A quick answer: Choosing the right pickleball paddle thickness involves balancing control, power, and manufacturing precision. Thicker paddles (16mm or more) generally offer enhanced power and a larger sweet spot, while thinner paddles (around 13mm) provide greater control and maneuverability. The selection should align with your product line's target performance specifications and manufacturing process capabilities.

In today’s competitive sports equipment market, product managers and procurement specialists must pay close attention to the intricate balance between paddle thickness, material composition, and production technology. This decision not only affects the paddle’s performance on the court but also influences manufacturing efficiency and product durability. In this article, we will compare key aspects of paddle thickness choice by reviewing the major production techniques—Hot Pressing1, Cold Pressing2, and Thermoforming3—as well as material and core selections. Our aim is to empower you to make data-backed decisions when developing your pickleball product line.

Paddle thickness plays a vital role in defining the playing characteristics of a pickleball paddle. The thickness of a paddle is one of the most critical design parameters because it affects several performance aspects:

• Sweet Spot Size: Thicker paddles tend to have a larger sweet spot, which can generate more power.

• Control and Maneuverability: Thinner paddles typically offer better control thanks to their lower weight and precision in handling.

• Vibration Reduction: Core materials and thickness work in tandem to minimize vibrations during play, impacting both comfort and durability.

• Impact Resistance: A thicker core usually provides enhanced impact resistance, making the paddle more durable under intense play conditions.

For product lines targeting varied market segments—from recreational players needing precision to competitive players demanding aggressive power—the choice of thickness is paramount.

