Advanced foam injection1 techniques improve pickleball paddle durability by enhancing edge impact resistance and shock absorption while reducing material fatigue2.

In today's competitive sports equipment market, enhancing the durability and performance of pickleball paddles is of utmost importance. Traditional edge designs often face issues such as chipping and cracking over time, which can hinder overall performance. For B2B product developers, quality assurance managers, and procurement specialists, understanding advanced production methods is critical for making informed decisions. One such innovation is the integration of foam injection along the paddle’s edges. This article explores the challenges of traditional methods, the benefits of foam injection, and how incorporating this process can optimize paddle production.

Problem Description

Traditional manufacturing methods for pickleball paddles frequently rely on conventional edge treatments that may not fully protect the paddle from repetitive impacts. Over time, constant stress on the edges can lead to micro-cracks, material wear, and ultimately, paddle failure. Such drawbacks affect not only the player’s performance but also the overall competitiveness of the product in the sports equipment marketplace.

Key issues include:

• Reduced impact resistance due to inadequate edge protection

• Material fatigue2, leading to a shorter product lifespan

• Inconsistencies in manufacturing quality affecting overall performance

• Lack of shock absorption during high-impact play

For businesses striving to offer products that meet the highest standards of performance and durability, addressing these issues is essential. Traditional techniques, while effective to some extent, often fall short when faced with high-impact environments and rigorous competitive play.

Cause Analysis

Several factors contribute to the limitations of conventional paddle production methods:

- Material Fatigue: Constant play leads to repeated stress at the paddle’s edges, causing material fatigue which eventually results in cracks and decreased durability.

- Inadequate Impact Absorption: Traditional rigid materials and designs often lack enough cushioning to absorb shock effectively, leading to early wear.

- Production Process Constraints: Techniques such as hot pressing, cold pressing, or thermoforming3 may excel in specific areas but might not address all durability aspects, particularly on the edges where the force of impact is concentrated.

- Design Limitations: Many conventional paddles are designed without focusing on edge enhancement, prioritizing other performance factors such as weight distribution or grip ergonomics while compromising long-term durability.

Through understanding these challenges, manufacturers can better address the shortcomings with targeted production innovations.

