Graphite pickleball paddles are renowned for their excellent energy transfer and precision, making them well-suited for quick, controlled shots while still delivering strong performance. In this article, we compare Graphite with other high-performance paddle materials, explore production processes, and detail how these factors contribute to overall player performance.

Graphite, although not as commonly featured as carbon fiber1 in many high-performance paddles, offers a unique set of characteristics. The energy transfer on a graphite face paddle is optimized for "dinks" and controlled drives, which is why many competitive players favor it for its touch and responsiveness. Graphite paddles offer excellent balance in terms of weight and vibration reduction. Their structure allows for quick reaction times and accurate ball placement, which are crucial in fast-paced play.

Graphite contributes to:

- Enhanced energy transfer: Provides a crisp feel on the ball, ideal for players who rely on precision.

- Reduced vibration: The inherent properties of graphite help dissipate shock, improving comfort during extended play.

- Lightweight design: This ensures easier maneuverability and quick swings without compromising strength.

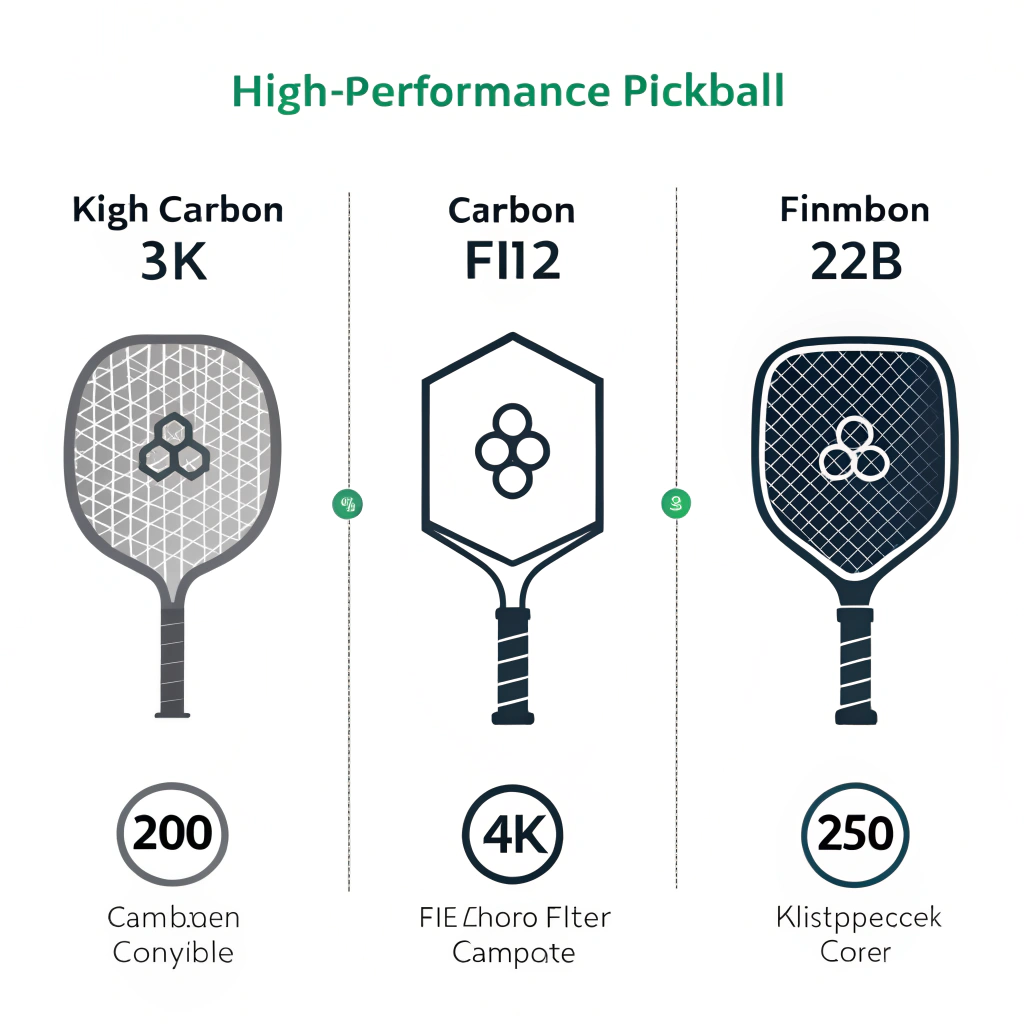

When evaluating paddle materials, procurement managers and product developers need to consider multiple factors such as strength, weight, durability, and overall performance. Below is a comparison between Graphite and other popular composite materials used in high-performance pickleball paddles.

| Material | Strength | Weight | Durability | Ball Control & Feel |

|---|---|---|---|---|

| Graphite | Good energy transfer | Lightweight | Moderate to High | Excellent for controlled shots |

| 3K Carbon Fiber | High strength & flex | Lightweight | High | Superior rebound and reduced vibration |

| 12K Carbon Fiber | Extremely strong | Lightweight | Very high | Smooth surface, higher hardness |

| Fiberglass Composite | Balanced power/control | Slightly heavier | High | Wider sweet spot, enhanced control |

| Bamboo/ Honeycomb Core | Good impact resistance | Ultra lightweight core | Very high shock absorption | Clear hitting feel and comfort |

This table provides a quick overview for decision-makers comparing key attributes. While Graphite is an excellent option for precision and reduced effort in shot execution, Carbon Fiber variants (3K and 12K) may offer enhanced durability and performance under competitive conditions.

