In today’s manufacturing landscape, high-performance pickleball paddles are more than just sporting equipment—they are the result of precise design decisions and advanced production techniques that together enhance game performance. This article quickly explains how selecting the right materials and production processes can significantly impact paddle performance, durability, and player experience. By understanding these elements, B2B buyers and product managers can make informed decisions that drive competitive advantage.

Pickleball paddles are a blend of art and engineering. Each design decision, from material selection to production method, plays a critical role in shaping the paddle’s power, control, and durability for players. For companies seeking to invest in high-performance equipment, understanding these factors is essential for offering products that meet market demands and deliver superior performance.

Despite the growing popularity of pickleball worldwide, many manufacturers struggle with balancing performance, durability, and production efficiency. This is compounded by challenges such as:

- Selecting materials that offer optimal strength and lightweight properties.

- Choosing production processes that maximize both product quality and efficiency.

- Ensuring that the paddle design meets the ergonomics and performance expectations of competitive players.

These issues can affect not only the sporting performance of players but also the reputation and reliability of the manufacturer in the B2B space.

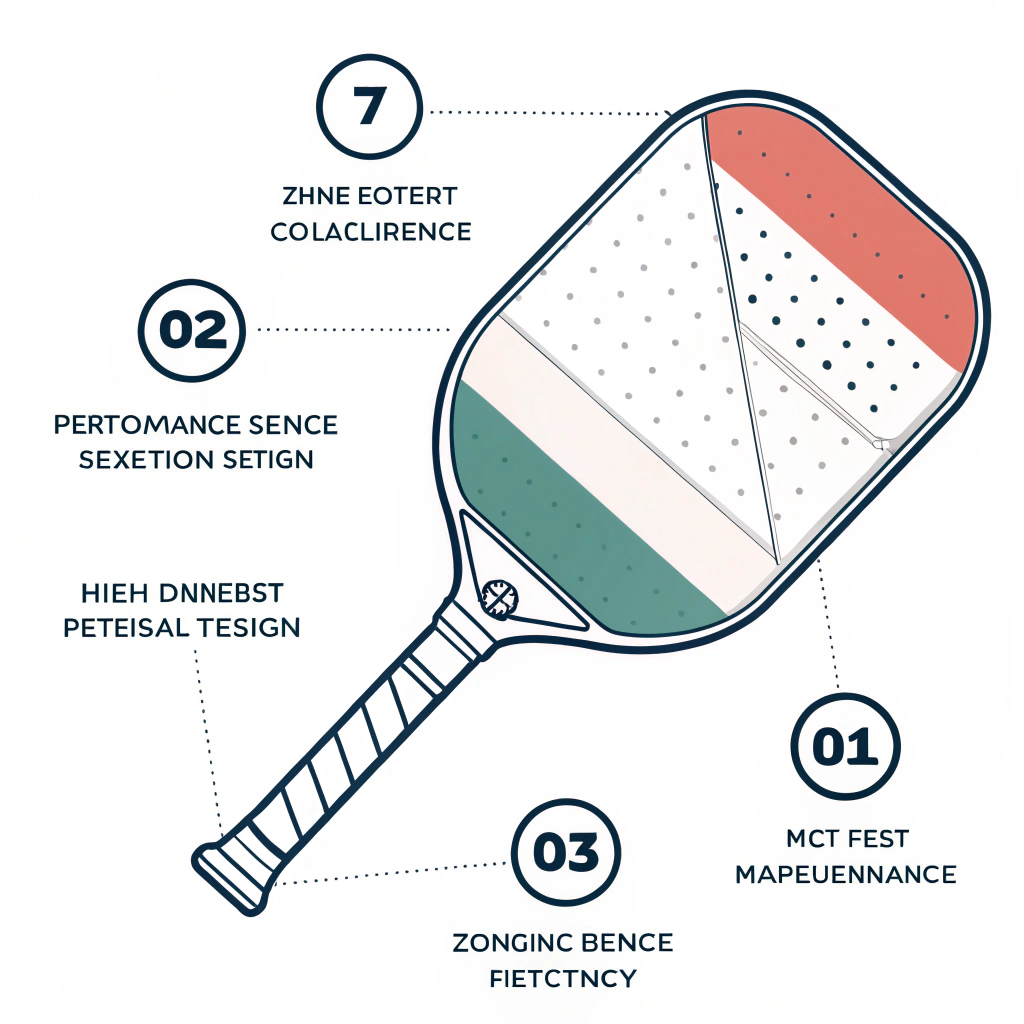

The impact of material selection is profound when designing a pickleball paddle. Different materials provide unique benefits that can significantly influence the playing experience.

