Eco-friendly carbon fiber technology offers high performance and sustainability benefits, making it an ideal choice for modern pickleball paddle manufacturing. It not only meets the demands for durability and precision but also aligns with green production practices, ensuring that businesses can achieve competitive advantage while committing to environmental responsibility.

In today’s sports equipment market, sustainability is becoming as critical as performance. As procurement managers and product developers seek to improve both the environmental impact and technical quality of their products, sustainable carbon fiber emerges as a material that bridges these two needs. This article provides a detailed comparative analysis of eco-friendly carbon fiber1 against traditional options such as fiberglass2. We will review key material properties, production techniques, and performance outcomes to help guide your sourcing decisions.

When selecting the best material for pickleball paddles, businesses must weigh both performance and environmental impact. Manufacturers have traditionally used materials like fiberglass for its balance between power and control. However, advances in sustainable carbon fiber technologies have made it possible to produce paddles that offer higher strength-to-weight ratios, improved durability, and a reduced ecological footprint.

Below is a summary table that contrasts traditional fiberglass with eco-friendly carbon fiber and other composite options:

| Material Type | Performance | Durability | Eco-Friendly Factor | Typical Use Case |

|---|---|---|---|---|

| Sustainable Carbon Fiber | Superior control and power | Excellent strength and rigidity | Lower carbon footprint with green manufacturing processes | High-performance competitive paddles |

| Graphite Carbon Fiber | Great handling and feel | High stress resistance | Moderate; improvements available through eco-friendly processing techniques | Premium paddles needing precise impact response |

| Fiberglass | Enhanced power due to flexibility | Good durability; wider sweet spot | Conventional process; opportunities exist for greener methods | Recreational and mid-level competitive use |

| Carbon Fiber & Fiberglass Composite | Balanced performance | Optimal mix of strength and elasticity | Can be optimized for eco-friendliness by modifying the composition | Players requiring both control and power |

This table illustrates that sustainable carbon fiber not only provides top-tier playing performance but also integrates green production methods, a key factor for companies with a focus on eco-friendly manufacturing.

