Our quality control process in pickleball paddle manufacturing ensures that every paddle not only meets industry standards but also delivers consistency, durability, and optimal performance on the court.

Quality control (QC) is the backbone of high-performance sports equipment manufacturing. In the fast-growing sport of pickleball, where every paddle’s performance can significantly affect competitive play, maintaining rigorous QC protocols is essential. At NEX Pickleball, we integrate advanced production techniques and systematic inspection measures to guarantee that each paddle leaving our facility meets strict quality criteria. By focusing on process efficiency and standardized testing at every stage—from raw material selection to final product inspection—we ensure that our paddles deliver unmatched performance and durability.

The primary challenge in pickleball paddle manufacturing is balancing performance, durability, and consistency. Without a robust QC process, even minor variations in production can lead to inconsistent paddle responses, affecting a player’s performance and safety. Common issues faced in the industry include:

- Variability in material properties due to inconsistent raw materials.

- Deviations in manufacturing processes such as hot pressing, cold pressing, and thermoforming.

- Lack of standardized measurement and testing protocols during production.

- Difficulties in scaling production without compromising quality.

In light of these challenges, procurement managers and quality assurance specialists in the sports equipment sector seek reliable manufacturing partners who have proven QC protocols. This ensures that every batch is consistent and meets the demanding requirements of competitive play and retail distribution.

At NEX Pickleball, our QC process is divided into several systematic phases designed to address potential quality issues at every step of production. These phases include:

Before production begins, each batch of raw materials—including carbon fiber (3K, 12K, T300), fiberglass, composite materials, and various core elements (Nomex1, aluminum, polymer honeycomb cores)—is inspected for quality. Our suppliers are carefully vetted, and we enforce strict standards to ensure every material meets our specifications.

Key Actions:

- Material composition and density measurement.

- Visual inspection for inconsistencies.

- Mechanical testing for elasticity and strength.

