Our OEM service1 propels startups to scale quickly by delivering high-performance pickleball paddles through advanced production techniques, reliable quality control, and comprehensive customization options.

Startups in the sports industry face unique challenges in their journey to market. They need to launch brands rapidly while ensuring that products meet high-performance standards. Limited resources and tight timelines can make manufacturing daunting. Our OEM service1 at NEX Pickleball bridges this gap by leveraging advanced production processes to deliver paddles designed for both quality and scalability.

In today’s competitive market, startups require partners who understand both the technical intricacies and the business imperatives of rapid scaling. Our service not only meets technical requirements but also helps startups accelerate their product launches, reduce time-to-market, and ultimately build a competitive advantage.

For early-stage businesses, the decision to invest in product manufacturing is fraught with risk. Startups often face questions such as:

- How can we ensure our products have the required performance characteristics?

- What production processes deliver consistency and quality at scale?

- How do we navigate the balance between innovation and cost-effectiveness?

These challenges are compounded when the products are highly technical, like high-performance pickleball paddles. The need for precision and durability demands advanced manufacturing techniques, which can be difficult for startups to access internally. Instead, partnering with an experienced OEM provider offers a swift, cost-effective route to market without compromising on quality.

OEM partners bring specialized expertise that startups may lack, particularly in production technology and quality control. Here are three key benefits:

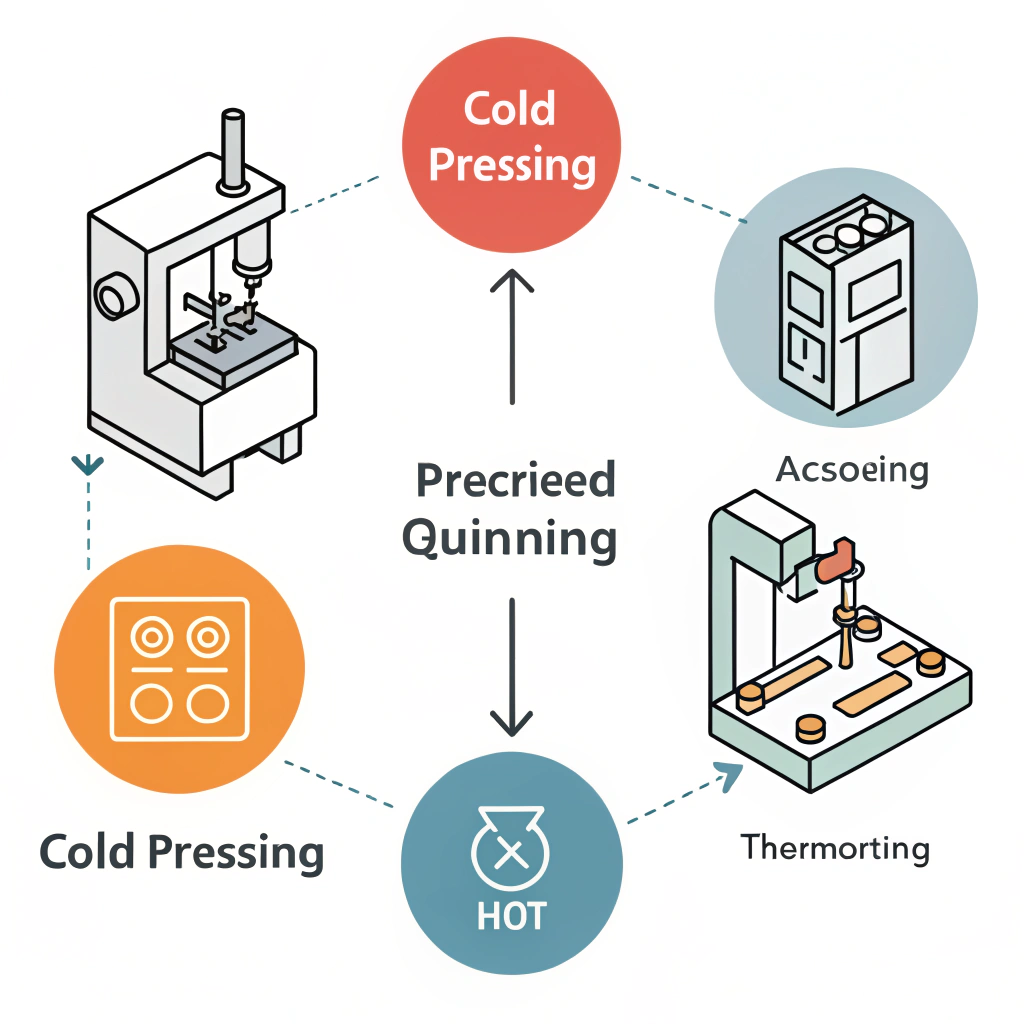

- Advanced Production Techniques: Our expertise in hot pressing, cold pressing, and Thermoforming2 ensures that every paddle meets the highest standards.

