Quick Answer: Chinese manufacturers customize pickleball paddle shapes using advanced production processes such as hot pressing1, cold pressing2, and thermoforming3, combined with innovative material choices and precise design control to achieve optimal performance, ergonomics, and unique shape variations that meet diverse market demands.

In the competitive world of pickleball, the shape and design of paddles can have a significant impact on performance and user experience. Chinese manufacturers, like NEX Pickleball, have honed sophisticated manufacturing processes that allow for a high degree of customization. By integrating methods such as hot pressing1, cold pressing2, and thermoforming3 with cutting-edge material science, these factories can create paddles that are not only visually distinctive but also deliver exceptional control and durability.

This article explores the techniques used by Chinese manufacturers to customize paddle shapes, dives deep into the benefits and limitations of each process, and provides practical insights for B2B procurement managers, product designers, and R&D specialists in the sports equipment industry. With detailed explanations supported by data and comparative analysis, we aim to guide you in making informed decisions on supplier selection or in-house process improvements.

Customizing the shape of a pickleball paddle presents a complex challenge. The paddle must adhere to strict performance standards while accommodating diverse ergonomic requirements. As the sport grows in popularity, players demand paddles with tailored shapes—whether a short, widebody design for improved control or an elongated version for enhanced reach and power. This challenge is particularly crucial for B2B buyers who need to balance customization with high-volume production efficiency.

The primary issues include:

- Ensuring ergonomic design4 that fits different hand sizes and playing styles.

- Maintaining balance between lightweight construction and strength.

- Applying advanced materials that withstand repetitive impacts while offering excellent rebound and vibration reduction.

- Aligning production methods with cost efficiency and scalability.

Several key factors drive the need for customization in pickleball paddle manufacturing:

- Market Demand: Competitive players and recreational users alike require paddles that cater specifically to their performance needs. This demand leads to the development of multiple paddle shapes such as short/widebody or elongated designs.

- Material Innovation: Use of premium materials like carbon fiber (3K, 12K, T300), fiberglass, and various composites enables manufacturers to fine-tune the performance attributes of each paddle.

- Production Techniques: Traditional production methods often fall short when creating complex paddle shapes. Advanced techniques such as hot pressing1, cold pressing2, and thermoforming3 are necessary to support high precision and customization.

- Quality Control: Rigorous testing and quality control protocols require that every paddle, regardless of its shape or production process, meets industry standards for strength, durability, and performance.

