The fastest way to select the optimal pickleball paddle is by comparing the differences in production methods and material performance. In this article, we explore the key aspects of paddle manufacturing—ranging from carbon fiber1 and fiberglass2 compositions to hot pressing, cold pressing3, and thermoforming4 processes—providing essential information for informed, bulk purchasing decisions.

Understanding the materials used in paddle manufacturing is fundamental for any procurement manager. Each material type brings unique performance benefits that impact power, control, durability, and ergonomics.

Carbon fiber1 has become a benchmark material in high-performance pickleball paddles due to its strength and lightweight properties. Manufacturers often choose from different types based on the desired paddle characteristics:

- 3K Carbon Fiber: Known for its strength and flexibility, this material enhances rebound force and reduces vibration. It's ideal for players looking for durability combined with excellent feedback.

- 12K Carbon Fiber: With a denser thread structure, 12K provides a smoother paddle surface with increased hardness and impact resistance. This makes it especially suited for high-competition environments.

- T300 Carbon Fiber: T300 offers a balanced profile with exceptional tensile strength, giving paddles a combination of power and light weight.

Fiberglass2 paddles are especially valued for their enhanced ball control and flexibility. They deliver a wider sweet spot, crucial for recreational and intermediate players who rely on precise ball handling. Using E-Glass Fiberglass ensures elasticity without compromising on tensile strength.

Furthermore, composite materials5 blend the advantages of carbon fiber and fiberglass. For example:

- Carbon Fiber and Fiberglass Composite: Delivers a harmonious balance between power and control, making it perfect for markets straddling competitive play and casual games.

- Bamboo Core Composite: Offers a lightweight solution with a clear, responsive hitting feel.

- Honeycomb Core: Often made from high-density polymer, it absorbs shocks effectively, reducing overall paddle vibration.

These material variations allow for tailoring paddle performance to cater to various user profiles—from beginners who need a forgiving touch to professionals requiring precise, high-impact responses.

