When selecting a pickleball paddle, it's essential to balance advanced materials and production processes to achieve the optimal performance that meets both player needs and market competitiveness.

For B2B procurement managers and niche sports retailers, choosing the right pickleball paddle is a critical decision that influences player satisfaction and competitive advantage. Today’s high-performance paddles combine premium materials with innovative production processes to deliver unmatched durability, control, and power. In this article, we compare different paddle technologies—ranging from various carbon fibers to fiberglass and Composite Materials1—and analyze the primary production processes including hot pressing, cold pressing, and thermoforming. Our goal is to guide you through a detailed comparison to make an informed purchasing decision for your market.

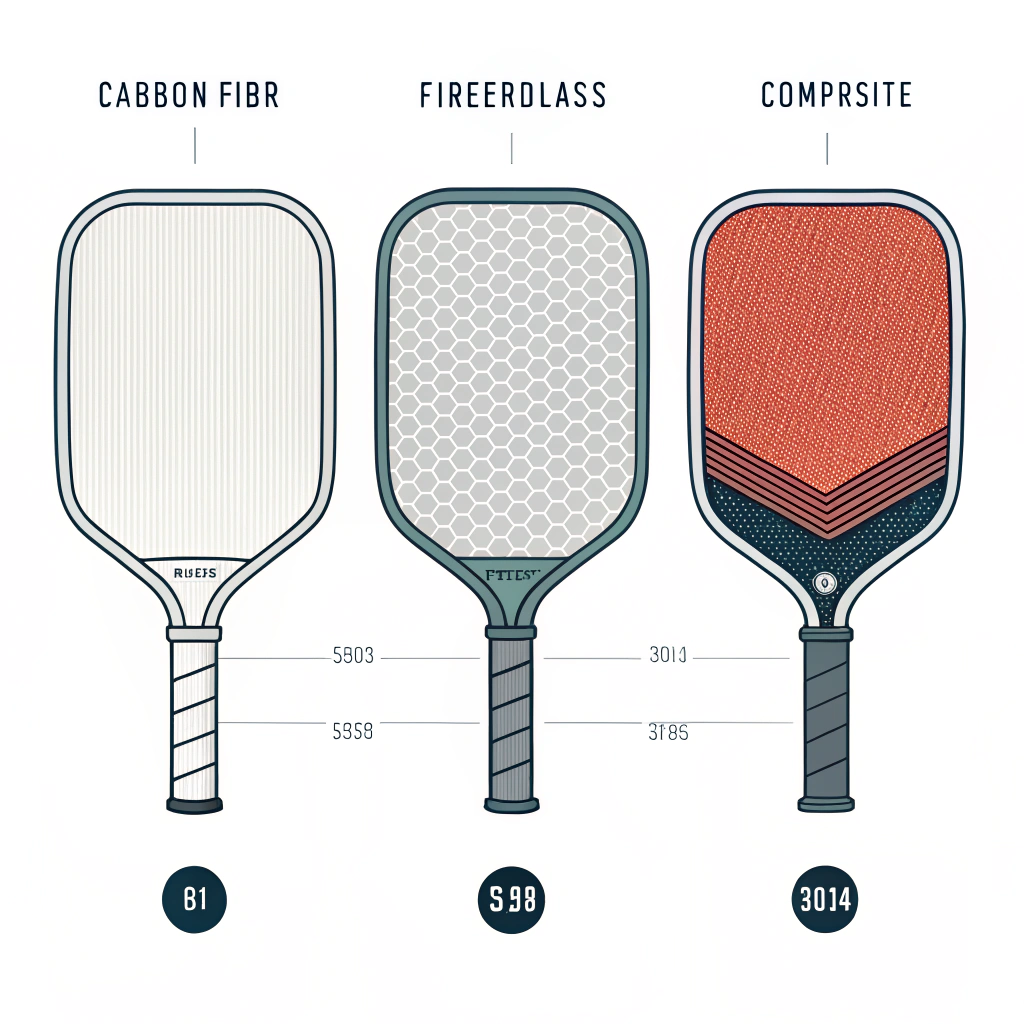

Understanding the difference between materials is the first step in selecting the ideal paddle. Each material has unique properties that cater to specific playing conditions and performance levels.

