Quick Answer: Optimal paddle weight1 is essential to ensure the perfect balance between power, control, and comfort in pickleball. At NEX Pickleball, integrating advanced materials and precision production techniques enables paddle customization tailored for competitive performance and long-lasting durability.

In the dynamic world of pickleball, selecting a paddle isn’t just about surface design or color—it’s about how weight influences every shot. For businesses evaluating pickleball paddles for their clientele, understanding the interplay between paddle weight, material composition, and production techniques is crucial. In this article, we will explore the factors affecting paddle weight, examine the pros and cons of various manufacturing processes, and provide actionable recommendations for procurement specialists and product managers.

Many sports equipment buyers face the dilemma of selecting a paddle that offers a balanced mix of power and control while ensuring player comfort. Paddle weight plays a significant role in performance. A paddle that is too heavy may provide extra power but can fatigue players quickly. Conversely, a paddle that is too light might compromise stability and reduce the potential for strong impact shots.

Within competitive and recreational spheres, the optimal paddle weight is not a one-size-fits-all concept. Instead, it is a finely tuned balance influenced by multiple factors:

- Material properties: The inherent characteristics of Carbon Fiber2, fiberglass, and various composites.

- Production processes: Techniques such as hot pressing, cold pressing, and Thermoforming3 directly influence material integrity and, subsequently, weight distribution.

- Design considerations: Ergonomic grip design and weight distribution adjustments can alter the paddle’s balance, impacting control and responsiveness.

When considering paddle weight, several interrelated aspects need attention:

-

Material Selection:

Carbon Fiber2 variants like 3K, 12K, and T300 provide varying degrees of strength and rigidity, directly affecting weight. For example:- 3K Carbon Fiber: Ideal for good flexibility and high rebound force.

- 12K Carbon Fiber: Offers higher density, ensuring a smoother surface and stronger resistance; this typically adds weight but enhances durability.

- T300 Carbon Fiber: Known for its excellent tensile strength, balancing strength and lightweight performance.

Fiberglass provides flexibility and enhanced ball control; its natural elasticity decreases the overall weight while maintaining a wide sweet spot for impact.

Composite Materials: Combining carbon fiber with fiberglass, or even integrating bamboo or honeycomb cores, offers dual benefits. These composites can fine-tune weight distribution and achieve desired hitting feels.

-

Core Material:

The core is the heartbeat of any paddle. At NEX Pickleball, we use different core constructions:- Nomex Honeycomb Core4: Provides superior shock absorption and stability.

- Aluminum Honeycomb Core: Offers balanced weight distribution for increased power.

- Polymer Honeycomb Core: Ideal for recreational players due to its vibration reduction and elastic properties.

Each core type contributes differently to the final weight and balance of the paddle.

-

Production Processes:

