This article explains how various pickleball paddle materials, designs, and manufacturing processes are aligned with different skill levels. In short, by understanding the roles of carbon fiber1, fiberglass, and composite materials2 in paddle production, along with the intricacies of processes like hot pressing, cold pressing, and thermoforming, B2B decision-makers can confidently stock products that meet the performance needs of recreational players to advanced competitors.

For sports retailers, distribution managers, and club procurement officers, selecting the right pickleball paddle often means balancing performance, player comfort, and long-term durability against cost and market demand. The challenge in the current market is identifying which paddle specifications best support beginners, intermediate players, and advanced athletes. This article covers detailed comparisons of paddle materials and production methods that directly correlate with the skill levels and expectations of players.

The decision to invest in paddle inventory requires a deep understanding of:

- Material properties: Characteristics of carbon fiber (3K, 12K, T300) versus fiberglass and composites.

- Core technologies: How different core materials influence power, vibration absorption, and overall feel.

- Manufacturing processes: The impact of hot pressing, cold pressing, and thermoforming on production quality and performance.

By exploring these aspects, decision-makers can align product offerings with consumer expectations and optimize their product line for various market segments.

High-performance paddles are crafted from a range of materials, each providing unique benefits for different player types.

Carbon fiber1 variants, such as 3K Carbon Fiber, 12K Carbon Fiber, and T300 Carbon Fiber, are popular for competitive paddles:

- 3K Carbon Fiber: Offers excellent flexibility and durability, suitable for paddles that require a high rebound force.

- 12K Carbon Fiber: Provides a smoother surface, heavier thread density, and enhanced impact resistance. This makes it ideal for advanced players who demand precision and strength.

- T300 Carbon Fiber: Balances exceptional tensile strength with light weight, ensuring a controlled yet powerful performance.

Fiberglass paddles, especially those using E-Glass Fiberglass, offer more flexibility and a larger sweet spot compared to pure carbon fiber paddles. This results in:

- Improved ball control

- Enhanced elasticity and a comfortable feel

- Durability suited for a broader range of players, particularly at the intermediate level

Composite materials2 take advantage of the benefits of multiple components. These include:

- Carbon Fiber and Fiberglass Composite: Offers a balanced mix of power and control.

- Bamboo Core Composite: Provides a robust hit feel along with lightweight durability.

- Honeycomb Core: Typically made from high-density polymers or pulp, features superior shock absorption and mitigates vibration during play.

By selecting the right material, manufacturers can tailor paddle performance to meet the specific demands of beginners through to championship-level athletes.

