In short, NEX Pickleball’s high-performance pickleball paddles deliver optimal power, control, and durability through advanced production techniques and premium materials, ensuring reliable and competitive B2B sourcing.

NEX Pickleball excels in manufacturing paddles that meet the rigorous demands of competitive play. Our paddles are crafted in a modern factory environment in Jiaxing, Zhejiang, China, using processes that ensure every paddle is consistent, durable, and high in performance. Today’s article explains the manufacturing process, quality control measures, and the material choices that distinguish our paddles in the global market. We also discuss how these elements contribute to reliable export quality, competitive pricing, and long-term business partnerships.

Our paddles are engineered with a focus on three core aspects:

• Material Quality: We use premium carbon fibers (3K, 12K, T300), fiberglass, and composite materials to provide power and control.

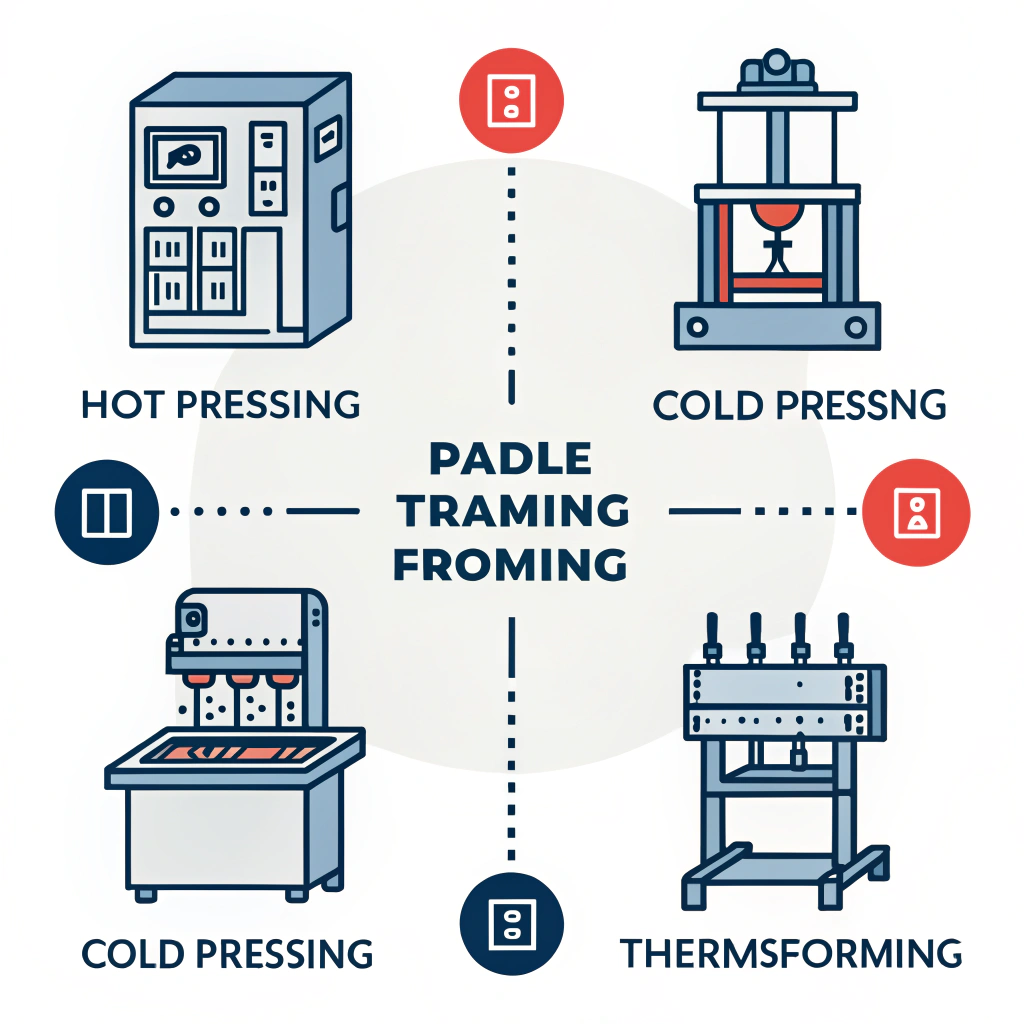

• Advanced Production Processes: Techniques like hot pressing, cold pressing, and Thermoforming1 ensure each paddle achieves consistent quality.

