Quick Answer: Enhancing the paddle’s sweet spot is achievable by optimizing material selection, refining core structures, and fine-tuning production processes such as hot pressing, cold pressing1, and thermoforming2. These technical adjustments deliver better ball control, reduced vibration, and overall improved paddle performance.

In today’s competitive pickleball manufacturing landscape, achieving the optimal sweet spot enhancement in paddle design is not just a matter of aesthetics—it directly affects game performance and player satisfaction. Technical product managers and R&D engineers can leverage advanced material science and production techniques to expand the sweet spot area while ensuring vibration reduction, impact resistance, and ergonomic balance.

This article outlines the problem behind limited sweet spot areas, examines the critical factors influencing paddle performance, and details actionable solutions incorporating advanced materials like carbon fiber, fiberglass, and composite materials3. Our discussion also reviews the pros and cons of different production processes to help you establish technical improvements and innovations in your paddle designs.

The sweet spot of a paddle represents the ideal area where the ball makes optimum contact, generating the best blend of power, control, and reduced vibration. However, many traditional paddle designs encounter challenges in this area due to:

- Inadequate material distribution leading to uneven weight.

- Core materials that either absorb too much vibration or fail to deliver sufficient rebound force.

- Production methods that compromise structural integrity during shaping.

Manufacturers often see a tradeoff between durability and performance. For example, while a thicker core may boost impact resistance, it might also narrow the effective sweet spot. Therefore, balancing these factors becomes crucial.

-

Material Selection:

- Carbon Fiber Variants:

• 3K Carbon Fiber offers strength and flexibility, ensuring durability and rapid rebound.

• 12K Carbon Fiber provides a smoother finish and enhanced impact resistance, ideal for precision play.

• T300 Carbon Fiber4 delivers a balanced performance between strength and weight. - Fiberglass: Offers a wider sweet spot with increased flexibility, optimizing ball control.

- Composite Materials: Utilizing a blend of carbon fiber, fiberglass, or bamboo core designs can achieve the dual goals of power and control.

- Carbon Fiber Variants:

-

Core Integration:

- Nomex Honeycomb Core5: Excellent for longevity and shock absorption.

- Aluminum Honeycomb Core: Balances weight, power, and control.

- Polymer Honeycomb Core: Provides elasticity and significantly reduces vibration.

-

Production Processes:

- Hot Pressing: Ensures structural integrity and strong paddles but may alter material feel.

- Cold Pressing: Delivers precise control over thickness and preserves natural material properties.

- Thermoforming: Allows the creation of complex shapes with accurate material distribution, vital for tailoring the sweet spot.

To enhance the paddle’s sweet spot, it is essential to diagnose the underlying issues in design and production:

A narrow sweet spot is often a result of uneven distribution of structural materials. When materials like carbon fiber and fiberglass are not balanced correctly, the available effective area becomes limited. In extreme cases, excessive rigidity in one zone can reduce overall paddle response.

Each production method has inherent limitations:

- Hot Pressing: While it offers high production efficiency and durability, high temperatures may modify material properties that ultimately reduce the sensitive balance needed for an expanded sweet spot.

- Cold Pressing: This method is ideal for precision but may suffer from lower production speed. Nevertheless, it is critical for maintaining the tactile feel of the paddle which is essential for ball control.

- Thermoforming: Suitable for intricate designs but has longer cycle times and higher equipment costs, which may restrict its use in mass production if not well managed.

Besides material and process issues, the ergonomic design and core structure greatly affect performance. A poorly designed grip or uneven weight distribution can lead to fatigue and mis-hits, thereby reducing effective performance during gameplay.

Improving the sweet spot involves a multi-faceted approach. Below are detailed solutions grounded in both material science and production engineering:

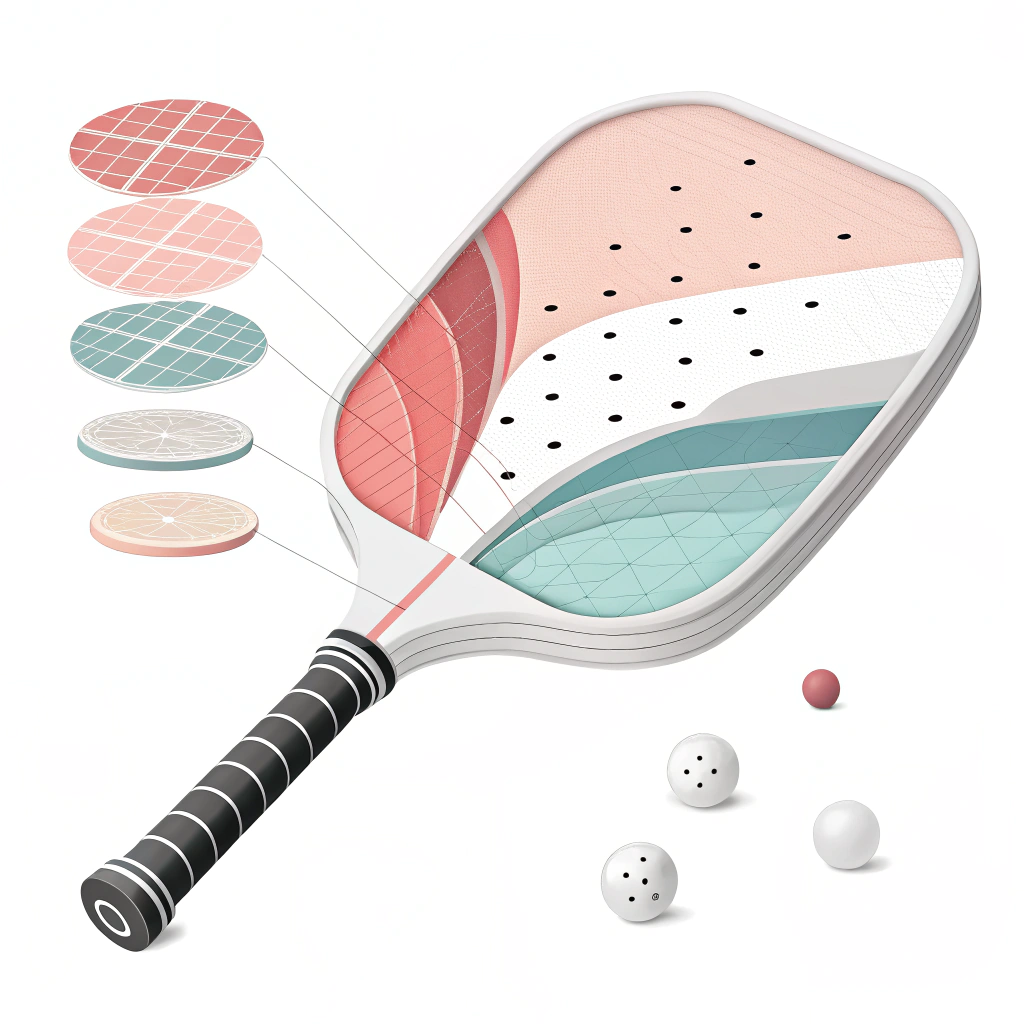

Carbon Fiber and Fiberglass:

Using a strategic combination of 3K, 12K, and T300 Carbon Fiber allows manufacturers to target different performance parameters across the paddle. Carbon fibers provide high stiffness and rebound efficiency, essential for an expansive sweet spot. Meanwhile, incorporating E-Glass Fiberglass can widen the effective contact area by enhancing flexibility and control.

Composite Structures:

By adopting composite materials, such as a hybrid of carbon fiber and fiberglass, manufacturers can achieve the ideal balance between durability and tactile sensitivity. Consider using a bamboo core composite combined with a honeycomb outer layer to yield a paddle that is both lightweight and impact-resistant.

Table 1: Material Attributes and Their Impact on the Sweet Spot

| Material Type | Key Attributes | Sweet Spot Impact |

|---|---|---|

| 3K Carbon Fiber | High strength, flexible | Enhances rebound while maintaining durability |

| 12K Carbon Fiber | Smoother finish, superior hardness | Provides extra impact resistance for precise hits |

| T300 Carbon Fiber | Optimal tensile strength, lightweight | Balances power and responsiveness |

| E-Glass Fiberglass | Elasticity, wider sweet spot | Improves ball control and provides a larger impact area |

| Bamboo Core Composite | Light weight, clear hit sensation | Ideal for consistent and elongated play performance |

The design and composition of the paddle core are pivotal. Tailoring the core material allows for a broader and more effective sweet spot. By deploying advanced honeycomb structures (Nomex, Aluminum, Polymer), manufacturers can offer:

- Precise weight distribution

- Superior vibration reduction

- Improved ball response

For instance, a polymer honeycomb core may be combined with a thin layer of Nomex to create a core that absorbs shocks without losing rebound energy. When integrated with advanced materials, this design ensures that the paddle maintains both power and finesse.

Each production process can be fine-tuned for sweet spot enhancement:

Hot Pressing Benefits:

- Efficient mass production with consistent results.

- High impact resistance if temperature and pressure are carefully controlled.

- Suitable for paddles that require reinforced strength.

Cold Pressing Benefits:

- Preserves natural material properties; precise control over the paddle’s structural dimensions, expanding the sweet spot.

- Ideal for specialized designs where tactile performance is paramount.

Thermoforming Benefits:

- Enables complex shapes that can be molded to maximize the paddle’s effective playing area.

- Allows designers to integrate varying material thickness in targeted zones, ensuring a larger and more resilient sweet spot.

- Best applied for custom products or premium series.

