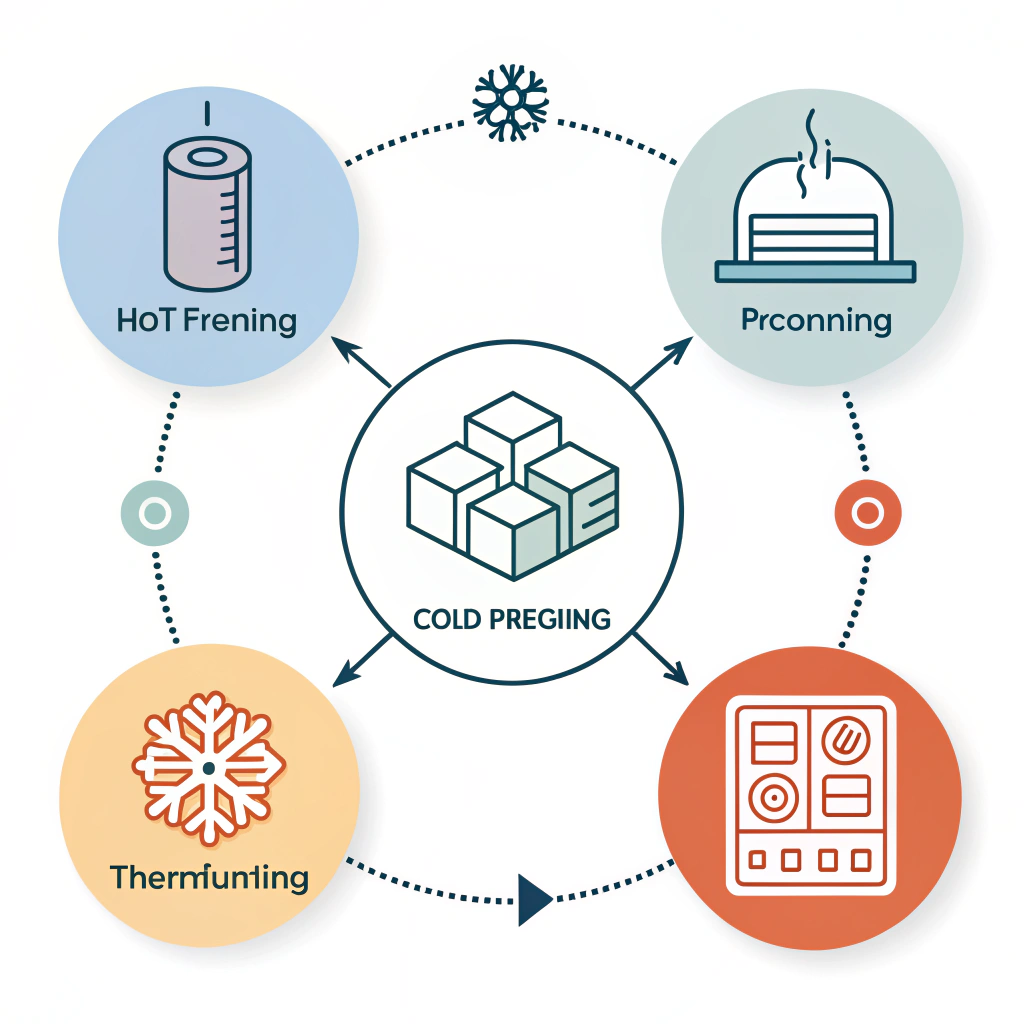

High-performance pickleball paddles combine premium materials, advanced production processes, and precise design to enhance player performance and drive success in competitive sports. In summary, the ideal paddle uses carbon fiber1, fiberglass2, or innovative composite materials3, and is manufactured using techniques like hot pressing, cold pressing, or thermoforming4 to ensure superior durability, control, and power. This guide explains the issues behind paddle performance challenges and outlines solutions to help you make data-backed procurement decisions.

For sports equipment distributors and club procurement specialists, selecting a high-performance pickleball paddle comes with challenges such as:

- Inconsistent paddle performance due to variations in materials.

- Quality differences arising from diverse manufacturing methods.

- Complex technical specifications that may confuse decision-makers.

Many buyers face confusion when balancing cost with performance. For instance, achieving the right blend of power, control, and durability can be difficult when manufacturers use different carbon fiber types or core materials. Without standardized quality measures, comparing options becomes challenging.

The performance and quality variations in pickleball paddles typically stem from two main areas:

-

Material Variability

- The choice between 3K, 12K, or T300 carbon fiber can lead to differences in strength, flexibility, and overall paddle rebound.