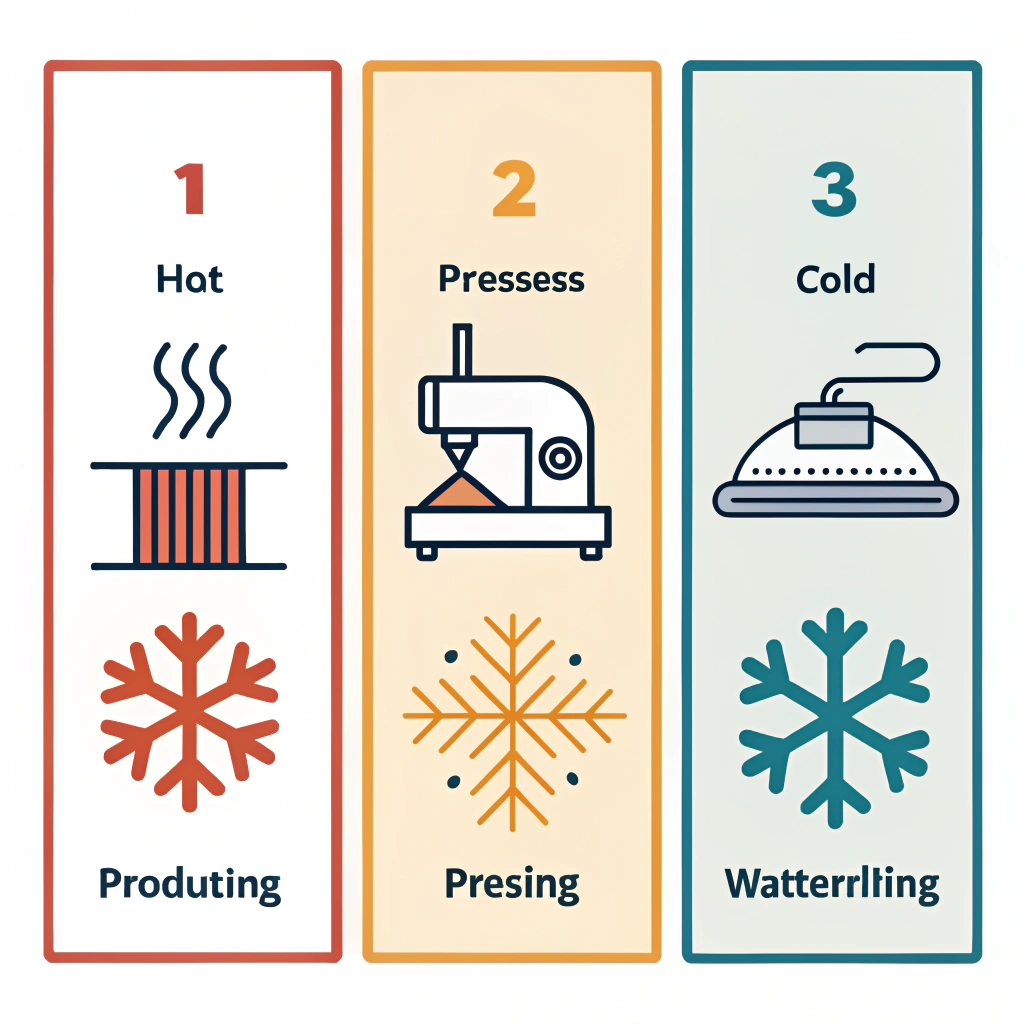

How a paddle is manufactured is equally influential:- Hot Pressing: Utilizes heat and pressure to ensure strong material bonds. This method enhances durability but can slightly increase the overall weight due to potential material density changes.

- Cold Pressing5: Conducted at room temperature, allowing for precise material layering. This method maintains the intrinsic properties of the materials, often resulting in a more controlled weight distribution and improved ball feel.

- Thermoforming3: Involves heating materials to a malleable stage and then molding them precisely. It enables the creation of paddles with intricate shapes and balanced weight distribution, though it may require a longer production cycle.

Each production technique has its own advantages and trade-offs, and the choice of process can determine whether a paddle is better suited for power shots or delicate control maneuvers.

To clearly understand how production techniques influence paddle weight and performance, consider the following table:

| Production Process | Advantages | Disadvantages | Impact on Weight & Balance |

|---|---|---|---|

| Hot Pressing | - High efficiency for large-scale production | - Potential alteration of material properties | - Yields a durable, slightly heavier paddle |

| Cold Pressing5 | - Precise control over thickness and material properties | - Longer production cycles | - Maintains a balanced and controlled feel |

| Thermoforming3 | - Enables complex and ergonomic designs | - Increased production time and equipment costs | - Optimal distribution for custom performance |

This table helps B2B professionals weigh options when selecting a supplier. For companies like NEX Pickleball, the decision often involves a trade-off between production speed and the nuanced control of paddle performance—a critical factor for the competitive market.

At NEX Pickleball, the design process integrates technical expertise with real-world performance data:

-

Ergonomic Design:

We focus on creating paddles with ergonomic grips that reduce player fatigue. The grip size is tailored to various hand dimensions, ensuring an optimal connection between the player and the paddle. This customization boosts both control and the overall user experience. -

Weight Distribution:

An ideal paddle must have an even weight distribution. By calibrating the density of the materials and fine-tuning the core structure, we guarantee that the paddle remains balanced during rapid movements. This balance not only enhances swing control but also improves follow-through accuracy. -

Surface Texture Treatment:

The paddle’s surface is specifically treated to enhance the ball impact zone. This results in reduced vibration and improved ball spin dynamics, thereby elevating both power and precision. The treatments are chosen to ensure durability under frequent, high-impact play.

Let’s consider two scenarios that illustrate how material selection and production processes can be aligned to create paddles fulfilling diverse needs:

A client required a paddle that delivers high rebound force and precise control for competitive play. The solution involved:

- Utilizing 12K Carbon Fiber for its high thread density and superior durability.

- Employing the Thermoforming3 process to mold precise shapes and maintain a consistent weight distribution.

- Incorporating an Aluminum Honeycomb Core to balance power with enhanced control.

The final paddle exhibited a robust hitting surface with minimal vibration and exceptional reaction time. This combination was especially effective in tournaments where players demand both aggressive power and pinpoint accuracy.

For a client targeting recreational use with a focus on comfort and extended play:

- The paddle was built using a composite of Fiberglass and Carbon Fiber for striking an optimal balance between power and control.

