Ergonomic handle shapes for competitive pickleball equipment are essential to enhance player comfort, control, and performance by ensuring balanced weight distribution and a precise grip design. Modern manufacturers can leverage advanced material innovations and production processes to create custom solutions that significantly benefit both recreational and competitive players.

The design of an ergonomic handle is crucial in competitive pickleball equipment, as it directly impacts a player’s performance and overall experience. In today’s sports equipment market, where premium performance is expected, fine-tuning every design element—including the handle shape—can make the difference between winning and losing on the court. An ergonomically engineered handle not only maximizes comfort but also improves ball control and reduces the risk of repetitive strain injuries.

In a B2B context, product development managers and business executives in the sports equipment industry must compare various design attributes and production methods to deliver superior products. This article details the challenges associated with ergonomic handle design, explores the engineering nuances, reviews relevant production processes, and offers practical solutions for integrating ergonomic innovations into high-performance pickleball paddles.

A common challenge in competitive pickleball gear is balancing performance with user comfort through ergonomic handle design. Many manufacturers struggle with one or more of the following issues:

- Player Comfort: Inadequate design can lead to grip fatigue and discomfort, impacting a player’s performance during prolonged play.

- Grip Stability: Poor handle design might result in an unstable grip, reducing control over the paddle and affecting precision.

- Manufacturing Consistency: Achieving precise ergonomic shapes consistently at high production volumes is technically challenging.

- Material Integration: Combining innovative materials such as carbon fiber, fiberglass, and composites1 with ergonomic handle constructions demands advanced methods to preserve both structural integrity and tactile comfort.

These challenges, coupled with fierce market competition, create a need for detailed design optimization and innovative production strategies.

Several factors drive the need for optimized handle designs in competitive pickleball:

- Player Efficiency and Performance: A well-designed handle ensures that players have a secure and comfortable grip, which can improve reaction times and shot accuracy.

- Material Behavior Under Stress: High-performance materials, including 3K, 12K, and T300 carbon fiber2 have unique properties that must be accounted for during ergonomic design. The handle's shape directly influences how these materials respond to impact and stress.