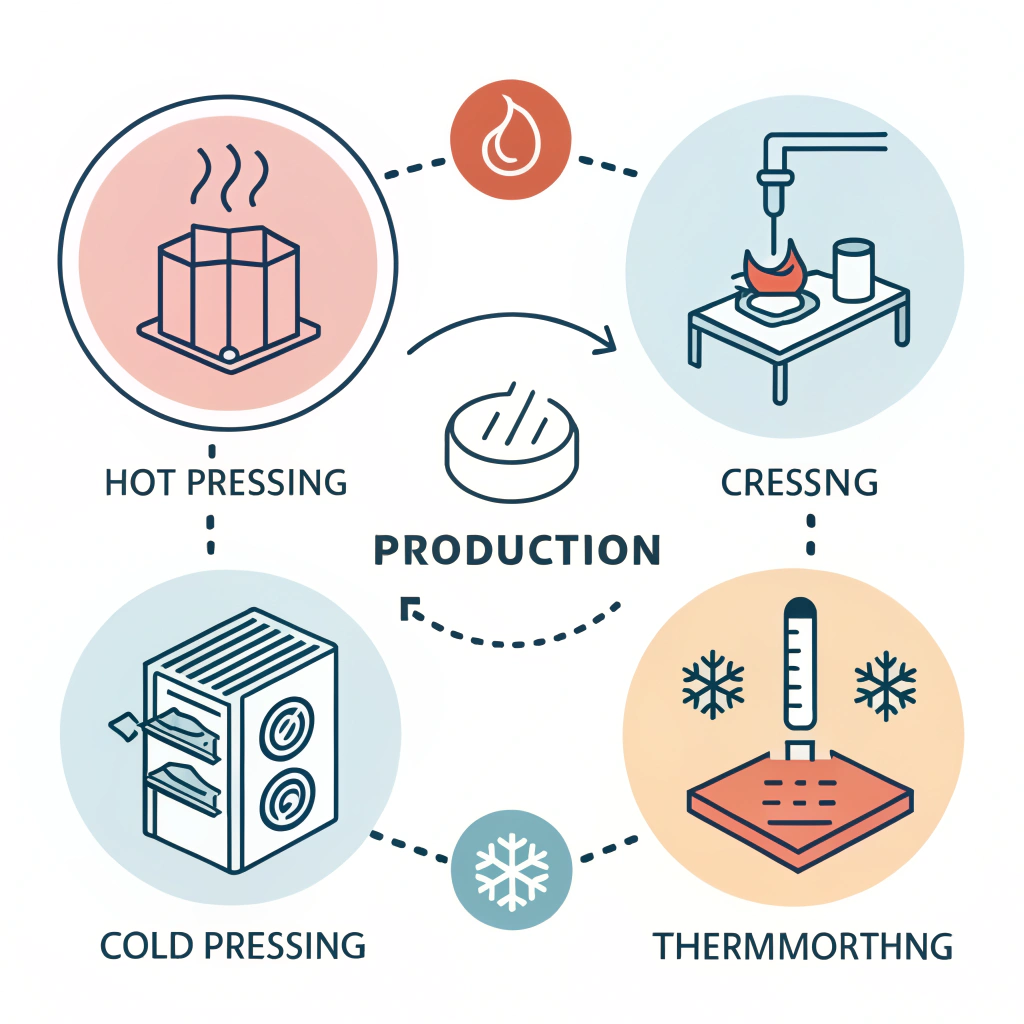

During the manufacturing process, we implement multiple checkpoints depending on the production technique used. Our main production processes include:

- Process Overview: Materials are heated and pressed under high pressure to form a durable paddle structure.

- QC Focus: Temperature control, pressure consistency, and time management are critical to ensuring the structural integrity of the paddle.

- Potential Issues: Overheating may alter material properties, affecting the paddle's feel.

- Process Overview: Materials are formed at room temperature under mechanical pressure, allowing for precise control.

- QC Focus: Consistency in pressure application and maintaining the material’s intrinsic properties for an optimal ball feel.

- Potential Issues: Extended production cycles may introduce variability if not meticulously monitored.

- Process Overview: Materials are softened via controlled heating and then shaped using molds.

- QC Focus: Precisely controlling heating time and mold accuracy to achieve desired shape and thickness.

- Potential Issues: Longer production times and higher equipment costs demand careful balancing of efficiency and quality.

To clarify, below is a summary table of our main production techniques, along with their advantages and challenges:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High production efficiency; strong and durable paddles | Potential alteration of material properties; high equipment cost |

| Cold Pressing | Precise control over paddle structure; retains material quality | Longer production cycle; requires precision equipment |

| Thermoforming | Enables intricate designs; maintains paddle stability | Increased production time; higher operational expenses |

After the manufacturing process, every paddle undergoes a stringent final inspection. Testing includes:

- Dimensional Accuracy: Verifying weight distribution, balance, grip size, and surface texture.

- Performance Testing: Ensuring rebound, impact resistance, and vibration dampening meet our high-performance criteria.

- Durability Assessments: Simulated long-term usage to check structural integrity.

Our QC protocols mirror industry standards and often extend to voluntary compliance with international guidelines. Although certification by bodies like the USAPA4 is not a requirement for every product, our internal standards are designed to align closely with these recognized protocols, ensuring that every paddle is fit for competitive play.

The integration of advanced production techniques such as hot pressing, cold pressing, and thermoforming is essential to producing paddles that meet the demands of modern pickleball. Let’s delve deeper into each method:

Hot pressing leverages high temperatures and pressure to create paddle layers that bond tightly. This process is critical for achieving a high level of impact resistance. However, slight deviations in temperature or pressure can impact the paddle’s elasticity. By employing real-time monitoring systems, we ensure consistent conditions, minimizing quality drift across production batches.

Cold pressing is particularly beneficial for producing paddles that require a delicate balance between stiffness and flexibility. Since the process occurs at room temperature, the material’s original properties are preserved, resulting in enhanced control and a superior ball feel. This method is particularly advantageous for paddles designed for players who emphasize precision and control.

Thermoforming combines the benefits of both heat and molding processes, allowing us to create paddles with intricate designs and precise thickness distributions. This process supports custom paddle designs that cater to individual player preferences or specific team branding needs. The challenge, however, lies in managing the extended production time and controlling the softening process to avoid compromising durability.

Each production process offers unique advantages that allow us to tailor our products to various player profiles—from beginners needing a cushioned experience to professionals requiring a finely tuned balance of power and control.

