Fiber: Offers a smoother surface, exceptional hardness, and heightened durability, which makes it perfect for high-impact competitive play.

- T300 Carbon Fiber: Provides outstanding tensile strength with a balanced mix of strength and light weight, delivering superior control.

Incorporating carbon fiber in production not only contributes to the power behind the paddle but also maintains responsiveness during fast-paced play.

While Fiberglass paddles are more flexible, they offer an excellent balance between power and control. The use of E-Glass Fiberglass provides elasticity and superior ball control. Compared to carbon fiber, fiberglass offers a wider sweet spot, making it a popular option, especially for recreational use and players seeking enhanced control.

Our commitment to performance is further demonstrated through the use of composite materials. By combining Carbon Fiber and Fiberglass, or using innovative cores such as:

- Bamboo Core Composite: Delivers a lightweight yet durable paddle with a distinctive hitting feel.

- Honeycomb Core: Made from high-density polymer materials, these cores provide superior shock absorption, reducing paddle vibrations and enhancing durability.

Each material and composite has been chosen not only for its inherent properties but also for its ability to be molded effectively through our production processes. This careful material selection allows us to meet the diverse needs of B2B partners, ensuring that the paddles excel both in performance and longevity.

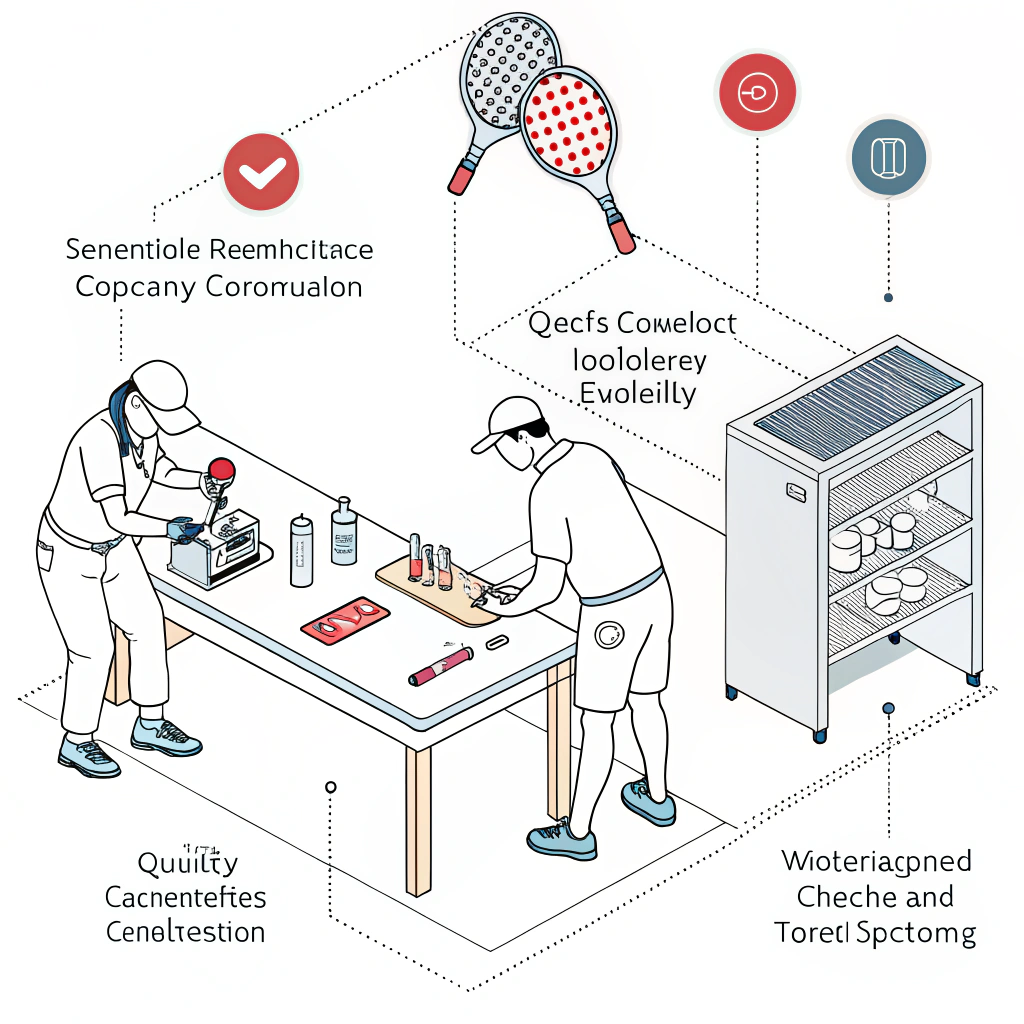

Meeting the diverse needs of global markets demands stringent quality control and flexible customization options. At NEX Pickleball, every paddle undergoes rigorous testing. Our quality control protocols include:

- Structural Integrity Checks: Ensuring durability under high impact.