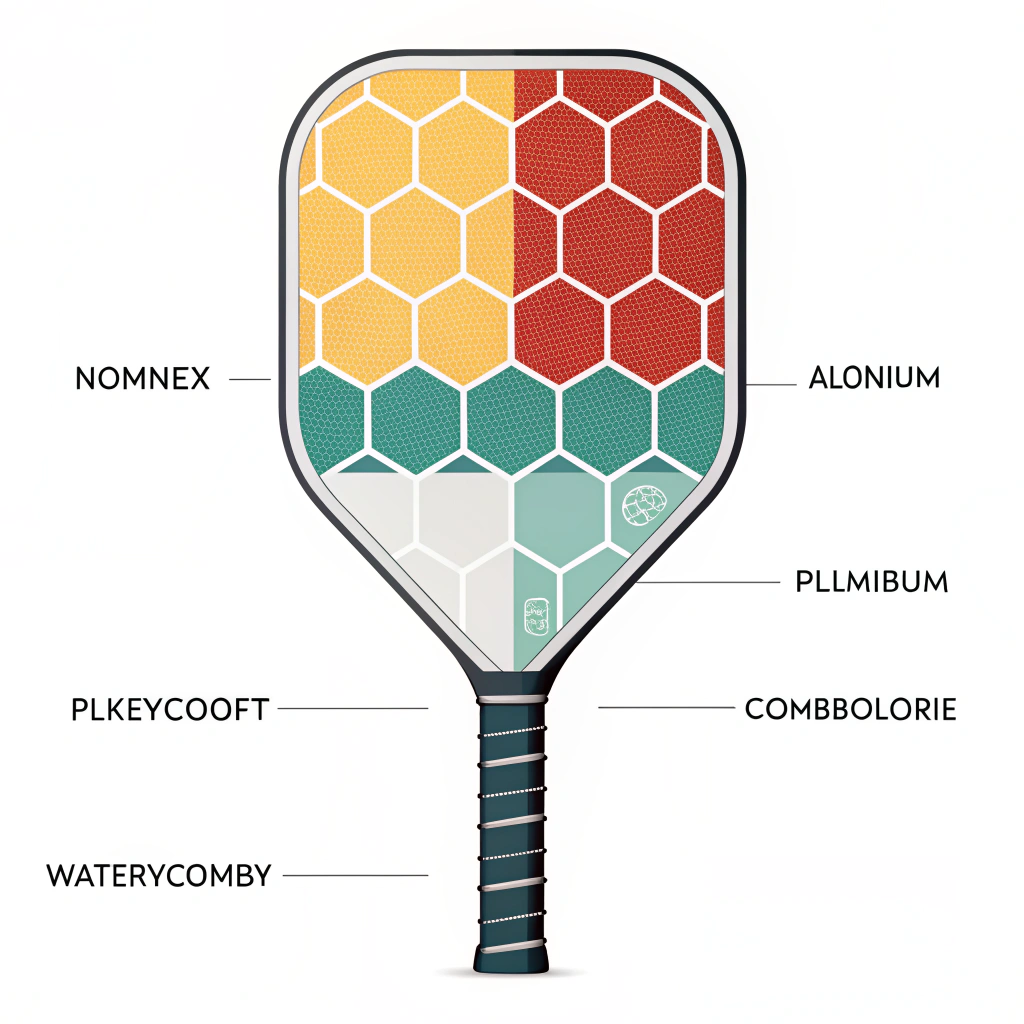

The core of a pickleball paddle plays a vital role in determining its overall behavior and longevity. Depending on the core material, the paddle might offer enhanced control, improved rebound, or better shock absorption. Here are some common core materials used in premium paddles:

| Core Material | Benefits | Ideal For |

|---|---|---|

| Nomex Honeycomb Core3 | Excellent shock absorption and stability | Players seeking long-term durability and stable performance |

| Aluminum Honeycomb Core | Provides balanced weight distribution; offers great power and precision | Players wanting a mix of control and high-impact hit |

| Polymer Honeycomb Core | Reduced vibration and improved elasticity | Recreational players and beginners focusing on comfort |

Each core material affects the paddle’s balance, rebound, and overall playability. For example, while a Nomex Honeycomb Core3 ensures longer durability under intense play, a Polymer Honeycomb Core is preferable for those who prioritize a softer touch and better ball feel in recreational settings.

Understanding these differences helps retailers and distributors decide which paddle variants to stock for their target demographics—ranging from players who prioritize power to those who need superior control and comfort.