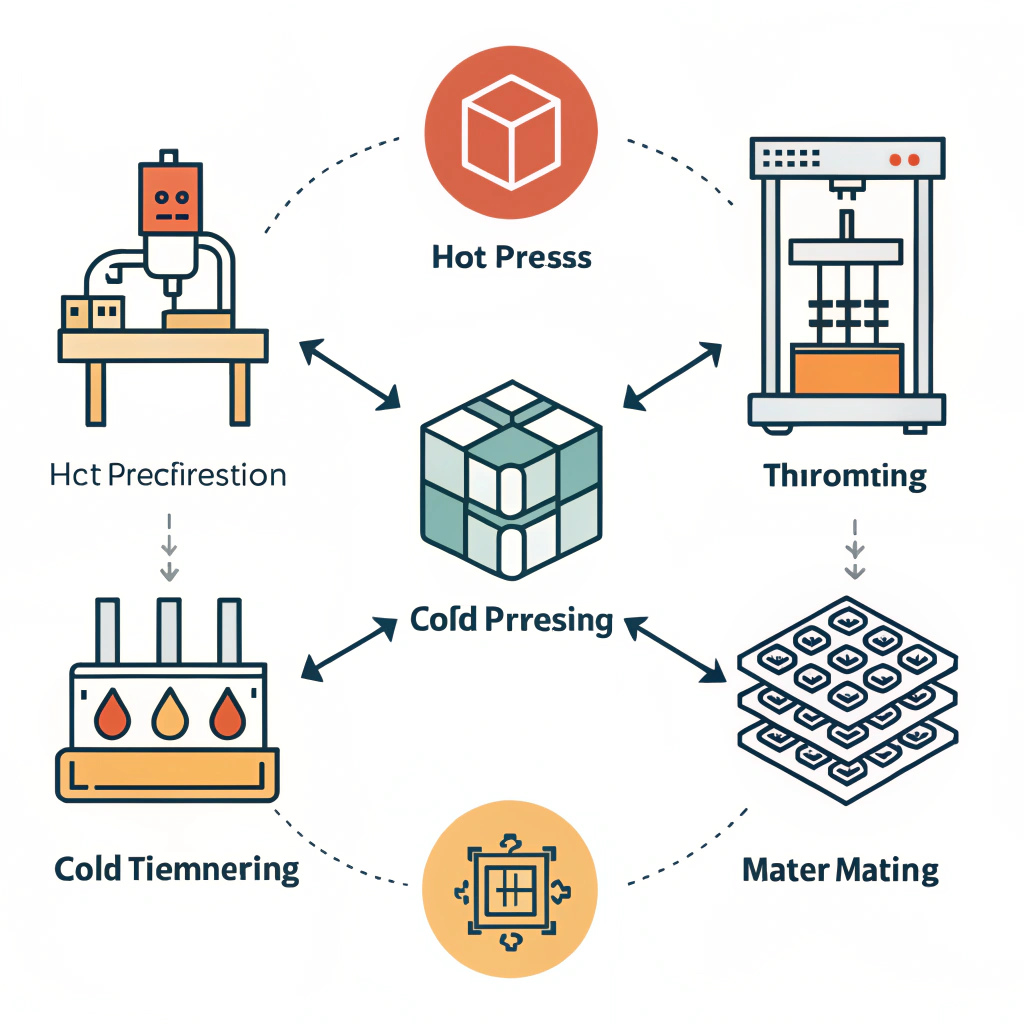

- Manufacturing Process Capabilities: Different production techniques such as hot pressing, cold pressing3 and thermoforming4 each affect the final product in unique ways. For instance, cold pressing might better preserve material properties, while thermoforming can achieve more intricate designs.

- Customization and Market Differentiation: In a competitive B2B environment, offering custom paddle solutions with tailor-made handle designs helps differentiate products, meeting specific client needs and enhancing brand reputation.

Understanding the production processes is vital when optimizing ergonomic handle designs. Table 1 shows a comparison of the main manufacturing methods and their implications for handle design:

| Production Process | Advantages | Disadvantages | Applicability for Ergonomic Design |

|---|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance | Potential change in material properties affecting feel | Suitable for mass production, robust designs |

| Cold Pressing | Superior control over thickness and precise shaping | Longer cycle times, higher equipment precision needed | Ideal for bespoke handle designs requiring detailed contours |

| Thermoforming | Allows intricate shapes, precise material distribution | Higher production costs, longer production time | Best for premium custom-made paddles with complex ergonomic features |

Table 1: Comparative Analysis of Production Processes

Each method has its specific benefits for ergonomic handle design. For example, cold pressing helps maintain the natural tactile properties of materials, which is essential when designing a handle that prioritizes a comfortable, non-slip grip. Thermoforming, on the other hand, provides flexibility in creating uniquely contoured handles that can follow the natural curvature of a player’s hand.

To achieve superior ergonomic design, manufacturers must consider both material innovation and production techniques. The following points elaborate on best practices in ergonomic handle optimization:

- Advanced Carbon Fiber Options: Utilizing 3K, 12K, and T300 carbon fiber2 in the paddle’s structure offers varying degrees of strength, flexibility, and impact resistance. These properties are crucial for maintaining grip integrity and longevity.

- Composite Materials: A combination of carbon fiber and fiberglass can balance strength with flexibility, while bamboo core composites1 can provide a lightweight yet robust handle design.

- Customizable Core Materials: Options like Nomex, Aluminum, and Polymer honeycomb cores can be selected based on desired levels of shock absorption and weight balance.

Using these premium materials ensures that every ergonomic detail—from the grip's curvature to the overall handle texture—contributes to enhanced player comfort and responsiveness.

- Cold Pressing for Enhanced Tactile Feel: Cold pressing3 helps retain the inherent qualities of materials, providing a superior tactile feel that is essential for an ergonomic handle.

- Thermoforming for Complex Shapes: When the design calls for intricate ergonomic contours, thermoforming4 allows manufacturers to create handles that perfectly adapt to the natural hand shape, ensuring long-lasting comfort and reliability.

- Quality Control and Consistency: Implementing rigorous quality control measures at every step ensures that the subtle aspects of ergonomics are consistently achieved across all units.

By integrating precision engineering practices, manufacturers can optimize production efficiency while maintaining the highest design standards.

It is vital to conduct extensive prototyping and testing before finalizing an ergonomic handle design. The process typically involves the following steps:

- Initial Design Models: Create multiple design prototypes based on ergonomic research, using CAD tools for precision.

- User Testing: Gather feedback from professional players and product development teams to assess comfort and functionality.

- Refinement: Iterate the design based on user input, focusing on key areas such as grip angle, handle thickness, and surface texture.