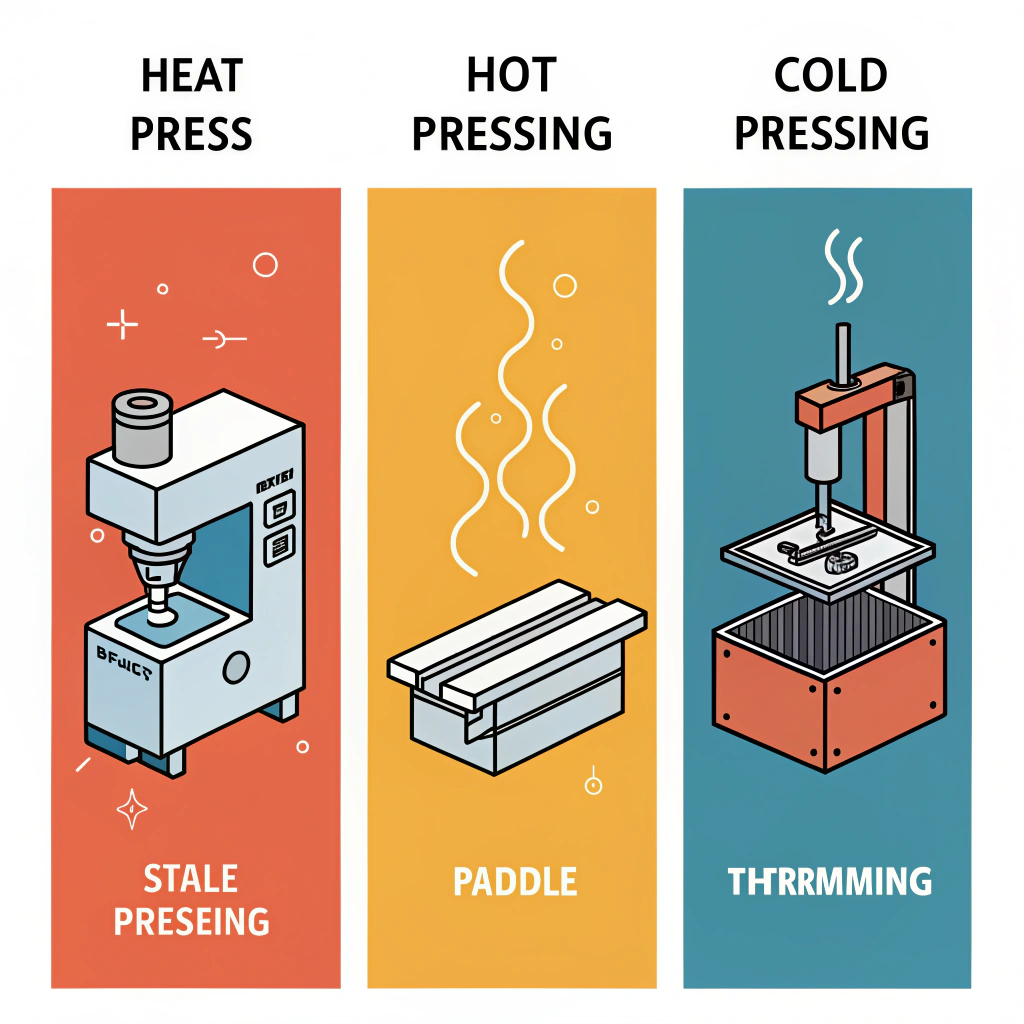

Different production processes interact with paddle thickness in unique ways. Here we compare the three primary techniques used in manufacturing pickleball paddles:

-

- Involves applying heat and pressure to mold the paddle materials.

- Advantages:

• High production efficiency for mass manufacturing.

• Results in robust paddles with excellent impact resistance.

• Ensures strong bonding of composite layers. - Disadvantages:

• Potential alteration of material properties, affecting the paddle’s feel.

• Requires significant capital investment in high-temperature equipment.

-

- Uses room temperature pressure to shape the paddle without applying heat.

- Advantages:

• Greater control over surface thickness and structural precision.

• Preserves intrinsic material properties, offering better control and feedback. - Disadvantages:

• Longer production cycles, reducing output speed.

• Demands high-precision equipment to achieve the needed consistency.

-

- Uses heat to soften the material before molding it into shape.

- Advantages:

• Allows creation of complex paddle designs with customized thickness profiles.

• Maintains even material distribution, ideal for high-performance paddles. - Disadvantages:

• Increased cycle times and higher equipment costs may limit its use for cost-sensitive lines.

These processes interact with the raw materials used in the paddle—for example, carbon fiber, fiberglass, or hybrid composites—to achieve different thickness and performance outcomes. The decision to use a particular process depends on the desired balance between performance (control versus power) and production considerations.

When selecting the ideal paddle thickness, it is crucial to evaluate how different materials and manufacturing processes complement each other. Below is a table that outlines the pros and cons of various thickness ranges alongside key material and process considerations:

| Thickness Range | Typical Characteristics | Materials & Core Options | Manufacturing Considerations | Recommended For |

|---|---|---|---|---|

| 13mm (Thin) | Enhanced control, lightweight | Polymer Honeycomb Core, Fiberglass | Best with cold pressing for precision control | Players seeking quick maneuverability and precision control |

| 16mm (Standard) | Balanced power and control | Nomex Honeycomb4, Composite (Carbon & Fiberglass) | Suitable for thermoforming for a stable, uniform feel | Players needing a blend of increased power and controlled play |

| Above 16mm (Thick) | Larger sweet spot, more power | Aluminum Honeycomb, Bamboo Core; sometimes thicker composite builds | Hot pressing often utilized for durability and mass production | Competitive players looking for aggressive shots with added impact resistance |

This detailed comparison table shows that the correct paddle thickness is not a one-size-fits-all decision. Instead, it must be mapped to particular player preferences, competitive standards, and manufacturing capabilities.