Carbon Fiber2 is favored for its lightweight strength and superior performance. There are multiple grades available:

- 3K Carbon Fiber: Known for its flexibility and ability to generate high rebound force. Ideal for producing swift responses during fast-paced games.

- 12K Carbon Fiber: Offers a higher thread density, resulting in greater hardness and durability. It is perfect for competitive play where impact resistance is paramount.

- T300 Carbon Fiber: Provides a balanced mix of strength and light weight, making it widely used in paddles that require both power and maneuverability.

While fiberglass paddles usually offer a wider sweet spot coupled with excellent ball control, they stand out because of their superior flexibility. Using E-Glass fiberglass, manufacturers can ensure:

- Enhanced elasticity for a smooth hitting experience.

- Improved ball control, making it ideal for players who prefer tactical gameplay over raw power.

Composite Materials1 use a strategic blend of materials to achieve the best results:

- Carbon Fiber and Fiberglass Composite: Merges the benefits of both materials offering excellent control, power, and shock absorption.

- Bamboo Core Composite: Provides a lightweight option with impressive impact resistance and a natural hitting feel.

- Honeycomb Core: Typically made with high-density polymer, this design reduces vibration and enhances durability, making paddles more enduring in rigorous play.

The choice of material directly influences the paddle’s performance. The addition of premium materials such as carbon fiber boosts power and durability, while fiberglass offers increased control and an expanded sweet spot. Choosing the right material depends on the specific needs of your target clientele and the style of play they favor.

In addition to material selection, the manufacturing process adopted significantly affects the overall performance and durability of pickleball paddles. Here we break down the three main production processes used by high-performance paddle manufacturers:

Hot pressing involves heating the material and applying pressure to form the paddle. This method is highly efficient for large-scale production.

Advantages:

- High production efficiency, ideal for bulk orders.

- Produces paddles with excellent impact resistance and structural integrity.

- Suitable for high performance and competitive use.

Disadvantages:

- High equipment investment is necessary.

- May alter some inherent material properties, affecting the tactile feel of the paddle.

Cold pressing is performed at room temperature, employing mechanical pressure to shape the paddle material.

Advantages:

- Offers precision in controlling paddle thickness and structure.

- Maintains the natural properties of the materials, ensuring optimal ball feel and control.

- Ideal for paddles that are targeted at players who value precision and playability.

Disadvantages:

- Longer production cycles can reduce manufacturing efficiency.

- Requires high-precision equipment to ensure consistent quality.

Thermoforming heats the material until it softens, and then forms it into the desired shape using molds.

Advantages:

- Allows for intricate and customized paddle designs.

- Ensures precise material distribution for consistent performance.

- Enhances stability and durability, making it well-suited for premium paddle production.

Disadvantages:

- Typically involves higher production costs.

- Slower production times, making it best for custom-made or high-end products.

Below is a table summarizing the key characteristics of these production processes:

| Process | Key Advantages | Main Disadvantages | Best Suited For |

|---|---|---|---|

| Hot Pressing | Fast production; strong impact resistance; scalability | High equipment cost; alters material feel | High-volume, high-performance models |

| Cold Pressing | Precise thickness and structure; intact material properties | Longer cycle times; precision demands | Paddles requiring superior control |

| Thermoforming | Intricate designs; even material distribution; enhanced stability | Higher costs; slower production | Custom or premium paddle ranges |

From a performance standpoint, the materials and production processes work together to maximize benefits for players at all levels. Here’s how each factor contributes:

Durability is crucial, particularly for competitive players who need reliable equipment over prolonged use:

- 12K Carbon Fiber offers durability and stiffness that can handle high-intensity play.

- Nomex Honeycomb Cores and Aluminum Honeycomb Cores deliver stability and resilience by absorbing shocks.

- Hot pressing processes further enhance impact resistance, ensuring that paddles remain robust even during aggressive play.

For retailers and procurement managers, control features in a paddle can boost a player’s game, especially in competitive scenarios:

- Fiberglass paddles provide a wide sweet spot for improved control.

- Cold pressing maintains the material's natural properties, delivering precise tactile feedback that is crucial for high-level play.

