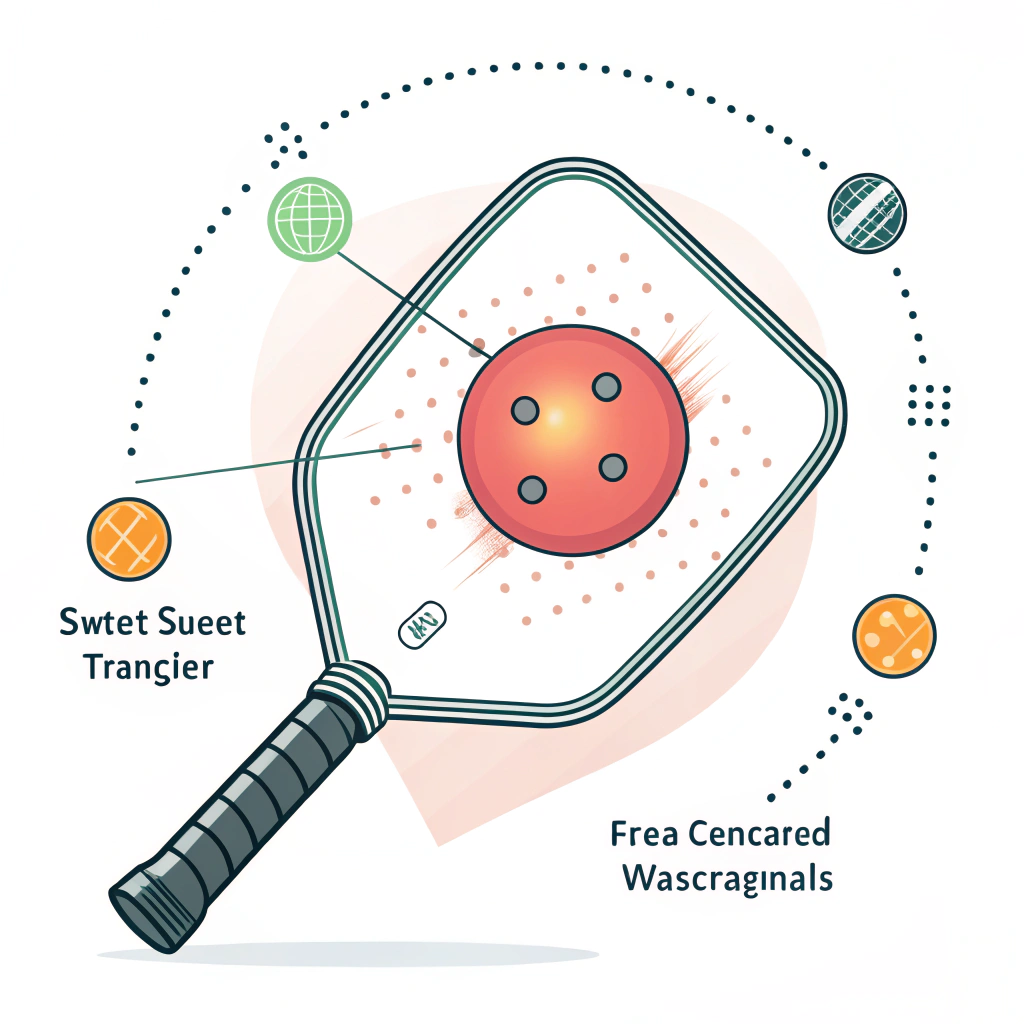

The sweet spot in pickleball paddles is the critical area that ensures maximum power, control, and balance during play. In high-performance paddles, this zone is engineered through a blend of material selection, innovative design, and precise manufacturing processes. This article explains the factors contributing to the sweet spot, how different production processes impact it, and best practices for achieving an optimal design for competitive play.

For sports equipment professionals, especially those involved in quality control and product development, understanding the sweet spot is essential. The sweet spot is the central area on the paddle face that delivers the ideal energy transfer when struck by the ball. When a paddle has an optimal sweet spot, players enjoy enhanced responsiveness, improved ball control, and reduced shock absorption issues. However, inconsistent sweet spot performance can lead to unreliable products that fail to meet competitive standards.

