Quick Answer: OEM partnerships1 in pickleball manufacturing drive innovation, improve product quality, and reduce risk through advanced production techniques such as hot pressing, cold pressing2 and thermoforming3. These collaborations enable businesses to leverage expert manufacturing processes and specialized materials like carbon fiber4 and fiberglass5 to create high-performance equipment tailored to competitive market demands.

Introduction

As the pickleball market continues to experience rapid growth, businesses are increasingly seeking ways to differentiate their products while ensuring the highest standards of performance and durability. OEM partnerships offer an effective solution by allowing companies to leverage expert manufacturing capabilities and advanced production techniques. In this article, we explore the advantages and challenges of forming OEM partnerships, with specific insights into production processes such as hot pressing, cold pressing, and thermoforming. Our discussion is aimed at business development managers, strategic procurement officers, and decision-makers in the sports equipment industry who are evaluating how these collaborations can spur innovation and enhance product quality.

Problem Description

The pickleball equipment market is highly competitive, marked by ever-evolving consumer preferences and technological advancements. Traditional manufacturing methods often fall short of meeting the dual demands of durability and precision performance required in modern sports. Many companies face challenges such as:

• Inconsistent product quality

• Limited customization options

• High production risks

• Balancing cost with performance

Many decision-makers find themselves in a dilemma when deciding whether to continue with in-house production or outsource to specialized OEM partners. The core challenge is not only achieving high-quality products but also maintaining competitive differentiation in a crowded market.

Cause Analysis

Several factors contribute to these manufacturing challenges:

- Rapid Technological Changes – As consumer expectations and technology evolve, meeting quality standards using traditional methods becomes increasingly difficult.

- Complex Material Requirements – High-performance pickleball paddles often use advanced materials like 3K carbon fiber, 12K carbon fiber, T300 carbon fiber, and various composite materials. Each type has distinct properties, making the manufacturing process more intricate.

- Pressure for Fast Production – High demand for quality products mandates fast production cycles, which conventional methods may not support efficiently.

- Inadequate Customization – The inability to offer a range of materials and grip designs limits product appeal and market differentiation.

These challenges necessitate a shift toward OEM partnerships that can provide expert production techniques and robust quality control.

Solution: OEM Partnerships to Enhance Pickleball Equipment Manufacturing

OEM partnerships offer a multi-faceted solution to the challenges faced in manufacturing high-performance pickleball paddles. The key advantages include:

-

Enhanced Innovation and Product Quality

Collaborating with a specialist OEM like NEX Pickleball provides access to advanced production processes. Technologies such as hot pressing, cold pressing, and thermoforming enable precise material manipulation and superior product performance. Innovative materials, for example, various forms of carbon fiber and fiberglass, are combined to deliver paddles that are both durable and high-performing. -

Streamlined Production and Cost Efficiency

OEM partners possess the infrastructure to manage large-scale production efficiently. This not only results in faster turnaround times but also in cost savings due to economies of scale. Strategic sourcing from established manufacturing bases, such as those in Jiaxing, Zhejiang, China, minimizes production risks and ensures timely delivery. -

Flexibility and Customization

OEM partnerships promote customization, facilitating tailored product designs that align with specific market needs. Clients can specify design parameters such as grip size, weight balance, and material composition. This level of customization is critical for businesses aiming to create a unique market presence.

