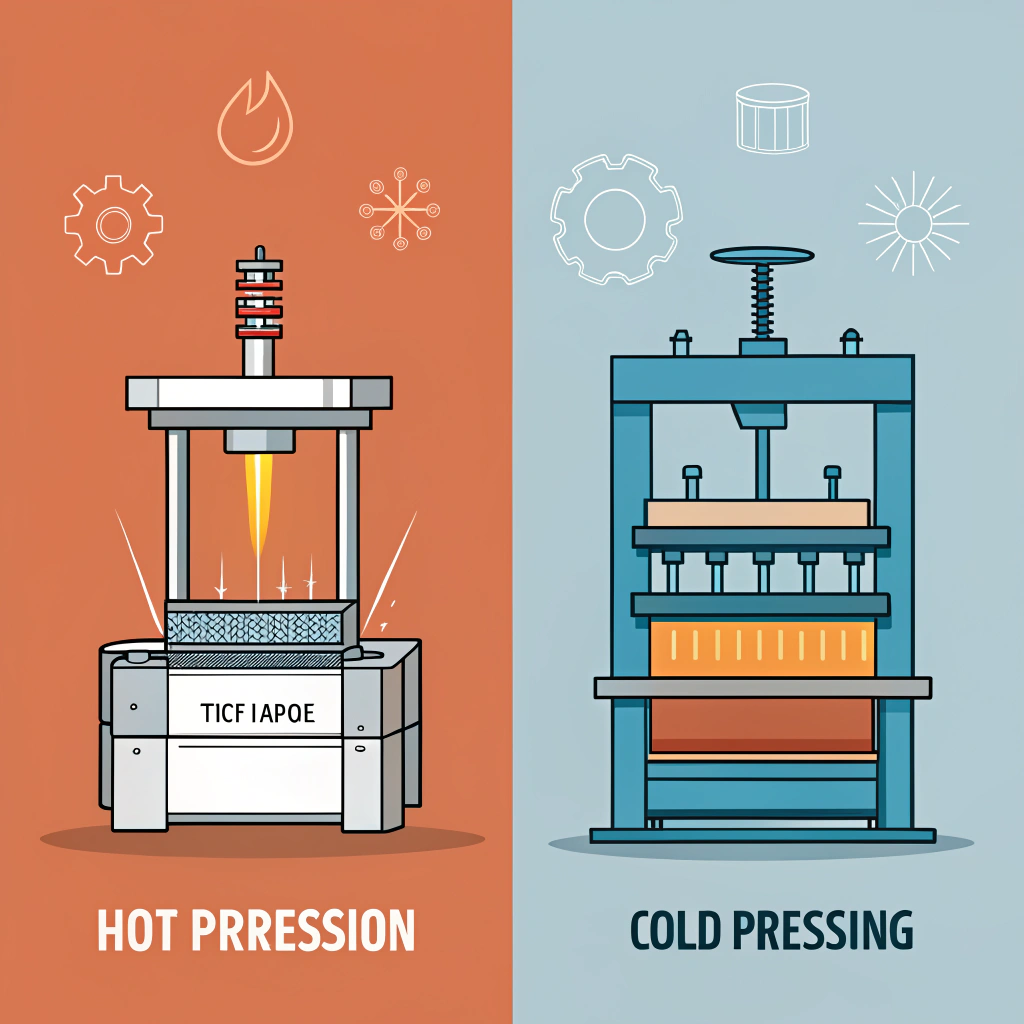

In short, hot pressing1 offers high production efficiency and improved impact resistance2 for high-performance pickleball paddles, while cold pressing3 provides exceptional control over material properties, resulting in a paddle with a more authentic feel and flexibility. Selecting the right method depends on your production priorities and the specific performance attributes you require for your product line.

In the competitive world of pickleball equipment manufacturing, the choice of production process can significantly influence not only the product quality but also the overall manufacturing efficiency and cost-effectiveness. For B2B procurement managers and product development professionals, understanding the nuanced differences between hot pressing and cold pressing is essential for optimizing paddle performance and meeting market demands.