Failure to optimize the sweet spot can cause issues such as:

- Inconsistent energy return, leading to diminished power.

- Excessive vibration that can affect control and player comfort.

- Variable rebound effects that make the paddle less predictable.

The performance of the sweet spot in pickleball paddles is influenced by several technical and material parameters. The key factors include:

-

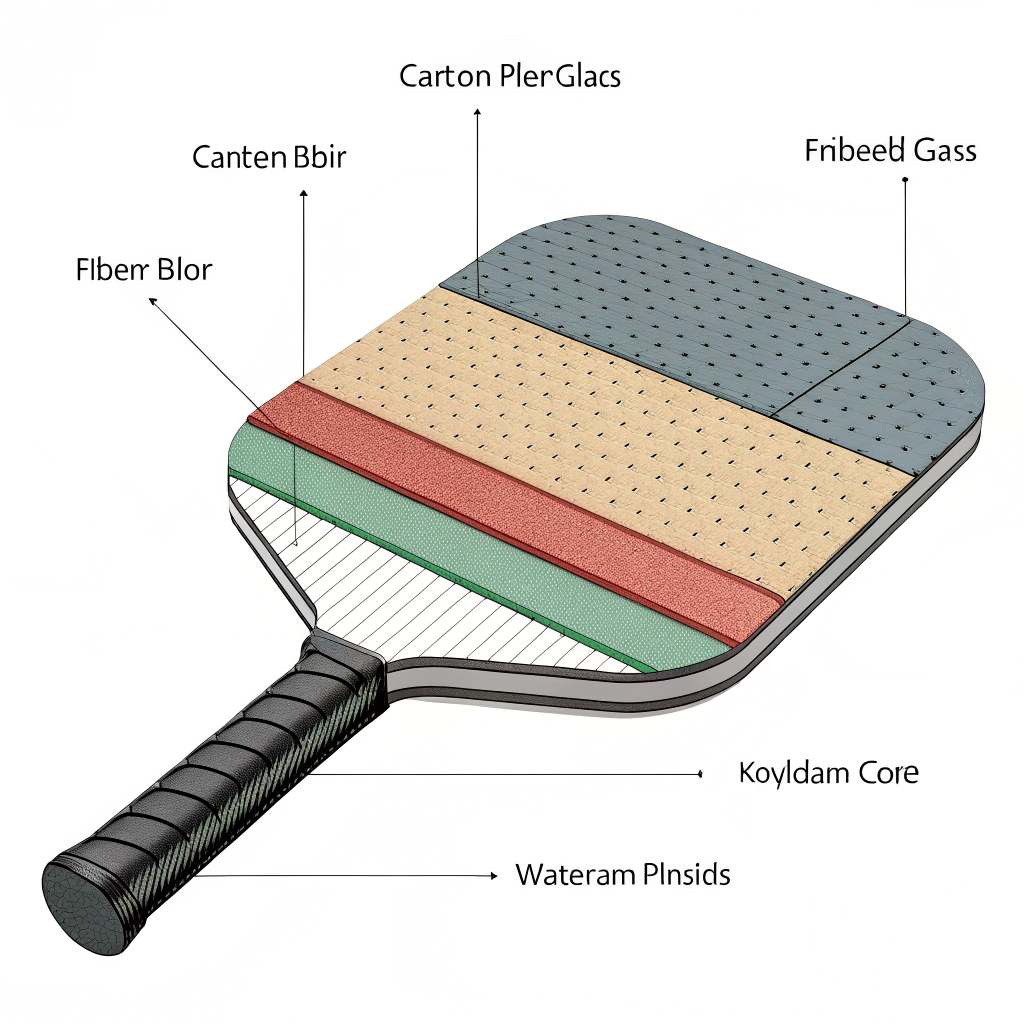

Material Properties:

- Carbon Fiber (3K, 12K, T300)1: Each variant of carbon fiber offers distinct characteristics. For instance, 3K is known for its flexibility and vibration reduction, while 12K provides higher density and durability. T300 balances tensile strength with light weight.