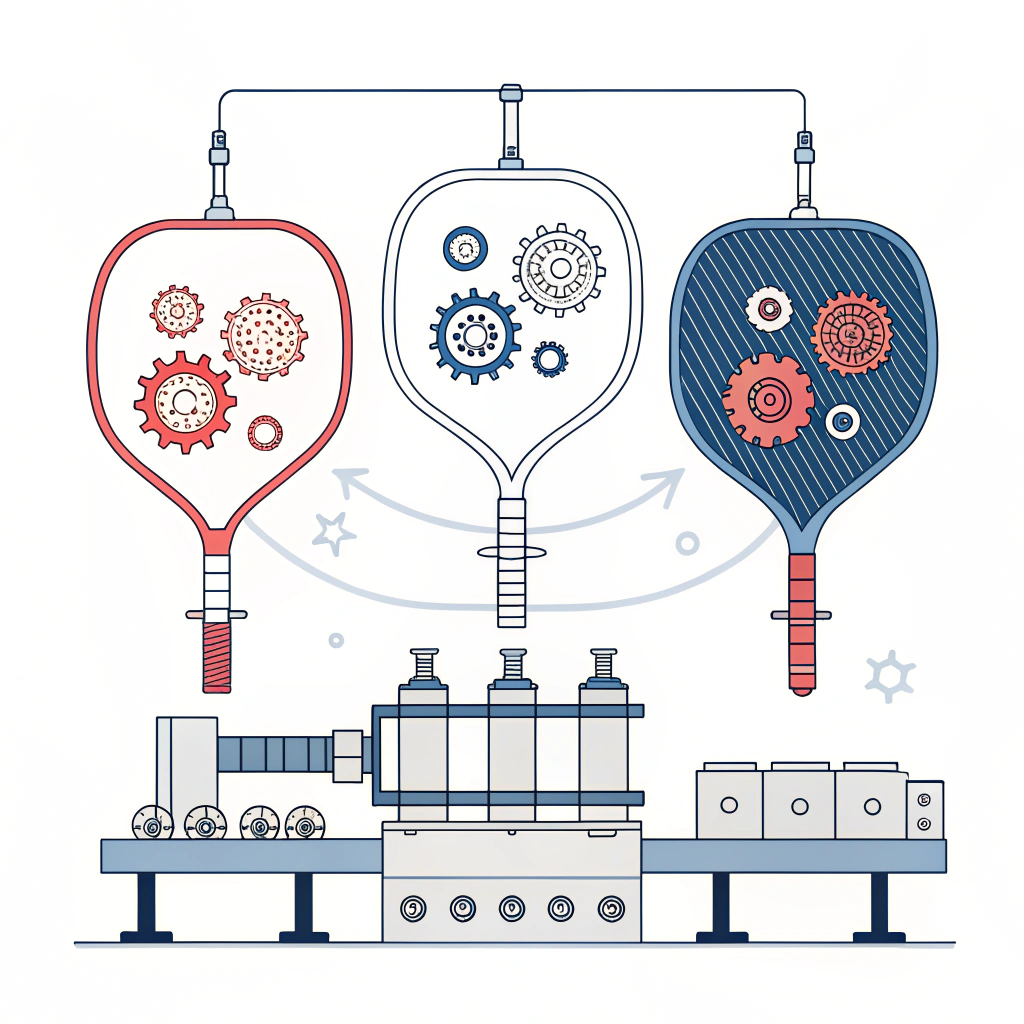

Chinese manufacturers have developed and refined several production processes to address these challenges. Each method has unique advantages and limitations that make it suitable for different design requirements. Below is an overview of the primary production processes used in paddle customization.