- Impact Resistance Testing: Confirming that the paddle can sustain repeated, high-force impacts.

- Ergonomic Grip Verification: Guaranteeing that the grip design meets ergonomic standards to enhance player comfort.

Customization is another pivotal advantage of partnering with us. B2B clients can specify design elements such as:

- Custom Weight Distribution: To cater to different player profiles.

- Ergonomic Grip Sizes: Accommodating diverse hand sizes across the target market.

- Visual Branding and Finishes: Allowing retailers to incorporate their branding seamlessly into our paddles.

By offering these customizations, we empower our clients to differentiate their product portfolio in a competitive market. This ensures that the final product not only satisfies performance demands but also aligns with the unique branding strategies of our partners.

The pickleball market has seen unprecedented growth. Several factors fuel this rise:

- Broad Demographic Appeal: Pickleball is accessible to players of nearly all ages, from youngsters to seniors, which expands the potential customer base significantly.

- Low Risk of Injury: With a low injury rate compared to other sports, more players are drawn to this sport, fueling demand for quality equipment.

- Cost-Effective Entry: The relatively low cost of entry into the sport further boosts its popularity.

The market growth is strongly supported by strategic marketing efforts. Effective platforms include Google ads, social media campaigns on Facebook, Instagram, and YouTube, and community engagement through local tournaments and leagues. As trends continue to shape consumer behavior, manufacturers must adopt production innovations that prioritize quality and modern aesthetics.

For B2B decision-makers, aligning with a manufacturing partner that understands both the technical and market aspects of pickleball equipment is crucial. Our advanced production capabilities, along with our flexible customization options and stringent quality checks, make us an ideal partner for companies looking to expand their product offerings. By leveraging state-of-the-art production techniques, our clients gain:

- Faster time-to-market with reliable, high-quality products.

- Enhanced product performance that translates directly into customer satisfaction.

- A competitive edge in the marketplace through innovative design and production processes.

Furthermore, our strategic positioning within the supply chain ensures resilience, even during periods of increased demand. With the ability to scale production efficiently, we help partners navigate market fluctuations without compromising on quality.

In summary, adopting advanced production techniques such as Hot Pressing, Cold Pressing, and Thermoforming can significantly impact the performance and marketability of pickleball paddles. Coupled with the use of premium materials like Carbon Fiber, Fiberglass, and innovative composites, these manufacturing processes deliver products that meet both the rigorous demands of competitive players and the aesthetic expectations of modern consumers.

For B2B stakeholders looking to strengthen their portfolio:

- Evaluate your production goals (mass production versus custom, premium offerings) alongside the benefits and limitations of each production technique.

- Consider partnering with a manufacturer with robust quality control measures and flexible customization services to ensure that your products remain competitive.

- Stay informed on market trends and consumer behavior to align product innovations with evolving demands.

Taking action now by integrating these insights into your operational strategy will empower your business to capitalize on the booming pickleball market. Enhanced production methods, reliable quality, and innovative design are the keys to propelling your business forward—ensuring you remain ahead in this dynamic sports equipment segment.

Q: Why is pickleball gaining in popularity so quickly?

A: Pickleball’s popularity is driven by its broad demographic appeal, low risk of injury, and low cost of entry, making it accessible to nearly everyone—from young children to seniors. These factors, along with increased media exposure and community engagement, contribute to its rapid growth.

Q: What is the marketing strategy of pickleball?

A: Effective marketing strategies for pickleball include using Google ads to capture high-intent audiences, leveraging social media platforms such as Facebook, Instagram, and YouTube, and engaging with communities by sponsoring local events and tournaments. These channels help reach a broad audience of enthusiasts and drive consumer interest.

Q: How to make money in the pickleball industry?

A: There are multiple revenue streams in the pickleball industry, including coaching services, court rentals, gear sales, merchandising, and organized tournaments or leagues. Identifying specific pain points and tailoring your offerings to meet the needs of distinct customer segments can further enhance profitability.

-

Hot Pressing: Reading this article will help you understand how applying heat and pressure during production can create strong, durable products that withstand high-impact usage. ↩ ↩

-

Cold Pressing: Discover the methods and benefits of using room-temperature pressure to maintain material properties, ensuring precision and optimal performance. ↩ ↩

-

Thermoforming: Learn about the process of molding heated materials into complex shapes, which is crucial for custom design and advanced product features. ↩ ↩

-

Carbon Fiber: Explore the advantages of incorporating carbon fiber in manufacturing, including its high strength-to-weight ratio and durability for high-performance applications. ↩ ↩

-

Fiberglass: Understand how fiberglass offers flexibility and a cost-effective solution for balancing power and control in product design. ↩ ↩