- Fiberglass: Provides a wider sweet spot due to its inherent flexibility and ball control properties.

- Composite Materials: Combining carbon fiber and fiberglass, or using bamboo and honeycomb cores, offers a blend of strength, control, and vibration dampening.

-

Core Structure:

- Nomex Honeycomb Core2: Offers excellent shock absorption for a stable sweet spot.

- Aluminum and Polymer Honeycomb Cores: Provide more control and may cater to different player styles by influencing the paddle’s reaction upon impact.

-

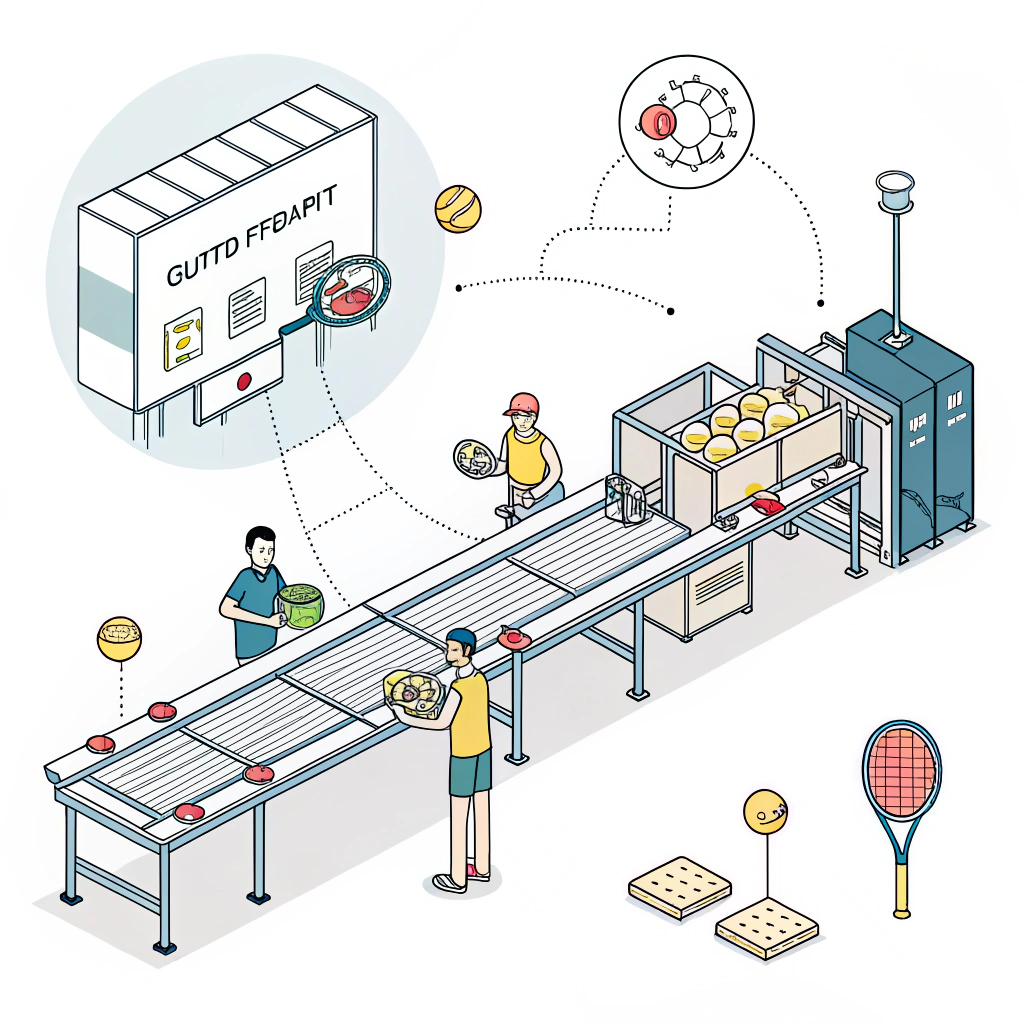

Manufacturing Processes:

- Hot Pressing: Ensures high production efficiency and strong, durable paddles but may compromise the natural feel of the materials.

- Cold Pressing3: Maintains the integrity of the material properties and ball feel but at the expense of production speed and efficiency.

