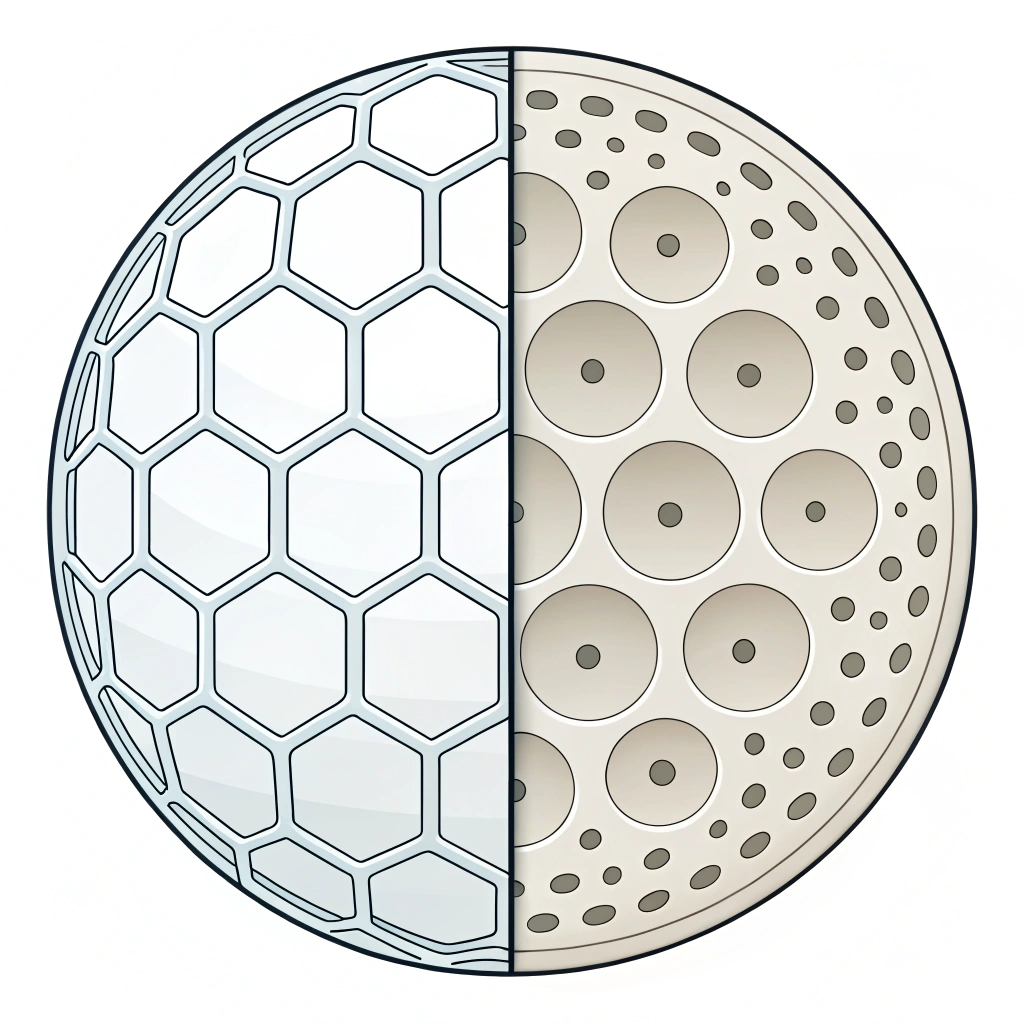

A quick answer: When selecting a core material for pickleball paddles, polymer honeycomb cores1 are often favored for their balanced performance in impact absorption, weight distribution, and durability, while foam cores2 can offer a distinct hitting feel but may fall short on longevity and stability under high-impact conditions.

Pickleball paddle design requires careful evaluation of core materials to achieve the optimal balance between performance, durability, and cost-effectiveness. As manufacturers explore innovative materials, understanding the advantages and limitations of foam core and honeycomb core structures is essential. In this article, we compare these core types, focusing on impact absorption, weight distribution, and production process efficiency to help product development managers make informed decisions.