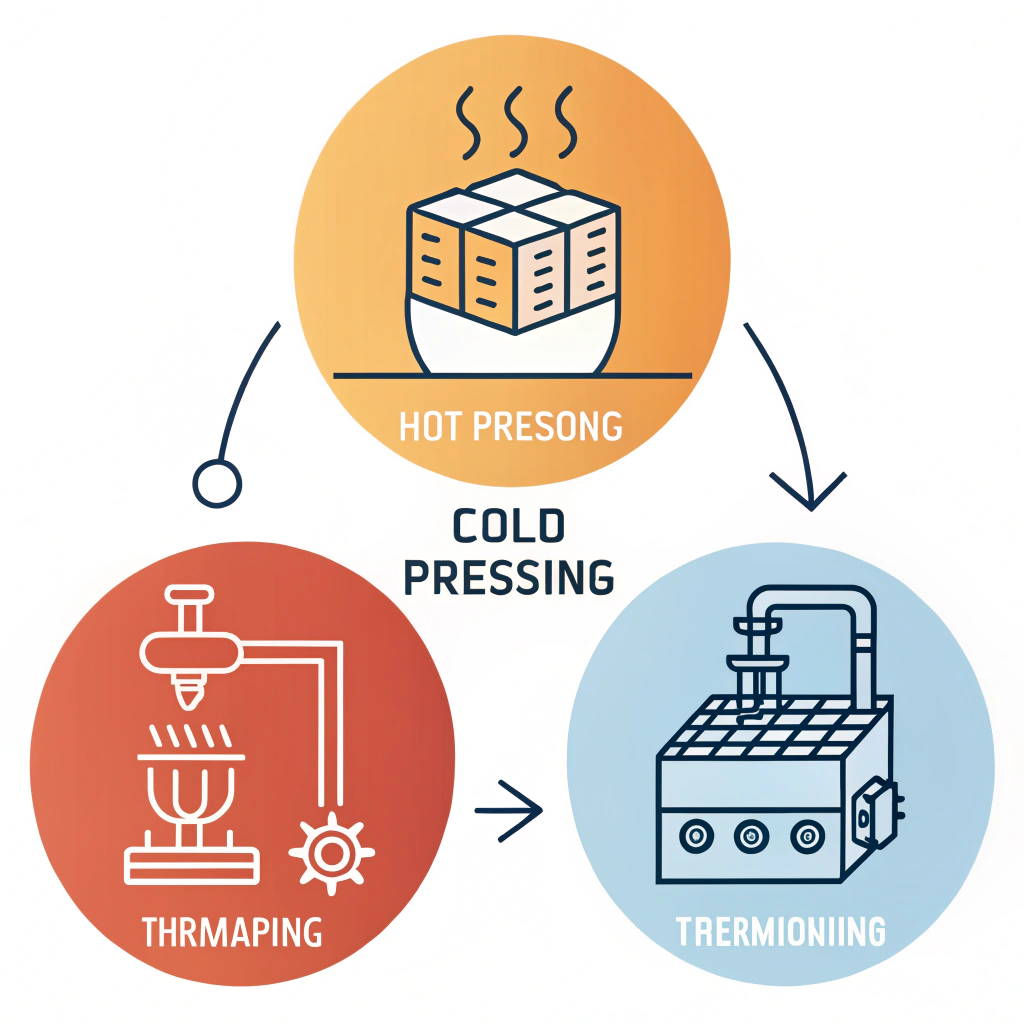

At the heart of producing high-performance, eco-friendly pickleball paddles lies state-of-the-art production techniques. Leading manufacturers like NEX Pickleball employ several advanced processes to shape their products. Each method offers unique advantages that contribute to both performance and sustainability.

Hot pressing involves heating components and applying pressure to form a paddle. This method:

- Delivers high production efficiency

- Produces paddles with strong structural integrity and excellent impact resistance

- Is suited for large-scale manufacturing

However, one must be cautious with hot pressing as the heat may alter some material properties, potentially affecting the paddle’s tactile feel. Despite this, when integrated within eco-friendly protocols—such as using renewable energy sources—the environmental impact can be minimized.

Cold pressing uses mechanical pressure at room temperature, preserving the integrity of the material’s inherent properties. This technique is known for:

- Providing precise control over paddle thickness and structure

- Enhancing the ball feel and responsiveness, key attributes for high-performance gameplay

- Reducing energy consumption during production since heating is not required

Cold pressing is particularly important when working with sensitive eco-friendly materials. It ensures that the sustainable carbon fiber retains its quality and that the final product meets the rigorous standards of today’s athletes.

Thermoforming heats materials to allow them to be molded into required shapes. Its benefits include:

- Enabling the creation of paddles with intricate designs and precise material distribution

- Helping maintain material stability and performance characteristics

- Allowing flexibility in using a mix of eco-friendly materials for improved overall product performance

Compared to the other methods, thermoforming demands longer processing times and higher initial equipment investments. However, for premium products or custom-made paddles, the investment is justified by the superior quality and performance outcomes.

The push for sustainable manufacturing in sports equipment is merging advanced material science with eco-friendly practices. By adopting eco-friendly carbon fiber, companies do not have to compromise on quality or durability. Here are several reasons why sustainable carbon fiber stands out:

-

Environmental Benefits:

Eco-friendly carbon fiber manufacturing techniques reduce reliance on non-renewable energy and lower greenhouse gas emissions compared to traditional production methods. Sustainable practices, such as energy recycling and waste reduction, are often integrated into the production process. -

Superior Material Properties:

Sustainable carbon fiber exhibits excellent strength-to-weight ratios, which enhance paddle performance by offering improved control, responsiveness, and durability. The material’s rigidity does not impede its ability to absorb shock, resulting in reduced vibration during play—a crucial factor for athlete comfort and injury prevention. -

Market Differentiation:

For sports equipment manufacturers, differentiating products in a competitive market is essential. Utilizing eco-friendly materials not only meets increasingly strict environmental regulations but also appeals to a growing market of eco-conscious consumers and professional sports teams committed to sustainability.

The material properties and sustainable benefits offer a competitive advantage, making eco-friendly carbon fiber the logical choice when tightening production standards and aligning with industry trends.