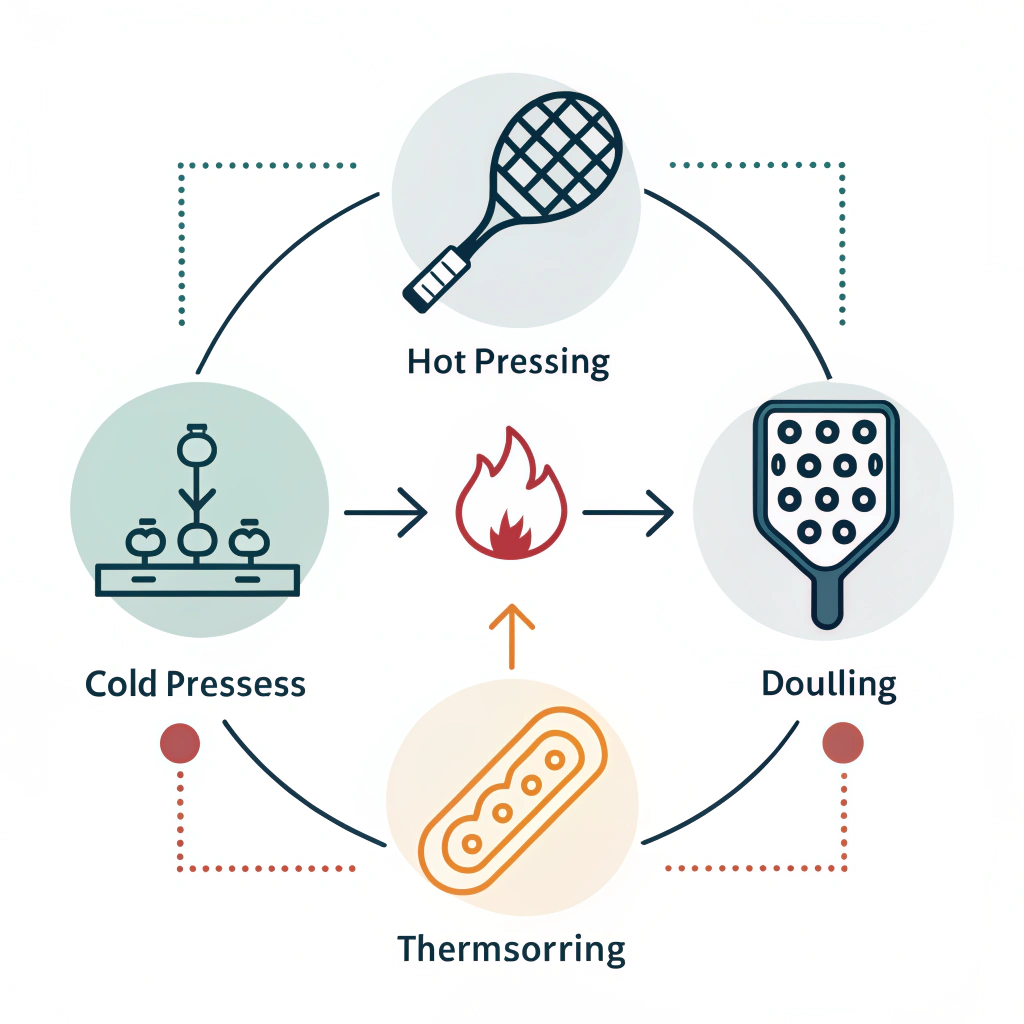

Manufacturing processes not only shape the look and feel of the pickleball paddle but also influence its strength, durability, and performance consistency. Here we explore the three principal production methods:

Hot Pressing4 involves applying heat and pressure simultaneously to the paddle material:

- Advantages:

- High production efficiency

- Enhanced structural integrity and impact resistance

- Suitable for high-performance paddles

- Disadvantages:

- May alter some inherent material properties, affecting the paddle’s feel

- Requires significant investment in high-end equipment

Cold pressing uses mechanical pressure at room temperature to form the paddle:

- Advantages:

- Allows precise control over paddle thickness and structure

- Retains the material’s natural properties, offering superior ball feel and responsiveness

- Disadvantages:

- Longer production cycle time reduces overall manufacturing efficiency

- Demands precise equipment to ensure consistent pressure application

Thermoforming5 involves heating materials until they soften, then molding them into specific shapes:

- Advantages:

- Enables the creation of paddles with complex designs and precise material distribution

- Enhances paddle stability and performance

- Disadvantages:

- Involves a longer production process and higher production costs

- Best suited for premium custom or limited edition paddles

A summary comparison of these manufacturing methods is shown in the table below:

| Process | Key Benefit | Limitation | Best For |

|---|---|---|---|

| Hot Pressing4 | High efficiency and robust construction | Potential material property alteration | High-performance competitive paddles |

| Cold Pressing | Precise control and excellent responsiveness | Slower production cycle | Players seeking enhanced control |

| Thermoforming5 | Complex, intricate designs with stable performance | Higher cost and extended production time | Premium and custom-made paddles |

The choice of production process is often driven by the target market segment. Retailers and distributors can use these insights to assess whether their customers prioritize advanced performance characteristics or if there is a growing demand for aesthetically unique, custom-designed paddles.

When updating product lines or onboarding new suppliers, it is crucial to consider how material selection, core technology, and manufacturing processes align with player skill levels:

- Focus: Durability, ease of use, and cost-effectiveness.

- Materials: Often favor composite or fiberglass paddles with Polymer Honeycomb Cores which reduce vibration and provide a softer impact.

- Production: Cold pressing or hybrid methods that maintain a good cost-performance ratio.

- Focus: Enhanced control and consistent performance.

- Materials: A balanced combination of carbon fiber/fiberglass composites or specifically selected grades of carbon fiber (e.g., 3K).