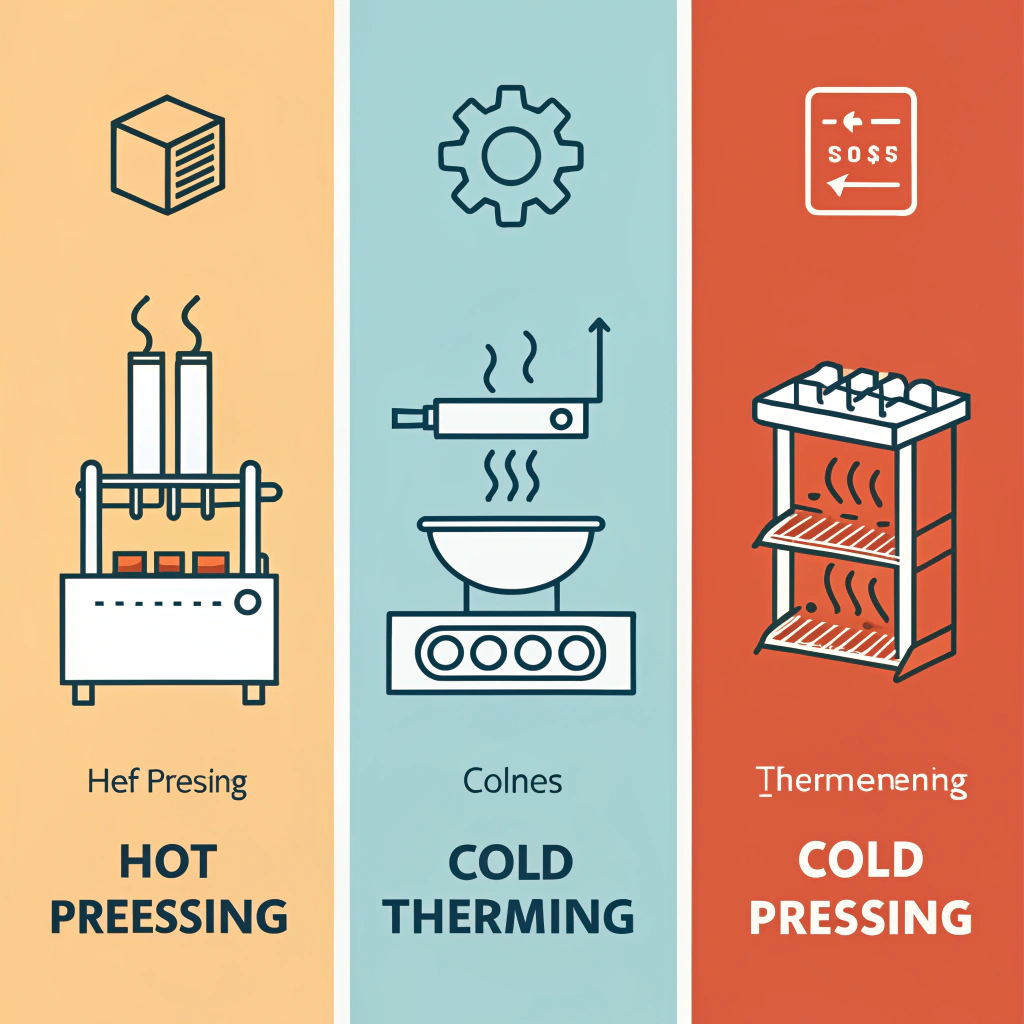

Different production methods translate into significant differences in paddle performance. Here, we compare the three main manufacturing processes used at facilities like NEX Pickleball: Hot Pressing, Cold Pressing, and Thermoforming.

Hot pressing uses heat and pressure to mold the paddle components into a solid structure.

- Advantages:

• High production efficiency.

• Produces strong, durable paddles with excellent impact resistance.

• Ensures structural integrity which is crucial for high-performance uses. - Disadvantages:

• The exposure to high temperatures can sometimes alter material properties, impacting the natural feel of the paddle.

• Requires significant initial investment in equipment.

Alternatively, cold pressing3 shapes materials at room temperature under mechanical pressure.

- Advantages:

• Maintains the natural properties of the materials, ensuring superior control and flexibility.

• Allows precise control over thickness and structure. - Disadvantages:

• Slower production cycles compared to hot pressing.

• Demands high-precision machinery and consistent quality checks to prevent deviations.

Thermoforming4 involves heating materials to soften them before molding them into desired shapes.

- Advantages:

• Ideal for achieving intricate, complex designs.

• Provides consistent material distribution, reinforcing paddle stability and performance. - Disadvantages:

• Longer production time and higher equipment costs are inevitable.

• Best suited for custom-made or premium product lines.

The following table summarizes the key differences:

| Production Process | Advantages | Disadvantages | Ideal For |

|---|---|---|---|

| Hot Pressing | High efficiency; strong structural integrity; high impact resistance | May alter material properties; high investment cost | High production volume, durable paddles |

| Cold Pressing | Precise control over design; preserves material properties | Slower production cycle; requires quality machinery | Custom designs, paddles emphasizing control and feel |

| Thermoforming | Intricate designs; consistent material distribution | Longer production time; higher costs | Premium paddles, custom orders |

Each method’s trade-offs impact pane performance characteristics and overall market positioning, helping businesses decide which technology aligns best with their customer demands.

For procurement managers, selecting paddles for sports clubs and retail chains involves not only understanding material and process parameters but also matching them to specific market segments.

- Paddle types for beginners:

Paddles designed for beginners should focus on comfort and control over an enormous sweet spot. Materials like fiberglass2 or softer composites with polymer honeycomb cores may provide the right balance between absorbing shock and delivering a consistent ball feel. - Paddles for competitive play:

For advanced users, durability and precision are key. Products made with 12K or T300 carbon fiber using hot pressing or thermoforming provide that extra performance edge when it comes to strength, responsiveness, and reduced vibration during play.

A comparative checklist can aid in specifying requirements:

| User Level | Material Preference | Core Material | Production Process | Key Performance Attributes |

|---|---|---|---|---|

| Beginner/Intermediate | Fiberglass, Carbon Fiber & Fiberglass Composite | Polymer Honeycomb | Cold Pressing | Optimal ball control; Elasticity; Comfortable feel |

| Competitive/Professional | 12K/T300 Carbon Fiber, 3K Carbon Fiber | Nomex/Aluminum Honeycomb | Hot Pressing or Thermoforming | High impact resistance; Enhanced power; Precision handling |

This systematic approach enables companies to exactly match paddle qualities with end-user expectations, significantly reducing market risk and enhancing product satisfaction.