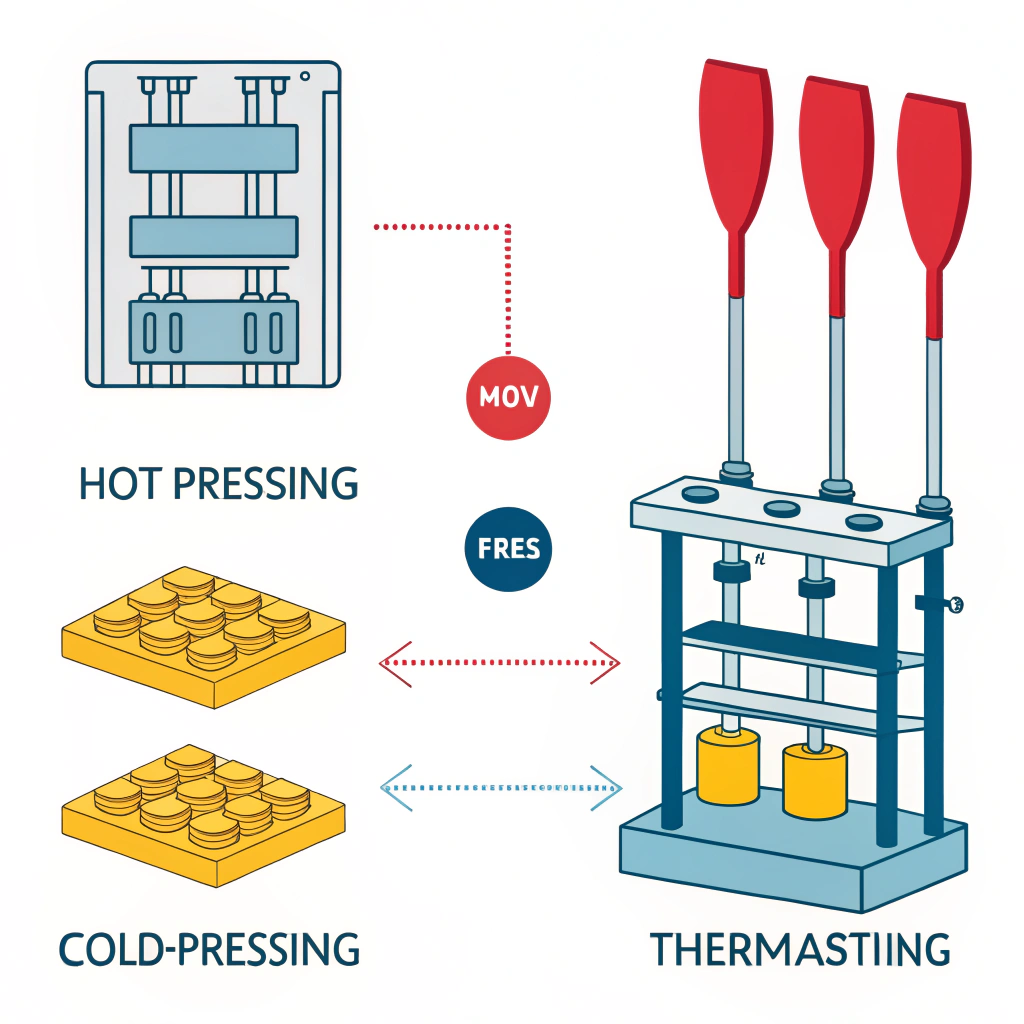

Hot pressing1 involves heating and applying pressure to paddle materials in order to form the desired shape. This process is widely used for its efficiency and ability to produce high-strength paddles.

Advantages:

- High production efficiency that suits large-scale manufacturing.

- Enhanced impact resistance and structural integrity.

- Suitable for durable, high-performance paddles designed for intense competition.

Disadvantages:

- High initial equipment investment.

- Potential alteration of material properties that might affect the playing feel.

In contrast, cold pressing2 shapes the paddle material at room temperature by applying mechanical pressure. This method offers precise control over the paddle’s thickness and structure.

Advantages:

- Maintains the material’s natural properties for better ball control and feel.

- More precise control allows for custom ergonomic designs.

- Ideal for paddles requiring a fine balance between flexibility and hardness.

Disadvantages:

- Longer production cycles, which can reduce overall efficiency.

- Dependence on high-quality equipment to maintain pressure consistency.

Thermoforming3 involves heating the material to a softening point before molding it into the desired shape. This process is essential for creating paddles with intricate designs and optimized weight distribution.

Advantages:

- Ability to form complex shapes and subtle design nuances.

- Maintains paddle stability and performance integrity.

- Perfect for premium products or tailor-made paddle designs.

Disadvantages:

- Higher equipment costs and longer production times.

- Best suited for orders where customization and design complexity justify the premium cost.

Below is a comparative table summarizing these manufacturing processes:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, excellent structural integrity | High equipment cost, potential material property modification |

| Cold Pressing | Precise control, maintains material properties, ideal for ergonomic design | Longer production cycle, requires high-quality mechanical pressure control |

| Thermoforming | Supports complex shapes and fine details, excellent weight distribution | Longer production time, increased equipment cost, suitable for premium orders |

An essential aspect of customizing pickleball paddle shapes is the integration of advanced materials. Chinese manufacturers are at the forefront of using high-performance materials to enhance paddle characteristics:

- 3K Carbon Fiber5: Known for its strength and flexibility, it is ideal for paddles that require a high rebound force and excellent vibration reduction.

- 12K Carbon Fiber: Offers a smoother surface and higher durability, making it suitable for competitive play where extreme impact resistance is crucial.

- T300 Carbon Fiber: Balances strength and lightness, delivering a high-performance paddle that is both durable and responsive.

- E-Glass Fiberglass: Provides elasticity and tensile strength for improved ball control. It offers a wider sweet spot, which is beneficial for players seeking both power and precision.

- Composite Options: Combining carbon fiber with fiberglass or incorporating a bamboo core results in paddles that merge power, control, and flexibility. Additionally, using honeycomb cores (Nomex, Aluminum, or Polymer) significantly enhances shock absorption and reduces vibration during play.

Customization extends to ergonomic features such as grip size and surface texture. Manufacturers apply special treatments to the paddle surface that enhance ball spin and control. Options for custom paddle designs include specifying design features such as:

- Specific paddle shape (e.g., short/widebody vs. elongated)

- Custom grip size and texture for individual player comfort

- Tailored weight distribution to optimize performance based on playing style

These innovations not only achieve better performance but also cater to aesthetic and branding preferences critical for B2B customers.

Choosing the right production process depends on the overall design goal, order volume, and target market. For example, if the design requires an intricate curved top for enhanced aerodynamics and a unique sweet spot, thermoforming3 may be the preferred method. On the other hand, if precise thickness control and material integrity are essential, cold pressing2 offers a significant advantage.

