Franklin’s Sweet Spot Training Pickleball Paddle stands out by integrating state-of-the-art materials and advanced manufacturing techniques that deliver unmatched performance, durability, and precision. For B2B procurement managers and product development specialists, this paddle represents a meticulous blend of innovative process engineering and premium materials, ensuring superior training outcomes and long-term ROI.

The performance of pickleball paddles is directly tied to the precise balance between power, control, and comfort. In today’s competitive sports equipment market, selecting a training paddle that delivers instant feedback, consistent ball contact, and minimal vibration is crucial. Franklin’s Sweet Spot Training Pickleball Paddle addresses these requirements by utilizing advanced composite materials1 and refined production processes. This article breaks down the challenges faced by procurement managers, explains why manufacturing precision matters, and provides actionable insights into how choosing the right paddle can elevate training performance.

B2B buyers in the sports equipment field must navigate a complex landscape of product features and manufacturing methods. Key challenges include:

• Ensuring material quality and durability to withstand competitive training sessions

• Maintaining balance between power and control for a wide range of players

• Meeting high standards for production consistency and performance testing

Manufacturers that want to secure partnerships must demonstrate not only quality products but also an in-depth understanding of how their materials and processes translate to performance benefits on the sporting court.

The superior performance of Franklin’s Sweet Spot Training Paddle is rooted in its advanced production methodology. Several factors contribute to its excellence:

• Material Innovation: The paddle employs premium materials such as various grades of carbon fiber (3K, 12K, T300) and high-quality fiberglass. Each material offers unique properties concerning strength, elasticity, and vibration reduction. The choice of composite materials like carbon fiber and fiberglass composite further enhances performance by combining the best of both worlds.

• Optimized Core Composition: The paddle’s core can be tailored using Nomex Honeycomb2, Polymer Honeycomb, or Aluminum Honeycomb. These cores are crucial in determining the paddle’s hardness, balance, and shock absorption properties – all vital for training scenarios where consistent contact and feedback are paramount.

