Quick Answer: Sourcing high-performance pickleball paddles from China involves a careful evaluation of supplier capabilities, an understanding of advanced production processes (like hot pressing1, cold pressing2, and thermoforming3), and a comprehensive approach to quality control and logistics. By partnering with experienced OEM/ODM manufacturers such as NEX Pickleball, procurement managers can secure reliable, cost-effective, and customizable solutions tailored for competitive and recreational use.

As the pickleball market expands globally, many businesses are looking to diversify their product lines and tap into new opportunities. For procurement managers and business owners in the sports equipment industry, sourcing high-quality pickleball paddles from China not only meets growing consumer demand but also helps optimize cost efficiency and product customization. However, the process can be complex due to variations in supplier quality, production processes, and logistics management.

In this article, we provide a step-by-step guide to successfully sourcing pickleball paddles from China. We discuss how to evaluate suppliers, understand the intricacies of manufacturing processes, negotiate effectively, and maintain strict quality control. This guide is designed with practical insights and data-driven support, ensuring you can confidently navigate the sourcing process and build a reliable B2B partnership.

The first step in sourcing pickleball paddles is identifying manufacturers with proven expertise in sports equipment manufacturing. Key considerations include:

- Industry Experience: Look for suppliers with a track record in producing pickleball paddles or similar sports equipment. Established manufacturers like NEX Pickleball, who have experience with brands such as Joola and Selkirk, offer credibility and reliability.

- Production Capabilities: Confirm that the supplier can handle the specific production processes you require (e.g., hot pressing1, cold pressing2, thermoforming3). Advanced processes ensure superior paddle performance.

- Certifications and Quality Standards: Check if the supplier holds relevant industry standards and certifications. Rigorous quality control practices are a sign that the manufacturer can deliver durable, high-performance products.

Once you have a list of potential suppliers, dig deeper into each candidate’s background:

- Production Techniques: Understand the production methods they employ. For instance, hot pressing might be preferable for creating high-strength paddles, whereas cold pressing is beneficial for precision control.

- Material Expertise: Evaluate the types of materials used. Leading manufacturers often use premium carbon fiber4 (3K, 12K, T300), fiberglass, and composite materials to tailor paddle performance.

- Customization Capabilities: If you require branded or customized paddles, ensure that the supplier offers ODM/OEM services with flexibility on design, weight, balance, and grip sizes.

- Client References and Case Studies: Ask for samples, client testimonials, or case studies which can provide insights into their performance consistency, on-time delivery, and after-sales support.