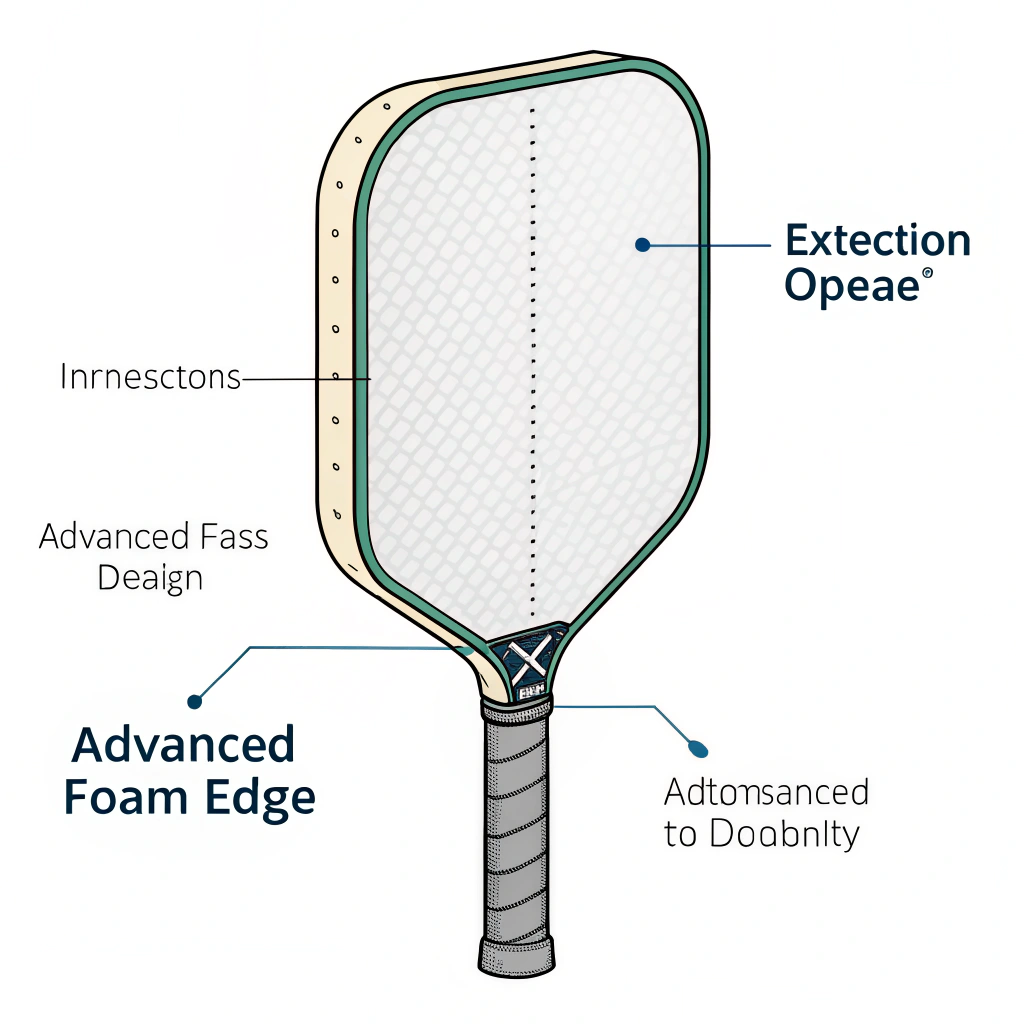

Solution: Integrating Foam Injection for Enhanced Durability

Foam injection represents a breakthrough in enhancing the durability of pickleball paddles. This production process involves injecting a carefully selected foam material along the paddle’s edges to provide added cushioning and shock absorption. Foam injection contributes significantly to extending the paddle’s lifespan and maintaining consistent performance across prolonged use.

Key benefits of foam injection include:

• Improved Edge Impact Resistance: The foam acts as a buffer against the shocks and vibrations experienced during gameplay.

• Enhanced Shock Absorption: The inner foam provides a cushioning effect, reducing the direct stress on the paddle's rigid materials.

• Reduced Material Fatigue: By alleviating extreme stresses on the paddle edges, the foam helps minimize material degradation over time.

• Optimized Production Consistency: Foam injection can be incorporated into existing processes with precision controls to ensure a consistent and high-quality product.

To put these benefits into perspective, consider the following comparison:

| Production Technique | Advantages | Disadvantages |

|---|---|---|

| Traditional Edge Design | Simpler production, lower initial cost | High risk of cracking, lower impact absorption |

| Foam Injection Edge | Enhanced shock absorption, improved durability, reduced fatigue | Requires investment in injection technology |

| Other Reinforcement Techniques | May add strength but often increase weight and reduce flexibility | Can compromise overall performance if not optimally designed |

This table outlines the clear advantages of integrating foam injection compared to relying solely on traditional edge fabrication methods.

