Our factory meets urgent paddle orders through a streamlined production process, rigorous quality control, and flexible capacity management. This ensures fast turnaround times without compromising the performance and durability of our high-performance pickleball paddles.

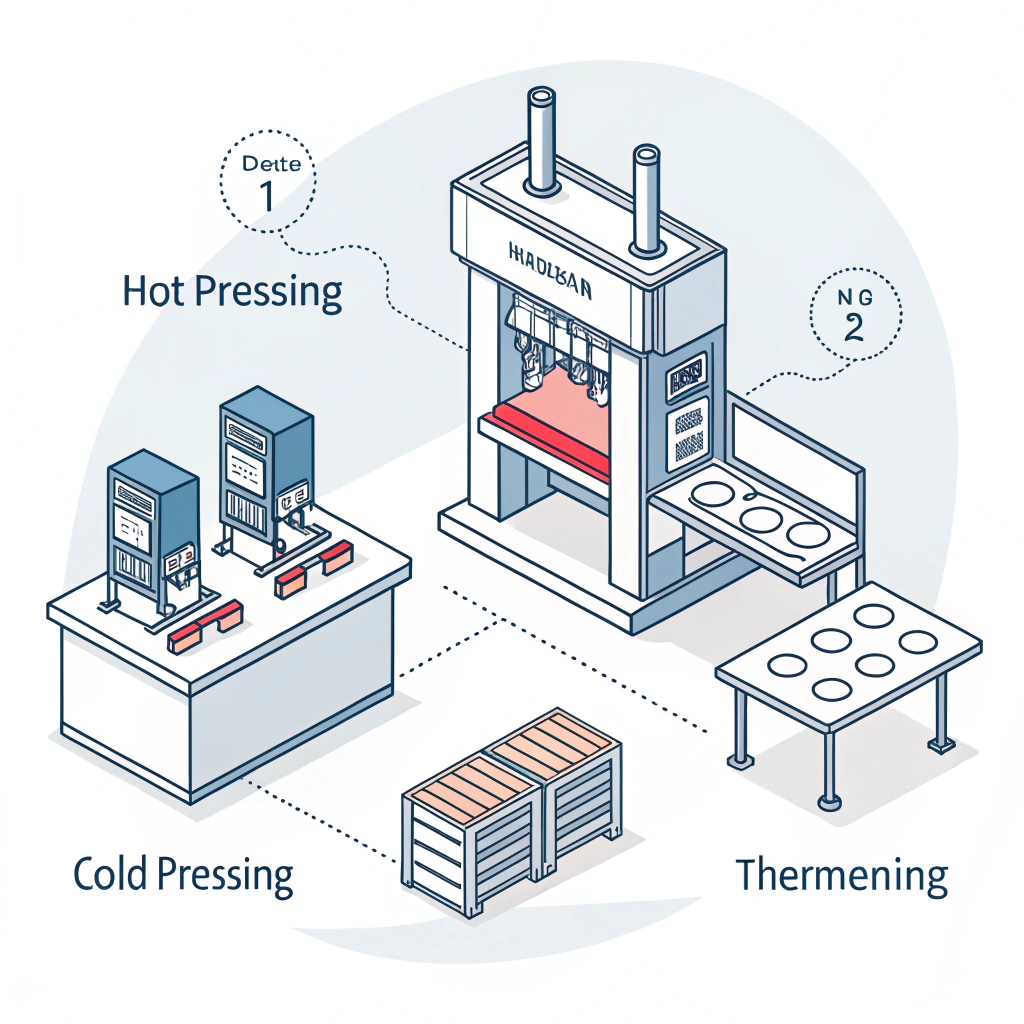

In today’s fast-paced sports equipment market, B2B buyers demand rapid responses and consistent quality. At NEX Pickleball, we have refined our production processes—hot pressing1, cold pressing2, and thermoforming3—to ensure that even urgent orders can be executed smoothly. Our robust quality control protocols and dedicated supply chain management enable us to meet high volumes, custom orders, and expedited deliveries with confidence.