At NEX Pickleball, where we specialize in advanced manufacturing techniques and quality assurance, we continuously assess how each production process affects paddle durability, material properties, and overall performance. This article provides a comprehensive comparison of hot pressing and cold pressing methods, offering practical insights, data-supported analysis, and clear recommendations to help you make well-informed procurement decisions.

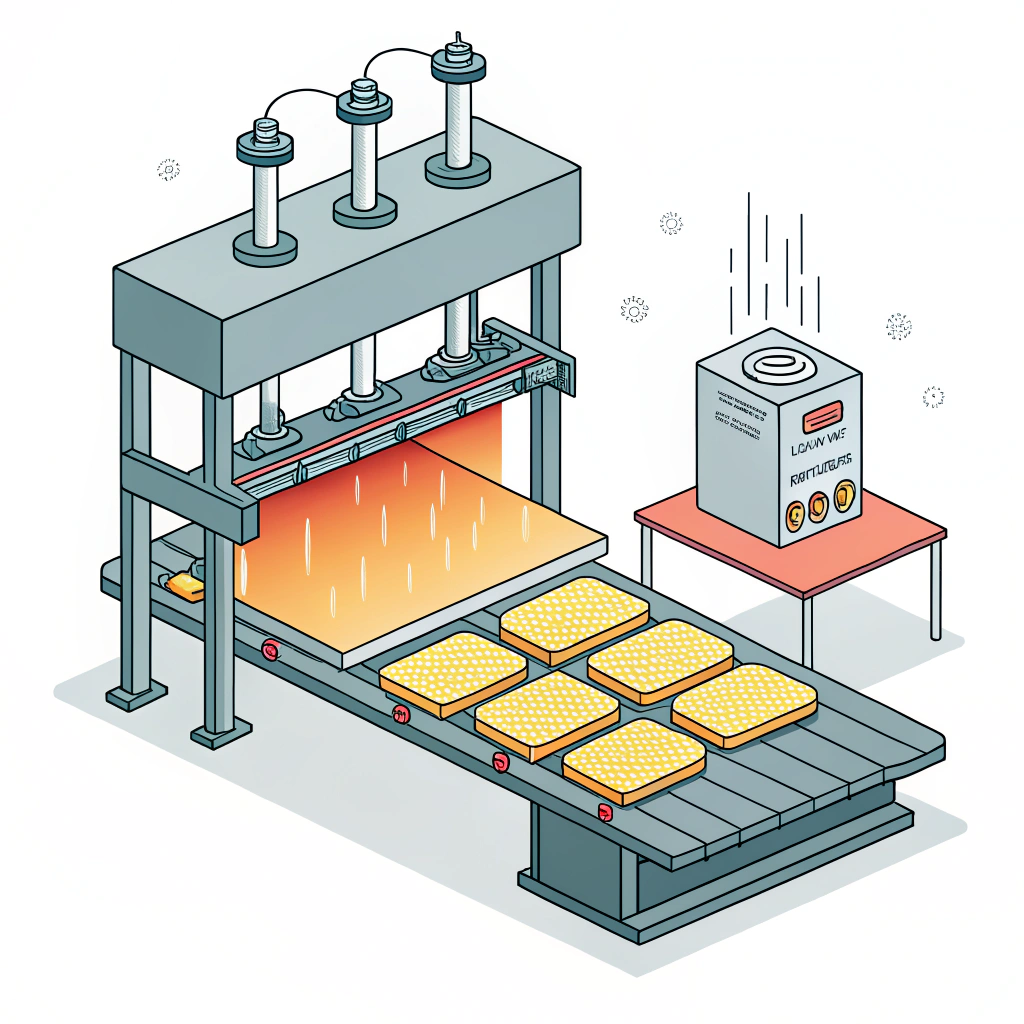

Hot pressing is a manufacturing process that involves heating the paddle materials to a specific temperature and then applying high pressure to mold them into the desired shape. This process is known for its ability to produce paddles with excellent structural integrity and impact resistance2, making it a preferred choice for high-performance paddles used in competitive play.

Advantages of Hot Pressing:

- High Production Efficiency: The process allows for faster cycle times, which is beneficial for large-scale manufacturing.