Core materials are the engine behind a paddle’s performance. The primary goal is to deliver the ideal “feel” while ensuring durability, impact resistance, and efficient weight distribution. Two widely discussed core technologies in the industry are foam cores and honeycomb cores.

Foam cores are typically made from a high-density polymer foam. This method is appreciated for its uniform consistency and ease of manufacturing, which can lead to cost advantages, especially at scale. Foam cores are generally lighter and can offer better elasticity and response for players who rely on quick paddle movements and precise ball control. However, foam materials often sacrifice long-term durability, particularly when exposed to repetitive high-impact force.

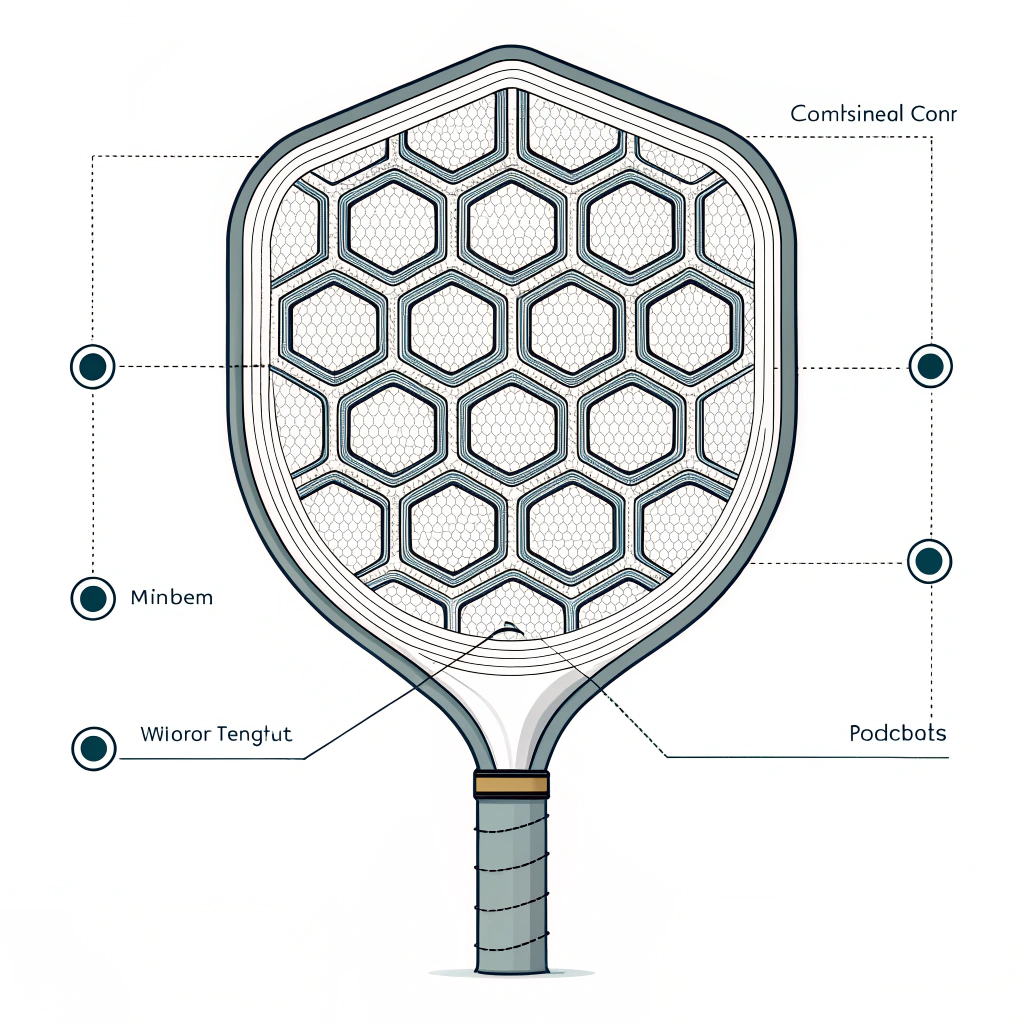

Honeycomb cores, on the other hand, are designed with a cellular structure resembling natural honeycombs. This architecture aims to maximize structural strength while minimizing material usage and overall weight. Honeycomb cores can be made from various materials, such as Nomex3, aluminum, or polymer, each bringing a unique blend of rigidity, shock absorption, and enhanced durability. These cores are especially popular among manufacturers who target high-performance paddles for competitive play.