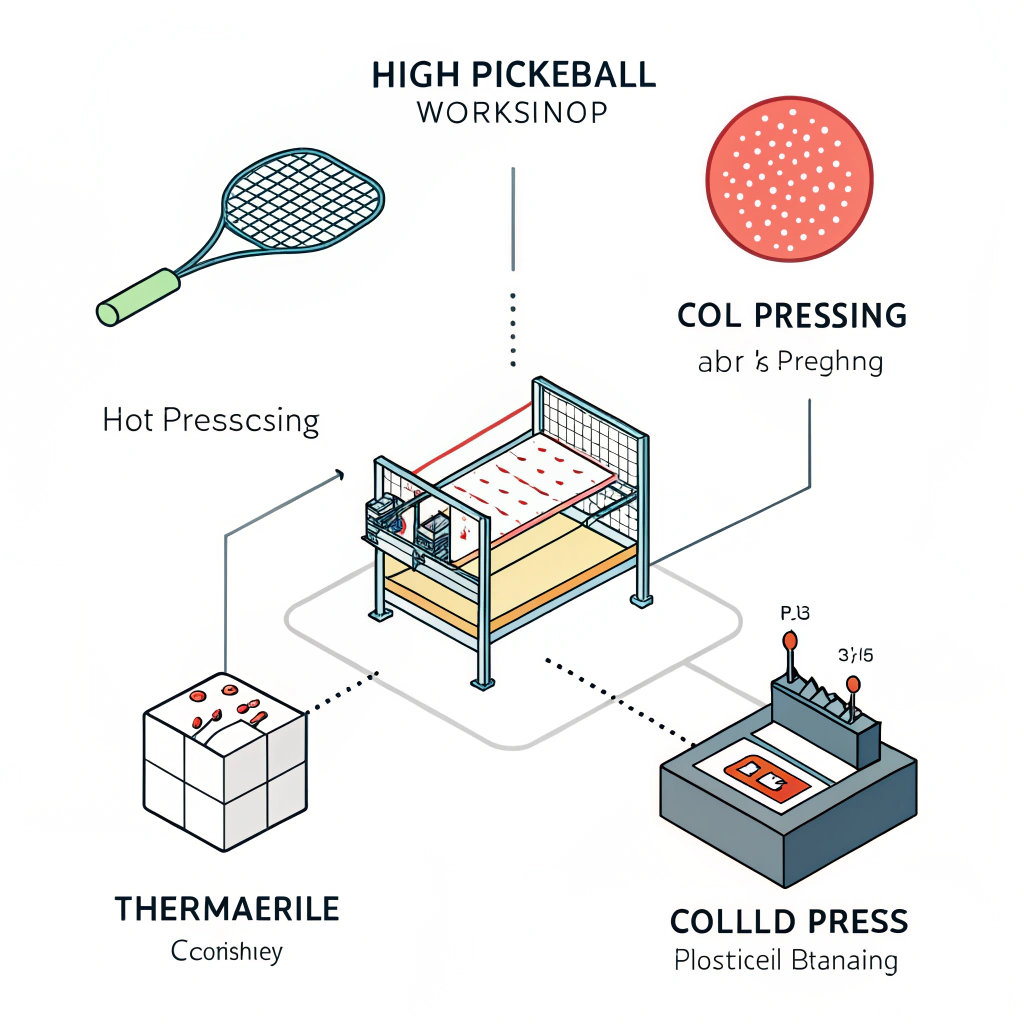

• Advanced Manufacturing Processes: Utilizing methods such as Hot Pressing3, Cold Pressing4, and Thermoforming5, the production techniques ensure that the paddle’s dimensions and structural integrity are maintained. Each process has its own set of advantages:

- Hot pressing is ideal for high production efficiency and creates a robust structure.

- Cold pressing preserves material properties essential for precise ball control.

- Thermoforming allows for the creation of intricate paddle shapes and uniform material distribution.

These factors not only optimize the paddle’s performance but also ensure that manufacturing variations are minimized, which is crucial for applications in professional training environments.

Below is a table summarizing the key materials and processes used in the paddle’s production:

| Material / Process | Advantages | Suitable For |

|---|---|---|

| 3K Carbon Fiber | High strength, excellent flexibility; reduces vibration | High rebound force and durability |

| 12K Carbon Fiber | Smoother surface, greater hardness; ideal for extreme strength | Competitive play, impact resistance |

| T300 Carbon Fiber | Outstanding tensile strength; balanced performance of strength and weight | Precision and high-speed play |

| E-Glass Fiberglass | Excellent elasticity and tensile strength; enhanced ball control | Wider sweet spot and control |

| Composite Materials | Combines benefits of carbon fiber and fiberglass; balanced power and control | Players requiring both attributes |

| Nomex Honeycomb Core | High shock absorption; long-lasting durability | Stability and endurance |

| Aluminum Honeycomb Core | Balanced weight; provides a mix of power and precision | Training and competitive use |

| Polymer Honeycomb Core | Better elasticity; reduced vibration | Comfort for beginners & recreational players |

| Hot Pressing | High production efficiency; strong impact resistance | High-performance, large-scale manufacturing |

| Cold Pressing | Precise control; superior ball feel and responsiveness | Designs requiring material integrity |

| Thermoforming | Allows complex designs; precise material distribution | Premium, custom-made paddles |

-

Hot Pressing:

This process involves subjecting the paddle material to both heat and pressure. It ensures that the composite materials bond effectively, resulting in a strong and durable paddle. However, the elevated temperature can sometimes alter subtle material characteristics. For B2B buyers focused on large-volume procurement, the efficiency of hot pressing is a significant benefit. -

Cold Pressing:

Operating at room temperature, cold pressing minimizes the risk of altering material properties. This process is vital for achieving the precise thickness and consistency necessary for optimum paddle performance. Although slower than hot pressing, the superior control it offers is essential when the focus is on maximizing paddle feel during training and gameplay. -