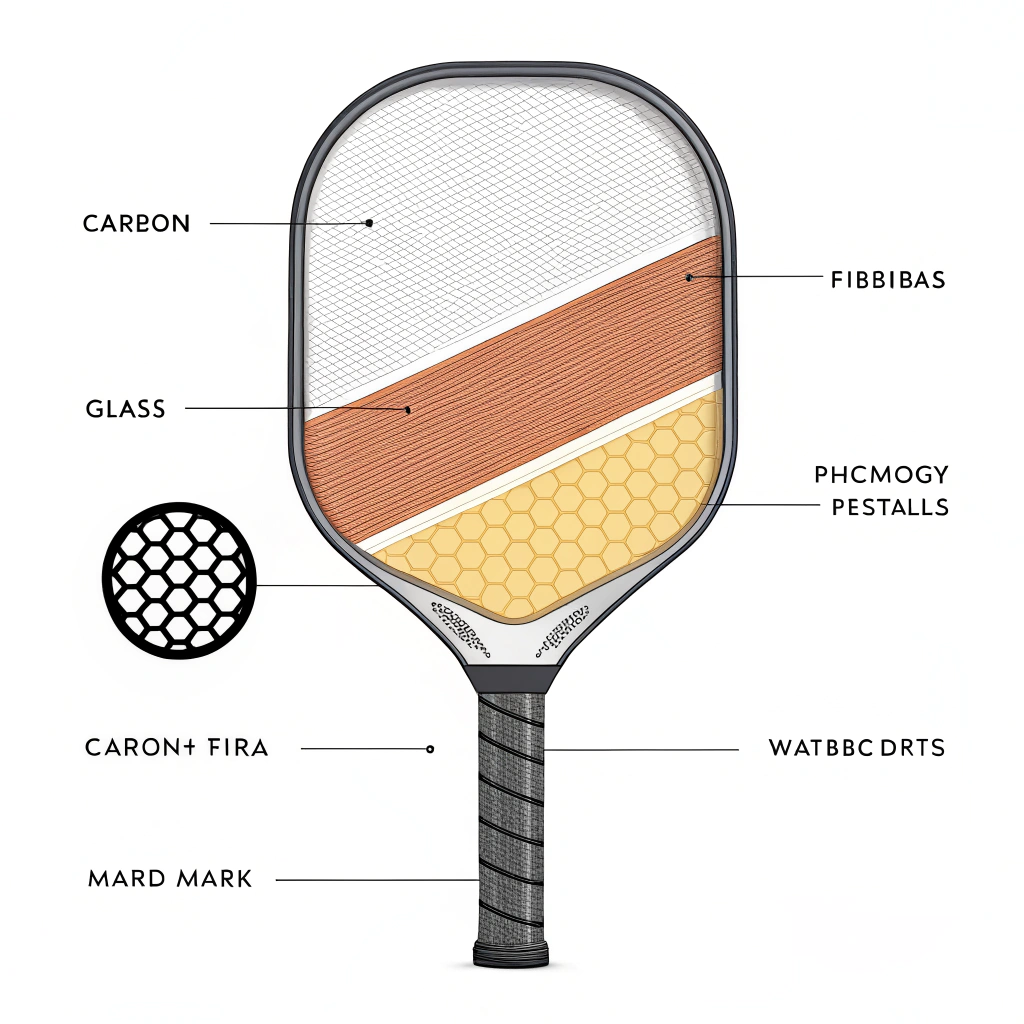

In addition to selecting the optimal thickness, it's essential to understand the role of materials in paddle performance:

• Carbon Fiber Variants:

- 3K Carbon Fiber: Offers a balance of strength and flexibility; ideal for managing vibration while increasing rebound force.

- 12K Carbon Fiber: Provides a smoother surface with increased hardness, making it favorable for extreme impact resistance.

- T300 Carbon Fiber: Known for its tensile strength and lightweight properties, ideal for achieving a well-balanced paddle.

• Fiberglass Options:

- E-Glass Fiberglass: Known for its elastic properties and tensile strength, delivering a well-rounded control and feel.

- Combining carbon fiber with fiberglass or using bamboo core composites can optimize both control and power, ensuring that the design meets specific performance benchmarks.

The core of a paddle further defines its gameplay characteristics. For example:

- Nomex Honeycomb Core: Provides excellent shock absorption combined with long-lasting durability.

- Aluminum Honeycomb Core: Balances power and precision with consistent weight distribution.

- Polymer Honeycomb Core: Offers elasticity and reduced vibration, providing a comfortable hitting experience for recreational players.

