This article explains the key technical terms and manufacturing processes in pickleball paddle production—such as the differences between various carbon fiber types, fiberglass, and composite materials, as well as production methods like hot pressing, cold pressing1 and thermoforming2—to help B2B procurement specialists make informed sourcing decisions quickly.

As the pickleball market grows, so does the need for clear and concise explanations regarding the advanced materials and production methods that define paddle quality. For procurement specialists and product managers in the sports equipment industry, understanding the technical vocabulary and manufacturing nuances is vital to comparing supplier offerings effectively. This article breaks down complex industry terminology and processes, providing a comprehensive glossary and solution-oriented analysis that empowers you to choose the right manufacturing partner and product for market demands.

For many in the sports equipment sector, especially those overseeing B2B sourcing, the variety of terms—ranging from 3K Carbon Fiber3 to Nomex Honeycomb Core4—often leads to confusion during supplier evaluations. How can one distinguish between materials that promise high performance and those that focus on durability and comfort? Moreover, traditional production processes like hot pressing, cold pressing1 and thermoforming2 each bring unique strengths and limitations. The resulting challenge lies in deciphering which attributes best meet client requirements and competitive standards.

The complexity arises from several factors:

- Varied Material Properties: Not all carbon fibers are created equal. For example, 3K offers excellent flexibility while 12K provides a smoother and more durable surface. Each type brings its own set of pros and cons.

- Multiple Production Methods: Production methods such as hot pressing, cold pressing, and thermoforming each affect the paddle's final weight, impact resistance, and performance feel. Variation in these processes can lead to significant differences in product quality.

- Customizability and Quality Control: With options for custom paddle manufacturing, subtle details like grip size or core composition can alter performance. Maintaining strict quality control in high-volume production further complicates comparison among suppliers.

To address the challenges mentioned above, it is essential to have a clear glossary that explains:

- Material types and their specific benefits.

- Detailed production processes.

- Their measurable impact on paddle performance.