For B2B operations managers and procurement specialists, the main challenge lies in balancing speed and quality. When large orders come in unexpectedly, it is essential to have:

• A well-organized supply chain capable of rapid scaling

• Streamlined production processes that maintain precision

• Rigorous quality checks that guarantee reliability

• Design flexibility to accommodate custom specifications

These factors are critical as delays or quality issues can have cascading effects on distributor and retailer schedules. Therefore, clear explanations of our production techniques, lead times, and capacity management are crucial for decision-making.

At NEX Pickleball, we use three main production processes to manufacture our paddles. Each process is chosen based on factors like targeted performance, material characteristics, and order urgency. Here, we breakdown each method:

Hot pressing involves heating materials and applying pressure to form the paddle. This process is ideal for producing highly durable paddles with excellent impact resistance.

Advantages:

- High production efficiency allows for large-scale manufacturing.

- Produces strong paddles with excellent shock absorption.

- Ensures structural integrity even under high demand.

Disadvantages:

- Can alter some material properties, slightly affecting the paddle’s feel.

- Requires significant investment in high-end equipment.

Cold pressing shapes the paddle material at room temperature under mechanical pressure. This method offers precise control over the paddle’s thickness and surface integrity.

Advantages:

- Maintains material properties to ensure superior ball control.

- Yields a consistent and ergonomic design, ideal for custom orders.

- Provides an excellent balance between precision and performance.

Disadvantages:

- Production cycles tend to be longer compared to hot pressing.

- Requires high-quality pressure control equipment to avoid inconsistencies.

Thermoforming involves heating the material until it softens and then shaping it using precise molds. This method is best suited for producing paddles with intricate designs and exact material distribution.

Advantages:

- Allows for detailed and complex designs to meet custom specifications.

- Maintains optimal stability and distribution of materials.

- Enhances the paddle’s performance by ensuring uniformity.

Disadvantages:

- Higher equipment costs and longer production times.

- More suitable for premium or custom product lines due to the complex setup.

The following table summarizes the key attributes of these three processes:

| Production Process | Advantages | Disadvantages | Best Used For |

|---|---|---|---|

| Hot Pressing | High efficiency, excellent impact resistance, structural integrity | Altered material properties, high equipment cost | High-volume orders requiring durability |

| Cold Pressing | Superior ball control, precise thickness control, ergonomic feel | Longer production cycles, high equipment precision required | Custom orders needing precision |

| Thermoforming | Intricate design capability, uniform material distribution, stability | High production cost, longer turnaround time | Premium and custom-designed paddles |

Quality control is fundamental to our manufacturing process. Every paddle undergoes rigorous testing at multiple stages to ensure it meets our high standards of strength, resilience, and feel. Key quality control measures include:

• Material Inspection: Each raw material batch is tested for consistency in strength and elasticity.

• Process Monitoring: Automated sensors and skilled technicians monitor temperature, pressure, and material distribution during each production stage.

• Post-Production Testing: Completed paddles are subject to performance tests such as vibration analysis, impact resistance, and durability checks.

• Final Assessment: Our quality assurance team inspects the paddles for any cosmetic defects and ensures all specifications are met before dispatch.

These steps not only maintain consistency but also allow us to identify any potential issues early in the production cycle to prevent delays or quality compromises. Continuous feedback from our testing protocols is used to refine our production techniques, ensuring that even under urgent manufacturing conditions, every paddle meets the high standards expected by our distributors and retailers.

When faced with urgent orders, a predictable challenge is capacity management—how to upscale without compromising the established quality. NEX Pickleball addresses this concern through several strategies:

-

Flexible Production Lines: Our advanced manufacturing facilities are equipped to switch between production methods (hot pressing, cold pressing, thermoforming) seamlessly. This ensures that order exigencies can be met without a slowdown in output.

-

Dedicated Expedited Order Teams: We have a team solely focused on handling high-priority and emergency orders. Their role is to adjust production schedules and liaise with the supply chain to secure necessary raw materials swiftly.

-

Technology Integration: Advanced ERP systems4 help track order progress and production timelines in real-time. This allows us to reallocate resources instantly when unexpected orders are received.

