Automation in Pickleball Production1 is revolutionizing manufacturing by leveraging advanced processes such as hot pressing, cold pressing, and thermoforming. These methods not only elevate production efficiency but also ensure industry-leading quality control and performance consistency for high-performance paddle manufacturing.

In today’s competitive sports equipment market, manufacturers must continuously innovate to meet consistently rising demand for superior products. The traditional production models are increasingly challenged by manual-intensive processes, inconsistent quality levels, and extended production cycles—all factors that slow down supply chains and elevate costs. With the emergence of automation technologies in Pickleball Production, companies gain a significant competitive edge by streamlining production processes and enhancing product performance.

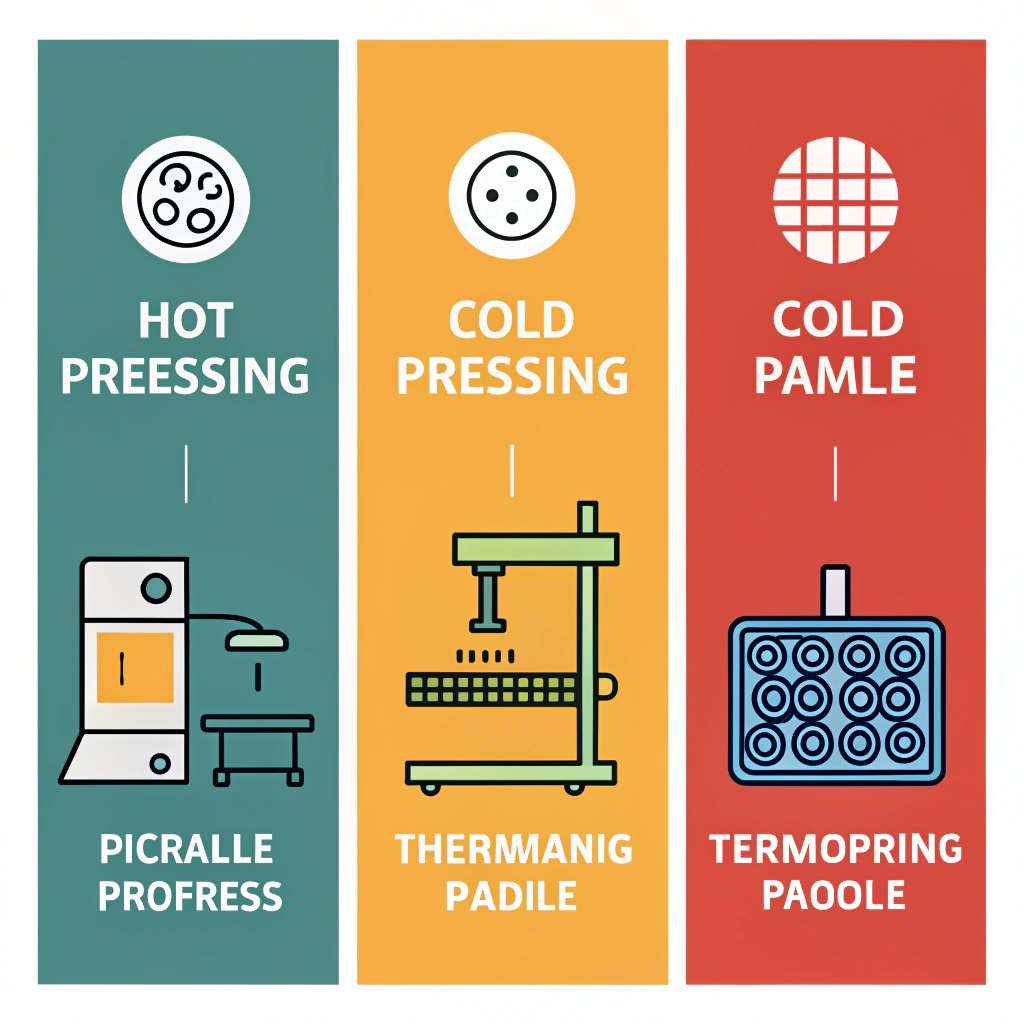

One of the major challenges faced by manufacturers is achieving precise control over paddle design and material integrity. For instance, the three primary production techniques employed by top-tier manufacturers such as NEX Pickleball include Hot Pressing2, Cold Pressing3, and Thermoforming4. Each process contributes uniquely to the final product’s attributes:

• Hot Pressing allows materials to be molded under high pressure and heat, ensuring strong structural integrity and high impact resistance, though it may sometimes alter the material’s natural feel.

• Cold Pressing preserves essential material properties by shaping products at room temperature, yielding better control and improved ball feel.

• Thermoforming brings versatility, capable of producing complex designs with precise material distribution, albeit with longer cycle times.

These processes reflect a broader shift towards smart manufacturing where automation plays a crucial role in reducing human error, ensuring consistency, and enhancing performance across every paddle produced.