Evaluating core materials requires a deep dive into key performance metrics. Let’s explore three critical aspects: impact absorption, weight distribution, and overall durability.

Impact absorption is crucial for controlling vibrations during play and protecting both the paddle and the player’s arm.

- Foam Core: Foam cores absorb a significant amount of energy upon impact due to the inherent cushioning properties of foam. This can result in a softer feel which some players find appealing, particularly in recreational settings. However, the energy dissipation may not be as repeatable or stable over extensive cycles of use.

- Honeycomb Core: The honeycomb structure naturally distributes impact forces across a larger area. This minimizes localized damage and maintains performance consistency over time. Variants such as polymer honeycomb cores are reported to deliver superior shock absorption while still preserving the paddle’s responsiveness.

For optimal performance, a pickleball paddle must maintain a balanced weight to facilitate both power and control.

- Foam Core: The lighter weight of foam cores can lead to rapid paddle maneuvers. However, the lack of a robust internal structure might sometimes lead to imbalances in weight distribution, especially when the paddle is coupled with heavier face materials.

- Honeycomb Core: Owing to their intricate design, honeycomb cores achieve excellent weight distribution. They help maintain a center-of-gravity that enhances both swing power and control. The ability to tailor the density of individual cells also allows manufacturers to fine-tune performance for different playing styles.

Durability is a key factor, especially as paddles are subject to stress from repeated impacts over many games.

- Foam Core: While foam cores are relatively inexpensive and easy to produce, they have a tendency to degrade over time, particularly if exposed to environmental stresses such as moisture and temperature fluctuations.

- Honeycomb Core: The engineered structure of a honeycomb core contributes to its longevity. Materials like Nomex3 or aluminum provide enhanced resistance to compression and wear, ensuring that high-performance paddles retain their responsiveness for lengthy competitive use.

The manufacturing process plays an equally important role in material selection. Different production techniques can affect material performance.

-

- Applied to both foam and honeycomb designs, hot pressing uses heat and pressure to bind the materials. This technique ensures high production efficiency and strong bonding.

- Advantages: Quick cycle times and robust structural integrity.

- Disadvantages: Can potentially modify material properties, which might affect the natural flexibility of a foam core.

-

Cold Pressing:

- More common in designs where precision is a priority, cold pressing preserves the original texture and properties of the core material.

- Advantages: Superior control over thickness and detail, which is crucial in honeycomb panels for ensuring uniform cell structure.

- Disadvantages: Longer production cycles, resulting in increased manufacturing costs.

-

- Thermoforming is ideal for complex paddle designs. It is often used when combining multiple materials (e.g., a composite structure with both foam and honeycomb layers).

- Advantages: Allows high customization and ensures the precise distribution of materials.

- Disadvantages: Best used in premium products due to the higher cost and extended production time.

When balancing cost with performance, manufacturers must consider raw material costs, production efficiency, and the respective lifetimes of the materials.

- Foam Core: Typically, foam cores command lower upfront material costs and require less specialized equipment, making them attractive for budget-oriented products. They may, however, result in increased maintenance or earlier product replacement.

- Honeycomb Core: Despite higher initial costs, honeycomb cores offer better performance longevity and may yield lower long-term lifecycle costs. Choosing materials like polymer or Nomex within a honeycomb structure often positions your product as a premium offering, with potential competitive advantages in high-performance segments.