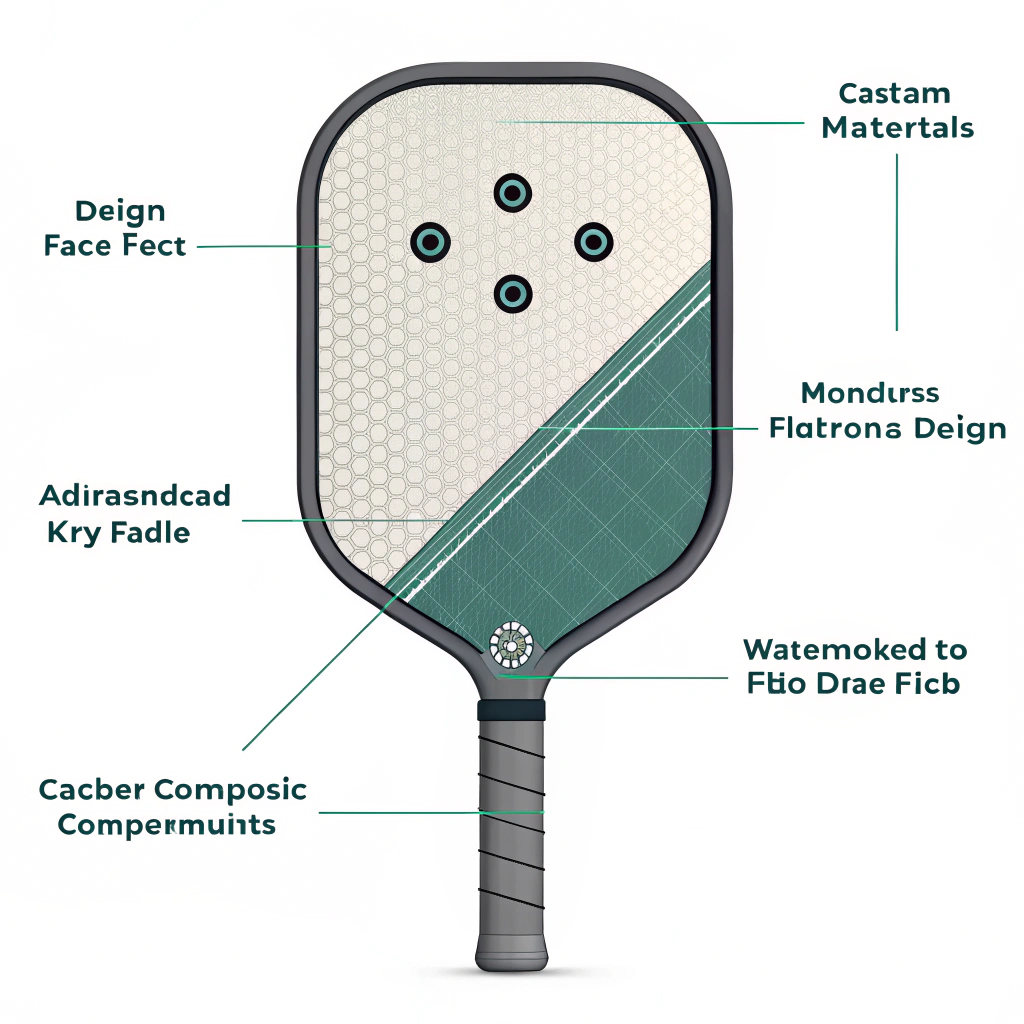

Below, we present a clear breakdown of the primary materials and production processes used in advanced pickleball paddle manufacturing.

- 3K Carbon Fiber: Known for its strength and flexibility, this fiber is typically used in paddles that require a high rebound force. Its excellent durability and vibration-damping properties make it suitable for competitive play.

- 12K Carbon Fiber: With a higher thread density than 3K, 12K provides a smoother surface and greater hardness. This type is perfect where extreme strength and impact resistance are critical.

- T300 Carbon Fiber: This high-performance fiber offers an optimal balance between tensile strength and weight, making it ideal for paddles that require both robust performance and light responsiveness.

- E-Glass Fiberglass5: Offers excellent elasticity and tensile strength, resulting in paddles with a wider sweet spot that balances power and control. It is known for enhanced ball feel and better accuracy during play.

- Carbon Fiber and Fiberglass Composite: Combining both materials, this composite leverages the benefits of strength, lightness, and flexibility. It is increasingly popular among players who require both powerful hits and precise control.

- Bamboo Core Composite: Lightweight and highly impact-resistant, bamboo core composites deliver clear hitting sensations while maintaining durability.

- Honeycomb Core: Made from high-density polymer, honeycomb cores absorb shocks efficiently, reduce vibrations, and extend the paddle’s lifespan.

- Nomex Honeycomb Core: This durable polymer core is recognized for its excellent shock absorption. Ideal for players looking for stability and long-term durability.

- Aluminum Honeycomb Core: Balances weight effectively, offering a good blend of power and precision. It is often preferred for its consistent performance.

- Polymer Honeycomb Core: Known for improved elasticity and reduced vibration, polymer cores provide a softer hitting experience, making them a popular choice among beginners and recreational players.