- Fiberglass paddles, such as those using E-Glass, offer a balance but may not provide the same rigidity as carbon fiber.

- Composite materials (e.g., carbon fiber and fiberglass composites or bamboo core composites) can blend benefits but require precise formulation and testing to ensure consistency.

-

Manufacturing Processes

- Hot Pressing: Produces strong, impact-resistant paddles, but may affect material feel.

- Cold Pressing: Provides precise control and better ball feel, though production cycles are slower.

- Thermoforming4: Enables intricate designs and precise material distribution at the expense of longer production times.

The root cause of many performance issues lies in the interplay between material properties and the manufacturing process. When either is not optimized or balanced correctly, players may experience shorter paddle lifespans, inconsistent hitting performance, or uncomfortable play experiences.

To address these challenges, NEX Pickleball has integrated advanced production techniques with high-quality materials, ensuring that each paddle meets the rigorous standards required by competitive players worldwide.

-

Material Excellence

NEX Pickleball utilizes premium materials such as 3K, 12K, and T300 carbon fibers, each chosen for specific performance attributes:- 3K Carbon Fiber: Offers a blend of strength and flexibility, enhancing rebound force.

- 12K Carbon Fiber: Provides a smoother surface with higher durability, perfect for competitive scenarios.

- T300 Carbon Fiber: Balances light weight with superior tensile strength.

Additionally, the use of E-Glass Fiberglass ensures excellent elasticity and ball control. The combination of carbon fiber and fiberglass in composite materials captures the best of both worlds, delivering a well-rounded paddle that meets diverse player needs.

-

Advanced Manufacturing Processes

By employing three key production methods, NEX Pickleball can tailor paddle performance to specific market needs:-

Hot Pressing:

Produces paddles with exceptional strength and impact resistance. This method is ideal for large-scale manufacturing where durability and cost-effectiveness are paramount. -

Cold Pressing:

Focuses on precision, ensuring that each paddle has optimal thickness and reinforces the ball feel. This leads to greater control and responsiveness essential for tactical gameplay. -

Thermoforming4:

Allows the creation of intricate designs with precise material layout, ensuring consistent balance and performance across different paddle models.

-

-

Rigorous Quality Control and Testing

NEX Pickleball’s commitment to quality means every paddle undergoes extensive testing to ensure resilience, optimal weight distribution, and ergonomic grip design. By continually refining production processes, the company guarantees stable performance, extended durability, and a superior playing experience.

To aid procurement decision-making, here is a comparative overview of the key materials and manufacturing processes used in high-performance pickleball paddles:

| Material Type | Key Benefits | Ideal For |

|---|---|---|

| 3K Carbon Fiber | Strong, flexible, high rebound force | Recreational and competitive play |

| 12K Carbon Fiber | Smoother surface, high durability, impact resistance | Competitive players |

| T300 Carbon Fiber | Balanced strength and light weight | Players seeking overall performance |

| E-Glass Fiberglass | Excellent elasticity and precise ball control | Improved ball feel and control |

| Composite Materials | Blend of strength, lightness, and flexibility | Versatile applications |

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, sturdy structure | May alter material feel, high equipment investment |

| Cold Pressing | Precise control, maintains material properties, enhanced ball feel | Lower production speed, requires precision equipment |

| Thermoforming | Intricate design, even material distribution, optimal stability | Longer production cycle, higher cost for custom makes |

This table enables decision-makers to quickly compare the options and select the manufacturing process that best aligns with their market strategy and performance expectations.

For retailers and distributors, understanding the performance metrics tied to each material and production process is vital. When choosing a paddle line to promote or purchase, consider:

-

Player Profile:

Assess whether your target audience is composed of competitive athletes seeking peak power and control, or recreational players who may prefer enhanced comfort and durability. -

Usage Frequency:

High-performance paddles for professional play require materials that can withstand frequent, intense use. In cases of heavy usage, the durability imparted by Nomex honeycomb5 or polymer cores becomes critical. -

Cost vs. Performance:

While high-end carbon fiber paddles might come at a premium, the superior performance and longer lifespan can justify the higher initial investment, particularly in settings where players perform at their best.

NEX Pickleball is more than just a manufacturer—it’s a technology partner committed to driving success. Their tailored production solutions mean you can choose various configurations such as different core materials and grip sizes to serve a diverse clientele. The possibility of on-demand printing for custom designs further amplifies the appeal for club branding or team-specific promotions.

Furthermore, NEX Pickleball’s strong quality management system minimizes inconsistencies, ensuring that every batch delivers the same high standard. In an industry where performance variations can lead to customer dissatisfaction, this consistency is a major competitive advantage.