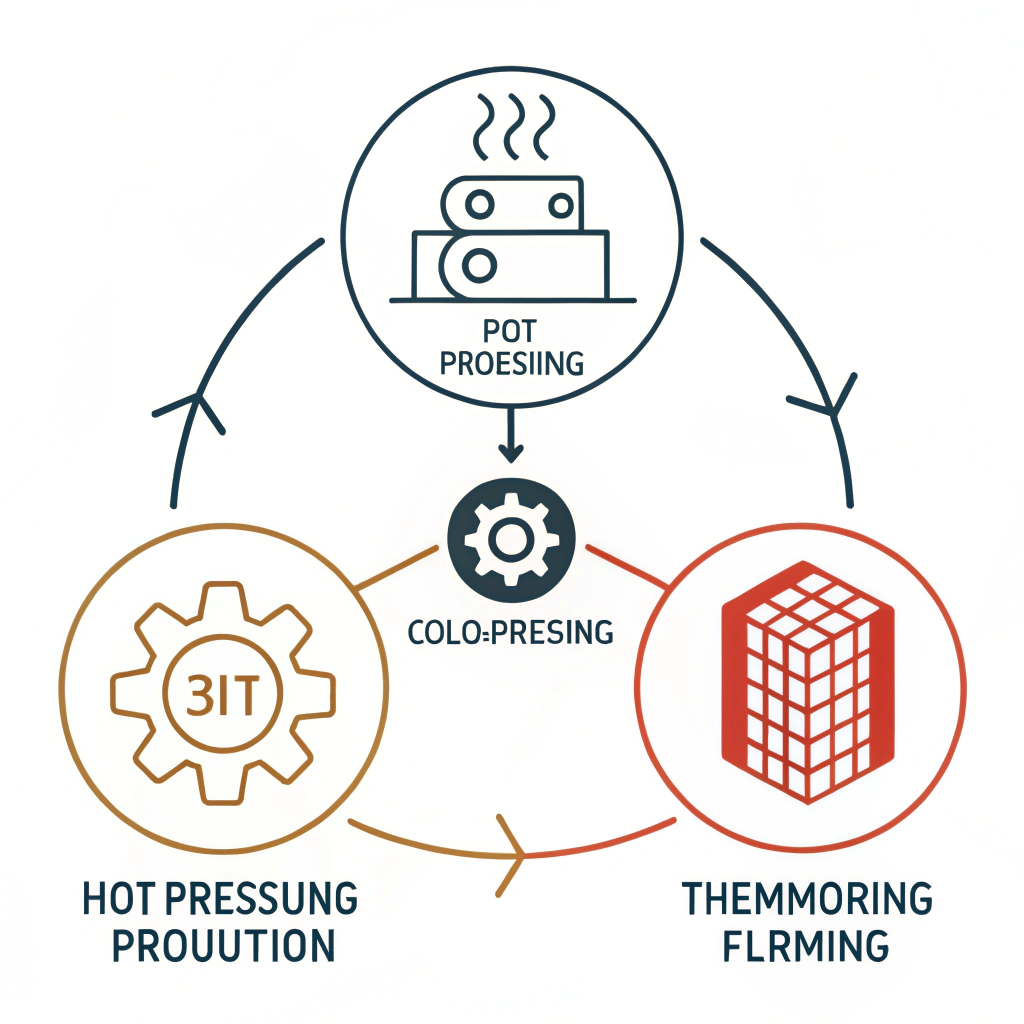

The manufacturing techniques used significantly affect a paddle’s performance, durability, and playability. With advanced production such as hot pressing, cold pressing, and thermoforming, every detail in paddle design is optimized. Below is a detailed comparison in table format:

| Production Process | Advantages | Disadvantages | Suitable For |

|---|---|---|---|

| Hot Pressing | - High production efficiency - Excellent impact resistance - Strong structural integrity | - Potential alteration of material properties - High equipment investment | Large-scale manufacturing; competitive play paddles |

| Cold Pressing | - Precise control over paddle thickness - Maintains material properties - Enhanced ball feel | - Longer production cycles - Requires precise pressure control | Designs emphasizing control and responsiveness |

| Thermoforming | - Detailed, intricate designs possible - Consistent material distribution - Enhances product stability | - Longer production time - Higher equipment costs | High-end paddles; custom-made products |

Each process offers a trade-off between speed and precision. For example, while hot pressing is optimal for mass production, cold pressing yields superior control for specialized paddle designs. By understanding these processes, you can better match your product needs with the manufacturer’s expertise.

Quality control is vital for ensuring competitiveness. Establish a rigorous quality control program with your supplier:

- Testing Protocols: Ensure that every batch of paddles undergoes extensive round of tests, including durability, tensile strength, and vibration reduction tests to confirm consistent performance.

- Incoming Material Inspection: Verify the quality of raw materials such as carbon fiber, fiberglass, or composite materials before production. This minimizes defects in final products.

- In-Process Checks: Schedule routine inspections during production to guarantee that each paddle meets industry specifications, such as proper weight distribution and surface treatment.

- Final Product Certification: Require documentation confirming that the final product meets internationally recognized standards. Certifications provide added assurance for your customers.

Customization plays a significant role in differentiating your product offerings:

- Material Customization: Leverage advanced materials like 12K Carbon Fiber for stronger paddles or Bamboo Core Composite5 for a unique playing feel.

- Design Personalization: Offer custom grips, paddle shapes, and surface treatments. This can also include logo printing and color adjustments through on-demand-print services.

- Application-Specific Tweaks: Tailor the paddle properties based on whether the target market comprises competitive players or recreational users. Competitive users might prefer paddles offering greater rebound force, whereas recreational players may value enhanced comfort and control.

A well-planned customization strategy not only sets your products apart but also builds strong brand loyalty. It is essential to communicate precise product specifications to the supplier to avoid any misalignments during production.

When sourcing products from China, cost management is crucial. Consider the following steps:

- Breakdown of Costs: Identify key cost components such as raw materials, labor, logistics, inspection, and any customization fees. A detailed cost breakdown helps in comparing quotes from various suppliers.

- Volume Discounts and MOQs: Understand the minimum order quantities (MOQs) and evaluate if higher volume orders can secure more favorable pricing. Negotiate volume discounts where possible without compromising quality.

- Total Cost of Ownership (TCO): Look beyond initial production costs. Factor in logistics, customs duties, warehousing fees, and potential warranty or after-sales costs. A comprehensive TCO analysis can reveal the true cost competitiveness of a supplier.

Efficient logistics ensure that products arrive on schedule and in perfect condition:

- Lead Time Management: Work with suppliers that have a proven record of delivering on time. Understand the production cycles for different processes, as they can vary significantly.

- Packaging and Transit Protection: Verify that the supplier uses adequate protective packaging to prevent damage during shipping. Custom padding, weather-proof packaging, and secure sealing can mitigate risk.