Detailed Production Techniques Comparison

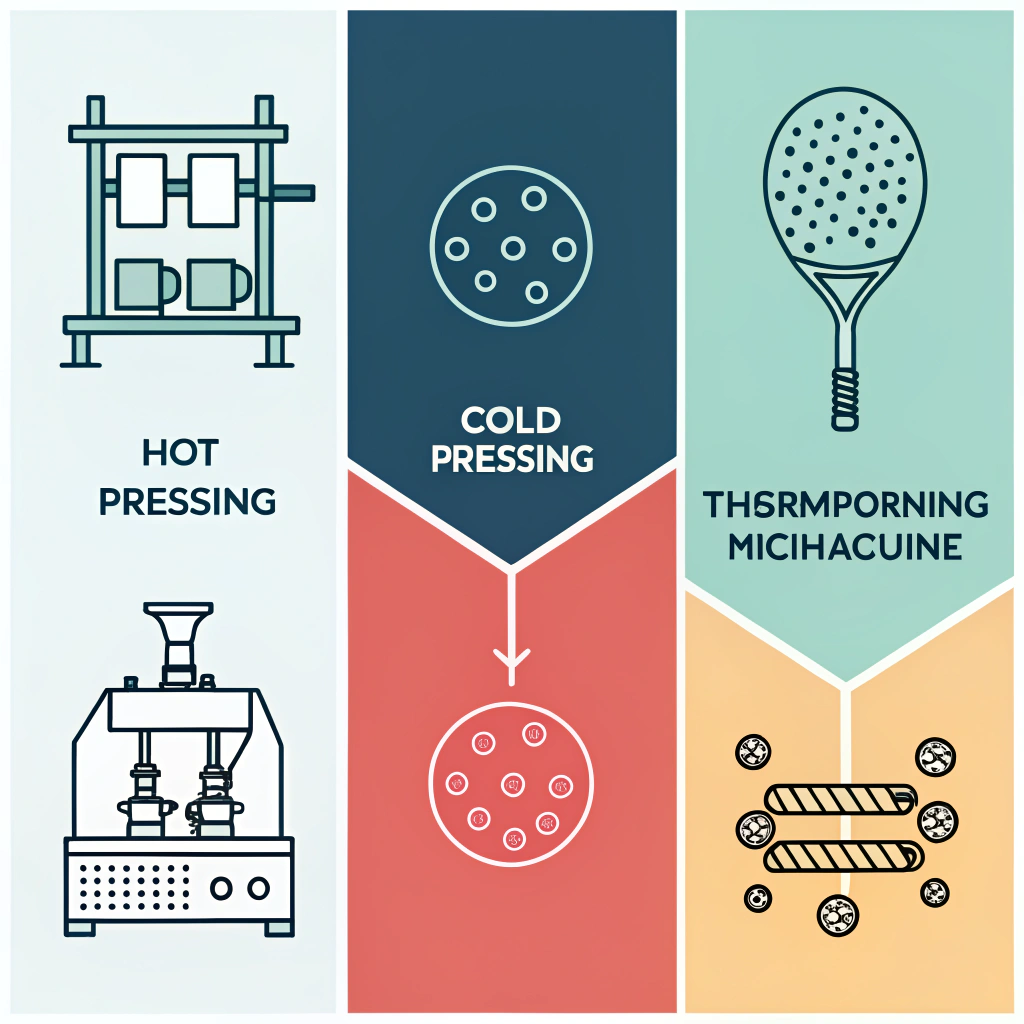

Understanding the specifics of manufacturing processes is pivotal for selecting the right OEM partner. Below is a detailed comparison of the three primary production methods used in high-performance pickleball paddle manufacturing:

| Production Method | Advantages | Disadvantages | Suitable For |

|---|---|---|---|

| Hot Pressing | • High production efficiency • Strong, durable paddles • Excellent impact resistance | • Equipment investment is high • Slight material property alteration | High-demand production requiring robust paddles |

| Cold Pressing | • Precise material control • Preserves material properties • Superior ball feel and responsiveness | • Longer production cycles • Requires high-quality pressure control | Products where precision and control are paramount |

| Thermoforming | • Intricate paddle designs • Precise material distribution • Enhanced product stability | • Longer production time • Higher equipment costs | Premium products with complex design requirements |

This table demonstrates the unique benefits and limitations of each method, offering clear insights into which production technique aligns best with your business needs.

Case Study: NEX Pickleball’s OEM Partnership Success

NEX Pickleball, as a leading manufacturer based in Jiaxing, Zhejiang, exemplifies the capabilities of an ideal OEM partner. With expertise in hot pressing, cold pressing, and thermoforming, NEX Pickleball consistently delivers products that merge cutting-edge design with superior performance. Here are some notable contributions from such an OEM partnership:

• Tailored Production: NEX Pickleball provides clients with the option to customize paddle specifications, enabling brands to create a distinct market identity.

• Quality Assurance: Every paddle undergoes rigorous testing to ensure it meets stringent standards for durability and control. This minimizes the risk of product failure, thereby enhancing brand reliability.

• Material Innovation: The skilled use of various carbon fiber types (3K, 12K, T300) and composite materials allows for the development of paddles that excel in both strength and performance. This has been instrumental in reducing vibrations and enhancing ball control across various levels of play.

• Efficiency in Scale: With a focus on scalable production methods such as hot pressing, NEX Pickleball ensures consistent product delivery even during peak demand periods.

Such case studies underline the effectiveness of leveraging OEM partnerships to achieve production excellence and market differentiation.