Offering custom paddle design can provide additional value. By allowing specification of design details—such as grip size, weight, balance, and special surface treatments—manufacturers can address niche market requirements. Whether these paddles are for branding by sports clubs or tailored equipment for individual professionals, the ability to adjust materials and production processes often is the deciding factor for bulk buyers.

Quality control is a cornerstone of reliable production. At manufacturers like NEX Pickleball, each paddle undergoes rigorous testing protocols which include:

- Structural Testing: Examining the durability and impact resistance of each paddle.

- Ergonomic Assessments: Ensuring that grip designs and weight distributions meet precise standards for comfort and control.

- Material Integrity Checks: Verifying that the unique properties of each material, be it high-performance carbon fibers or resilient fiberglass, are maintained throughout the production process.

Additionally, ergonomics plays a critical role in product performance. Adequate grip design and appropriate weight distribution not only enhance playability but also reduce the risk of fatigue during prolonged athletic activities. Custom paddle options can be tailored further to ensure that they cater gracefully to various hand sizes and playing styles.

By combining these rigorous quality checks with advanced production processes, manufacturers create paddles that offer a blend of durability, precision, and comfort—key qualities that procurement managers seek for markets with diverse performance needs.

In summary, selecting the right pickleball paddle involves a deep dive into the interplay between materials, production processes, and final performance attributes. For a sports equipment procurement manager or retail chain buyer, the key points to consider include:

• The choice of material—whether carbon fiber, fiberglass, or composite—determines the inherent power, control, and durability of a paddle.

• Production methods such as hot pressing, cold pressing, and thermoforming each offer unique advantages and potential trade-offs; your decision should reflect the selected material’s optimal performance.

• Customization capabilities can provide a competitive edge, ensuring that each paddle is tailored to the precise needs of its intended market.

• Comprehensive quality control paired with ergonomic design is essential for ensuring that every paddle meets the high performance standards demanded by today’s market.

For procurement managers evaluating bulk purchases, it is crucial to balance performance specifications with practical considerations such as production scalability and cost efficiency. Whether your channel caters to beginner clubs or professional sports teams, understanding these manufacturing nuances will empower you to make decisions that enhance customer satisfaction and entry into high-demand competitive markets.

By focusing on detailed material analysis and comparing manufacturing processes, businesses can confidently select products that offer the best value proposition and meet end-user expectations. The integration of rigorous quality control and bespoke customization leads to products that not only improve player performance but also strengthen your product portfolio.

To move forward, consider scheduling a consultation with your manufacturing partner to review current production capabilities, customization options, and quality control measures. This collaborative approach will ensure your selected paddles are in line with evolving market needs, positioning your product offerings as leaders in performance and value.

• How do I find the right pickleball paddle for me?

Finding the right paddle involves matching weight, grip comfort, and balance to the player’s skill level. Beginner options favor light-to-medium weight and a larger sweet spot for power and control, while advanced paddles are often made with high-performance materials and tighter sweet spots.

• Do more expensive pickleball paddles make a difference?

Higher-end paddles often incorporate advanced materials such as carbon fiber and fiberglass, which can enhance control, power, and spin. However, a higher price does not guarantee better performance for all players, as individual needs and play styles vary.

• What is the most recommended pickleball paddle?

The recommendation depends on user requirements and performance characteristics. Leading models vary from professional-grade paddles designed for precision and strength to more forgiving models ideal for beginners. Evaluating paddle materials, core composition, and manufacturing techniques can help determine the best fit for your market needs.

-

Carbon fiber: Read more to understand its high strength-to-weight ratio, detailed production considerations, and its role in enhancing product performance for high-demand markets. ↩ ↩ ↩2

-

Fiberglass: Discover how this material offers excellent ball control and flexibility, and learn about its applications in varying paddle designs for diverse user segments. ↩ ↩ ↩2 ↩3

-

Cold pressing: Explore the process that preserves natural material properties, enabling precision control and tailored manufacturing solutions in competitive product environments. ↩ ↩ ↩2

-

Thermoforming: Learn about this flexible production method that enables intricate designs and consistent material distribution, ideal for custom and premium product lines. ↩ ↩ ↩2

-

Composite materials: Understand how combining different materials can optimize performance by balancing strength, control, and cost-efficiency for a wide range of market needs. ↩ ↩