Production Process Integration

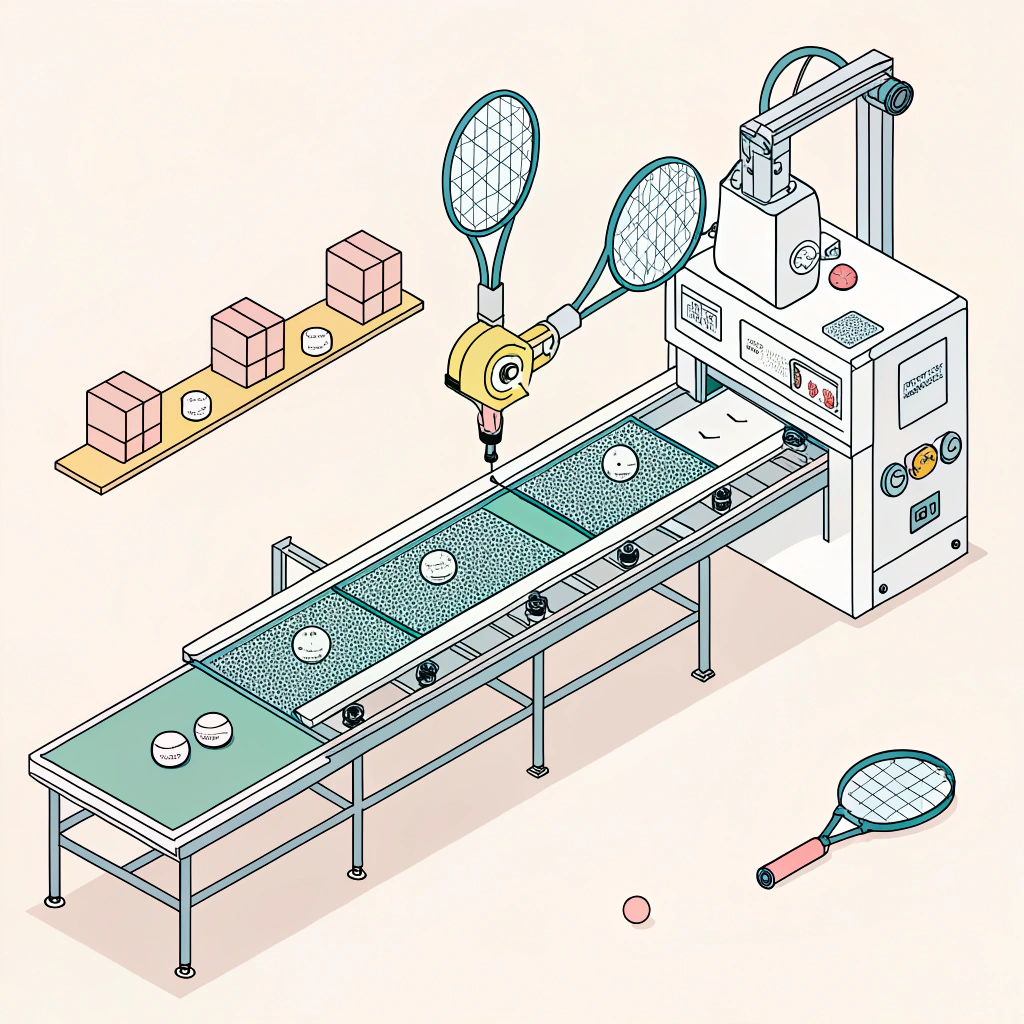

Integrating foam injection into paddle production involves a series of carefully controlled steps. Manufacturers like NEX Pickleball continuously refine their processes to incorporate advanced techniques using hot pressing, cold pressing, and thermoforming in tandem with foam injection. Here is a step-by-step overview of how foam injection is integrated into the production process:

-

Pre-Processing & Material Selection

The first step is selecting high-quality materials suited for foam injection. For superior performance, materials like carbon fiber4 or fiberglass5 are prepared alongside the specialized foam. The foam selected is engineered to provide optimal shock absorption while maintaining low weight. -