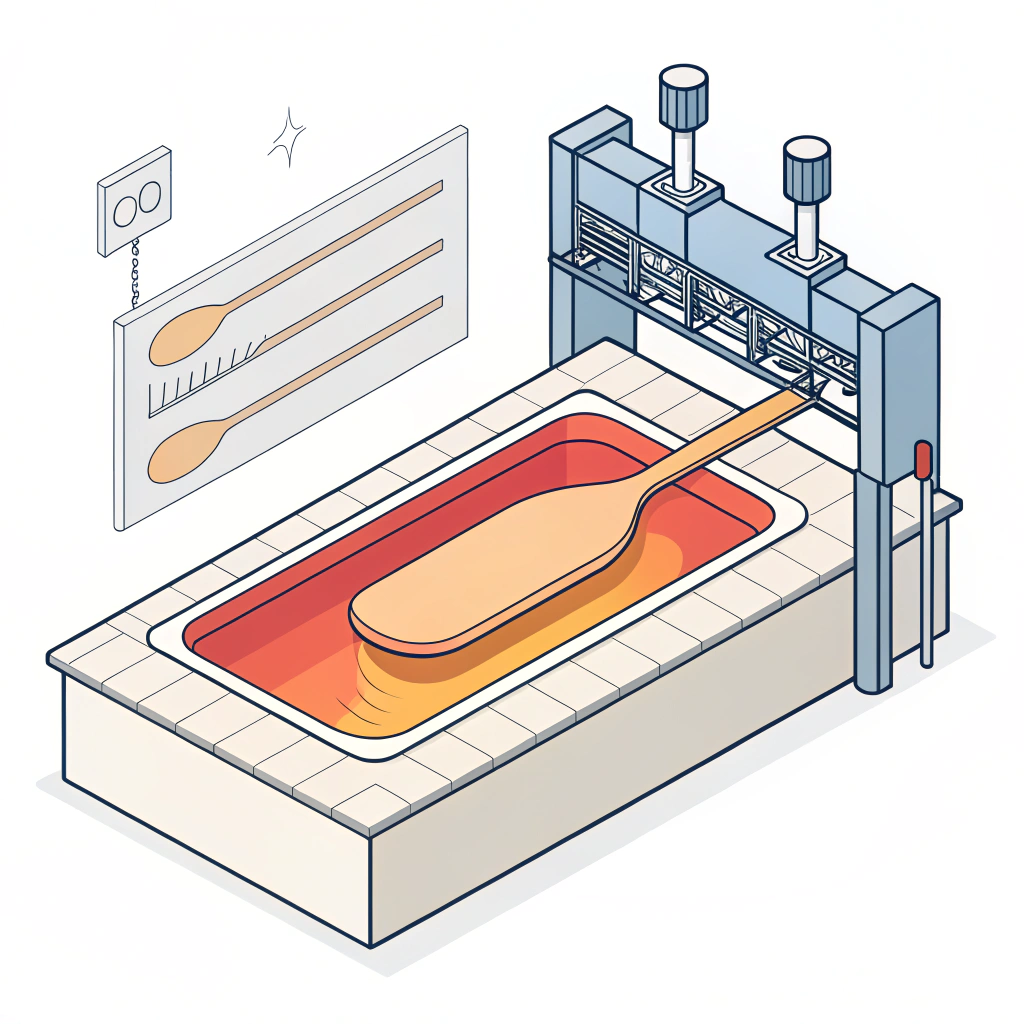

Thermoforming:

Thermoforming uses heat to soften the materials, which are then molded into the paddle’s final shape using precise molds. This method enables intricate design details that optimize material distribution and overall paddle stability. It is most suitable for premium or customized paddle solutions where design intricacies can enhance performance outcomes.

The careful selection of production methods ensures that every Franklin paddle is engineered for excellence. These processes are not mutually exclusive; many paddles benefit from a blend of techniques that maximize their strengths while mitigating any inherent weaknesses associated with a single process.

For procurement managers seeking to improve their product lines with high-performance training equipment, Franklin’s Sweet Spot Training Paddle offers several compelling benefits:

• Enhanced Performance: The advanced composite materials and optimized core designs deliver excellent shock absorption, reducing vibration and improving ball control. This results in a noticeable improvement in training outcomes for players at all levels.

• Manufacturing Consistency: The use of cutting-edge production processes, along with rigorous quality control measures, ensures that each paddle meets strict performance criteria. This consistency is critical for large-scale procurement where product uniformity across thousands of units is essential.

