In today’s fast-paced sports retail market, selecting the right beginner pickleball paddle can make all the difference between customer satisfaction and costly returns. This guide provides a quick answer: When procuring paddles for beginners, balance performance, durability, and cost-effectiveness through a careful comparison of materials, manufacturing processes, and design features. By understanding these critical factors, B2B procurement managers and sports equipment buyers can confidently choose products that satisfy both end-user expectations and business objectives.

Selecting the perfect beginner paddle starts with understanding the types of materials used. Paddle materials directly impact performance attributes such as power, control, and durability. The most common materials include carbon fiber, fiberglass, and composite materials1. Each offers unique benefits that affect the paddle’s behavior on the court:

• Carbon Fiber Paddles:

- Available in variants like 3K, 12K, and T300 carbon fiber.

- 3K Carbon Fiber provides high strength and flexibility, reducing vibration during play.

- 12K Carbon Fiber offers a smoother surface and exceptional durability which is ideal for competitive play.

- T300 Carbon Fiber strikes a balance between strength and light weight, ensuring responsive performance.

• Fiberglass Paddles:

- Known for a broader sweet spot and improved ball control.

- E-Glass Fiberglass offers enhanced elasticity and tensile strength, making it effective for beginners who require forgiving yet responsive paddles.

• Composite Materials:

- Combines benefits of different materials to maximize performance.

- Options like Carbon Fiber and Fiberglass Composite offer both strength and control, while Bamboo Core Composite provides lightweight durability with a clear hitting feel.

- Other composites, such as those incorporating a Honeycomb Core, improve shock absorption and reduce the paddle’s vibration.

Below is a detailed comparison of these materials:

| Material Type | Key Advantages | Best Suited For |

|---|---|---|

| Carbon Fiber (3K, 12K, T300) | Excellent strength, minimal vibration, high durability | Competitive play; power and control balance |

| Fiberglass (E-Glass) | Wider sweet spot, enhanced ball control, cost-effective | Recreational play; beginner-friendly |

| Composite (Bamboo Core, Honeycomb) | Balanced performance with control and power; superior shock absorption | Customized paddle options; on-demand products |

Understanding these materials is crucial, as they form the foundation for a successful paddle that meets both operational and performance needs. B2B buyers must consider supplier consistency in quality, production reliability, and after-sale support to ensure a stable supply chain.

