The article quickly answers the question: An optimal ergonomic handle design for high-performance pickleball paddles balances advanced geometry, premium materials, and precise manufacturing techniques, ensuring maximum grip comfort and competitive play performance.

Comparing Ergonomic Handle Designs and Manufacturing Processes for High-Performance Pickleball Paddles

For procurement and product development managers in the sports equipment industry, selecting the right combination of ergonomic design and manufacturing process is critical. High-performance pickleball paddles require innovations in handle geometry, careful material selection, and advanced production methods to deliver superior grip optimization, durability, and performance. In this article, we compare key ergonomic handle designs along with the manufacturing processes—Hot Pressing1, Cold Pressing2, and Thermoforming3—and discuss their impact on player performance. Our goal is to provide a detailed technical insight that will guide your purchasing and customization decisions.

Ergonomics is the science of designing products that fit the human body and its cognitive abilities. In pickleball, the handle design significantly influences player comfort, control, and overall performance. A well-designed handle ensures:

- Maximized grip comfort: Optimal dimensions and textures help reduce hand fatigue during long sessions.

- Enhanced control and accuracy: A balanced handle geometry supports precision in shot execution.

- Reduced injury risk: Proper ergonomics minimizes wrist and forearm strain.

In competitive environments, these factors translate into improved power, consistent ball contact, and quick maneuverability. The evolution of handle design mirrors advances in material science—moving from simple shapes to innovative geometries that optimize both the tactical grip and the overall balance of the paddle.

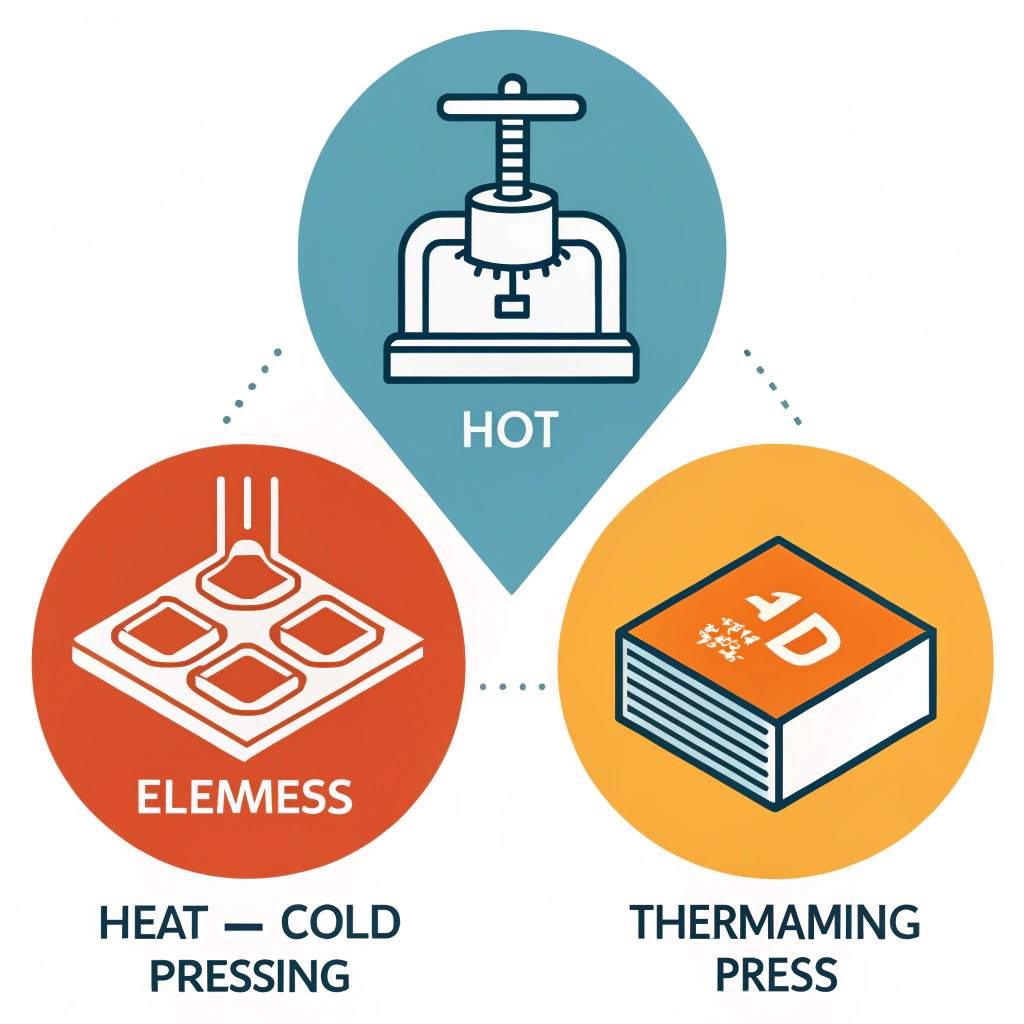

At NEX Pickleball, our manufacturing methods play an equally vital role in ensuring that our ergonomic designs not only feel comfortable but also retain durability and performance under multiple stress conditions. Let’s examine the three primary production methods we use:

Hot pressing involves heating materials and applying pressure simultaneously to form the paddle. This method is known for its high production efficiency and the ability to create durable, high-impact products.