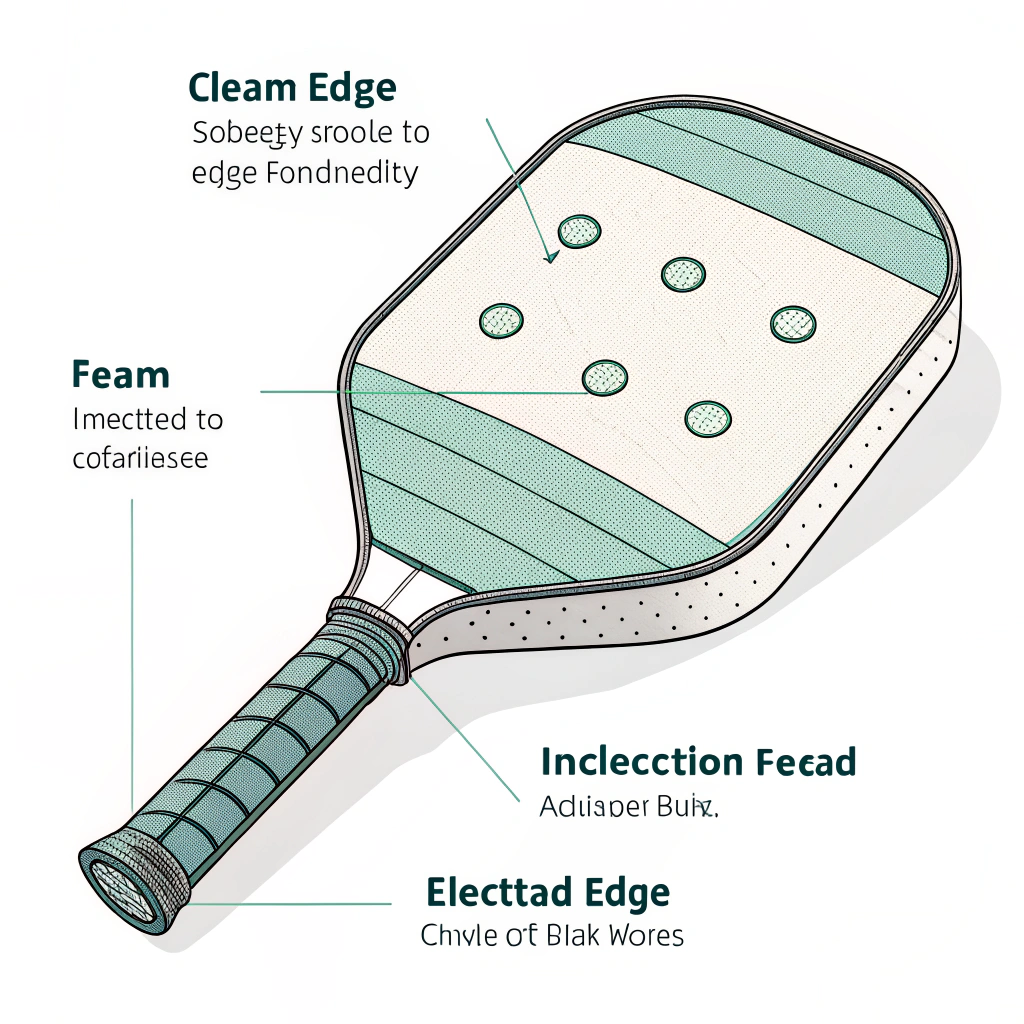

Core and Edge Assembly

During the paddle assembly process, the core material (such as Nomex honeycomb or polymer core) is combined with the paddle’s surface layers. The edges, which are particularly susceptible to wear and tear, are specifically prepared for foam injection. Precise alignment and securing of the paddle components ensure that the foam integrates uniformly. -

Injection Process

Advanced injection systems then inject the foam into the designated edge areas. This step is critical as it requires tight control over the foam's viscosity and curing time. The foam quickly fills gaps, forming a continuous protective barrier along the edge. Automation in this phase minimizes human error and guarantees consistency. -

Curing & Finishing

Once the foam injection is complete, the paddle undergoes a curing process to solidify the foam. Subsequent finishing steps ensure that the protective layer not only adheres well but also integrates seamlessly with the paddle’s design features, such as grip texture and weight distribution. -

Quality Control & Testing

After production, every paddle is rigorously tested to ensure it meets quality standards. Impact tests, flexibility assessments, and durability tests are critical components of the quality control process. With foam injection, testing includes verifying the foam's adhesion and its effectiveness in mitigating impact-related damage over prolonged play.

Real-World Impact and Case Studies

At NEX Pickleball, integrating foam injection into paddle manufacturing has proven to significantly enhance product longevity. Our extensive testing pipeline includes simulated play scenarios that subject paddles to rigorous impacts and vibrations. Results indicate that paddles with foam-injected edges demonstrate superior performance, with reduced crack formation and lower overall material degradation.

For example, one case study comparing paddles produced with and without foam injection showed that foam-injected models maintained their structural integrity over 30% more high-intensity play sessions compared to conventional designs. This not only reinforces the benefit of foam injection in terms of durability but also boosts confidence among distributors and end users.