The performance characteristics of a paddle depend not only on the raw material but also on the production processes. At NEX Pickleball, our advanced manufacturing practices ensure that every paddle meets the highest technical standards.

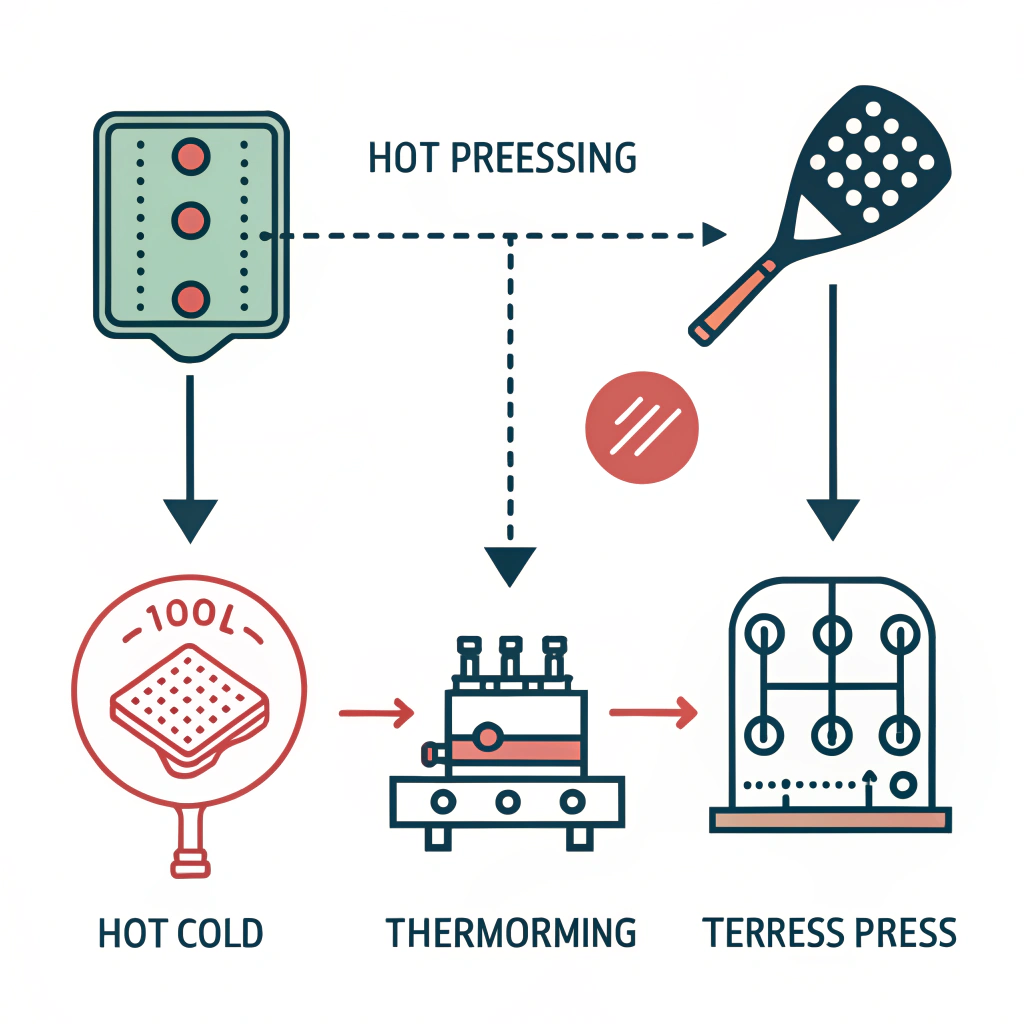

Hot pressing involves heating the paddle material and applying pressure to form the structure. For materials like Graphite and carbon fiber composites, hot pressing can:

- Increase structural integrity.

- Enhance impact resistance.

- Ensure rapid production cycles for consistent quality.

However, this method requires high investment in equipment and could slightly alter the intrinsic feel of the material. Nonetheless, it is highly effective for producing paddles designed for aggressive play.

Cold pressing shapes materials under mechanical pressure at room temperature. This method is especially beneficial for preserving the natural properties of delicate materials like Graphite. By avoiding high temperatures, cold pressing maintains:

- A precise control over thickness.

- The original material’s natural energy transfer properties.

- High-quality feel and tactile response during play.