Carbon Fiber is renowned for its strength-to-weight ratio, making it a prime choice for high-performance paddles. There are several types:

- 3K Carbon Fiber: Known for its excellent flexibility and strength, this material provides high rebound force and reduces vibration, making it ideal for competitive use.

- 12K Carbon Fiber: With a denser thread configuration, 12K offers a smoother surface, enhanced hardness, and improved durability, especially under intense impact.

- T300 Carbon Fiber: Offers a balanced mix of strength and lightweight properties, making it suitable for paddles requiring both power and maneuverability.

These fibers enhance the paddle's responsiveness and ensure that players can deliver powerful and accurate shots consistently.

2. Fiberglass2

Another key material is Fiberglass. Often used in combination with carbon fiber or alone, fiberglass paddles provide a wider sweet spot and excellent ball control. They are inherently more flexible, which helps players achieve superior control during play while still maintaining a robust performance envelope.

Composite paddles, which combine carbon fiber with fiberglass or other materials like bamboo cores, are engineered to bridge the gap between power and control. For example:

- Carbon Fiber and Fiberglass Composite: This combination harnesses the rigidity and power of carbon fiber with the enhanced ball feel of fiberglass.

- Bamboo Core Composite & Honeycomb Core: These enhance shock absorption and provide a balanced hitting feel, critical for long-lasting play and reducing player fatigue.

The strategic use of composite materials allows manufacturers to fine-tune paddle performance based on specific player needs.