-

Advantages:

- High production rates suitable for large-scale manufacturing.

- Results in paddles with excellent impact resistance and structural integrity.

- Enhances shock absorption, which can reduce the risk of material fatigue in handle regions.

-

Disadvantages:

- Elevated temperatures may alter material properties slightly, influencing the natural feel.

- Requires substantial upfront investment in specialized equipment.

The use of hot pressing can be particularly effective when combining composite materials4 with carbon fibers. These composites, particularly those blending T300, 3K, or 12K carbon fibers with fiberglass, offer the right balance of stiffness, strength, and lightweight comfort—key aspects in an optimized ergonomic handle.

With cold pressing, materials are shaped at room temperature using mechanical pressure. This method preserves the original characteristics of the materials, which directly benefits the ergonomic design and tactile feedback of the handle.

-

Advantages:

- Precise control over thickness and structure preserves the natural properties of the material.

- Excellent feel and responsiveness, essential for precise grip and control.

- Retains flexibility and ensures that ergonomic elements such as contours and grip textures remain intact.

-

Disadvantages:

- Production cycles are longer, potentially impacting manufacturing efficiency.

- Requires meticulous pressure control, which demands high-quality machinery and monitoring systems.

Cold pressing excels when producing customized handle designs with intricate shapes. For instance, incorporating customized grip textures and tailored ergonomic curves can enhance comfort for extended play.

Thermoforming uses heat to soften materials and molds them into complex shapes, which is ideal for sophisticated ergonomic designs that demand intricate detailing and precise material distribution.

-

Advantages:

- Highly adaptable for creating custom, complex handle designs.

- Ensures a consistent distribution of material, which is crucial for maintaining balance and tool-like precision.

- Supports designs that require multiple material layers, such as combining bamboo core composites with carbon fiber reinforcements.

-

Disadvantages:

- Generally involves a longer production time.

- High equipment costs may be a barrier for lower-scale runs.

Thermoforming allows for significant customization, enabling designers to work on prototypes and custom handles that meet specific player requirements. This process is particularly beneficial when performance enhancement is directly tied to the fine details of handle geometry.

Below is a table summarizing the differences between the three distinct production processes and their effect on ergonomic handle design optimization:

| Production Process | Advantages | Disadvantages | Impact on Ergonomic Design |

|---|---|---|---|

| Hot Pressing | High efficiency; excellent structural integrity; improved shock absorption | High investment; potential alteration of material feel | Enhances durability and consistency in load-bearing areas, ideal for rugged, performance-oriented designs |

| Cold Pressing | Precise control; retains material’s inherent properties; excellent tactile feedback | Slower production; requires precise equipment | Ideal for achieving complex ergonomic contours and custom textures that improve grip comfort |

| Thermoforming | Superior for complex shapes; high customizability; consistent material distribution | Longer process time; higher equipment costs | Best suited for advanced handle designs where manufacturing precision and material layering are crucial |

Beyond the production processes, the choice of materials is vital to achieving the right balance of performance and comfort in a paddle handle. NEX Pickleball employs a range of high-end materials:

-

Carbon Fiber (3K, 12K, T300):

- 3K: Offers flexibility with a strong rebound, making it ideal for players needing extra power without sacrificing comfort.

- 12K: Provides a smoother surface and greater hardness, suitable for competitive play where durability is essential.

- T300: Balances strength and reduced weight, creating ergonomic handles that feel responsive and light.

-

Fiberglass:

- Known for its balance between power and control, it provides a wider sweet spot and enhances handling, especially in ergonomic handle designs focused on comfort.

-

Composite Materials: Composite Materials4

- Innovations such as a blend of carbon fiber and fiberglass or bamboo core composites are increasingly popular for creating superior ergonomic features and improved shock absorption.

These materials are chosen not only for their performance gains but also for their contribution to the overall ergonomic structure. For example, using a Nomex Honeycomb Core5 in the handle area can provide additional stability and tactile comfort while reducing overall paddle weight.

Customization is often the deciding factor for sports equipment procurement. At NEX Pickleball, we offer tailor-made options that let you specify design parameters, including handle geometry, grip size, and balance adjustments to suit specific player needs. Here are some customization options to consider:

-

Grip Texture and Size:

By offering multiple grip sizes and tactile finishes, you can cater to players with differing hand dimensions. An optimal grip texture ensures that players maintain a secure hold during high-intensity play. -

Custom Weight Distribution:

Adjusting the weight along the handle can improve control and reduce lag during rapid movements. This is particularly important for competitive players who require split-second responsiveness. -

Material Combinations:

Combining different materials, such as a carbon fiber exterior with a polymer or aluminum honeycomb core, can yield a handle that offers both firmness and shock absorption, thus enhancing comfort during prolonged play. -

Ergonomic Contouring:

Advanced ergonomic contouring based on anthropometric data ensures that the handle fits naturally in the hand, minimizing stress and enabling better maneuverability under varied playing conditions.

