A strategic manufacturing partnership with an advanced producer like NEX Pickleball can streamline your production process, ensure consistent quality, and drive brand scaling through cutting-edge processes such as hot pressing1, cold pressing2, and thermoforming3.

In today’s competitive pickleball market, brands looking to grow must overcome the challenges of maintaining product quality, controlling production costs, and reducing supply chain complexities. Many companies are juggling multiple suppliers, which often leads to inconsistency in product performance and greater complexities in logistics. Consolidating manufacturing under one advanced partner offers a smart solution that minimizes operational hurdles while maximizing production efficiency. In this article, we explore the challenges faced by growing pickleball brands, analyze the factors behind these challenges, and outline practical strategies for consolidating manufacturing processes through exclusive partnerships.

For many brands, the manufacturing process is fragmented. Companies often source products from different plants or manufacturers, each with its own production technique, material sourcing criteria, and quality management standards. This fragmentation can lead to:

• Variations in product quality

• Longer lead times and potential delays

• Complexity in managing supply chain and production planning

• Reduced economies of scale4, thereby increasing overall costs

When you work with multiple manufacturers, quality control becomes challenging. For instance, slight deviations in the formulation or assembly process of pickleball paddles can affect performance attributes such as power, control, and vibration damping. This inconsistency ultimately harms the brand’s reputation and customer satisfaction.

Several key causes contribute to the production inefficiencies experienced by brands that struggle with multiple manufacturing partnerships:

- Lack of unified production standards: Without a single set of operating procedures, it is hard to guarantee consistent product performance and reliability.

- Varied material inputs: Different manufacturers may have varied quality standards for premium materials such as carbon fiber5, fiberglass, or composite cores. The result is a mix of paddle quality in the market.

- Operational inefficiencies: Multiple production sites often mean different logistic channels, inventory management strategies, and communication challenges between stakeholders.

- Limited production innovation: When the manufacturing process is split among various companies, investing in advanced production techniques (like thermoforming or cold pressing) becomes fragmented, reducing speed in adopting innovative processes.

Consolidating production with an advanced partner like NEX Pickleball can help address these issues holistically, ensuring a single source of truth for quality and efficiency.

Partnering exclusively with a high-performance manufacturer like NEX Pickleball offers a suite of solutions that streamline production and drive strategic scaling. Some of the key benefits include:

-

Unified Quality Control:

With a single point of production, brands can enforce strict quality standards. Every paddle is subjected to rigorous testing, ensuring excellent performance, durability, and consistency. This unified approach minimizes the risk of inconsistent product behavior. -

Advanced Production Techniques:

NEX Pickleball leverages hot pressing, cold pressing, and thermoforming, each offering unique advantages. A quick breakdown of these techniques is shown in the table below:Production Process Advantages Limitations Hot Pressing • High efficiency

• Strong, durable paddles

• Excellent impact resistance• May alter material feel

• Requires high capital investmentCold Pressing • Precise control over thickness

• Maintains material integrity

• Superior ball feel• Longer production cycle

• Demands high-quality equipmentThermoforming • Intricate design possibilities

• Uniform material distribution

• Enhanced stability• Increased production time

• Higher equipment costsThis table highlights how each process offers a specific balance of advantages and challenges. For brands, understanding these differences helps make informed decisions that align with their quality and market positioning goals.

-

Economies of Scale:

Consolidating production allows brands to capitalize on bulk manufacturing. Economies of scale enable lower per-unit costs, increased production speeds, and significant cost savings. With production under one roof, negotiation with other supporting services like logistics and quality control becomes more streamlined and cost-efficient. -

Material Optimization:

When you partner with a company that utilizes premium materials—such as various grades of carbon fiber (3K, 12K, T300), fiberglass, and composite materials—your products benefit from improved performance characteristics. For instance, carbon fiber paddles offer superior strength and vibration reduction, enhancing the playing experience for competitive athletes. -

Strategic Customization Options:

With an exclusive partner, customization can be integrated into the production process. Brands can specify design requirements, weight preferences, grip dimensions, and even print on-demand services to match their branding efforts. This customization ability extends market reach, appealing to both recreational players and competitive athletes. -

Enhanced Supply Chain Visibility:

Working with one advanced manufacturer simplifies supply chain management. This improved visibility means brands can better forecast production schedules, reduce the risk of downtime, and respond rapidly to market changes. It also helps streamline communication, ensuring all aspects of the production process—from raw material sourcing to final inspection—are tightly coordinated.