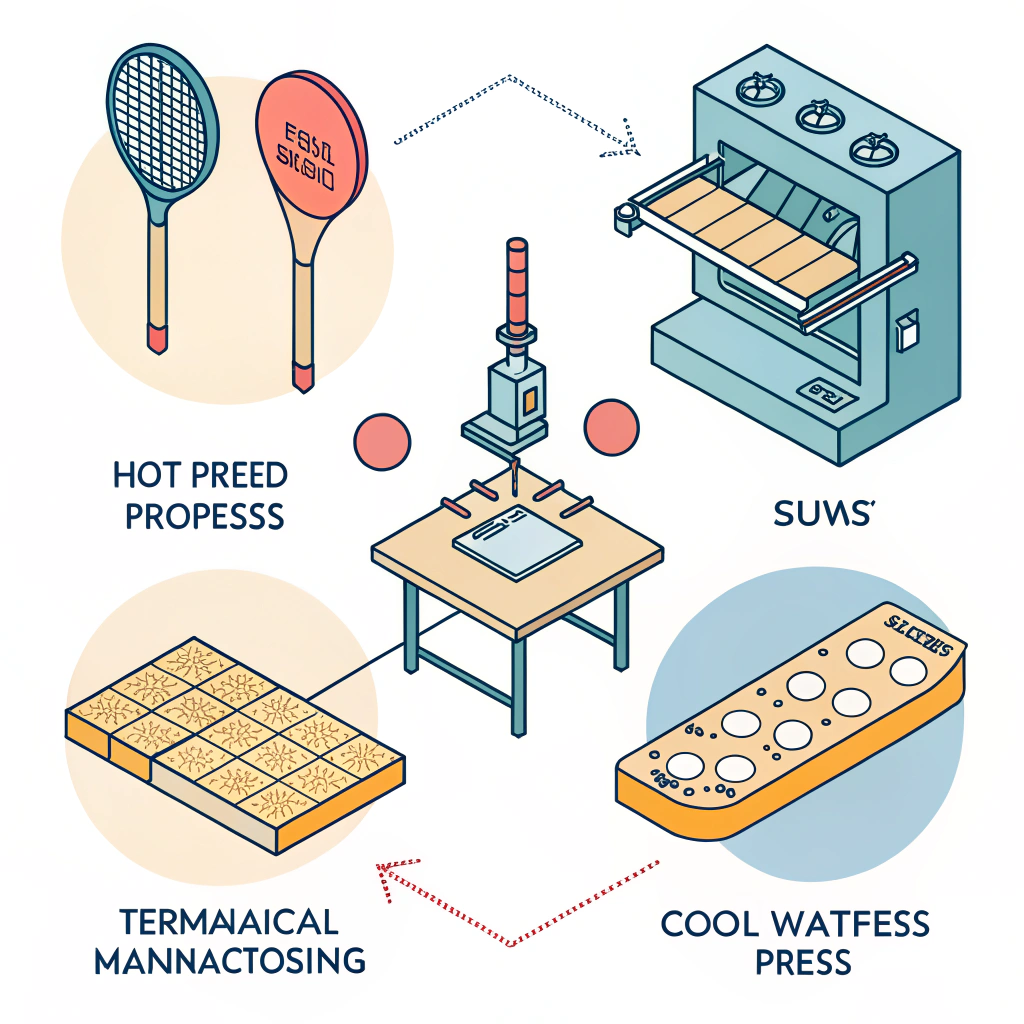

The manufacturing process of each pickleball paddle plays a crucial role in determining its overall performance and durability. Let’s explore the three primary methods and their impacts:

Hot pressing involves heating the material and applying significant pressure to form and mold the paddle.

- Advantages:

- High production efficiency.

- Produces robust paddles with excellent impact resistance.

- Ensures structural integrity, suitable for high-performance play.

- Limitations:

- Potential alteration of some material properties may affect the paddle's feel.

- Requires high capital expenditure for equipment.

In cold pressing, mechanical pressure at room temperature is applied to shape the paddle, ensuring that the material retains its original properties.

- Advantages:

- Provides precise control over paddle thickness and structure.

- Maintains material properties, delivering enhanced ball feel and responsiveness.

- Great for paddles that require finely tuned performance characteristics.

- Limitations:

- Longer production cycles, reducing efficiency.

- Demands high-quality machinery to maintain uniform pressure.

Thermoforming involves heating the paddle material to a softening point before molding it using customized forms.

- Advantages:

- Enables intricate paddle designs and precise material distribution.

- Enhances paddle stability and performance.

- Particularly suited for premium products or custom-made paddles.

- Limitations:

- Longer production time.

- Higher equipment costs, making it best for lower-volume, high-end markets.

Below is a comparative table summarizing these methods:

| Production Process | Key Advantages | Limitations | Best For |

|---|---|---|---|

| Hot Pressing | High efficiency; strong impact resistance; robust construction | Potential alteration of material properties; high equipment cost | High-performance paddles requiring durability |

| Cold Pressing | Precise thickness control; retains material properties; excellent ball feel | Longer production cycle; requires quality machinery | Designs requiring precise control and responsiveness |

| Thermoforming | Intricate design; precise material distribution; superior stability | Extended production time; higher cost | Custom or premium paddle products |

At NEX Pickleball, we have streamlined these processes to ensure that each paddle meets the highest standards. Our approach is built on three pillars:

- Material Excellence: Our selection process for carbon fiber variants, fiberglass, and composite materials ensures that each paddle is tailor-made to offer optimal performance. Whether clients require the rebound force from 3K carbon fiber or the smooth impact resistance of 12K, every choice is backed by thorough testing and proven performance data.