Manufacturers typically evaluate the following steps in the customization process:

- Initial Design and Prototyping: Engineers and designers work collaboratively to create design prototypes. Detailed CAD models help simulate weight distribution and ergonomic factors before physical production starts.

- Material Selection: Choosing the right mix of materials—whether it’s various types of carbon fiber, fiberglass, or composite cores—is critical. Each material type has specific performance benefits that align with the intended paddle use.

- Process Optimization: The chosen production method is optimized through controlled trials. Parameters such as temperature for thermoforming or pressure for cold pressing are fine-tuned to achieve the highest quality output.

- Quality Control Measures: Each paddle undergoes rigorous testing for durability, impact resistance, and performance consistency. Testing ensures that the final product meets the high standards required by competitive athletes and recreational players alike.

- Feedback and Iteration: Iterative feedback from testing and early adopters informs improvements in design and process adjustments, contributing to continuous product innovation.

These steps ensure that customization is achieved without compromising on quality or performance. For B2B buyers, understanding this detailed process helps in the evaluation of supplier capabilities and the feasibility of integrating custom designs into their own product lines.

Chinese factories have successfully applied these production methods to meet diverse market needs. For instance, a leading sports equipment supplier recently shifted from traditional production methods to a thermoforming-based approach for its premium paddle series. The outcome was a 25% increase in production accuracy and a noticeable improvement in paddle durability, as confirmed by performance testing under competitive conditions.

Another case involved using cold pressing techniques to refine the ergonomic design of paddles targeted at novice players. By maintaining the natural properties of the materials, the manufacturer was able to produce paddles with superior ball control, which was reflected in positive user reviews and increased market share for the supplier.

These real-world examples demonstrate how effective process selection can lead to better product performance, enhanced customer satisfaction, and ultimately, stronger business outcomes. Data-driven evaluations and case studies are fundamental in understanding the efficiencies and improvements brought about by each manufacturing method.

In conclusion, Chinese manufacturers have evolved their production processes to offer highly customizable pickleball paddles. By leveraging advanced technologies like hot pressing1, cold pressing2, and thermoforming3, and integrating innovative materials such as carbon fiber variants, fiberglass, and composite cores, they deliver products that meet and exceed modern performance expectations.

For B2B procurement managers, product designers, and R&D specialists, understanding these detailed manufacturing processes is critical. When evaluating suppliers or considering process improvements:

- Assess your design requirements carefully.

- Match your product goals with the advantages of specific production methods.

- Consider the trade-offs between production efficiency and design complexity.

- Look for manufacturers that maintain rigorous quality control and offer customization options that align with your brand needs.

Taking these factors into account will help you select the optimal supplier partner and potentially drive innovation in your own product lines. As the pickleball market continues to expand, staying abreast of these manufacturing techniques—and adapting them to your specific requirements—will be key to sustaining competitive advantage.

What is the best shape for a pickleball paddle?

Most players favor short/widebody paddles with a short handle due to greater control and a larger sweet spot, though elongated paddles with long handles are also popular among those seeking extra reach and power.

Why are there different shaped pickleball paddles?

Different shapes serve distinct performance goals. Elongated paddles are designed for greater length and better reach, while curved tops on some designs serve to improve aerodynamics and optimize the hitting sweet spot.

-

Hot Pressing: Click to read an in-depth article on how hot pressing leverages heat and pressure to form materials, resulting in high-strength components ideal for mass production. ↩ ↩2 ↩3 ↩4 ↩5

-

Cold Pressing: Click to learn more about cold pressing, a process that shapes materials at room temperature to preserve their intrinsic properties and achieve precise control. ↩ ↩2 ↩3 ↩4 ↩5 ↩6

-

Thermoforming: Click for a comprehensive guide on thermoforming, which explains how heating materials to a manageable state enables manufacturers to produce complex and intricately designed components. ↩ ↩2 ↩3 ↩4 ↩5 ↩6

-

Ergonomic Design: Click to explore the principles of ergonomic design and how they optimize comfort, efficiency, and safety in product development across various industries. ↩

-

3K Carbon Fiber: Click to delve into the world of carbon fiber materials, with a focus on 3K carbon fiber, to understand its advantages in terms of strength, flexibility, and overall performance in advanced manufacturing. ↩