- Composite designs combine materials strategically, enhancing both control and power without compromising the playing experience.

Power is derived from material strength and the efficiency of the production process:

- T300 Carbon Fiber balances lightweight and strength, generating powerful hits while minimizing fatigue.

- Thermoformed paddles, with their precise material distribution, ensure that every swing is maximized for power.

- Advanced materials integrated into composite designs help achieve that extra pop, making the paddle ideal for quick, decisive plays.

When evaluating paddles for your retail or wholesale portfolio, consider the following factors:

-

Target Audience Requirements:

Consider whether your customers prioritize power, control, or a combination. Recreational players might favor fiberglass for its wide sweet spot, while competitive players might lean towards carbon fiber variants for their strength and lightweight nature. -

Production Volume and Customization:

If your market demands high-volume orders with consistent quality, hot pressing might be the best approach. For custom or premium lines, cold pressing and thermoforming offer tailored features that can command a higher price point. -

Cost-Benefit Analysis:

Higher-end paddles, although more expensive, may offer enhanced performance due to premium materials like carbon fiber and advanced production techniques. However, there is a balance between cost and performance—affordable options that offer good control and durability are still competitive. -

Branding and Differentiation:

Customizable paddles provide an opportunity for retailers to offer branded equipment tailored to the customer’s preferences, from grip size to weight distribution. This added value can be a key differentiator in a crowded market. -

Long-Term Value:

Consider the longevity of the paddle under rigorous use. High-durability paddles with robust cores and advanced materials tend to have a longer lifecycle, enhancing customer satisfaction and reducing replacement frequencies.

A strategic mix of these considerations can help you align product offerings with market demands, ensuring that you provide paddles that not only meet technical standards but also offer tangible benefits to your customers.

In summary, the selection of a high-performance pickleball paddle hinges on a careful evaluation of materials and production processes. Carbon Fiber2, fiberglass, and Composite Materials1 each offer their distinct advantages when paired with the appropriate manufacturing method—whether it’s hot pressing, cold pressing, or thermoforming. For procurement managers, the decision-making process should evaluate the target market’s needs, production volume, and potential for customization.

To move forward, we recommend:

- Assessing your customer base to understand whether they prioritize power, control, or durability.

- Requesting samples or technical data from manufacturers to see firsthand how different production techniques impact paddle performance.

- Considering long-term value and potential market differentiation when selecting paddles for your portfolio.

By carefully navigating these factors, you can confidently select paddles that enhance player performance and set your market offerings apart from the competition.

How to figure out what pickleball paddle is best for you?

When choosing the best pickleball paddle, consider factors such as weight, grip size, materials, shape, and core composition. The paddle should match your playing style, preferences, and skill level, ensuring you strike the right balance between power and control.

How to choose pickleball paddle for advanced players?

For advanced players, the paddle selection should hinge on reaching extra power and enhanced control. Hybrid or elongated designs, with premium materials like advanced carbon fibers and optimized core structures, provide extra reach and pop while maintaining an oversized sweet spot for superior performance.

Do more expensive pickleball paddles make a difference?

More expensive paddles often feature higher-end materials such as carbon fiber, fiberglass, and custom composite blends, leading to significant improvements in control, power, and overall durability. However, performance benefits depend on individual playing style, so it's important to balance cost with the specific needs of the player.

-

Composite Materials: Click to explore how composite materials integrate multiple substances to optimize control, power, and shock absorption in products designed for competitive play. ↩︎ ↩ ↩2 ↩3

-

Carbon Fiber: Click to learn about this advanced material's properties, its lightweight strength, and its impact on enhancing the performance and durability of high-performance sporting equipment. ↩︎ ↩ ↩2

-

Hot Pressing: Click to understand the hot pressing manufacturing process, its benefits in terms of production efficiency and product durability, and how it influences the final product quality. ↩︎ ↩

-

Cold Pressing: Click to discover the cold pressing process, which preserves the natural characteristics of materials for enhanced tactile control and precision in performance. ↩︎ ↩

-

Thermoforming: Click to learn about thermoforming, a versatile process that allows for intricate design customization and even material distribution to produce high-end, performance-focused products. ↩︎ ↩