Manufacturers should use quality control tests to determine the optimal process for specific paddle designs. Running pilot production cycles can help balance the tradeoffs between production efficiency and sweet spot performance.

Table 2: Production Processes Comparison

| Production Process | Advantages | Limitations | Sweet Spot Implications |

|---|---|---|---|

| Hot Pressing | High consistency; quick cycle times | Potential material alteration | Ideal for high-impact regions but may slightly reduce tactile sensitivity |

| Cold Pressing | Preserves material properties; precise control | Longer production cycles | Enhances tactile response and ball control, expanding the effective sweet spot |

| Thermoforming | Flexible design; complex shapes possible | High cost; longer cycle time | Allows precise material distribution, optimizing the sweet spot for premium products |

Ergonomics play a critical role in how the sweet spot translates to player performance. Adjustments in grip size, weight distribution, and handle design ensure that the paddle remains comfortable during extended play. By incorporating ergonomic adjustments:

- Fatigue is reduced.

- Player control is enhanced.

- Stress on the sweet spot is minimized during repetitive impacts.

Manufacturers should conduct extensive playtesting and ergonomic evaluations to ensure that adjustments made for a larger sweet spot do not inadvertently disturb the overall balance of the paddle.

Once theoretical strategies are in place, implementation should follow a rigorous testing cycle:

-

Prototype Development:

Develop prototypes using different combinations of materials and production methods. Record performance data focusing on rebound speed, vibration reduction, and energy transfer during play. -

Performance Testing:

Utilize both laboratory equipment and real-world gameplay simulations. Data on ball control, impact resistance, and sweet spot size should be documented and analyzed. -

Iterative Optimization:

Use the collected data to refine design parameters. This could include minor adjustments in production pressure during thermoforming, slight variations in the carbon fiber layering, or modifications in core thickness. -

Quality Assurance:

Ensure that every paddle meets strict quality standards and maintains an ergonomic design. Rigorous quality checks guarantee that each paddle delivers consistent performance across batches.

Industry best practices suggest involving both technical experts and experienced players in the testing phase to obtain a comprehensive evaluation from engineering and practical perspectives. Such collaboration can uncover subtle performance differences and confirm that strategic changes deliver enhanced competitive performance.

Enhancing the paddle’s sweet spot requires an integrated approach:

- Selecting the right materials: Use a mix of carbon fiber variants and fiberglass to balance durability and control.

- Optimizing core designs: Tailor honeycomb structures to manage weight distribution and reduce vibration, critical for performance.

- Refining production processes: Implement hot pressing, cold pressing, or thermoforming based on your production needs. Each process presents its own trade-offs affecting the tactile and impact properties of the paddle.

- Emphasizing ergonomic design: Ensure adjustments to the paddle do not compromise player comfort, leading to a more reliable performance during extended matches.

Actionable Recommendations:

• Run controlled pilot tests to determine the optimal material mix and production process.

• Collaborate with design and testing teams to incorporate ergonomic adjustments that bolster the sweet spot.

• Systematically iterate on prototypes by integrating insights from both lab testing and field performance data.

By carefully addressing these points, manufacturers can achieve a marked improvement in the paddle’s sweet spot, ultimately delivering products that provide enhanced control, power, and overall game performance.

Q1: How do pickleball paddles achieve an optimal sweet spot?

A1: Pickleball paddles achieve an optimal sweet spot through a balanced combination of advanced materials such as carbon fiber and fiberglass, precise core designs, and tailored production processes like cold pressing and thermoforming. This balance enhances ball control and reduces vibration for improved play.

Q2: What materials are best for enhancing the sweet spot in paddle design?

A2: The best materials include various types of carbon fiber (3K, 12K, T300) for strength and rebound efficiency, paired with fiberglass for flexibility. Composite materials that integrate bamboo or honeycomb cores also help in expanding the effective sweet spot area.

Q3: Which production process offers the best performance for sweet spot optimization?

A3: There is no one-size-fits-all answer—each process has its trade-offs. Cold pressing is excellent for preserving material properties and enhancing ball feel, while thermoforming allows intricate designs that optimize material distribution. The ideal choice depends on specific performance requirements and production scale.

-

cold pressing: Click to read an article about the cold pressing process, explaining how it preserves material properties while achieving precise control over product dimensions. ↩ ↩

-

thermoforming: Click to learn more about thermoforming, a process that enables the creation of complex shapes with accurate material distribution for tailored product performance. ↩ ↩

-

composite materials: Click to explore composite materials, detailing how combining different fibers can balance durability and sensitivity in advanced manufacturing. ↩ ↩

-

T300 Carbon Fiber: Click for an in-depth look at T300 Carbon Fiber, a high-performance material variant offering an optimal balance between strength and weight in engineering applications. ↩ ↩

-

Nomex Honeycomb Core: Click to read about Nomex Honeycomb Core, a specialized core structure that improves shock absorption and longevity in high-performance products. ↩ ↩