Adopting paddles from a manufacturer that understands both the technical and user-centric dimensions of paddle design translates directly to performance benefits on the court. Key improvements include:

-

Enhanced Ball Control:

Paddles with optimal weight distribution and precise surface treatments offer increased spin and accuracy, granting competitive players a strategic edge. -

Improved Durability:

By using robust materials and production processes, players enjoy an extended product lifecycle with less need for frequent replacements. This is particularly beneficial in a market where paddle reliability directly affects player reputation and team performance. -

Customization for Specific Needs:

The flexibility in adjusting core materials, grip sizes, and surface textures allows clubs and retailers to target niche markets effectively. Whether your clientele consists of beginners needing forgiving paddles or pros requiring razor-sharp performance, the options are both varied and robust.

Surveys and field test reports reveal that paddles made using a combination of T300 carbon fiber with a Nomex honeycomb core show a measurable improvement in impact resistance and reduced vibration during play. Retail feedback indicates that customers are willing to invest more in paddles that consistently deliver these benefits, thereby driving higher sales margins for distributors.

Additionally, leveraging advanced processes like thermoforming ensures that artists produce paddles with ergonomic grips and streamlined designs, meeting the evolving expectations of both professional and amateur players. These operational enhancements have been integral in positioning NEX Pickleball as a trusted partner in the competitive sports equipment market.

To ensure you offer and stock the best high-performance pickleball equipment in your portfolio, consider these steps:

- Evaluate your customer base’s requirements by collecting feedback on current paddle performance.

- Compare the technical specifications of different materials and production processes using the provided tables.

- Schedule a trial shipment with NEX Pickleball to assess on-court performance and durability.

- Consider the benefits of custom paddle options for team branding or exclusive distributor promotions.

- Monitor industry trends to adapt purchasing decisions as technology and player preferences evolve.

Taking these steps can help maximize your ROI while ensuring that you contribute to an enhanced player experience, ultimately boosting sales through superior product performance.

In the competitive world of pickleball, a high-performance paddle is indispensable for both player success and market differentiation. By understanding the intricacies of material properties and production processes, distributors and club procurement specialists can make informed decisions. NEX Pickleball’s expertise in advanced manufacturing—encompassing hot pressing, cold pressing, and thermoforming—coupled with the use of premium materials like carbon fiber and fiberglass, ensures each paddle delivers unmatched performance, durability, and precision.

Deciding to partner with a high-caliber manufacturer like NEX Pickleball means you enable your customers to achieve superior game performance while benefiting from the reliability and innovation that comes with every product. As the market evolves and performance demands increase, aligning with a partner that prioritizes quality and technical excellence will be key to staying ahead of the competition.

Q1: What are the key materials used in high-performance pickleball paddles?

A1: High-performance pickleball paddles typically use premium materials such as various types of carbon fiber (including 3K, 12K, and T300), fiberglass, and innovative composite materials that combine the strengths of different components. These materials are selected for their ability to provide balance, strength, and durability while delivering enhanced power and precision.

Q2: How do different manufacturing processes impact paddle performance?

A2: Manufacturing processes like hot pressing, cold pressing, and thermoforming directly influence a paddle’s structural integrity, feel, and durability. Hot pressing creates a strong, impact-resistant paddle, cold pressing ensures greater precision and ball control without altering material properties, and thermoforming allows for intricate designs with consistent material distribution—each method tailored for specific performance outcomes.

Q3: What factors should B2B buyers consider when selecting pickleball paddles for their market?

A3: Buyers should evaluate material types, production processes, player preferences, durability, and overall cost-versus-performance ratios. Customization options, such as varying core materials and ergonomic grip designs, also play a significant role in ensuring that the paddle meets the needs of both competitive and recreational players.

-

Carbon fiber: Click to explore in-depth insights on the properties, manufacturing techniques, and performance benefits of carbon fiber in high-demand sports equipment production. ^Return ↩

-

Fiberglass: Click to learn about the role of fiberglass in ensuring durability, elasticity, and precise ball control in competitive sports gear. ^Return ↩

-

Composite materials: Click to discover how composite materials combine multiple components to deliver balanced strength and lightweight performance in advanced equipment manufacturing. ^Return ↩

-

Thermoforming: Click to read about the thermoforming process, a critical manufacturing technique for creating intricate geometries and even material distribution in high-performance products. ^Return ↩ ↩2 ↩3

-

Nomex honeycomb: Click to delve into the benefits of Nomex honeycomb cores, including enhanced durability and impact resistance, which are pivotal for maintaining long-term product performance in heavy-use settings. ^Return ↩