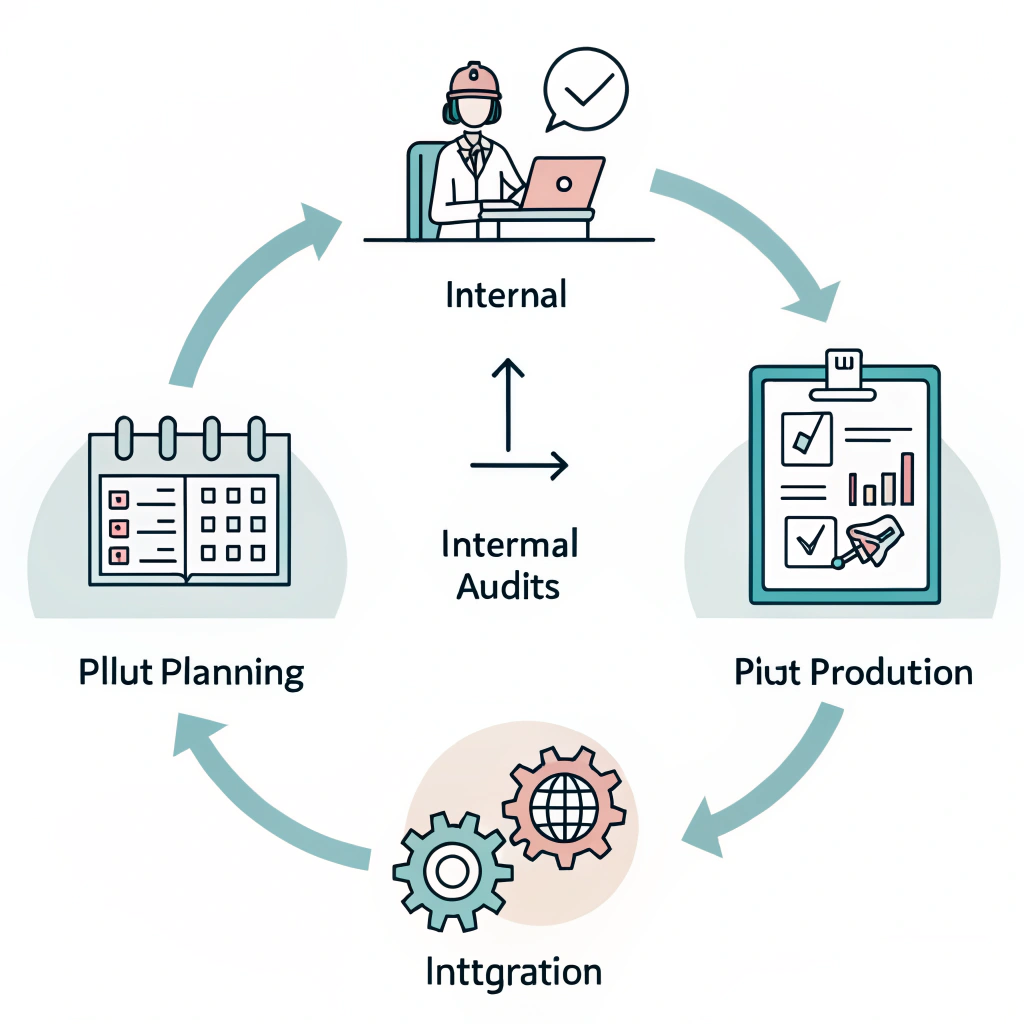

Transitioning to an exclusive manufacturing partner like NEX Pickleball is a strategic process that involves careful planning and communication. Here are the key steps:

-

Internal Audit:

Begin with a detailed internal review of your current production process. Identify the inefficiencies and gaps in quality control posed by using multiple suppliers. An audit will help pinpoint areas where consolidation can have the maximum impact. -

Evaluate Production Techniques:

Understand the strengths and limitations of each production process you currently utilize. Comparing them side by side against advanced methods—hot pressing, cold pressing, and thermoforming—can reveal potential gains in efficiency and quality if modernized. -

Engage in Strategic Discussions:

Initiate discussions with potential manufacturing partners. Prioritize companies with advanced production techniques and a proven track record in quality assurance. Ask for case studies or data to validate their capabilities in offering a unified supply chain solution. -

Develop a Consolidation Plan:

Create a detailed roadmap that outlines timelines, resource allocation, and quality benchmarks. This plan should include measures for risk mitigation, such as quality control checkpoints and clear communication channels between your brand and the manufacturer. -

Integration and Pilot Production:

Start with a pilot production run to validate that the consolidated process meets your quality and efficiency targets. Use feedback from this initial phase to refine the process and address any issues before scaling up. -

Full-Scale Rollout & Continuous Improvement:

Once the pilot phase confirms the benefits, transition to full-scale production. Monitoring key performance indicators (KPIs) and regularly reviewing production data ensure that the manufacturing process continuously meets evolving market demands.