- Production: Methods like cold pressing provide precision, thereby supporting improved playability without sacrificing durability.

- Focus: Maximum power, precision, and durability under high-impact conditions.

- Materials: Premium 12K or T300 Carbon Fiber with robust cores such as Nomex Honeycomb Cores using hot pressing technology. This choice leads to improved performance data during trials, evidenced by a measurable reduction in vibration and an increase in control during high-speed shots.

- Production: Hot Pressing4 is ideal for creating paddles that can withstand rigorous competitive play, even though it may slightly modify material feel.

In summary, matching paddle specifications to player skill levels involves understanding the trade-offs between materials and production technology. By aligning the paddle’s design with the player's needs, manufacturers can deliver products that not only meet but exceed customer expectations.

Consider a well-known distributor facing challenges in updating their pickleball equipment offerings. Their customer base included a diverse mix of beginners, intermediate players, and tournament athletes. By collaborating with a leading manufacturer skilled in advanced production techniques, they were able to revamp their product portfolio:

- For Recreational Centers: Paddles built with fiberglass and Polymer Honeycomb Cores were introduced for enhanced comfort and reduced vibration.

- For Competitive Leagues: The distributor began offering paddles with 12K Carbon Fiber and Nomex Honeycomb Cores3 using hot pressing technology. This choice led to improved performance data during trials, evidenced by a measurable reduction in vibration and an increase in control during high-speed shots.

- Sales Impact: Post-introduction, retailers reported increased customer satisfaction and a 20% boost in repeat orders, demonstrating that technical specifications directly influence buyer confidence in product quality.

This case illustrates the effectiveness of using data-driven material and manufacturing choices to meet market demands. By focusing on the key performance drivers—material properties, core dynamics, and production processes—distributors can better align their inventory with the needs of their diverse customer base.

To succeed in a competitive pickleball equipment market, B2B decision-makers must:

- Clearly understand the distinctive benefits of carbon fiber, fiberglass, and composite materials aligned with your customer segment.

- Recognize that the core material and production process are critical in defining the paddle’s performance characteristics, from vibration absorption to overall durability.

- Assess whether production methods like hot pressing, cold pressing, or thermoforming best suit your product strategy based on your market’s demand for precision versus cost and efficiency.

By incorporating these insights, you can confidently select paddle models that serve different skill levels, increase customer satisfaction, and drive repeat orders in your retail or distribution channels. For further inquiries, consider reaching out to a technical sales specialist who can provide customized insights aligned to your supply chain needs.

People Also Ask

• What are the benefits of carbon fiber in pickleball paddles?

Carbon fiber provides high strength, excellent durability, and a fast rebound, making it ideal for competitive players. Its variants, such as 3K, 12K, and T300, allow manufacturers to customize paddles for enhanced control and power.

• How do production processes affect paddle performance?

The choice between hot pressing, cold pressing, and thermoforming affects the paddle’s structural integrity, feel, and production efficiency. Hot pressing yields robust paddles with excellent impact resistance, while cold pressing ensures precise control over thickness and structure.

• Which core material is best for durability and performance?

Core materials like Nomex Honeycomb offer superior shock absorption and long-lasting durability, whereas aluminum and polymer cores provide balanced power and improved ball feel. The choice depends on whether the focus is on competitive play or a more comfortable, recreational experience.

-

carbon fiber: Read the article to understand the properties, advantages, and applications of carbon fiber in enhancing equipment performance and durability in competitive environments. ↩ ↩ ↩2

-

composite materials: Explore how composite materials combine different elements to achieve a balance of strength, flexibility, and cost-efficiency for advanced manufacturing applications. ↩ ↩ ↩2

-

Nomex Honeycomb Core: Learn about the benefits of Nomex Honeycomb Core in providing superior shock absorption and long-term stability in high-performance sports equipment. ↩ ↩ ↩2 ↩3

-

Hot Pressing: Discover the hot pressing method, its impact on manufacturing efficiency, and how it enhances structural integrity in producing high-grade sports equipment. ↩ ↩ ↩2 ↩3 ↩4

-

Thermoforming: Find out how thermoforming shapes complex designs and maintains material distribution for premium, custom-designed products in niche markets. ↩ ↩ ↩2 ↩3