- Customization and Flexibility: Startups can customize paddle designs, payload materials, and core constructions to align with their brand vision without the heavy investment in production equipment.

- Scalable Supply Chain: A robust supply chain means faster production cycles, quicker turnaround times, and a steady supply of premium products for rapid market penetration.

This turnkey manufacturing solution transforms the risk of in-house production into a strategic advantage, allowing startups to focus on innovation, marketing, and customer acquisition.

At NEX Pickleball, our OEM service is designed to support startups as they scale. With our deep industry knowledge and cutting-edge technology, we manage every aspect of production—from material selection and process control to final quality checks. Our experience as a trusted OEM partner for major brands like Joola and Selkirk underscores our commitment to excellence.

Our integrated approach ensures that each paddle is built with precise weight distribution, an ergonomic grip, and surface treatments that enhance ball control. These factors are critical for players and help boost a brand’s reputation in a competitive market. Startups, therefore, can leverage our capabilities to quickly build their product portfolio and capture market share.

Successful paddle manufacturing depends on selecting the right production process. We use several advanced techniques to produce high-performance paddles, each with distinct advantages and considerations. These include:

Hot pressing involves heating and applying pressure to composite materials, resulting in strong, durable paddles with excellent impact resistance.

- Advantages:

• High production efficiency

• Strong impact resistance

• Structural integrity for high-performance use - Disadvantages:

• Can alter material feel

• Requires significant equipment investment

Cold pressing shapes the paddle material at room temperature under controlled mechanical pressure, keeping the inherent material properties intact.

- Advantages:

• Precise control over thickness and structure

• Preserves material properties for better ball feel

• Enhanced control and flexibility - Disadvantages:

• Longer production cycles

• Demands high precision in pressure control

Thermoforming involves heating the material to a softening point and then forming it using molds, ideal for paddles requiring intricate designs and precise material distribution.

- Advantages:

• Creation of complex shapes and precise designs

• Maintains paddle stability

• Suitable for custom-made premium products - Disadvantages:

• Longer production time

• Higher equipment and maintenance costs

The table below summarizes these production techniques:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, reliable build | Alters material feel, high initial investment |

| Cold Pressing | Precise control, preserved material properties, flexibility | Longer cycle times, precision equipment required |

| Thermoforming | Complex design capabilities, precise material distribution | Extended production time, higher cost |

These processes are executed with strict quality control measures to ensure that every paddle delivers consistent performance on the court.

When it comes to paddle manufacturing, the choice of materials and customization options plays a crucial role. At NEX Pickleball, we offer a range of premium materials that enable startups to differentiate their products in a crowded marketplace:

-

Carbon Fiber3:

• 3K Carbon Fiber: Balances strength and flexibility, enhancing rebound and durability.

• 12K Carbon Fiber: Offers a smoother surface and greater hardness for high-impact play.

• T300 Carbon Fiber: Combines excellent tensile strength with lightweight performance. -

Fiberglass:

• E-Glass Fiberglass: Provides a wider sweet spot, excellent elasticity, and superior ball control. -

Composite Materials4:

• Combining carbon fiber and fiberglass to maximize both power and control.

• Bamboo core composites for a lightweight, impact-resistant paddle.

• Honeycomb cores made from high-density polymer for shock absorption and reduced vibration. -

Core Materials:

• Nomex Honeycomb Core: Excellent for shock absorption and stability.

• Aluminum Honeycomb Core: Provides balanced weight distribution for a mix of power and precision.

• Polymer Honeycomb Core: Ideal for players who seek a comfortable, vibration-free hit.

Through these materials and customization options, startups can craft paddles that not only perform at a high level but also reflect their brand identity and innovation ethos.