- Enhanced Impact Resistance: Heating combined with pressure results in a dense, durable paddle surface that can withstand repeated impacts.

- Strong Structural Integrity: The method ensures that the materials bond well, leading to a robust product capable of enduring high-performance demands.

Disadvantages of Hot Pressing:

- Alteration of Material Properties: The high temperature may alter the intrinsic feel of the paddle, potentially affecting the tactile response during play.

- High Equipment Investment: The need for specialized heating and pressing equipment can increase initial production costs.

- Limited Control Over Specific Features: Fine-tuning specific aspects such as paddle thickness may be challenging compared to alternative methods.

Cold pressing, by contrast, is a technique where materials are shaped at room temperature using mechanical pressure. This method minimizes alterations to the material’s properties, ensuring that the paddle retains its original texture and flexibility. It is particularly appealing for designs that require a high level of precision and detailed control over paddle dimensions.

Advantages of Cold Pressing:

- Precise Control Over Paddle Structure: By eliminating heat, manufacturers can more accurately control the skin and core thickness, preserving the original characteristics of the material.

- Preservation of Material Properties: The process maintains the natural properties of materials such as carbon fiber4, fiberglass, and composite blends, ensuring optimal responsiveness.

- Enhanced Ball Feel and Responsiveness: The tactile attributes of the paddle remain intact, providing players with a superior ball response during play.

Disadvantages of Cold Pressing:

- Longer Production Cycles: Without the speed advantages of heat activation, processing times are typically longer, reducing overall efficiency.

- Demand for High-Precision Equipment: The technique requires advanced tooling and precise pressure control machinery, which can drive up production costs.

- Potential Limitations in Large-Scale Production: Due to the slower cycle time, scaling up production may require significant process optimization.

For decision-makers comparing these methods, a structured review across multiple dimensions is invaluable. The following table outlines key parameters of each process:

| Parameter | Hot Pressing | Cold Pressing |

|---|---|---|

| Production Efficiency | High cycle times, suitable for large-scale runs | Slower cycle, best for precision and small batches |

| Impact Resistance | Superior due to high temperature-induced bonding | Depends on material; generally less robust impact absorption |

| Material Preservation | May alter tactile feel due to heat exposure | Maintains original material properties |

| Precision in Thickness | Less control; uniformity comes at the expense of nuance | High precision; allows for tailored paddle design |

| Equipment Investment | Requires high-end heating and pressing machines | Needs precise pressure automation and calibration tools |

| Cost Efficiency | Economical when scaling up production | Higher per-unit cost due to extended cycle times |

| Suitability for Custom Designs | Limited flexibility in fine-tuning design details | Ideal for custom designs and pilot runs |

This comparison highlights that while hot pressing is best suited for manufacturers seeking to maximize volume and impact strength, cold pressing serves those who prioritize the natural feel and precise dimensions of their paddle design.

When evaluating your production process requirements, consider the following factors:

-

Market Demand and Player Expectations:

- Competitive players often prefer paddles with a strong rebound and minimal vibration, traits which can be enhanced by hot pressing.

- Recreational players or markets emphasizing fine control may benefit more from cold pressed paddles where the material's inherent properties are preserved.

-

Cost and Production Volume Requirements:

- For large-scale production with a focus on cost reduction per unit, hot pressing offers a clear advantage despite its initial equipment costs.

- In scenarios where small-batch or highly customized production is required, cold pressing is ideal, even if the production cost per unit is higher.

-

Technical Specifications and Customizability:

- Designs requiring uniformity and structural integrity under high-stress conditions are best achieved with hot pressing.

- Conversely, if the goal is to maximize the paddle’s feel and control characteristics with specific design nuances (such as varying grip sizes or precise thickness specifications), cold pressing is the preferred approach.

-

Long-Term Manufacturing Goals:

- For companies looking to scale rapidly, investing in hot pressing can be more beneficial due to its higher throughput.

- If your company values iterative design improvements and tailored product development, cold pressing may offer the flexibility needed to refine product features over time.