Implementation Guidelines: How to Successfully Establish an OEM Partnership

For companies considering OEM partnerships, it is essential to manage the transition strategically. Here is a step-by-step guideline to ensure a successful collaboration:

-

Evaluate Potential OEM Partners

Conduct thorough research on prospective OEM partners. Look for those with a strong track record in high-performance manufacturing, technological expertise, and robust quality control measures. -

Define Your Customization Needs

Clarify your product specifications including material preferences, gripping designs, paddle weight, and overall ergonomics. Open communication on these fronts will facilitate a tailored production process. -

Assess Production Techniques

Ensure that the OEM partner employs the most suitable production techniques—be it hot pressing, cold pressing, or thermoforming—for your product type. Understanding the pros and cons through detailed comparisons, as provided earlier, can guide your decision. -

Negotiate Terms and Pricing

Discuss pricing structures, production timelines, and quality assurance protocols. Transparent negotiations will lead to a partnership where both parties benefit, balancing cost efficiency with performance quality. -

Establish Quality Control Protocols

Strong quality control mechanisms are crucial. Regular inspections and performance tests should be agreed upon to maintain consistency in product quality. -

Develop a Long-Term Strategy

OEM partnerships are not one-off transactions. Develop a long-term strategic plan that allows for flexibility, scalability, and responsiveness to market changes. This can include periodic reviews and adjustments based on market feedback.

Table: Key Considerations for Assessing OEM Partners

| Consideration | Details |

|---|---|

| Technological Capabilities | Advanced production methods (hot pressing, cold pressing, thermoforming) |

| Material Expertise | High-performance materials like diverse carbon fibers and composites |

| Customization Options | Ability to meet personalized design requirements |

| Quality Control | Rigorous testing protocols and inspection standards |

| Scalability & Efficiency | High production efficiency and reliable delivery timelines |

Benefits for Strategic Procurement and Business Development

OEM partnerships not only elevate the manufacturing quality but also provide strategic advantages in sourcing and procurement. Here are the key takeaways:

• Risk Reduction: Outsourcing production to a proficient OEM partner reduces operational risks related to quality inconsistencies and production downtime.

• Enhanced Competitive Advantage: Leveraging innovative production techniques and materials, companies can differentiate their products, add unique features, and potentially command higher market prices.

• Cost Efficiency: Advanced manufacturing technologies allow for reduced material wastage and energy consumption, thereby lowering production costs in the long run.

• Market Responsiveness: Customizable production cycles make it easier to respond to market trends and consumer demands swiftly. Companies can launch new designs and iterate existing products faster.

• Improved Investment Decision Making: With clear insights into production quality, customization, and financial structuring, decision-makers are better equipped to assess ROI and long-term benefits.

By aligning with an OEM partner that uses cutting-edge techniques and maintains rigorous quality standards, companies can focus on strategic growth rather than daily manufacturing challenges.

Conclusion

In summary, OEM partnerships represent a strategic solution for sports equipment companies looking to innovate and improve product performance in the highly competitive pickleball market. By leveraging advanced production techniques such as hot pressing, cold pressing, and thermoforming, businesses can produce high-quality, customized equipment that stands out in the marketplace.

The combination of efficient production, access to premium materials, and robust quality control elevates product performance and reduces operational risks. As industries continue to evolve, establishing a reliable OEM partnership will be a key differentiator that fuels long-term business success and market leadership.

For decision-makers in the sports equipment industry, now is the ideal time to explore OEM partnerships and invest in innovative production technologies. Not only will this strategy enhance your product offering, but it will also provide a competitive edge in a rapidly transforming market landscape.

People Also Ask

Q: What are the main advantages of OEM partnerships in pickleball manufacturing?

A: OEM partnerships enhance innovation, improve product quality, and reduce production risks through access to advanced production techniques and robust quality control systems.

Q: How do production processes like hot pressing, cold pressing, and thermoforming benefit pickleball paddle manufacturing?

A: These processes offer unique benefits; hot pressing provides efficiency and durability, cold pressing ensures precise control and superior ball feel, while thermoforming allows for intricate designs and stable structure in premium paddles.

Q: What factors should be considered when evaluating an OEM partner for pickleball equipment production?

A: Key factors include technological capabilities, material expertise with high-performance components like various carbon fibers, customization options, quality control standards, and the partner's ability to scale production efficiently.

-

[OEM partnerships]: Click to learn how partnering with OEMs can drive innovation, enhance product quality, and reduce production risks through specialized manufacturing strategies. ↩ ↩

-

[cold pressing]: Click to explore how cold pressing preserves material properties and enables precise control, crucial for maintaining product quality in manufacturing processes. ↩ ↩

-

[thermoforming]: Click to understand thermoforming, a process that offers intricate design capabilities and precise material distribution to achieve premium product finishes. ↩ ↩

-

[carbon fiber]: Click to read about carbon fiber’s properties, its advantages in enhancing performance, and its applications in high-performance sports equipment. ↩ ↩

-

[fiberglass]: Click to discover the role of fiberglass in manufacturing, highlighting its durability and cost-effectiveness in the production of competitive sports equipment. ↩ ↩