These steps highlight the practicality involved in moving from a fragmented production approach to an exclusive, advanced manufacturing partnership that delivers tangible benefits.

Consider a leading pickleball brand that recently transitioned to an exclusive manufacturing partnership. Prior to consolidation, the brand sourced products from multiple suppliers, leading to varied paddle performance and supply chain challenges. After partnering with an advanced manufacturer, the outcomes were notable:

• Quality Improvement:

The brand observed a significant reduction in product inconsistencies. Unified production processes led to enhanced paddle durability and performance, directly translating into higher customer satisfaction scores.

• Cost Reductions:

With economies of scale and streamlined supply chain management, the production cost per paddle dropped by 20%. This cost saving provided the brand with the flexibility to either lower prices to gain market share or invest in further innovation.

• Faster Time-to-Market:

Leveraging advanced production techniques, the manufacturer reduced the lead time by 30%. This improvement allowed the brand to respond promptly to market trends and maintain a competitive edge.

• Enhanced Customization Capabilities:

The exclusive partnership allowed the brand to offer tailored paddles, combining unique design elements with performance features. This customization not only improved brand loyalty but also attracted niche market segments looking for specialized products.

Such case studies underscore the transformational potential of consolidating production under a single advanced manufacturing partner. The process not only simplifies operations but also empowers brands to scale effectively in a competitive marketplace.

For business decision-makers in the pickleball market, partnering exclusively with an advanced manufacturer such as NEX Pickleball is a strategic move that can significantly impact brand performance. By consolidating production, brands ensure consistent quality, reduce lead times, and capitalize on cost efficiencies—all crucial for scaling operations and enhancing market competitiveness.

To summarize, here are the key action steps for brands considering this strategic transition:

• Conduct an internal review to map production inefficiencies.

• Evaluate advanced production processes like hot pressing, cold pressing, and thermoforming for potential improvements.

• Engage with potential partners that demonstrate strong quality control and the ability to scale.

• Develop a comprehensive integration plan, followed by a pilot production run to validate effectiveness.

• Transition to full-scale production while monitoring quality and performance metrics continuously.

Adopting this streamlined strategy not only forestalls the common pitfalls of fragmented manufacturing but also positions your brand for long-term growth and competitive excellence in the dynamic world of pickleball.

• What is the profit margin on pickleball paddles?

Typical profit margins for pickleball paddles can hover around 50–56%. This calculation is based on a base manufacturing cost (approximately $28.50 per unit), combined with shipping, payment processing, and quality control expenses. When paddles are sold at retail prices between $80 and $130, these margins reflect both efficiency in production and effective cost management.

• What is the markup on pickleball paddles?

Dealers typically purchase pickleball paddles at a discount of 30% to 50% off the retail price. In many cases, major online dealers may even target a full 100% markup. For example, if a dealer buys a paddle for $100, it could then be sold at a retail price of $200, ensuring a healthy profit margin and value for both the dealer and the end customer.

• Can I create my own paddle for pickleball?

While there are options for customizing pickleball paddles, producing a high-quality product usually requires partnering with an experienced manufacturer. Some companies offer customization services for bulk orders, typically starting at around 20 units. For serious players looking for performance, it is advisable to work with specialized manufacturers who can deliver paddles with the precision and quality experienced on the competitive circuit.

-

hot pressing: Click to learn more about the hot pressing process, its benefits in enhancing efficiency and durability in manufacturing, and how it compares with other production techniques. ↩ ↩

-

cold pressing: Click to explore how cold pressing contributes to precise material control and maintains material integrity, offering a different set of advantages in production. ↩ ↩

-

thermoforming: Click to understand the thermoforming process, including its design possibilities and challenges, and why it is a key technique in modern manufacturing. ↩ ↩

-

economies of scale: Click to learn about the concept of economies of scale, its significance in reducing production costs, and how it can impact a company's competitive advantage in the market. ↩ ↩

-

carbon fiber: Click to dive into the world of carbon fiber, its various grades, properties, and how its use in manufacturing can enhance performance and structural strength. ↩ ↩