• Customization Options: Beyond standard designs, buyers can request custom paddles featuring specific weight distributions, grip sizes, and material compositions to cater to unique training needs. This level of customization helps align the product with the specific requirements of professional training programs or competitive teams.

• Cost-Effective Durability: Although the manufacturing methods involve advanced techniques and premium materials, the overall cost-to-performance ratio remains attractive. Durable paddles translate to lower replacement costs and a higher long-term ROI.

To put these benefits in context, consider the challenges faced by several retail chains and sports training facilities that upgraded their inventory with high-performance paddles. In each instance, the switch not only boosted player performance but also elevated the brand's reputation among customers who demanded reliability and excellence.

A simplified checklist for B2B buyers:

- Verify the material composition: Check for the use of quality carbon fiber variants and composite materials.

- Evaluate manufacturing techniques: Confirm whether the supplier uses hot pressing, cold pressing, or thermoforming based on your performance needs.

- Assess customization flexibility: Determine if the supplier offers tailored options for weight distribution and ergonomic design.

- Ensure quality consistency: Look for rigorous quality control protocols and performance testing that align with your training outcomes.

One notable example involves a large sports training facility that transitioned to using Franklin’s Sweet Spot Training Paddle. Initially, their training sessions suffered from inconsistent performance due to lower-quality equipment. After integrating these paddles into their regimen, the facility reported:

• Improved control and precision on courts

• Reduced vibration leading to lower occurrence of training-related injuries

• Positive feedback from athletes regarding enhanced ball feel and immediate responsiveness

A data-driven approach confirmed that the enhanced materials and manufacturing processes not only improved performance metrics but also extended the service life of the paddles. This translated into both immediate performance improvements and long-term cost savings, making a compelling case for B2B procurement in the sports equipment industry.

Franklin’s Sweet Spot Training Pickleball Paddle exemplifies how advanced material science combined with sophisticated manufacturing processes can revolutionize training equipment. Key takeaways include:

• The integration of premium carbon fiber, fiberglass, and composite materials leads to superior paddle performance.

• Advanced production techniques such as hot pressing, cold pressing, and thermoforming ensure product consistency and durability.

• Customization options allow businesses to cater to specific performance needs, enhancing training outcomes and user experience.

• Real-world case studies demonstrate measurable improvements in training efficiency and cost-effectiveness.

For procurement managers and product development specialists considering a partner in high-performance sports equipment, Franklin’s Sweet Spot Training Paddle represents a proven solution that addresses both technical and commercial demands. We invite you to reach out for more detailed specifications, samples, or a comprehensive consultation. Take the next step in maximally equipping your training facilities with tools engineered for elite performance.

People Also Ask

Q: What is the best pickleball training paddle?

A: The best pickleball training paddle effectively combines power, control, and durability. High-performance paddles, such as Franklin’s Sweet Spot Training Paddle, leverage premium materials and innovative manufacturing processes to deliver consistent ball contact and reduced vibration, ensuring optimal training outcomes.

Q: Does sweet spot training work pickleball?

A: Yes, sweet spot training paddle designs work exceptionally well in pickleball. They provide instant feedback and consistent contact with the ball, substantially improving control, precision, power, and overall confidence on the court.

Q: Does Franklin make a good pickleball paddle?

A: Absolutely. Franklin’s Signature Pro Paddle, developed by a champion, meets the rigorous standards required by top players, featuring an extra textured surface to enhance ball spin and traction, ensuring superior performance during competitive play.

-

advanced composite materials: Read the external resource to understand how combining different fiber-reinforced materials enhances durability, strength, and overall performance in sports equipment. Return ↩

-

Nomex Honeycomb: Explore how Nomex Honeycomb technology provides exceptional shock absorption and stability, critical for high-performance sports gear. Return ↩

-

Hot Pressing: Discover the hot pressing process that uses heat and pressure to bond composite materials, resulting in robust and efficient manufacturing outcomes. Return ↩

-

Cold Pressing: Learn about cold pressing, a method that maintains optimal material integrity by operating at room temperature for precise control and ball feel. Return ↩

-

Thermoforming: Understand thermoforming, a process that employs heat to mold materials into intricate designs, ensuring even material distribution and customization opportunities. Return ↩