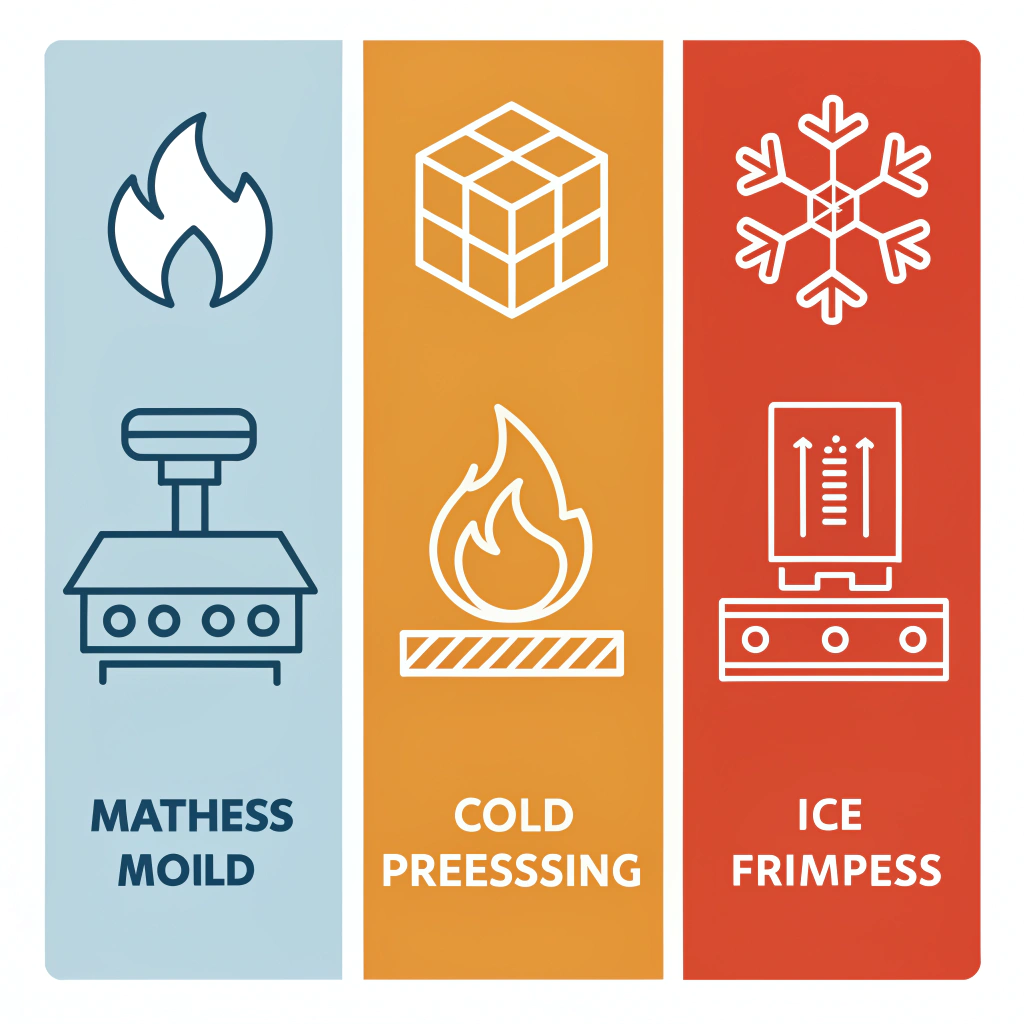

Advanced production techniques are pivotal in ensuring that the material benefits are fully realized. Three main production processes contribute to the final product’s quality:

Hot pressing involves heating the materials and applying pressure to mold them into the desired shape. This method is characterized by:

-

Advantages:

- High production efficiency suitable for large-scale output.

- Strong integration of materials providing excellent impact resistance.

- Enhanced structural integrity for high-performance play.

-

Disadvantages:

- Potential alteration of material properties, which can influence paddle feel.

- Requires significant investment in specialized equipment.

Cold pressing is the process of shaping paddle materials at room temperature using mechanical pressure. This method helps preserve the original properties of the materials, leading to:

-

Advantages:

- Precise control over thickness and structural integrity.

- Superior ball feel and responsiveness.

- Preservation of natural material characteristics.

-

Disadvantages:

- Longer production cycles compared to hot pressing.

- Necessitates high-precision equipment to maintain consistent pressure.

Thermoforming relies on heating materials to a pliable state and then forming them in molds to achieve complex designs and thickness variations.

-

Advantages:

- Ability to create intricate designs that maintain stability during play.

- Excellent distribution of material properties to enhance performance.

- Suitable for custom-made and premium paddle products.

-

Disadvantages:

- Increased production time and equipment costs.

- Best suited for high-end products where customization is key.

To provide a clear overview, the following table outlines the advantages and disadvantages of each method:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong product integrity, durable design | Possible material alteration, high equipment cost |

| Cold Pressing | Precise control, excellent ball feel, preservation of material properties | Longer production cycles, precision requirements |

| Thermoforming | Intricate design possibilities, consistent stability, custom options | Higher production time, cost overhead |

The careful selection of production processes is as critical as material choice. The best manufacturing approach addresses both performance objectives and cost efficiency, ensuring that the final paddle not only excels on the court but also meets market demands.

A successful pickleball paddle is the result of a synergistic approach that integrates both material characteristics and the chosen production process. Here is how these elements interact:

- Enhanced Power & Control: A combination of high-quality carbon fiber with precise cold pressing methods delivers a paddle that enhances player control while generating the necessary power for fast-paced games.

- Durability & Stability: Employing techniques like hot pressing can yield a robust paddle that withstands the rigors of competitive play. Durable composites and rigorous manufacturing protocols ensure that the paddle remains stable under high-impact situations.

- Customization & Ergonomics: Thermoforming allows manufacturers to tailor paddle designs for different grip sizes and ergonomic requirements. Custom options not only cater to player comfort but also provide branding opportunities for teams and sports organizations.

By balancing these factors, manufacturers can respond effectively to the needs of diverse market segments—from recreational players to elite competitors—ensuring that each paddle achieves high standards in performance and durability.