The selection of specific manufacturing processes must align with both the production requirements and the performance attributes sought by the end-user. The strategic integration of advanced materials—ranging from various types of Carbon Fiber (3K, 12K, T300) to Fiberglass and composite materials with specialized cores—further supports product innovation. For instance, using a composite of carbon fiber and fiberglass can balance strength with lightweight performance, ideal for competitive play.

Consider the following table which outlines the key elements of the three major production processes:

| Process | Advantages | Disadvantages | Ideal For |

|---|---|---|---|

| Hot Pressing | High production efficiency; strong, durable paddles; structural integrity | May alter material properties; high equipment investment | Mass production of high-strength paddles |

| Cold Pressing | Precise thickness control; preserves material properties; excellent ball feel | Longer production cycles; requires precise pressure control | Customized paddle feel and precision |

| Thermoforming | Creates intricate designs; precise material distribution; stable product performance | Longer cycle time; higher equipment costs | Premium, complex paddle designs |

This overview not only reveals the inherent trade-offs of each method but also underscores why manufacturers are increasingly incorporating automation to optimize these processes for better quality control and efficiency.

The automation leap in Pickleball Production brings several key benefits beyond just production speed. Automated systems deliver enhanced reproducibility and precision by strictly controlling parameters such as temperature, pressure, and timing. With advanced robotics and computerized monitoring systems in place, manufacturers can consistently produce paddles that meet the stringent demands of competitive play.

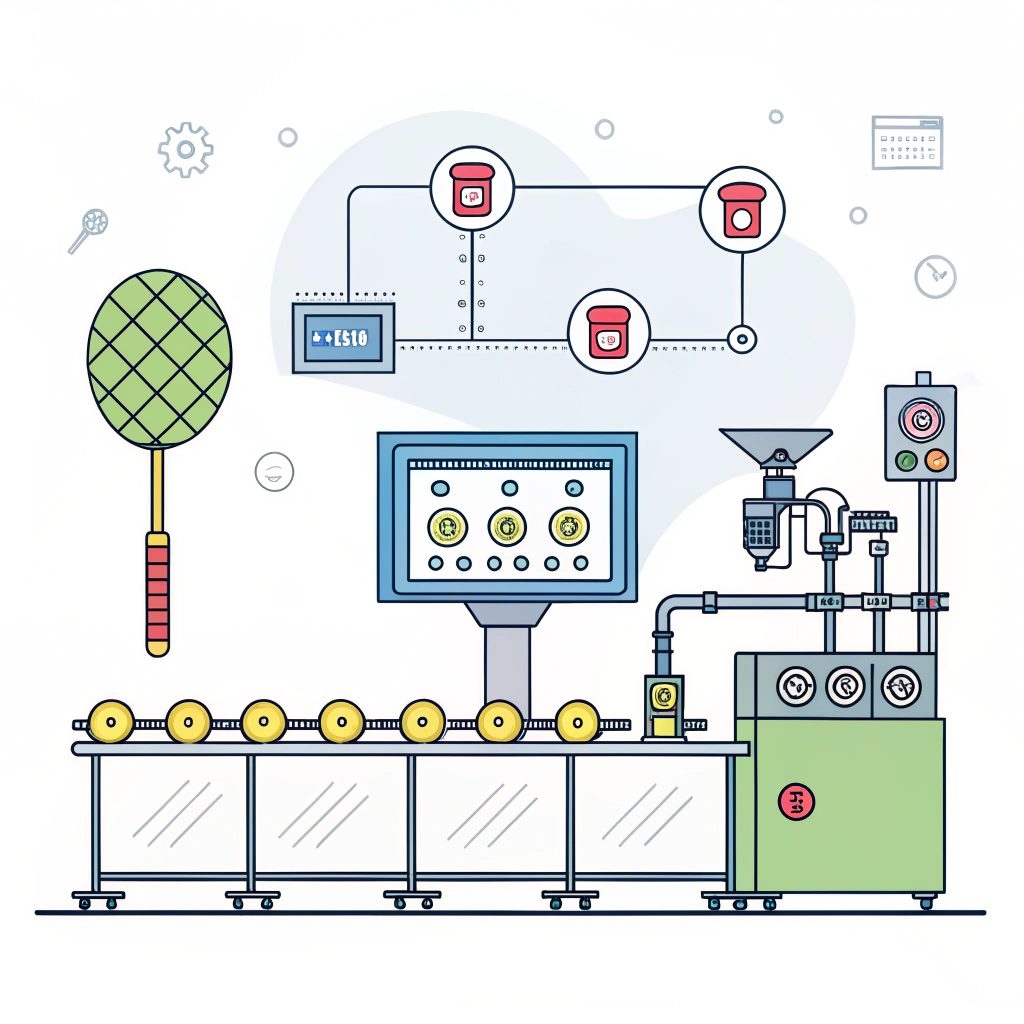

Automation also paves the way for real-time quality control. Sensors integrated within the production lines monitor the properties of advanced materials such as 3K Carbon Fiber and Nomex Honeycomb Core5, enabling immediate adjustments before the product reaches the final assembly stage. This not only minimizes waste but also significantly reduces the cost per unit by limiting the occurrence of defects and rework cycles.