While this process takes longer, its benefits in maintaining the paddle’s inherent sensitivity are crucial for players who demand superior control.

Thermoforming involves heating materials to a soft stage and then molding them using specialized shapes. It allows for:

- Intricate design details.

- Consistent material distribution across the paddle.

- Flexibility in producing custom paddle shapes suited to both aesthetic and performance requirements.

Though thermoforming is best suited for premium products and often carries a higher production cost, its ability to enhance performance attributes by optimizing material layout is unmatched.

Customization5 and Quality Control at NEX Pickleball

Customization is at the core of our philosophy at NEX Pickleball. We understand that different playing styles require different paddle characteristics. Our unique customization options let clients specify design features such as weight distribution, balance, and grip size to suit:

- Professional competitive play: Where precision and performance are paramount.

- Recreational play: Where comfort and ease-of-use play key roles.

Every paddle that leaves our factory undergoes rigorous testing. We check for factors such as:

- Consistency in weight distribution.

- Structural integrity and resistance to impact.

- Accurate replication of design parameters, ensuring that every paddle meets stringent quality standards.

These quality control measures ensure that whether a customer chooses a Graphite paddle with precise energy transfer or a composite version with superior shock absorption, the paddle will perform reliably under various playing conditions.

For a procurement manager in the sporting goods sector, the final decision may boil down to a careful consideration of several technical and commercial factors:

| Factor | Graphite Pickleball Paddles | Alternative Composite Options |

|---|---|---|

| Energy Transfer | Excellent for dinks and controlled drives | Carbon fibers may provide a stronger rebound |

| Weight & Maneuverability | Extremely lightweight for quick swings | Comparable lightness with enhanced durability |

| Durability | High, but might be less robust under extreme conditions | 12K Carbon Fiber offers superior longevity under competitive play |

| Cost Considerations | Moderately priced considering performance | Higher production cost for premium composites may affect pricing |

| Customization Options | Well-suited for precise, performance-driven designs | Extensive options to tailor performance satisfies diverse consumer needs |

When comparing Graphite with materials like carbon fiber or fiberglass, it is critical to balance advantages such as ease of energy transfer and lightweight design against enhanced durability and impact performance. Many professional paddles integrate a mix of materials to maximize both control and power.

Procurement managers should also consider market trends and consumption patterns: if the target market prioritizes quick, controlled play with lower exertion in generating power, Graphite remains a top choice. Alternatively, for products aimed at high-level competitive play, integrating carbon fiber materials might hit the mark due to their proven track record in professional circles.

In summary, while Graphite pickleball paddles offer unmatched precision for controlled play and are a strong candidate for players who value fast energy transfer and reduced effort, they represent just one option among many high-performance compositions. Factors such as production methods, material integration, and customization capabilities are all crucial in creating a product that meets the diverse needs of players at all levels.

For procurement managers and product developers:

- Consider Graphite for product lines targeting players who prioritize finesse and quick shot execution.

- Evaluate carbon fiber variants like 3K and 12K for products aimed at competitive markets demanding robust performance.

- Leverage the benefits of advanced production processes such as cold pressing and thermoforming to maintain the unique properties of each material.

- Use our detailed comparison and quality control measures to ensure that every paddle delivered meets your market’s performance expectations.

By balancing material performance, production technologies, and market demands, purchasers can make informed decisions that cater precisely to the nuanced needs of modern pickleball players.

For further insights or to discuss your specific requirements, please reach out to our expert team at NEX Pickleball.

-

Are graphite pickleball paddles better?

Graphite pickleball paddles excel in energy transfer, making them ideal for precision shots such as dinks and controlled drives. Their design minimizes vibration and offers a responsive feel, which is why many competitive players prefer them for fast-paced, power-driven play. -

What's the best material for pickleball paddles?

Experts in pickleball performance often favor carbon fiber variants for their superior strength, durability, and precise control. However, graphite remains an excellent option for players seeking energy efficiency and fine shot control, depending on specific playing styles and performance requirements. -

What paddle do most pickleball pros use?

Professional players tend to select paddles that balance control with power. Top pro models often incorporate advanced materials such as carbon fiber composites while some also integrate elements of graphite for enhanced energy transfer. This blend ensures both precise shot-making and robust performance under competitive conditions.

-

carbon fiber: Click to learn more about the properties, manufacturing processes, and applications of carbon fiber in high-performance sports equipment. ↩ ↩

-

Hot Pressing: Click to understand how hot pressing enhances structural integrity and impact resistance in composite materials. ↩ ↩

-

Cold Pressing: Click to discover the benefits of cold pressing in preserving material properties and achieving precise thickness control. ↩ ↩

-

Thermoforming: Click to explore how thermoforming allows for intricate designs and consistent material distribution in manufacturing. ↩ ↩

-

Customization: Click to learn how customization options can be leveraged to meet specific performance requirements and market demands in product development. ↩ ↩