- Cold Pressing5 was chosen to maintain the original material properties, ensuring excellent ball feel.

- A Polymer Honeycomb Core was integrated to further reduce vibration, making it comfortable even during long practice sessions.

This tailored approach ensured that the paddle was both durable and versatile, catering effectively to beginners and recreational players by combining softness with performance-enhancing features.

When evaluating pickleball paddles for procurement, it is essential to consider the following factors:

-

Intended Use and Player Level:

The choice of paddle weight and production process should align with whether the paddle is meant for competitive play or recreational use. High-performance paddles tend to favor materials and processes that maximize durability and power, while recreational paddles benefit from enhanced grip comfort and reduced vibration. -

Material Quality:

Always assess the grade and source of carbon fiber, fiberglass, or composite materials used. At NEX Pickleball, rigorous quality control ensures each material layer meets specific performance standards essential for consistency across products. -

Customization Capabilities:

B2B buyers should seek manufacturers that offer on-demand customization. Adjustments in weight distribution, grip size, and even aesthetic elements, such as print options (custom branding), can significantly enhance the product's market appeal and usability. -

Manufacturing Technology:

Keep an eye on the manufacturing technology in use. Companies that leverage advanced techniques such as hot pressing, cold pressing, and thermoforming are more likely to deliver paddles with high performance and reliability. A clear understanding of these processes helps in making informed decisions that align with strategic procurement goals. -

Cost versus Performance Trade-offs:

Although high-performance paddles may carry a premium, the investment often pays off in terms of durability and player satisfaction. Evaluating factors like production efficiency and the potential for defects or returns is crucial to ensure the best value for money. -

After-Sales Support and Quality Assurance:

Ensure that the supplier provides robust quality control, testing protocols, and after-sales support. The longevity of the paddle should match the performance expectations, supporting both retail distribution and long-term use by end consumers.

Manufacturing the perfect pickleball paddle is a balancing act—literally and figuratively. The paddle weight is a key determinant of performance, influencing the power, control, comfort, and durability that players experience. By leveraging cutting-edge materials like high-grade carbon fiber and advanced production techniques, NEX Pickleball delivers products that meet the rigorous demands of both competitive athletes and recreational players.

For procurement specialists and product managers in the sports equipment industry, the takeaway is clear: evaluate your end users’ needs carefully, understand the technical nuances of different production methods, and choose a supplier whose quality control and customized options align with market demands.

Here are our key actionable recommendations:

- Assess the specific performance needs of your target market—whether it leans towards power for competitive play or comfort for extended recreational use.

- Compare material options based on your application. Prioritize paddles that use advanced carbon fiber variants if durability and power are critical.

- Evaluate the manufacturing processes. Consider cold pressing for superior ball feel and thermoforming for precise weight distribution if customization is required.

- Ensure robust after-sales quality control to minimize downtime and maintain high player satisfaction.

At NEX Pickleball, our deep commitment to technological innovation and quality assurance ensures that our paddles not only meet but exceed the expectations of both high-performance and recreational markets. We invite you to consider our paddle solutions for your next procurement cycle, ensuring your clientele receives the very best in pickleball equipment.

-

What is the importance of paddle weight in pickleball?

Paddle weight significantly influences control, power, and comfort. A well-balanced paddle enhances maneuverability and reduces player fatigue, while optimizing the force transmitted to the ball. -

How do different materials affect paddle weight and control?

Different materials such as various types of carbon fiber, fiberglass, and composites offer unique weight and stiffness properties. High-density fibers can increase strength and weight, whereas fiberglass contributes flexibility and a larger sweet spot for improved control. -

What production processes impact paddle balance and durability?

Processes such as hot pressing, cold pressing, and thermoforming each impact the final product differently. Hot pressing offers robust durability, cold pressing preserves material integrity for better control, and thermoforming allows for optimal weight distribution and customized design features.

-

paddle weight: Click here to read more about how paddle weight influences power, control, and overall performance in sports equipment. Back ↩

-

Carbon Fiber: Click here to learn about the properties of carbon fiber and how different variants are used to enhance strength and reduce weight. Back ↩ ↩2

-

Thermoforming: Click here for an in-depth explanation of thermoforming processes and how they enable precise shaping and balanced weight distribution. Back ↩ ↩2 ↩3 ↩4

-

Nomex Honeycomb Core: Click here to discover the advantages of honeycomb core constructions like Nomex in shock absorption and stable weight distribution. Back ↩

-

Cold Pressing: Click here to understand the cold pressing technique, its benefits in maintaining material properties, and its impact on paddle performance. Back ↩ ↩2 ↩3