One of our long-term partners in the sports equipment industry recently faced a decision between the two methods. Their analysis, driven by detailed field testing and quality control data, revealed the following insights:

-

Using Hot Pressing for Competitive Models:

The partner increased production efficiency by 25% while maintaining the durability standards required for competitive play. The paddles produced under hot pressing showed higher resistance to impacts and were more robust in high-stress situations. However, players reported a slight reduction in the natural ball feel compared to earlier models. -

Employing Cold Pressing for Custom Orders:

In contrast, for a limited-run series targeting amateur enthusiasts and training centers, the cold pressing method allowed for greater customization. Though the production cycle was longer, the enhanced precision in paddle thickness led to a product that players found offered superior control and comfort on the court. This niche market segment responded very favorably, resulting in increased brand trust and customer satisfaction.

These real-world examples demonstrate that the selection of a production process should be aligned with your target market and product goals. The ability to balance performance quality with cost and production efficiency is key to achieving long-term success in the competitive sports equipment market.

Based on the comprehensive comparison provided above, here are practical steps for B2B procurement managers considering your next sourcing decision:

-

Evaluate Your Production Volume Needs:

If your operation requires high-volume output, lean towards the hot pressing method to capitalize on its superior production efficiency. -

Assess the End-User Requirements:

Collaborate with your product development team or conduct market surveys to determine whether your target consumer values impact resistance or tactile control more. This decision will directly impact the production process you select. -

Consider Future Customization Needs:

If your market strategy includes offering custom designs or frequent product iterations, cold pressing provides the flexibility to adjust paddle dimensions and material properties with precision. -

Balance Equipment Investment Against Efficiency:

While both methods involve significant upfront investments, compute the long-term return on investment (ROI) based on production volume projections and market demand. The cost efficiency of hot pressing may balance out for high-production runs, whereas cold pressing’s adaptability could lead to premium product positioning in the market. -

Plan a Phased Implementation Strategy:

For companies uncertain about the scale of future demand, consider a hybrid approach: utilize hot pressing for your core product lines while integrating cold pressing for special edition or experimental models.

In a nutshell, the choice between hot pressing and cold pressing for manufacturing high-performance pickleball paddles hinges on your specific product goals, production scale, and market expectations. Hot pressing is ideal for high-volume production where durability and impact resistance are critical, whereas cold pressing offers unparalleled control over material properties, essential for products tailored to deliver a superior ball feel and precise performance.

By carefully analyzing your manufacturing requirements and aligning them with these technical insights, you can make a procurement decision that optimizes both cost efficiency and product quality. We encourage product development and procurement managers to consider all aspects of these processes for a comprehensive, forward-looking sourcing strategy that meets evolving market demands.

What paddle do most pickleball pros use?

Most professional pickleball players tend to use paddles that integrate advanced materials like carbon fiber composites. These paddles are often manufactured through processes that enhance rebound force and vibration reduction. While the choice ultimately depends on personal preference and playing style, many top pros favor paddles that balance durability with precise control.

Do more expensive pickleball paddles make a difference?

Higher-end pickleball paddles generally incorporate advanced materials such as carbon fiber or fiberglass and refined production techniques. These elements provide improvements in control, power, and spin, making a noticeable impact for competitive play. However, the value proposition depends on individual player needs and playing conditions.

What is the best type of pickleball paddle?

There is no single “best” type of pickleball paddle as performance depends on the player’s style and preferences. Typically, paddles featuring a soft, flexible polymer core are considered versatile for a balanced play experience, offering excellent shock absorption while delivering power and control.

-

hot pressing: Click here to access an in-depth explanation of hot pressing, a process that uses high temperatures and pressure to mold materials, enhancing bonding and structural integrity for high-volume, durable product manufacturing. ↩ ↩

-

impact resistance: Click here to learn more about impact resistance, including testing methods and its critical role in ensuring the longevity and performance of high-impact sports equipment. ↩ ↩ ↩2

-

cold pressing: Click here to explore the cold pressing process, a method that shapes materials at room temperature using mechanical pressure to preserve natural material properties and enhance design precision. ↩ ↩

-

carbon fiber: Click here to gain insights into carbon fiber technology, its composite properties, and why it’s integral to producing lightweight and high-performance products in advanced manufacturing. ↩ ↩