Several aspects of our approach contribute to this success:

• A focus on precise foam formulation suited for high-performance needs

• A streamlined injection process integrated with our established production lines

• Comprehensive quality testing protocols ensuring that each paddle meets strict durability standards

The impact of this integration has also positioned our products favorably in the market. Feedback from professional players and sports retailers underscores the reliability and extended lifespan of foam-injected paddles, reinforcing our commitment to innovation and quality.

Additional Considerations and Best Practices

While foam injection significantly boosts paddle durability, manufacturers must consider several key aspects for optimal integration:

-

Process Calibration:

The foam injection process requires precise calibration. Maintaining consistent temperature, pressure, and curing time is essential to ensure uniform coating and adhesion. Deviations can impact the foam's performance, reducing the overall benefit and potentially damaging the paddle structure. -

Material Compatibility:

Not all paddle materials are equally compatible with foam injection. For instance, carbon fiber4 and fiberglass5 have distinct properties, and the foam formulation must complement these materials to prevent adverse chemical interactions. Testing different foam-material combinations to refine the process is recommended. -

Equipment Investment:

Incorporating foam injection technology may require additional investments in specialized machinery and quality control systems. However, the long-term benefits—improved durability and reduced warranty claims—often justify the cost. A detailed cost-benefit analysis should be conducted to evaluate this investment. -

Production Scalability:

As demand increases, the production process needs to scale without sacrificing quality. Automation in foam injection ensures that the process remains consistent even at higher volumes. Implementing rigorous quality control throughout the production chain is vital to maintaining high standards. -

Continuous Improvement:

The field of material engineering is constantly evolving. It is important to keep abreast of emerging technologies and innovations in foam formulations and injection techniques. Regularly reviewing and updating production protocols helps maintain a competitive edge in the market.

Conclusion and Action Recommendations

Foam injection is a transformative technique that addresses one of the most critical challenges in pickleball paddle manufacturing—edge durability. By providing a buffer against impact and distributing stress more evenly across the paddle, this method enhances both performance and product lifespan. Companies considering upgrading their manufacturing processes should explore integrating foam injection into their production lines, especially when the goal is to offer a superior, durable product in a competitive market.

Actionable steps for B2B buyers and production specialists include:

• Conducting pilot tests with foam injection to analyze performance improvements

• Collaborating with material scientists to select the best foam formulations

• Investing in process automation to ensure consistent quality

• Engaging with experienced manufacturing partners like NEX Pickleball who have successfully integrated this technology

Integrating advanced production techniques, such as foam injection, into your manufacturing process not only enhances product durability but also delivers measurable benefits in market competitiveness and customer satisfaction. By adopting these innovations, companies can ensure that their pickleball paddles remain at the forefront of the industry, withstand rigorous play, and ultimately drive long-term value for both businesses and end users.

People Also Ask

Q: What is the most durable pickleball paddle material?

A: Carbon fiber is widely recognized as one of the most durable materials for pickleball paddles, offering excellent power generation and resistance to wear over time. Its high-strength properties make it a popular choice among competitive manufacturers.

Q: What material pickleball paddles are best for not breaking?

A: Carbon fiber paddles are a leading option for those seeking break-resistant pickleball paddles. They combine stiffness and lightweight properties to provide unparalleled durability, making them ideal for high-impact play.

Q: What type of pickleball paddle lasts the longest?

A: While carbon fiber paddles are renowned for toughness, many manufacturers find that fiberglass paddles can offer a balance between longevity and performance. The inherent flexibility of fiberglass helps absorb impacts better, contributing to a longer-lasting paddle.

-

foam injection: Reading this article will help you understand how foam injection works to enhance product durability and performance by providing improved shock absorption and edge reinforcement. ↩

-

material fatigue: Explore the concept of material fatigue, its impact on product longevity, and strategies to mitigate its effects in high-impact environments. ↩ ↩2

-

thermoforming: Gain insights into thermoforming, a manufacturing process that uses heat to shape plastic materials, enhancing production efficiency and design precision. ↩

-

carbon fiber: Discover the properties and advantages of carbon fiber, a high-strength material known for its lightweight durability and performance in sports equipment. ↩ ↩2

-

fiberglass: Learn about fiberglass, its role in balancing durability with flexibility, and how it contributes to the overall performance of sports gear. ↩ ↩2