-

Scalability Measures: By maintaining close partnerships with trusted suppliers and investing in scalable production technologies, we ensure that our manufacturing capacity expands with demand.

-

Custom Order Flexibility: Custom paddle orders, including specific grip sizes or unique material combinations (such as Carbon Fiber and Fiberglass Composite or Bamboo Core Composite), are managed through a dedicated design and engineering unit. This unit works closely with B2B clients to tailor the product while keeping production timelines under strict control.

These measures ensure that even under high-pressure, urgent orders, we can deliver products on time—ensuring your supply chain runs smoothly and product availability meets market demand.

One illustrative case involved a major sporting goods distributor who needed a large shipment of custom-designed pickleball paddles for an upcoming regional tournament. With just under three weeks before delivery, the following steps were undertaken:

-

Initial Consultation: Our production team immediately assessed the design requirements, current production schedule, and raw material availability.

-

Process Adjustment: We shifted a portion of our production capacity from standard orders to expedited production, primarily using cold pressing to maintain material integrity for the unique design.

-

Enhanced Quality Checks: Additional quality assurance checkpoints were integrated to ensure that the sped-up process did not compromise paddle performance.

-

Supply Chain Coordination: Our real-time ERP system coordinated with our suppliers to secure premium materials—like 12K Carbon Fiber and Nomex Honeycomb Core5—at short notice.

-

Final Delivery: The order was completed on schedule, meeting the distributor’s urgent supply requirements without sacrificing the paddle’s performance or durability.

This example not only highlights our commitment to rapid delivery but also demonstrates our capability to manage custom orders at scale—a key assurance for any prospective partner.

For B2B buyers, the key message is clear: With NEX Pickleball, fast turnaround times, high quality standards, and flexible production systems go hand in hand. Our proven techniques in hot pressing, cold pressing, and thermoforming ensure that whether you are placing a standard or a custom order, you can trust in our ability to deliver high-performance paddles exactly when needed.

Actionable Recommendations for Procurement Managers:

- Evaluate your current supplier’s capacity and responsiveness.

- Consider partnering with manufacturers that use advanced production methods and robust quality control measures.

- Emphasize clear communication about order urgency and customization needs to ensure a seamless manufacturing process.

- Always plan for scalable production capabilities to manage future demand surges.

By aligning your supply chain strategies with a partner that understands the technical and logistical demands of high-performance equipment manufacturing, you can secure timely deliveries and uphold your market reputation.

How did pickleball get so popular so fast?

Pickleball’s rapid popularity can be attributed to its lighter equipment, easier on the body compared to tennis, and simple underhand serves. The low barrier to entry makes it accessible to players of all ages and skill levels.

What is the return policy for bread and butter pickleball?

For paddle orders placed with certain suppliers, a 30-day “Love it or Return it” policy is often in place, offering a full refund (minus shipping costs) if buyers are not satisfied with their product. However, policies vary by supplier and it is important to confirm the details with your chosen provider.

What are the illegal pickleball paddles?

Certain paddle models have been banned due to regulatory issues such as core thickness or surface texture that do not comply with standards set by pickleball authorities. For example, some ProKennex and JOOLA models have faced restrictions because they provided an unfair advantage or did not meet specific quality standards.

-

hot pressing: Reading this article will help you understand the process of applying heat and pressure to form materials for durable, high-impact products, and how it optimizes manufacturing efficiency. ↩ ↩

-

cold pressing: This resource explains how applying mechanical pressure at room temperature helps maintain material integrity and achieve precise product specifications essential for custom orders. ↩ ↩

-

thermoforming: Explore the thermoforming process to learn how controlled heating and molding can produce intricate designs and uniform material distribution in manufacturing. ↩ ↩

-

ERP systems: Learn about Enterprise Resource Planning (ERP) systems and their role in integrating and managing production, order tracking, and real-time resource allocation for streamlined operations. ↩ ↩

-

Nomex Honeycomb Core: Discover how Nomex Honeycomb Core technology provides a lightweight yet robust structure, enhancing the strength and durability of high-performance products in advanced manufacturing environments. ↩ ↩