Integrating these advanced materials into your product line involves a careful call on production technique. For instance, while thermoforming can support the creation of intricate composite layers, cold pressing may be preferable for designs that need precise control over thickness.

When planning your next pickleball paddle product line, consider the following points:

-

Target Market and Player Type:

- Understand if your intended consumer is competitive or recreational. Competitive players often favor thicker paddles that offer enhanced power while recreational players look for greater control.

-

Manufacturing Process Alignment:

- Evaluate whether your production capabilities align better with hot pressing, cold pressing, or thermoforming based on the scale and precision your product line requires.

-

Material Selection and Core Composition:

- Choose materials that complement your desired thickness specification. For example, if you plan on introducing a 16mm paddle, opt for composite materials that offer a suitable balance between power and control, like combining carbon fiber with fiberglass.

-

Performance Trade-offs:

- Thicker paddles typically give more power due to a larger sweet spot; however, they might sacrifice some maneuverability. Conversely, thinner paddles offer precision and swift handling but may not generate the same impact force.

-

Quality Control and Testing:

- Ensure that each production batch undergoes rigorous testing to verify that the chosen material and thickness combination meets your performance and durability standards.

-

Customization Options:

- Consider offering custom paddle options. By allowing adjustments in thickness and material combinations, you can better cater to diverse customer needs, providing both a standard product line and personalized options for teams or retail brands.

By balancing these factors, you can optimize your product design to achieve a competitive edge in the market. The decision on paddle thickness should not be made in isolation; rather, it must integrate with broader product strategy, production technology, and market positioning.

To sum up, choosing the right pickleball paddle thickness is a multi-faceted decision depending on various technical and market-related factors:

• Begin with a clear categorization of your target market—knowing if your focus is on power-focused competitive play or precision-driven recreational use will guide thickness choices.

• Align your production process (hot pressing, cold pressing, or thermoforming) with the desired performance outcomes and material properties.

• Use detailed comparative analysis and testing to ensure that your chosen thickness and material combinations deliver the required balance of performance, durability, and cost-effectiveness.

• Consider offering customization options for your clients to address different playing styles and competitive needs, setting your product line apart with tailored manufacturing solutions.

By addressing these key points, procurement specialists and product managers can develop a robust and competitive pickleball paddle line that meets modern market demands.

-

Do I want a 13mm or 16mm pickleball paddle?

A 16mm paddle generally delivers a balanced performance with enhanced power and control. While 13mm paddles are lighter and provide better maneuverability, modern production processes like thermoforming have enabled 16mm paddles to achieve a plush feel and greater dwell time, making them a popular choice. -

Is 19mm too thick for a pickleball paddle?

While 16mm is the standard for a thick core paddle, some paddles go over 16mm. Thicker paddles, such as 19mm models, are less common and generally used when the goal is to achieve a higher degree of control for blocks, resets, and drop shots—though they might sacrifice some raw power. -

Is it better to have a thicker pickleball paddle?

Thicker paddles tend to provide more power owing to a larger sweet spot and increased weight, which benefits players who favor aggressive shots. However, thinner paddles typically offer better control and maneuverability, making the choice dependent on the player's style and requirements.

-

Hot Pressing: Click to learn more about this high-temperature molding technique that applies both heat and pressure for efficient mass production and robust bonding of paddle materials. ↩ ↩ ↩2

-

Cold Pressing: Click to discover how this room-temperature process enhances surface precision and preserves material properties for superior paddle control. ↩ ↩ ↩2

-

Thermoforming: Click to explore how heat-softening techniques allow the creation of complex paddle designs with customized thickness profiles and even material distribution. ↩ ↩ ↩2

-

Nomex Honeycomb: Click to find out more about this core material renowned for its excellent shock absorption and lightweight durability in paddle construction. ↩ ↩

-

Composite Materials: Click to delve into the benefits of combining materials like carbon fiber and fiberglass, which optimize paddle performance by balancing strength, flexibility, and responsiveness. ↩ ↩