Strict quality control protocols underpin every stage of the paddle manufacturing process. At companies like NEX Pickleball, quality control is integrated throughout production to monitor and ensure that every paddle exhibits:

- Consistent Material Performance: Regular testing of carbon fiber, fiberglass, and composite materials to verify strength and flexibility.

- Optimal Production Settings: Continuous monitoring of parameters during hot pressing, cold pressing, and thermoforming to maintain production precision.

- Ergonomic and Performance Standards: Rigorous assessments to confirm that the finished paddle meets the desired ergonomic design, ensuring excellent grip and hitting feel.

These protocols are essential not just for maintaining quality, but also for building trust with B2B partners. Reliable quality control leads to products that consistently perform well, reducing the likelihood of returns and fostering repeat business.

For B2B buyers and product managers, several actionable insights emerge from our discussion:

- Evaluate Material Benefits: Consider the advantages offered by different materials such as carbon fiber variants and fiberglass. Their impact on rebound force, durability, and ball control can directly influence the paddle’s performance.

- Assess Production Methods: Understand the trade-offs between hot pressing, cold pressing, and thermoforming. Each method caters to different production needs and end-user requirements.

- Understand Customization Capabilities: Look for manufacturers who offer tailor-made options. Custom grips, weight distribution, and balance adjustments can significantly enhance a paddle’s market appeal.

- Focus on Quality Assurance: Prioritize suppliers with stringent quality control practices. This ensures that the paddles perform consistently under various playing conditions and withstand wear and tear.

- Leverage Data and Case Studies: Inquire about industry trends, production data, and real-world performance metrics. Evidence-based decisions can help justify investments and refine product strategies.

High-performance pickleball paddles are the culmination of precise material selection and advanced production processes. By focusing on the integration of carbon fiber, fiberglass, and composite materials with tailored production techniques like hot pressing, cold pressing, and thermoforming, manufacturers can deliver products that meet high performance, durability, and ergonomic standards.

B2B buyers should consider the following steps:

- Conduct a comprehensive evaluation of material properties and production processes.

- Collaborate with manufacturers like NEX Pickleball, who exemplify expertise and innovation in paddle design.

- Ensure rigorous quality control systems are in place to maintain consistency.

- Leverage customization options to target specific market segments and enhance product differentiation.

Ultimately, a well-informed decision on design impact and production methods leads to paddles that not only perform exceptionally on the court but also add tremendous value throughout the supply chain.

People Also Ask

Q1: How does material selection impact pickleball paddle performance?

A1: Material selection directly affects a paddle’s strength, weight, and vibration damping. Choosing between various carbon fiber types, fiberglass, or composite materials enables manufacturers to tailor performance for power, control, and durability.

Q2: What are the advantages of using different production methods in paddle manufacturing?

A2: Production methods like hot pressing, cold pressing, and thermoforming offer unique benefits. Hot pressing provides high efficiency and impact resistance, cold pressing allows for precise control and superior ball feel, and thermoforming enables complex designs and customizations.

Q3: Why is quality control essential in manufacturing high-performance pickleball paddles?

A3: Quality control ensures that every paddle maintains consistent material properties, precise construction, and ergonomic standards. This reliability minimizes performance variations and builds trust among B2B buyers and end-users.

-

Carbon Fiber: Reading this article will help you understand how carbon fiber’s high strength-to-weight ratio and versatile properties are leveraged in advanced paddle design and manufacturing. ↩

-

Fiberglass: Discover how fiberglass contributes to paddle performance by offering flexibility, improved ball control, and a wider sweet spot for enhanced play. ↩

-

Hot Pressing: Learn about hot pressing techniques that integrate materials under high pressure and temperature, ensuring durability and structural integrity in mass production. ↩

-

Cold Pressing: Explore the cold pressing method that preserves material properties and provides precise control over paddle design, resulting in superior ball feel. ↩

-

Thermoforming: Understand how thermoforming allows manufacturers to create complex, custom designs by heating and molding materials, offering unique advantages for high-end paddle products. ↩