For procurement professionals, selecting a manufacturer is not just about cost but also about reliability. A well-defined QC process demonstrates a manufacturer’s commitment to excellence. At NEX Pickleball, our QC protocols serve as a robust foundation for supplier reliability:

- Consistency: Our systematic inspection at each production stage minimizes variations.

- Traceability: Detailed records allow us to track material properties, production parameters, and inspection results, ensuring continuous improvement.

- Certifications and Testing: Even though third-party certification (e.g., USAPA-approved testing) is separate from our internal QC, our processes are designed to facilitate compliance with such external requirements if needed.

- Customer Confidence: By consistently delivering high-performance paddles, we build trust with our partners. Our detailed QC reports and transparent processes help B2B procurement managers confidently choose us as their long-term supplier.

The integration of automated testing equipment and data analytics in our QC process supports scalable production without sacrificing quality. This makes us a reliable partner for bulk orders and custom manufacturing projects, where maintaining consistency across large shipments is critical.

Recent industry data has shown that paddles produced with rigorous QC measures tend to have a significantly lower rate of product returns and warranty claims. Adopting data-driven quality assurance practices enables us to continuously refine our processes:

- Real-Time Monitoring: Sensors and automated monitoring systems track critical parameters (e.g., temperature, pressure) during production, reducing human error.

- Statistical Process Control (SPC): We use Statistical Process Control (SPC)5 to monitor variations during production in order to identify trends and intervene before quality issues escalate.

- Feedback Loops: Customer feedback, combined with field performance data, helps us identify areas for improvement and fine-tune manufacturing parameters.

- Continuous Training: Our staff is continually trained on the latest industry standards and QC methodologies, ensuring that everyone from the operator to the quality assurance manager understands the importance of precision.

Best practices in QC are not only about meeting but exceeding industry benchmarks. This commitment to excellence has made NEX Pickleball a trusted name in both competitive and recreational markets.

Quality control in pickleball paddle manufacturing is the cornerstone of consistency, performance, and customer satisfaction. By integrating rigorous QC protocols, using advanced production techniques, and employing continuous monitoring and data analytics, NEX Pickleball ensures that every paddle meets the highest quality standards.

Procurement managers can take confidence in knowing that our detailed inspection processes—from raw material sourcing and in-process evaluations to final product testing—are designed to deliver paddles that excel in both performance and durability. For businesses seeking a reliable manufacturing partner, our commitment to innovation, quality assurance, and consistent delivery makes us the preferred choice.

If you are evaluating suppliers for your next bulk paddle order or exploring custom paddle solutions, consider partnering with a manufacturer that places quality control at the forefront of production. Contact us today to learn more about how our advanced QC processes can benefit your business and ensure the highest standards for your end product.

Q: Is there a process to certify pickleball paddles and balls?

A: Certification of pickleball paddles is generally performed by organizations such as the USAPA4, which rely on approved testing laboratories and certified evaluators to ensure that each paddle complies with established guidelines. At NEX Pickleball, our internal quality control protocols are designed to align with these rigorous certification standards, ensuring consistency and performance even before external testing occurs.

Q: How to choose the correct pickleball paddle?

A: Selecting the right pickleball paddle depends on your player type and performance requirements. For beginners, comfort, ease of swing, and a larger sweet spot are key features, while competitive players might prioritize paddles designed for greater power and precision. Important factors include paddle weight, balance, grip size, and material composition. Our range of paddles, built under strict quality control measures, caters to both recreational and high-performance needs, ensuring you find the best match for your playing style.

-

Nomex : Read the article to understand the properties and industrial applications of Nomex, a fire-resistant material widely used in high-performance manufacturing. ↩

-

Hot Pressing : Read the article to explore how hot pressing utilizes heat and pressure to form robust composite structures in manufacturing. ↩

-

Thermoforming : Read the article to learn about thermoforming techniques that shape materials into intricate designs with precision. ↩

-

USAPA : Read the article to understand the role of USAPA in certifying pickleball equipment and maintaining industry standards. ↩ ↩2

-

Statistical Process Control (SPC) : Read the article to gain insights into SPC methods that monitor production variability and drive quality improvements. ↩