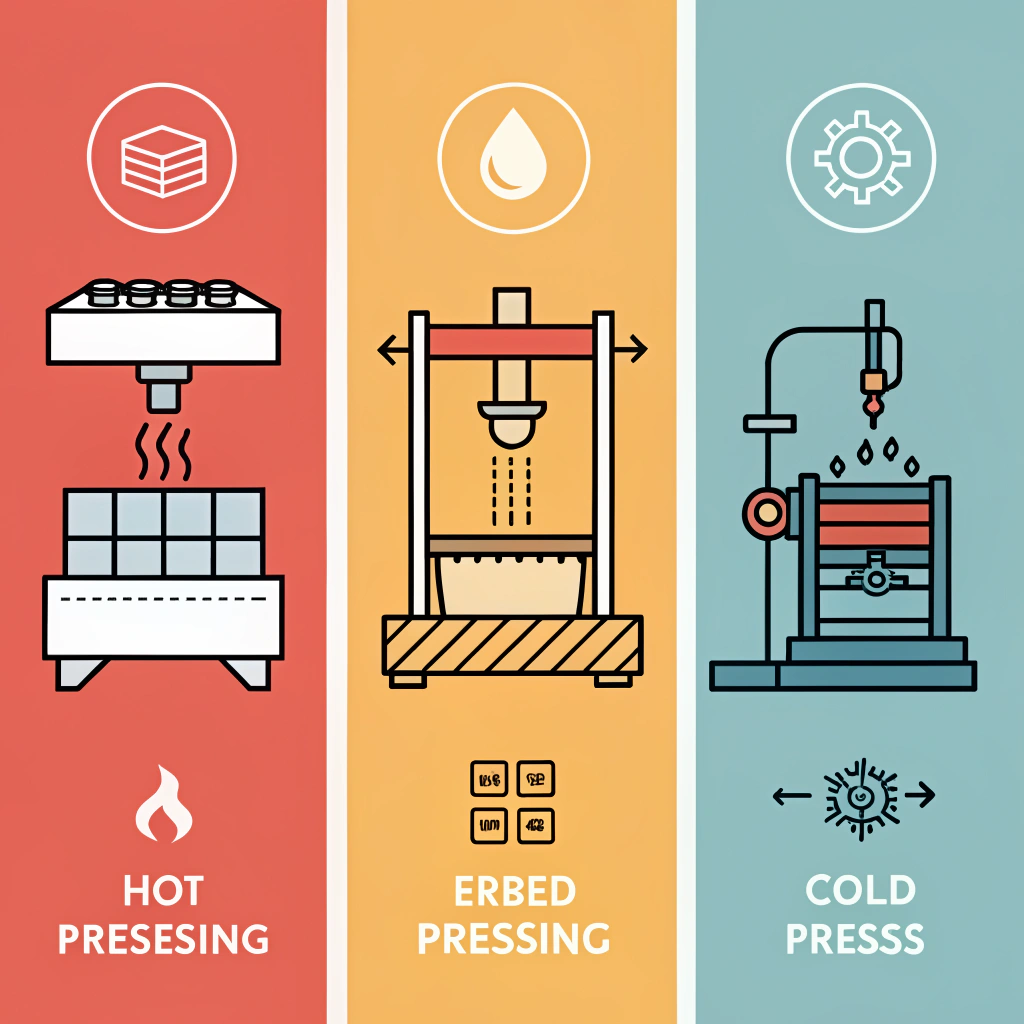

The production methods further influence a paddle's performance and price point. Hot pressing, cold pressing2, and thermoforming3 are the three primary manufacturing techniques used in modern pickleball paddle production. Each process has distinct advantages and can affect aspects like weight distribution, paddle balance, and overall feel.

• Hot Pressing:

- Involves heating the paddle materials and applying pressure to create a strong, durable structure.

- Offers high production efficiency, making it suitable for large-scale manufacturing with consistent quality.

- May slightly alter some inherent material properties, impacting the feel of the finished product.

• Cold Pressing:

- Uses ambient temperature combined with mechanical pressure to shape the paddle.

- Maintains the natural properties of the materials, which can result in enhanced control and a soft feel.

- This process is slower, which might increase production costs, but the precision it offers is a significant advantage for specialized products.

• Thermoforming:

- Combines heat and molds to form complex paddle shapes with precise material distribution.

- Ideal for creating premium or custom-designed paddles with specific ergonomic features.

- Though it requires longer production cycles and higher equipment investment, its flexibility in batch customization often justifies the cost in niche markets.

Below is a comparison table of these manufacturing methods:

| Process | Advantages | Disadvantages | Typical Use Case |

|---|---|---|---|

| Hot Pressing | High efficiency; strong, durable paddles; structural integrity | May affect material feel; high equipment cost | Large-scale, high-performance products |

| Cold Pressing | Precise control over thickness; preserves material properties | Longer production cycle; precision equipment needed | Custom products; products emphasizing control |

| Thermoforming | Excellent for complex designs; precise material distribution | Extended production time; higher equipment costs | Premium and custom-made paddles |

Choosing the right production process is essential when balancing scale and quality. B2B procurement managers should consider the supplier’s capacity to consistently deliver products that meet set performance and durability standards. Confirming that the manufacturing process aligns with your business and your customer’s expectations can ultimately lead to higher customer satisfaction and loyalty.

While material and production methods are critical, design elements such as weight distribution and grip design can make a paddle especially appealing for beginners. These design factors contribute significantly to usability and playability:

• Weight Distribution:

- Paddles designed with optimal weight distribution offer a balanced feel that reduces arm fatigue and improves swing control.

- Ensuring that the center of gravity is well-balanced enhances both power and accuracy, a key requirement for novice players.

• Grip Design:

- Ergonomic handles, available in multiple sizes, ensure that paddles can accommodate different hand sizes comfortably.

- Grips that feature specially treated surfaces can enhance friction, allowing for better control and reducing the likelihood of mishits.

• Surface Texture:

- A textured or patterned surface can aid in imparting spin on the ball, a feature that can significantly benefit new players who are still mastering control.

Additionally, the ability to offer on-demand printing services4 allows for custom branding. This makes the paddles especially attractive for sports clubs or gyms looking to promote their identity, or for retailers aiming to offer exclusive products with unique aesthetics.

For example, a sports club purchasing beginner paddles might prefer customized color schemes and logos that align with their team's branding, while still retaining the high performance offered by quality materials and precise manufacturing. Providing this custom option adds value and differentiates the product in a competitive market.

In today's competitive sports equipment landscape, customization has become a significant selling point. NEX Pickleball offers tailored solutions where retailers and sports clubs can specify design, weight distribution, and grip size to meet their specific needs. This customization ensures that:

• The paddle meets the precise requirements of different playing styles and user preferences.

• Branding opportunities are maximized, as custom designs can help build brand identity among end consumers.

• Quality control is maintained, ensuring every customized paddle performs reliably across various conditions.

B2B clients benefit from a range of options, including choosing between different core materials like Nomex Honeycomb Core5, Aluminum Honeycomb, or Polymer Honeycomb. Each core type influences the paddle’s overall performance in unique ways. For instance:

- Nomex Honeycomb Core: Provides exceptional shock absorption and durability, perfect for players looking for longevity and stable performance.