Below is a simplified table summarizing some customizable features:

| Customization Option | Benefit | Applicable Enhancements |

|---|---|---|

| Grip Size & Texture | Increased comfort; improved ball control | Tactile finish, measured sizing |

| Weight Distribution | Enhanced control; reduced response lag | Custom core materials (Nomex, Aluminum, Polymer) |

| Material Combinations | Optimal strength and shock absorption | Carbon Fiber + Fiberglass, Bamboo Core Composite |

| Ergonomic Contouring | Natural hand fit and improved precision | Data-driven design based on player hand dimensions |

For decision-makers evaluating ergonomic handle designs, consider the following guidelines:

-

Emphasize Material Quality:

Choose handles that integrate premium materials like carbon fiber and high-density composites. These materials not only offer durability but also enhance the tactile and performance qualities essential for competitive play. -

Balance Production Efficiency with Customization:

- If large-scale manufacturing is your priority, the Hot Pressing1 method offers efficiency and robust performance.

- For products that need to differentiate in terms of user-specific ergonomics, Cold Pressing2 provides finer control over handle intricacies.

- When the design demands highly customized, intricate shapes, consider Thermoforming3 despite its longer production cycle.

-

Incorporate Data-Driven Ergonomic Principles:

Use consumer feedback and player performance data to refine handle designs. Ergonomic testing can help determine the best balance between grip comfort and responsive control. -

Leverage Customization for Brand Differentiation:

Customized handles can serve as a unique selling proposition. Offering variety in grip texture, weight, and balance not only meets the needs of advanced players but also positions your products as innovative choices in a competitive market. -

Support with Quality Control and Rigorous Testing:

Ensure that every design change undergoes thorough testing for strength, vibration absorption, and overall performance consistency. This commitment to quality can validate your purchase decision and build customer trust over time.

At NEX Pickleball, our comprehensive approach incorporates advanced manufacturing techniques with state-of-the-art ergonomic designs. By leveraging processes such as Hot Pressing1, Cold Pressing2, and Thermoforming3—paired with premium materials and custom options—we ensure that every paddle meets the evolving demands of competitive pickleball players.

In summary, the selection of an ergonomic handle design optimized for competitive pickleball hinges on a balanced approach that considers material innovations, precise manufacturing processes, and available customization options. Each production method offers distinct advantages and trade-offs which must be weighed against your specific product needs:

- Hot Pressing delivers efficiency and robustness.

- Cold Pressing maintains material integrity for intricate designs.

- Thermoforming enables high customization for complex handle shapes.

For procurement or product development managers, the next actionable steps include evaluating your product volume needs, the level of customization required, and the specific ergonomic improvements needed for your target market. The technical details provided in this article can serve as a blueprint to make informed purchasing decisions and further optimization of your high-performance pickleball paddles.

Q1: How do different manufacturing processes affect the feel of a pickleball paddle handle?

A: Different processes—Hot Pressing1, Cold Pressing2, and Thermoforming3—impact material properties and tactile feedback. Hot Pressing offers robust structure but may slightly alter material feel, while Cold Pressing maintains material integrity for a more natural grip. Thermoforming enables custom shapes that can finely tune the ergonomic fit.

Q2: What role do high-performance materials play in enhancing ergonomic handles?

A: Materials such as various carbon fibers and composite combinations provide superior strength, shock absorption, and balanced weight distribution. These qualities are essential for achieving an ergonomic handle design that improves comfort, control, and overall paddle performance.

Q3: Can customization of handle geometry really improve player control?

A: Yes, custom ergonomic contours tailored to individual hand sizes and grip preferences can substantially improve both comfort and control. Customization options like grip texture, weight distribution, and precise geometric shaping are critical for enhancing performance during high-intensity play.

-

Hot Pressing: Explore an in-depth guide on hot pressing to understand its heat-and-pressure process, advantages in production efficiency, and its impact on product durability. ^Return ↩ ↩2 ↩3 ↩4 ↩5

-

Cold Pressing: Learn how cold pressing uses mechanical pressure at ambient temperatures to retain material properties, ensuring precise control over texture and structure. ^Return ↩ ↩2 ↩3 ↩4 ↩5

-

Thermoforming: Discover how thermoforming leverages heat to mold materials into complex shapes, offering high customizability for intricate design features. ^Return ↩ ↩2 ↩3 ↩4 ↩5

-

Composite Materials: Delve into the world of composite materials, engineered by combining multiple constituents to enhance strength, reduce weight, and achieve superior overall performance in high-end products. ^Return ↩ ↩2

-

Nomex Honeycomb Core: Understand the benefits of using a Nomex Honeycomb Core, a lightweight yet high-strength material that enhances stability and shock absorption in premium sports equipment. ^Return ↩