- Tracking and Communication: Use digital tracking systems for real-time updates on the shipment. Establish clear communication channels with the supplier to quickly address any issues.

- Customs and Import Regulations: Stay up-to-date on international trade policies, import duties, and customs processes applicable when importing sports equipment from China. This helps in avoiding unforeseen delays or complications during customs clearance.

By adopting a meticulous approach to both negotiation and logistics, you not only improve cost efficiency but also maximize product quality and delivery reliability.

Building a long-term partnership with your supplier is critical to sustained success. Consider the following recommendations:

- Regular Audits and Reviews: Schedule periodic audits of the supplier’s facility and production processes. This reaffirms quality control measures and maintains transparency.

- Open Communication Channels: Maintain frequent communication to address concerns, share feedback, and swiftly resolve issues. Understand market shifts and be proactive in discussing potential product improvements.

- Collaborative Product Development: Engage with the supplier during the product development phase. Sharing insights on market trends and consumer preferences can drive innovation and lead to mutual benefits.

- After-Sales Support and Service: Evaluate the supplier’s capability to provide after-sales support, such as warranty management and replacement policies. Reliable after-sales service ensures customer satisfaction and reinforces trust.

By following these practices, you can transform a transactional relationship into a strategic partnership that bolsters your competitive edge in the market.

One successful case is that of a sports equipment distributor who, after evaluating multiple Chinese manufacturers, selected a partner specializing in advanced composite paddle production. The distributor reported the following benefits:

- A 15% reduction in unit cost due to effective volume negotiation and optimized logistics.

- Enhanced product performance with a 20% improvement in paddle durability and reduced vibration, validated by third-party testing.

- Improved market position through customized branding and consistently high product quality.

This case exemplifies how data-driven decision-making and meticulous supplier evaluation can result in cost efficiency, product quality, and customer satisfaction.

Sourcing pickleball paddles from China involves a multifaceted approach that spans supplier selection, understanding manufacturing processes, and optimizing supply chain logistics. Key takeaways include:

• Start with thorough market research and supplier evaluation to ensure that the manufacturer meets your quality and production standards.

• Dive deep into understanding the different production processes—hot pressing, cold pressing, and thermoforming—and align them with your product goals.

• Establish robust quality control protocols that cover raw material inspection, in-process checks, and final product certification.

• Negotiate based on a detailed cost breakdown and be mindful of MOQs and TCO to secure a competitive pricing strategy.

• Optimize logistics by managing lead times, ensuring proper packaging, and staying informed about international trade regulations.

• Finally, nurture a long-term relationship with your supplier through regular audits, open communication, and collaborative innovation.

By following these recommendations, procurement managers and business owners can confidently source high-performance pickleball paddles, ensuring both innovation and customer satisfaction in their product offerings.

Q1: What factors should be considered when sourcing pickleball paddles from China?

A1: When sourcing pickleball paddles from China, it is essential to evaluate the supplier’s production capabilities, quality control measures, cost breakdown, and logistical efficiency. Assessing the manufacturing techniques (such as hot pressing, cold pressing, and thermoforming) and material quality (like different types of carbon fiber and composite cores) is crucial to ensure that the final product meets performance and durability standards.

Q2: How does the production process impact paddle performance and quality?

A2: The production process plays a vital role in determining paddle performance. For instance, hot pressing yields high-strength paddles suitable for competitive play, while cold pressing offers enhanced control and precision. Thermoforming allows for intricate designs and optimal material distribution, which can improve stability and overall playing experience. Each process has its unique advantages and trade-offs, influencing material properties, weight distribution, and vibration control.

Q3: What steps can be taken to ensure a reliable supplier partnership?

A3: Ensuring a reliable supplier partnership involves regular audits, open communication, and collaborative product development. It is important to conduct thorough background checks, verify quality certifications, and monitor the supplier’s production process through scheduled audits. Additionally, establishing clear negotiation terms, understanding logistics, and developing a proactive after-sales support system help build a strong, long-term relationship with the supplier.

-

hot pressing: Click to read an in-depth article about the hot pressing process, including its benefits for high-volume production and performance enhancement. ↩ ↩ ↩2

-

cold pressing: Click to explore detailed insights on cold pressing techniques, which provide precise control and improved material retention during manufacturing. ↩ ↩ ↩2

-

thermoforming: Click to learn more about thermoforming, a process that enables intricate designs and stable material distribution for high-end products. ↩ ↩ ↩2

-

carbon fiber: Click to understand carbon fiber, its properties, and why it’s widely used for superior strength and lightweight components in sports equipment. ↩ ↩

-

Bamboo Core Composite: Click to discover the advantages of Bamboo Core Composite materials, known for providing a unique balance of strength and playability in paddle manufacturing. ↩ ↩