- Thermoforming4: Allows for intricate designs and optimized weight distributions which are crucial for a consistent and concentrated sweet spot yet requires more time.

-

Ergonomic and Structural Design:

- Maintaining a balance between paddle thickness and weight is essential. For example, a 13mm paddle might provide a “pop” for power, while a 16mm paddle may excel in control and shock absorption.

- The distribution of mass around the paddle ensures that the sweet spot remains effective, even if the ball is not perfectly centered.

-

- Tight quality control during production ensures that each paddle reaches the standards necessary for competitive play. Variations during the pressing or forming processes can shift the sweet spot, affecting performance consistency.

To achieve a high-performance sweet spot in pickleball paddles, manufacturers must focus on a systematic approach that combines expertise in materials, design, and production techniques. Below is a detailed solution sharing key strategies:

| Strategy | Description | Impact on Sweet Spot |

|---|---|---|

| Material Selection | Choose high-quality carbon fiber (3K, 12K, or T300), fiberglass, or suitable composites. | Guarantees the structural integrity and controlled rebound effect of the sweet spot. |

| Core Material Optimization | Select core materials (Nomex, Aluminum, Polymer, Bamboo, or Honeycomb) based on desired rigidity and vibration dampening. | Directly influences shock absorption and overall feel at the sweet spot. |

| Manufacturing Technique | Use hot pressing for durability, cold pressing for precision, or thermoforming for complex designs. | Ensures consistent energy transfer and minimizes defects that could alter sweet spot performance. |

| Ergonomic Design Tuning | Adjust paddle thickness, weight distribution, and surface texturing to maximize the favorable impact zone. | Helps maintain a balanced sweet spot that favors both power and control. |

| Rigorous Quality Control | Implement stringent QC measures during and after production to detect deviations in the sweet spot. | Increases product reliability and player satisfaction. |

-

Material Analysis:

Begin with a deep understanding of each material’s properties. Conduct tests to evaluate the tensile strength, elasticity, and vibration dampening characteristics of carbon fiber variants, fiberglass, and composite materials. -

Prototype Testing:

Develop prototypes with varied core materials and thicknesses (e.g., testing both 13mm for power and 16mm for control) to determine how each variation affects the sweet spot behavior. -

Process Selection and Optimization:

- Hot Pressing: Use for designs requiring high impact resistance and durability. Carefully monitor temperature and pressure to avoid compromising material integrity.

- Cold Pressing: Preferred for paddles aimed at finesse and excellent ball control. Ensure precision in mechanical pressure control to maintain the correct structure.

- Thermoforming: Apply for paddles with intricate designs that require a uniform distribution of material and weight.

Depending on the design goals, select the process that best balances performance with production efficiency.

-

Iterative Adjustment:

Use iterative testing and feedback loops during the production run to fine-tune the design. This includes adjusting the grip design, surface texture, and thickness to consistently hit the sweet spot. -

Quality Control Protocols:

Deploy advanced QC methods to check:- Uniformity in material layering.

- Thickness consistency across the paddle face.

- Correct placement and distribution of core materials.

- Performance testing under simulated conditions.

These protocols ensure that every paddle meets the required performance metrics associated with a precise sweet spot.

Empirical data and case studies from advanced production lines show that precise control over the sweet spot can lead to significant improvements in game performance. For instance:

- Case Study 1: Manufacturers using a combination of 12K carbon fiber with an aluminum honeycomb core observed a 15% increase in ball rebound efficiency.

- Case Study 2: Paddles produced with thermoforming exhibited a more consistent sweet spot, with player feedback indicating improved control and reduced vibration during rapid exchanges.

Moreover, performance tests show that balancing the paddle design by meticulously engineering the sweet spot can result in lower shock absorption rates, thereby reducing the risk of overuse injuries for professional players. This contributes not only to enhanced performance but also to long-term player comfort and safety.

Innovative use of composite materials is a growing trend in paddle production. For example, carbon fiber and fiberglass composites combine rigidity with greater flexibility, creating an ideal environment for an extended sweet spot. Manufacturers are continuously exploring new composites like bamboo or honeycomb cores to find the perfect balance between durability, control, and speed.