Moreover, linking automation with digital manufacturing methods allows real-time data capture and analysis. This digital insight empowers manufacturers to optimize their supply chain management, monitor production trends, and predict maintenance needs to avoid downtime. The result is a coherent, end-to-end production system that boosts both operational efficiency and product quality.

Increasing automation in manufacturing processes has also directly impacted the supply chain dynamics. For sourcing managers and operations directors, this means enhanced transparency and predictability in production cycles—a critical factor when planning for seasonal demand fluctuations. Automated systems can provide detailed performance metrics, from the energy consumption of each process to the exact output rate per production line, ensuring that capacity planning is both data-driven and aligned with market needs.

Furthermore, the controlled environment of automated production allows manufacturers to experiment with new materials and designs on a smaller scale, refining their products before a complete rollout. This agile production approach guarantees that innovations—such as custom paddle configurations and on-demand print services—are quickly tested, validated, and scaled, reducing both risk and time-to-market.

At NEX Pickleball, our journey toward integrating expansive automation started with recognizing the limitations of manual telescoping methods in paddle production. By investing in cutting-edge machinery for Hot Pressing, Cold Pressing, and Thermoforming, we have not only streamlined our operations but also maintained the highest standards of product performance and durability. Rigorous testing protocols and quality assurance measures are embedded throughout our automated production lines. This ensures that every paddle delivered meets the heavy demands of top-tier competition and everyday recreational use.

Moving forward, manufacturers across the sports equipment industry are expected to further embrace automation solutions. The integration of emerging technologies such as artificial intelligence (AI) and the Internet of Things (IoT) will likely polish production cycles even more, offering predictive analytics to preempt manufacturing defects and further enhance operational throughput. For companies looking to optimize production processes, the path is clear: embracing automation is not merely a technical upgrade—it’s a strategic imperative.

When planning the implementation of automation in production, it is critical to account for certain operational constraints:

• Capital Expenditure: Advanced machinery and control systems require significant upfront investment. However, the long-term reduction in operating costs and improved product reliability often justify these expenses.

• Skill Development: Operating and maintaining automated systems demands specialized knowledge. Training programs and technical support become essential for maximizing the benefits of automation over time.

• Customization Versus Standardization: While automation enhances consistency, companies must balance this with the ability to offer customized solutions for unique market segments. Leveraging flexible automation setups can help bridge this gap by accommodating individualized customer requirements.

• Integration with Existing Processes: For companies transitioning to automated production, the interoperability of new systems with legacy operations is often a concern. Careful planning and phased implementation can mitigate potential disruptions during the transition phase.

To assist in the decision-making process, companies can adopt a systematic approach to evaluating automation technologies. This might involve a detailed audit of current production lines, pilot testing of automated processes, and rigorous cost-benefit analyses to forecast potential operational improvements and savings.

In summary, automation in Pickleball Production is not just about replacing human labor with machines; it’s about fundamentally transforming how products are conceived, produced, and delivered. Automation bridges the gap between traditional production limitations and the current demand for high-performance, reliable sports equipment. As manufacturers continue to adopt automated processes, they can expect not only improved efficiency and quality but also a more agile and responsive production system capable of rapidly advancing innovation.

For sourcing managers and operations directors, understanding these technological advancements is critical. The integration of hot pressing, cold pressing, and thermoforming in an automated production environment offers robust operational advantages, elevating production standards and setting new benchmarks in quality control. By focusing on data-driven decision-making and continuous improvement, companies can optimize their manufacturing processes to better serve a global market characterized by intense competition and evolving consumer expectations.

People Also Ask

Q: Is pickleball growing in China?

A: Yes, pickleball is gaining traction in China, following trends seen in the United States. While traditionally a lesser-known sport, several Chinese cities have started embracing pickleball, with some even adopting the title of "pickleball city."

-

Pickleball Production: Click to learn how the production and automation of pickleball equipment are transforming manufacturing processes, enhancing product quality and efficiency. ↩ ↩

-

Hot Pressing: Click to explore the benefits and challenges of hot pressing techniques in manufacturing, including its impact on material properties and product durability. ↩ ↩

-

Cold Pressing: Click to understand cold pressing technology, its role in preserving material integrity, and its advantages for customized production. ↩ ↩

-

Thermoforming: Click to delve into thermoforming processes, covering its capacity for intricate design creation and material distribution challenges. ↩ ↩

-

Nomex Honeycomb Core: Click to read about Nomex Honeycomb Core, its applications in high-performance composite structures, and how it contributes to lightweight yet robust designs. ↩ ↩