• Customization Capability: Our custom paddle options help clients match equipment to the playing and branding requirements of teams, retailers, and distributors worldwide.

To achieve top-tier performance, NEX Pickleball employs three distinct production processes. Choosing the right process is critical as it affects paddle strength, weight, and feel.

Below is a table summarizing the key differences and trade-offs among the three major processing techniques:

| Production Process | Advantages | Disadvantages | Ideal Usage |

|---|---|---|---|

| Hot Pressing | High production efficiency; ensures strong paddles with excellent impact resistance; maintains structural integrity | May affect the paddle’s feel due to material changes; high equipment investment | High-performance paddles needing durability and power |

| Cold Pressing | Precise control over paddle thickness; preserves material properties; offers excellent ball feel and responsiveness | Longer production cycles; requires high-quality pressure control systems | Paddles focused on control and flexibility |

| Thermoforming | Allows for intricate designs and optimal material distribution; maintains stability during high-intensity play | Requires more production time; higher equipment costs | Premium products or custom designs with complex shapes |

Hot Pressing is widely used for large-scale manufacturing since it offers production efficiency and consistently strong paddles. On the other hand, Cold Pressing preserves material properties and provides players with a softer ball feel, meeting the demands of those seeking control and precision. Thermoforming is perfect for customized designs, ensuring even the most detailed paddle configurations maintain structural balance and performance.

At NEX Pickleball, the performance of our paddles is significantly influenced by the quality of the materials used. Here’s a breakdown of our key material categories:

We employ various types of carbon fiber for specific performance outcomes:

- 3K Carbon Fiber: Valued for its strength and flexibility, 3K is ideal for paddles requiring high rebound force and vibration reduction.

- 12K Carbon Fiber: With a higher thread density, this variant offers a smoother surface, enhanced hardness, and exceptional durability, perfect for competitive play.

- T300 Carbon Fiber: Known for its superior tensile strength, T300 strikes a balance between rigidity and lightweight performance.

These carbon fibers ensure that players experience maximum power while retaining precise control over their shots.

Fiberglass paddles, particularly those made with E-Glass Fiberglass2, offer a balance between power and control. They possess a wider sweet spot and increased flexibility, making them excellent for ball control and offering greater durability on the court.

In addition to pure material types, our composite paddle designs combine different materials to harness the best of each:

- Carbon Fiber and Fiberglass Composite: This blend provides a remarkable balance of strength and responsiveness, serving players seeking both power and tactile feedback.

- Bamboo Core Composite: The use of bamboo adds lightweight resilience and a clear hitting feel, ideal for prolonged play.

- Honeycomb Core3: Constructed from high-density polymers, the honeycomb core offers superior shock absorption, reducing vibration and extending paddle life.

By carefully selecting and combining these materials, we ensure that each paddle provides a competitive advantage on the court while meeting export quality standards.

Quality control is paramount in B2B sourcing. At NEX Pickleball, every paddle undergoes rigorous testing to ensure it meets or exceeds industry standards. Our testing protocols include stress tests, balance assessments, and durability trials to guarantee that the paddle can withstand high-impact play.

- Material Inspection: All raw materials, including carbon fiber, fiberglass, and composite elements, are inspected to ensure they meet premium quality standards.

- Process Monitoring: Each manufacturing step—whether it’s hot pressing, cold pressing, or thermoforming—is carefully controlled. Automated and manual checks guarantee consistent performance and quality.

- Final Product Testing: Finished paddles are evaluated for weight distribution, grip comfort, and impact resistance to assure quality before shipment.

Recognizing that every client has unique requirements, we offer custom paddle designs where purchasers can select features such as core material, grip size, weight, and even graphic detailing. This tailored approach is crucial for companies looking to market exclusive or branded sports equipment to end users.