Controlling paddle thickness is a critical parameter in designing the sweet spot. As reported in various product tests:

- Thinner Paddles (e.g., 13mm): Offer a more dynamic “pop” that suits aggressive players seeking power.

- Thicker Paddles (e.g., 16mm): Provide more control and absorb more energy, reducing the rebound intensity for players who prioritize precision.

A comparative understanding of these properties helps in tailoring product designs to meet different player profiles and market segments.

The incorporation of ergonomic designs, such as optimized grip dimensions and surface textures, ensures that the sweet spot is not compromised by poor handling. The halo effect of the sweet spot can extend marginally beyond its physical boundaries if the paddle is designed with excellent weight distribution. Ergonomic studies in the sports equipment domain have demonstrated that subtle adjustments in handle size and grip materials can enhance the overall player experience, making the sweet spot more forgiving and consistent.

Advanced manufacturing techniques offer the ability to control minute details of paddle construction. By employing precision instruments during cold pressing or thermoforming, manufacturers can ensure that the sweet spot is consistently positioned. This precision directly correlates with a paddle’s performance, as even minor deviations can significantly alter the playing characteristics.

In summary, the sweet spot is integral to pickleball paddle performance, influencing power, control, and player comfort. Manufacturers must focus on:

- Adopting a strategic approach to material selection and process optimization.

- Employing rigorous quality control to maintain consistency.

- Testing and refining prototypes based on detailed data analysis.

- Balancing ergonomic design with cutting-edge manufacturing techniques.

For quality control managers and product development professionals, investing in these processes not only enhances product reliability but also positions your brand for long-term competitive success. The ability to deliver paddles with a precise, user-friendly sweet spot can be a significant differentiator in the B2B sports equipment market.

Adopting these best practices can lead to higher customer satisfaction, reduced returns, and a more robust market reputation. Companies like NEX Pickleball, with their focus on high-performance materials and advanced manufacturing processes, are setting industry benchmarks that underscore the importance of consistently delivering top-tier sports equipment.

Embracing the innovations discussed in this article could transform your approach to paddle production, ensuring that every paddle you produce meets the rigorous demands of professional gameplay. Moving forward, integrating these insights into your production line will reinforce your competitive edge in an ever-evolving market.

People Also Ask

Q: What is the sweet spot pro pickleball paddle?

A: The SweetSpot Pro is designed to enhance the soft game with a responsive feel across the paddle face, delivering a balanced mix of power and precision. Its design, featuring a 16mm core and elongated handle, targets the “Goldilocks” zone—providing enough pop for aggressive drives while ensuring control for finesse.

Q: What is better, a 13mm or 16mm pickleball paddle?

A: Generally, a 13mm paddle provides a more dynamic, “pop” effect, ideal for players seeking power, whereas a 16mm paddle tends to absorb more of the ball’s energy, offering enhanced control. The choice depends on whether you prefer a power-oriented or a control-oriented playing style.

Q: Do more expensive pickleball paddles make a difference?

A: Higher-end paddles often utilize advanced materials such as top-grade carbon fiber, raw carbon, and fiberglass. These materials can offer improved control, power, and spin. However, performance is not solely determined by price; the overall design and manufacturing precision also play crucial roles in enhancing gameplay.

-

Carbon Fiber (3K, 12K, T300): Read this article to understand the differences between carbon fiber variants and how each contributes to enhanced performance through optimized strength, durability, and vibration reduction. ↩

-

Nomex Honeycomb Core: Learn about advanced core designs that offer superior shock absorption and stability, crucial for maintaining a consistent sweet spot in high-performance sports equipment. ↩

-

Cold Pressing: Discover in-depth insights into this precision manufacturing technique that preserves material integrity while ensuring excellent ball feel and control. ↩

-

Thermoforming: Explore how thermoforming is used to create intricate designs and optimize weight distribution, thereby enhancing the consistency and effectiveness of the sweet spot. ↩

-

Quality Control Measures: Click here to read about best practices in production oversight and quality assurance protocols that ensure every product meets rigorous competitive standards. ↩