For procurement managers and product developers, choosing the right material and production process is a strategic decision with long-term implications. When sourcing paddles, consider the following aspects:

-

Regulatory Compliance:

Environmentally-friendly production methods often help companies meet both local and international green manufacturing standards. This reduces regulatory risks while bolstering your brand’s reputation. -

Customization Capabilities:

With custom paddle options available, businesses can tailor design, weight, and balance. Options such as bamboo core composites or honeycomb cores allow further optimization for both performance and sustainability. -

Cost Efficiency Over Time:

While premium raw materials and dedicated eco-friendly processes might incur higher upfront costs, the long-term benefits of durability, reduced repair rates, and enhanced performance lead to overall cost savings. Additionally, consumers increasingly value eco-responsible products, which can translate into marketing and brand advantages. -

Production Scalability:

Technologies like cold pressing ensure that production scales efficiently without degrading the quality of the material. This is crucial in maintaining consistency as orders ramp up.

Below is a checklist that procurement teams can use when evaluating suppliers:

| Evaluation Criteria | Key Questions |

|---|---|

| Sustainability Practices | Does the supplier use renewable energy and eco-friendly materials? |

| Material Performance | Are the paddles tested for durability, control, and responsiveness? |

| Production Process Efficiency | Which production processes are used and how do they impact performance? |

| Customization and Flexibility | Can the final product be tailored to specific performance needs? |

| Regulatory Compliance | Do the products meet international green manufacturing standards? |

This checklist provides a straightforward method to systematically assess the benefits and trade-offs of switching to or integrating eco-friendly carbon fiber paddles.

Consider a sports equipment company that traditionally used fiberglass paddles. While their products were popular, the company faced growing pressure from both regulatory bodies and eco-conscious consumers. The decision was made to integrate eco-friendly carbon fiber due to its superior performance characteristics and lower environmental impact.

Key steps in their transition included:

- Collaborating with a supplier experienced in environmentally sustainable manufacturing, such as NEX Pickleball.

- Conducting extensive evaluations of production processes, favoring cold pressing to maintain the material's natural properties.

- Gradually introducing the new product line with clear communication of the environmental benefits and performance improvements to both trade partners and end consumers.

- Monitoring and documenting product performance and customer feedback, which ultimately confirmed the market demand for sustainable, high-performance paddles.

This case study illustrates the strategic advantage of pivoting to sustainable technologies. The company not only improved product performance and durability but also enhanced brand perception and market share.

In conclusion, eco-friendly carbon fiber technology represents a sustainable yet high-performance option for pickleball paddle manufacturing. Its superior material properties, when combined with modern production techniques such as hot pressing, cold pressing, and thermoforming, offer significant benefits over traditional materials like fiberglass. The integration of these technologies supports both enhanced performance and responsible sourcing, which is increasingly valued in today’s competitive sports equipment market.

For procurement managers and product developers, the following steps are recommended:

- Evaluate current material sourcing strategies and consider the potential benefits of switching to eco-friendly carbon fiber.

- Partner with manufacturers that prioritize green production practices without compromising on performance.

- Use detailed technical evaluations and performance benchmarks to make data-driven decisions.

- Communicate the sustainability benefits and improved product quality to stakeholders and end customers.

Adopting these recommendations can lead to substantial improvements in product quality, operational efficiency, and market differentiation, positioning your company as a leader in both innovation and environmental responsibility.

People Also Ask

Q: Which is better graphite carbon fiber or fiberglass pickleball paddle?

A: Graphite carbon fiber is generally chosen for its excellent handling and feel, making it ideal for players seeking precise control, while fiberglass paddles tend to offer more power due to their flexibility. The best choice depends on the specific performance attributes you prioritize in your paddle design.

-

eco-friendly carbon fiber: Click to read an in-depth discussion on the lifecycle, performance benefits, and environmental sustainability of eco-friendly carbon fiber in high-tech manufacturing. ↩

-

fiberglass: Click to explore how fiberglass compares to modern composite materials in terms of durability, performance, and environmental impact in industrial applications. ↩

-

Hot Pressing: Click to learn about hot pressing techniques, including how controlled heat and pressure are used to achieve superior material bonding and structural integrity. ↩

-

Cold Pressing: Click to understand cold pressing methods, focusing on how mechanical pressure at room temperature preserves material properties and enhances production efficiency. ↩

-

Thermoforming: Click to delve into thermoforming processes, covering the benefits of heat-molding materials for precision shaping and consistency in high-performance products. ↩