Our ODM (Original Design Manufacturer) and EMS (Electronics Manufacturing Services) capabilities ensure that clients receive both innovation and reliability. We work closely with each partner to adapt our production processes to meet specific needs, ensuring that every order—no matter how complex—is handled with the utmost precision and care.

NEX Pickleball is renowned not only for its product quality but also for its reliable global export service. Our streamlined production processes and strict quality control enable us to offer competitive pricing in the sports equipment market. For procurement executives and sourcing managers looking for long-term partnerships, our export track record reflects consistent on-time deliveries, quality consistency, and excellent after-sales service.

Competitive pricing is achieved through continuous improvements in production efficiency. By adopting cutting-edge techniques such as automated pressing and precise temperature controls in thermoforming, we lower production costs and pass on the savings to our partners.

As global demand for pickleball paddles continues to surge, sourcing managers must navigate a field of competitive suppliers. Here are some data-driven insights and strategies for selecting a long-term manufacturing partner:

- Manufacturing Processes: Ensure the supplier employs advanced and reliable techniques. A comprehensive understanding of hot pressing, cold pressing, and thermoforming is essential, as these directly impact product performance.

- Material Quality: The source and quality of materials such as carbon fiber and fiberglass are crucial. Prioritize suppliers that use diversified materials to offer both high durability and performance.

- Customization Capabilities: For brands looking to differentiate in a crowded market, the ability to customize design details and performance features is a strong advantage.

- Quality Control: Look for detailed documentation of quality assurance and testing protocols. Consistency in production is a hallmark of a reputable manufacturer.

- Export Performance: With global export as a critical factor, assess the supplier’s track record in meeting international quality standards, on-time delivery, and after-sales support.

- Schedule a Factory Visit: Gain firsthand insight into the production environment, observe quality control measures, and discuss customization options directly with the production team.

- Request Sample Paddles: Evaluate the product performance, material quality, and customization options before placing a large order.

- Compare Production Methods: Use the process comparison table provided to understand which production method aligns best with your business needs and market expectations.

- Assess Export Credentials: Review the supplier’s export records and certifications to ensure compliance with global quality and safety standards.

- Engage in Long-Term Partnership Discussions: Consider the supplier’s willingness to collaborate on product development, as this is key to ongoing innovation and market success.

In today’s dynamic sports equipment market, choosing the right supplier can significantly impact your business's long-term success. With NEX Pickleball, you have a partner committed to excellence—from advanced manufacturing capabilities and high-quality materials to rigorous testing and reliable export performance. This integrated approach not only meets current market demands but also anticipates future trends, ensuring that your sourcing strategy remains competitive and responsive.

• Which pickleball paddles are not made in China?

While many high-performance pickleball paddles are manufactured in China due to proven quality and cost advantages, several products are made in the USA, such as the Gamma 405 Graphite, PROLITE Stealth GS2 Carbon Fiber, and Paddletek Bantam Carbon Fiber paddles.

• What company sells the most pickleball paddles?

Leading brands such as CRBN, JOOLA, OWL, and Paddletek are recognized as best selling in the market. These companies have established their reputation through innovation, quality craftsmanship, and widespread distribution.

• Where are Joola paddles manufactured?

Joola paddles are manufactured in China using advanced production processes. Although Joola is a German-based company, its paddles are produced in China and then distributed via multiple centers globally.

-

Thermoforming: Read the article to understand how thermoforming is used to shape composite materials for consistent quality and intricate design in sports equipment manufacturing. ↩ ↩

-

E-Glass Fiberglass: Read the article to understand the unique properties of E-Glass Fiberglass and its role in balancing power and control in paddle construction. ↩ ↩

-

Honeycomb Core: Read the article to explore the advantages of honeycomb core structures in enhancing shock absorption and durability in high-performance sports equipment. ↩ ↩

-

ODM: Read the article for insights on Original Design Manufacturer practices and how partnering with an ODM can drive product innovation and customization in the B2B sector. ↩ ↩

-

EMS: Read the article to learn about Electronics Manufacturing Services and their benefits for streamlining production processes and ensuring high-quality output. ↩ ↩