- Aluminum Honeycomb Core: Offers a balanced blend of power and control thanks to its even weight distribution.

- Polymer Honeycomb Core: Emphasizes comfort by reducing vibration and enhancing the overall feel during sustained play.

A simple decision table for core selection can be helpful:

| Core Material | Key Benefit | Ideal For |

|---|---|---|

| Nomex Honeycomb | Superior shock absorption, long-lasting durability | Competitive and extended play |

| Aluminum Honeycomb | Balanced weight distribution, optimal power control | Casual play and clubs requiring versatility |

| Polymer Honeycomb | Reduced vibration, enhanced comfort | Beginners and recreational play |

The ability to offer on-demand printing further elevates the product value, making customized paddles a smart choice for businesses looking to cater to niche markets. This approach not only meets the specific requirements of a target audience but also enhances the retailer's brand image.

Real-world examples underscore the importance of material selection and manufacturing processes in delivering high-performance paddles at a cost-effective price point. For instance, several leading sports retailers have transitioned to using thermoformed paddles because of their ability to produce intricate designs while maintaining excellent material stability. This transition has led to higher customer satisfaction, as players enjoy both improved performance and a unique, branded look.

Moreover, data from industry reports suggest that customized paddle designs—especially those featuring advanced composite materials—are increasingly popular among novice players. The market trend highlights a growing demand for products that provide both functional excellence and aesthetic appeal. B2B procurement leaders can capitalize on these insights by aligning their purchasing strategies with emerging trends in sports equipment manufacturing.

At NEX Pickleball, our expertise in manufacturing high-performance paddles has been honed through meticulous production processes and continual investments in state-of-the-art technology. Our relationship as the OEM manufacturer for renowned brands like Joola and Selkirk underscores our capability to deliver products that meet rigorous standards. The combination of advanced processes—hot pressing, cold pressing, and thermoforming—ensures that our paddles reliably enhance performance on the court while accommodating customization requests.

For sports equipment procurement managers, the ultimate decision to purchase beginner paddles depends on balancing several factors:

-

Material Quality: Ensuring the paddle material—whether it be carbon fiber, fiberglass, or a composite—is of high quality for durability and performance.

-

Manufacturing Excellence: Choosing a supplier with proven production processes such as hot pressing, cold pressing, or thermoforming guarantees consistent quality and precise design specifications.

-

Design and Customization: Prioritize paddles with ergonomic designs that offer optimal weight distribution and grip comfort, while also providing options for on-demand printing and customization.

-

Cost-Effectiveness: It is essential to weigh the production cost against performance benefits, ensuring that the paddles meet performance requirements without overrunning budget constraints.

In conclusion, the journey to select the perfect beginner paddle is all about carefully evaluating the comparative benefits of materials, manufacturing techniques, and design features. B2B procurement managers can significantly improve their purchasing decisions by understanding these factors and asking the right questions—ultimately ensuring that the paddles not only meet but exceed customer expectations on performance and durability. For businesses seeking to boost their competitive edge in the sports retail market, a well-informed decision backed by industry insights offers a recipe for long-term success.

Q1: What are the key materials used in beginner pickleball paddles?

A1: Beginner pickleball paddles typically feature materials such as carbon fiber (including variants like 3K, 12K, and T300), fiberglass, and composite materials that blend benefits from both. These materials provide a balance of power, control, and durability suitable for new players.

Q2: How do manufacturing processes impact paddle performance?

A2: Manufacturing processes—such as hot pressing, which boosts efficiency and durability; cold pressing, which preserves material properties for enhanced control; and thermoforming, which allows for complex designs—directly affect weight distribution, shock absorption, and overall playability.

Q3: What customization options are available for paddles?

A3: Customization includes tailored design features like grip size, weight distribution, color schemes, and on-demand printing for branding. Options for core materials (such as Nomex, Aluminum, or Polymer honeycomb cores) further allow customization to meet specific performance and aesthetic requirements.

-

Composite Materials: Click here to learn how integrating diverse materials can yield paddles that balance strength, flexibility, and durability, enhancing performance across various play styles. ^Return ↩

-

Cold Pressing: Click here to read about cold pressing, a manufacturing process that preserves the natural properties of paddle materials while providing enhanced control and a softer finish. ^Return ↩

-

Thermoforming: Click here to explore the thermoforming process, which uses heat and molds to create complex paddle designs while ensuring precise material distribution for optimal performance. ^Return ↩

-

On-demand printing services: Click here to understand how on-demand printing enables custom branding and personalization, adding value and uniqueness to sports equipment offerings. ^Return ↩

-

Nomex Honeycomb Core: Click here to discover the benefits of using a Nomex Honeycomb Core, renowned for its superior shock absorption and durability in high-performance sports equipment. ^Return ↩