Below is a table that summarizes the performance characteristics of foam core and honeycomb core options for pickleball paddles:

| Feature | Foam Core | Honeycomb Core |

|---|---|---|

| Impact Absorption | High initial energy damping but gradual wear | Consistent energy distribution and shock absorption |

| Weight Distribution | Lighter but can be less balanced | Excellent balance through engineered cell design |

| Durability | Lower long-term resilience | Superior longevity, especially with Nomex/Polymer |

| Production Efficiency | Lower cost, faster production cycles | Higher production cost and time, but premium feel |

| Customization Flexibility | Moderate – relies on uniform density | High – adjustable through cell structure control |

When deciding between a foam core and a honeycomb core for your pickleball paddle product line, consider the following practical aspects:

-

Performance Needs:

Evaluate the target market's preferences. For recreational players who prioritize a softer hit and lower costs, foam cores might seem attractive. However, competitive players demanding enhanced power, precision, and durability will benefit more from the stability offered by honeycomb cores. -

Production Scale:

Consider your manufacturing capabilities. If you aim for high-volume production with lower costs, foam cores can meet those needs. For specialized or premium product lines, where quality and innovation drive competitive advantage, the detailed design control in honeycomb cores is a strategic investment. -

Lifecycle and Market Perception:

Product lifespan and customer satisfaction are intertwined with material choice. A honeycomb core can produce profiles with longer durability and consistent performance, influencing brand reputation. Meanwhile, the quicker turnover of foam cores might necessitate frequent redesigns or replacements, which could impact customer relationships. -

Industry Standards and Testing Requirements:

Adhere to sports equipment standards to ensure safety and performance claims. The iterative testing and quality assurance process becomes crucial when exploring newer materials like composite honeycomb cores, where field testing and player feedback play significant roles in product success.

In summary, selecting the best core material for pickleball paddles involves balancing several factors: immediate performance characteristics, durability under competitive conditions, production cost, and overall product positioning. Honeycomb cores—particularly those using advanced polymers or Nomex—tend to offer a more balanced solution for high-performance paddles with excellent weight distribution, impact absorption, and long-term resilience. Conversely, foam cores provide benefits in cost and ease of manufacture but might not meet the performance standards required by competitive players.

For product development managers, the recommendation is to thoroughly test both materials in pilot runs or controlled field tests to understand how each performs under your specific use conditions. Use your data from manufacturing insights and performance metrics to decide if a premium honeycomb approach can justify the higher investment through improved consumer performance ratings and brand differentiation.

Implementing detailed technical comparisons such as the table above, along with iterative testing, will refine your paddle designs and help you align with evolving market demands. Ultimately, your choice will depend on balancing these multifaceted criteria to drive innovation and maintain competitive edge in the sporting goods market.

People Also Ask

Q1: What is the best core material for a pickleball paddle?

A1: Generally, while lower-end paddles often use full Nomex or aluminum cores, polymer cores1 have proven superior for most competitive pickleball paddles due to their balanced performance in impact absorption, weight distribution, and overall durability.

Q2: What is the best core thickness for a pickleball paddle?

A2: Pickleball paddles generally range between 11mm and 16mm in thickness. Thinner paddles tend to offer more “pop” off the surface, while thicker paddles are better at absorbing the ball's energy, which can affect the overall hitting feel.

Q3: What is honeycomb core pickleball paddle?

A3: A honeycomb core pickleball paddle is built with a structure of empty cells similar to a natural honeycomb. This design increases strength and durability without adding extra weight, and these cores can be made from materials such as polymer, aluminum, or Nomex for improved shock absorption and performance.

-

polymer honeycomb cores: Read this article to understand the advanced polymer composite technology behind honeycomb cores, including its benefits in shock absorption and balanced weight distribution for high-performance paddles. ↩ ↩ ↩2

-

foam cores: Click here to explore the properties of foam cores including manufacturing techniques and their impact on paddle responsiveness and cost efficiency. ↩ ↩

-

Nomex: Learn more about Nomex, a high-performance material used in honeycomb structures, known for its exceptional durability and lightweight properties. ↩ ↩ ↩2

-

Hot Pressing: Discover how hot pressing is employed in manufacturing to enhance bonding and structural integrity in both foam and honeycomb paddle cores. ↩ ↩

-

Thermoforming: Click to read about thermoforming, a process that offers high customization in paddle design by precisely distributing multiple materials in the composite structure. ↩ ↩