Enhancing Supply Chain Agility5 for Faster Time-to-Market

Speed is essential for startups, and a flexible supply chain can be the difference between capturing market demand or missing the window of opportunity. Here’s how our OEM service enhances supply chain agility:

-

Quick Turnaround Times:

Our optimized production cycles mean faster manufacturing, allowing startups to launch products sooner than competitors. -

On-Demand Customization:

From different core materials to grip sizes, our custom paddle options ensure that startups receive products tailored to their specific market needs without long delays. -

Reliable Delivery:

With a robust logistics network, we guarantee timely deliveries, helping startups maintain steady inventory levels and satisfy customer demand.

By offering these advantages, our OEM service transforms potential roadblocks into growth opportunities, enabling startups to scale rapidly and confidently.

Consider the stories of several startups that partnered with us for their manufacturing needs. Each chose our service to leapfrog typical production challenges and quickly establish a strong market presence.

-

Case Study 1: Innovative Sports Start-Up

A startup focused on developing lightweight, durable sports equipment leveraged our advanced thermoforming and carbon fiber expertise. By opting for a customized production approach, they reduced prototype iteration times by 40%, rapidly increasing their market traction. -

Case Study 2: Tech-Driven Athletic Brand

Another company specializing in smart athletic gear required paddles with integrated sensor technology. Our precision cold pressing process ensured that the material properties remained optimal for embedding sensors. Within six months, they transitioned from concept to full-scale production, delighting early adopters and investors alike. -

Case Study 3: Niche Pickleball Enthusiasts Hub

A company catering to a niche segment of pickleball players chose an OEM partner that could offer both premium quality and visual customization. Our use of composite materials, along with on-demand custom printing services, allowed them to experiment with limited-edition designs, which led to a 30% increase in repeat orders.

These stories highlight how our technical expertise, combined with industry experience, can catalyze growth for startups willing to innovate and scale quickly.

For startups looking to scale rapidly, the choice of an OEM partner is critical. Here are the main takeaways:

- Leverage Advanced Techniques: Use production processes like hot pressing, cold pressing, and thermoforming to ensure high product performance.

- Embrace Material Innovation: Select from high-quality materials such as Carbon Fiber3, fiberglass, and composite options to differentiate your product offering.

- Opt for Customization: Tailor your product to your exact market needs without significant delays by utilizing on-demand customization services.

- Ensure Supply Chain Agility: A flexible, reliable manufacturing partner will help you meet market demands and maintain a competitive edge.

- Focus on Quality and Consistency: Rigorous quality control and consistent production are central to building trust and a reputable brand in a competitive landscape.

Startups can maximize their growth potential by partnering with experienced OEM providers like NEX Pickleball. Our commitment to innovation, quality, and scalability makes us the ideal partner to help you bring your vision to life. If you're ready to take your sports brand to the next level, consider how our comprehensive OEM service can transform your manufacturing process and accelerate your market entry.

Q1: What is an OEM service and how does it help startups?

A1: An OEM service provides end-to-end manufacturing solutions, enabling startups to access advanced production techniques, customize products, and scale rapidly without investing in in-house production facilities.

Q2: How do advanced production processes like hot pressing, cold pressing, and thermoforming benefit paddle manufacturing?

A2: These production processes ensure high-quality paddles by optimizing strength, durability, and design precision. Hot pressing offers high efficiency and impact resistance; cold pressing maintains material integrity for better control; and thermoforming allows for intricate designs and customizations.

Q3: What advantages do specialized materials and customization options offer in paddle manufacturing?

A3: Specialized materials such as Carbon Fiber3, fiberglass, and composite cores enhance performance and durability. Customization options enable brands to create unique designs, tailor performance specifications, and differentiate their products in a competitive market.

-

OEM service: Click here to learn how Original Equipment Manufacturing services streamline production, reduce costs, and provide scalability for startups entering competitive markets. ↩ ↩ ↩2

-

Thermoforming: Click here to explore the thermoforming process, its benefits, and how it enables the creation of complex, custom designs in modern manufacturing. ↩ ↩ ↩2

-

Carbon Fiber: Click here to understand the properties of carbon fiber, its applications in high-performance products, and why it is chosen for advanced manufacturing scenarios. ↩ ↩ ↩2 ↩3

-

Composite Materials: Click here to discover how composite materials combine various fibers and resins to enhance durability, flexibility, and performance in product design. ↩ ↩

-

Supply Chain Agility: Click here to read about the importance of supply chain agility, strategies to achieve it, and its impact on reducing time-to-market for startups. ↩ ↩