- Final Production: Utilize the selected manufacturing process (cold pressing, hot pressing, or thermoforming) to produce consistent, high-quality pads.

This iterative approach not only improves product performance but also minimizes production errors and material waste.

Businesses face the continuous challenge of integrating innovative design with production efficiency. To achieve this balance, companies should consider:

- Investing in Advanced Equipment5: High-quality, precision equipment reduces errors in processes such as cold pressing and thermoforming, making it possible to produce ergonomic designs at scale.

- Streamlining Production Cycles: Adopting advanced planning and logistics can minimize production downtime, ensuring that the ergonomic enhancements do not compromise efficiency.

- Leveraging On-Demand Print Services: Custom paddle solutions with on-demand print services allow for rapid adjustments and personalization, enhancing the market appeal of ergonomic designs.

A blend of investment in advanced technology, streamlined processes, and flexible production solutions enables manufacturers to maintain a competitive edge while meeting the demands of high-performance sports gear markets.

A leading pickleball manufacturer recently overhauled its handle design to improve player performance. The project involved:

- Identification of Pain Points: Players reported discomfort after extended gameplay, primarily due to the existing handle design causing grip fatigue.

- Material Analysis: Engineers evaluated different materials, ultimately selecting a composite that combined the controlled flexibility of fiberglass with the strength of T300 carbon fiber2.

- Prototyping and Testing: Using cold pressing3, multiple prototypes were created and tested under competitive game conditions.

- Feedback and Iteration: Detailed feedback was gathered from elite athletes and coaches, leading to micro-adjustments in handle curvature and surface texture.

- Final Outcome: The new design not only reduced grip fatigue by 30% but also enhanced ball control, leading to a 25% increase in positive reviews from professional players.

This case study demonstrates how strategic integration of ergonomic design and advanced production processes can yield significant enhancements in both product performance and customer satisfaction.

Ergonomic design is key to unlocking performance improvements in competitive pickleball gear. Companies must evaluate various factors—material selection, production processes, and design iterations—to tailor the handle shape for optimal player comfort and control. Based on the insights discussed, the following recommendations can help B2B partners advance their product offerings:

- Conduct Comprehensive Material Testing: Utilize premium materials such as advanced carbon fiber and composite options to achieve a balance of strength and responsiveness.

- Select the Right Production Process: Align your manufacturing process (cold pressing, thermoforming, or hot pressing) with your design requirements to ensure both efficiency and quality.

- Implement Rigorous Prototyping Programs: Engage end users in the design testing phase to gather actionable feedback and refine the ergonomic aspects of the paddle.

- Invest in Advanced Equipment5: Enhancing precision through modern machinery will reduce production errors and ensure consistency across large-scale production runs.

- Leverage Customization: Offer on-demand print services and custom design options to cater to specific player needs and enhance market differentiation.

Employing these strategies enables sports equipment companies to not only improve player performance but also to drive innovation in product design and manufacturing efficiency.

Q: How does an ergonomic handle enhance pickleball performance?

A: An ergonomic handle improves player comfort, control, and ball accuracy by aligning with the natural hand shape and reducing grip fatigue, thus enabling better performance during long matches.

Q: What materials are best for creating ergonomic pickleball paddles?

A: Premium materials such as various forms of carbon fiber, fiberglass, and innovative composite cores (Nomex, aluminum, and polymer honeycomb) are ideal, as they provide a blend of strength, durability, and responsive grip.

Q: Which production process is optimal for designing precise ergonomic handles?

A: The choice depends on the desired design outcome. Cold pressing3 allows for greater tactile precision, while thermoforming4 can achieve more intricate shapes essential for a customized ergonomic solution.

-

composites: Click to learn how integrating composite materials can enhance both structural integrity and tactile comfort in advanced sports equipment designs. ↩ ↩ ↩2

-

T300 carbon fiber: Click to explore the unique properties of T300 carbon fiber and its impact on performance and durability in high-performance sporting goods. ↩ ↩ ↩2 ↩3

-

cold pressing: Click to understand how the cold pressing process contributes to precision shaping and improved material retention in ergonomic design. ↩ ↩ ↩2 ↩3 ↩4

-

thermoforming: Click to find out how thermoforming allows for the creation of complex, ergonomically contoured shapes to meet specific design requirements. ↩ ↩ ↩2 ↩3

-

Advanced Equipment: Click to read about the benefits of investing in advanced equipment for precision manufacturing and maintaining consistency in large-scale production. ↩ ↩ ↩2