- Process Optimization: We adopt a hybrid strategy by using hot pressing for high-volume production while integrating cold pressing and thermoforming for custom orders. This flexible approach allows us to maintain product consistency and meet specific client requirements without compromising on quality.

- Rigorous Quality Control: Every paddle undergoes multiple testing phases, ensuring that its balance, weight distribution, and ergonomic grip align with the design specifications. This commitment to quality has made NEX Pickleball a trusted name for companies worldwide, including major brands like Joola and Selkirk.

When evaluating supplier offerings, consider the following:

- Performance vs. Production Efficiency: Balance the need for speed and volume with the requirement for custom performance. High-volume production lines that utilize hot pressing can be perfect for competitive markets, but custom orders may benefit more from cold pressing or thermoforming for precise tactile feedback.

- Material Suitability: Not all paddle designs perform well with every material. For example, players focused on control might lean towards fiberglass or polymer honeycomb cores, while those wanting power might opt for carbon fiber variants.

- Cost Implications: Advanced materials and specialized production processes can drive up costs. It’s crucial to assess whether the performance benefits justify the price for your target market.

- Customization Options: With an increasing demand for personalized sports equipment, the ability to tailor paddles based on grip size, weight, and core composition is a key differentiator. Ensure that the supplier can adapt their processes and materials to meet these custom requirements.

Case in point, a recent product launch at NEX Pickleball demonstrated that combining Carbon Fiber and Fiberglass Composite with a Nomex Honeycomb Core resulted in a paddle that balanced precision with power. This product was designed in response to market feedback demanding both durability and superior ball control—a clear example of how meticulous material selection and process optimization can deliver industry-leading performance.

Understanding the manufacturing processes and technical vocabulary in pickleball paddle production is not just a matter of industry knowledge—it is a key driver for making strategic, well-informed sourcing decisions. By dissecting terms like 3K Carbon Fiber, E-Glass Fiberglass, and various composite materials, and by comparing production techniques such as hot pressing, cold pressing, and thermoforming, procurement specialists can now better evaluate product offerings based on reliable quality, performance, and durability.

We recommend:

- Reviewing supplier specifications to ensure that the materials and processes align with your performance expectations.

- Requesting detailed quality control and testing data to verify production claims.

- Considering the long-term benefits of innovative manufacturing processes and customized solutions, especially when targeting niche market segments.

NEX Pickleball remains committed to delivering products that excel in both technical performance and customer satisfaction. Leverage these insights as you evaluate your next production partner to stay ahead in the competitive sports equipment market.

Q: What are the main differences between various carbon fiber types used in pickleball paddles?

A: Different carbon fiber types, such as 3K, 12K, and T300, vary in thread density, strength, and flexibility. 3K offers excellent flexibility and rebound, 12K provides a smoother and more durable surface, while T300 balances tensile strength with light weight.

Q: How do production methods like hot pressing, cold pressing, and thermoforming affect paddle performance?

A: Hot pressing offers high efficiency and strong impact resistance, cold pressing provides precise control and better material retention for ball feel, and thermoforming supports complex design and superior stability, though it often incurs higher costs and longer production times.

Q: Why is quality control important in the production of pickleball paddles?

A: Rigorous quality control ensures that each paddle meets performance standards by maintaining optimal weight distribution, impact resistance, and ergonomic design, which is critical for both high-performance and custom paddle production.

-

cold pressing: Read the article to understand cold pressing, a process that applies mechanical pressure at room temperature to preserve material properties while shaping the paddle, resulting in enhanced ball feel. ↩ ↩ ↩2

-

thermoforming: Read the article to explore thermoforming, a manufacturing process involving heating materials to a softening point before molding them, which allows for intricate designs and precise material distribution. ↩ ↩ ↩2

-

3K Carbon Fiber: Read the article to understand the properties of 3K Carbon Fiber—including its strength, flexibility, and vibration-damping characteristics—that make it suitable for high-performance paddle production. ↩ ↩

-

Nomex Honeycomb Core: Read the article to learn about Nomex Honeycomb Core, a durable polymer core renowned for its exceptional shock absorption and stability, essential for long-term paddle performance. ↩ ↩

-

E-Glass Fiberglass: Read the article to gain insights into E-Glass Fiberglass, a specific type of fiberglass offering excellent elasticity and tensile strength to improve paddle performance. ↩ ↩