An NDA1 is a critical tool for protecting your proprietary designs, production processes, and intellectual property when sourcing pickleball OEM2 products. In today’s competitive sports equipment market, a well-structured non-disclosure agreement not only safeguards sensitive information but also builds trust between manufacturers and partners.

When dealing with OEM manufacturing, particularly in a specialized field such as pickleball paddle production, there are significant risks to your confidential information. Without proper legal safeguards, your proprietary designs, innovative production techniques, and trade secrets may be exposed. This exposure could lead to competitive disadvantage, loss of market share, or even replicative counterfeiting.

For procurement managers and business development executives in sports retail and equipment organizations, securing your intellectual property during the early information-exploration stage is vital. An NDA can enforce confidentiality among all parties, ensuring that sensitive information remains protected throughout negotiations and production cycles.

Even though both parties may have a good relationship, verbal understandings or informal emails are insufficient when it comes to legal protection. Often, information may be shared casually in early discussions, but without an NDA in place, there is no enforceable commitment to confidentiality.

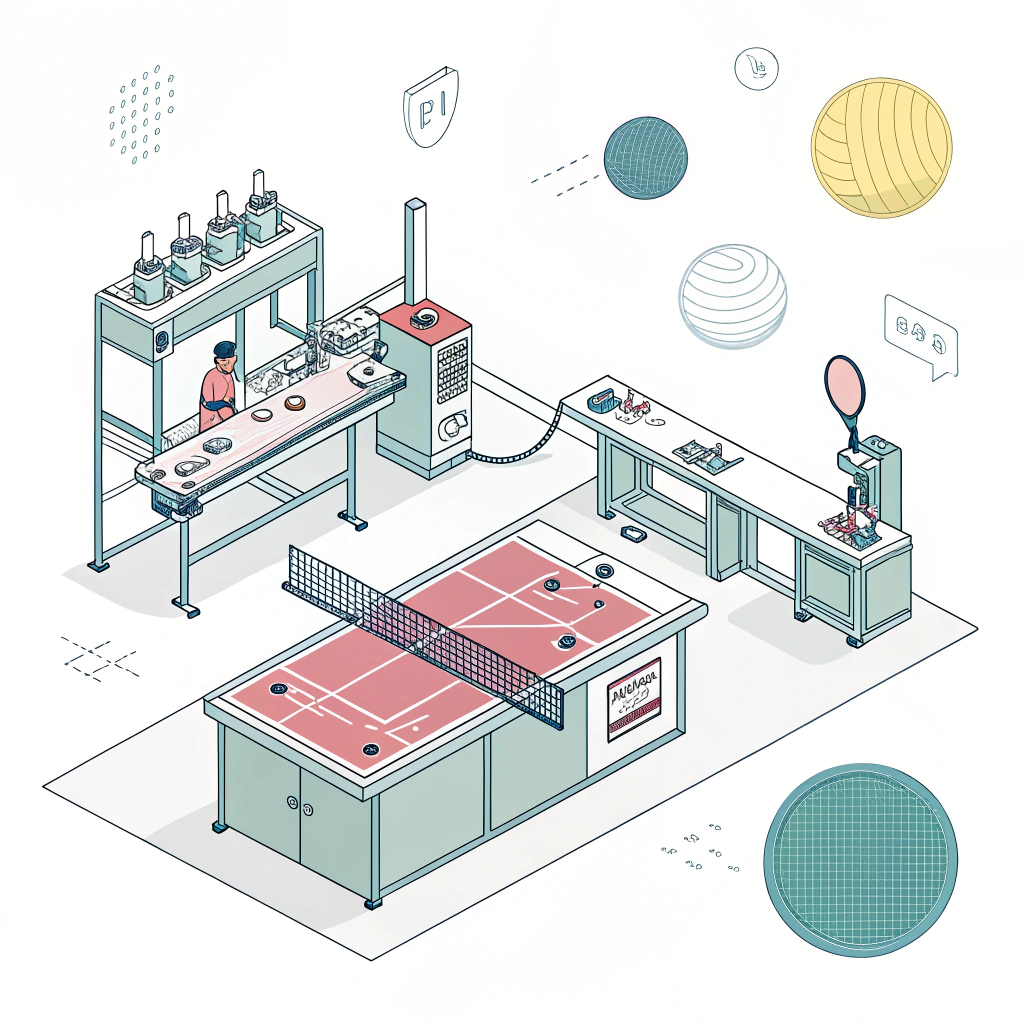

In the pickleball OEM industry, manufacturing involves advanced processes such as hot pressing, cold pressing, and thermoforming3. Given the complexity and uniqueness of these production methods, protecting technical know-how is vital. This is especially critical when you collaborate with established players like NEX Pickleball, who rely on proprietary processes and premium materials—including various types of carbon fiber4, fiberglass, and composite structures.

Your paddle designs, material compositions, and production techniques represent significant intellectual property (IP) investments. Losing control over these assets can lead to competitors duplicating your designs, causing market dilution. Lack of clear confidentiality terms makes it difficult to control the spread of such sensitive details.

Implementing a non-disclosure agreement in your OEM procurement strategy brings several key advantages:

- Legally Binding Protection: An NDA legally commits parties to keep shared information confidential. If a breach occurs, legal recourse is available.

- Risk Mitigation: Reduces the risk of intellectual property theft, unapproved use of sensitive commercial information, or market imitation by competitors.

- Clear Boundaries: Establishes clear guidelines on what constitutes confidential information, thereby reducing misunderstandings during negotiations.

- Enhanced Trust: Builds a foundation of trust between your company and manufacturing partners, ultimately leading to more productive collaboration.

Below is a systematic process to ensure your proprietary data remains secure throughout the OEM process:

-

Identify Critical Information:

List all proprietary data, including design blueprints, production methods, and client details. Emphasize components like advanced carbon fiber techniques (3K, 12K, T300) and unique core materials (Nomex Honeycomb, Aluminum Honeycomb, Polymer Honeycomb). -

Draft a Comprehensive NDA:

Work with legal professionals to create an agreement that covers all key aspects:- Scope of confidentiality (what information is protected)

- Duration of confidentiality obligations

- Permitted and prohibited uses of the data

- Associated penalties in case of breach

-

Clear Definition of Parties:

Clearly identify the disclosing and receiving entities in the document. Ensure both parties understand their roles and responsibilities, providing legal protection for sensitive details along the entire production chain. -

Due Diligence in Partner Selection:

Prior to full engagement, review potential OEM partners' history with intellectual property management. A partner with a robust approach — similar to the practices at NEX Pickleball — is critical for ensuring production consistency and product quality. -

Regular Audits and Updates:

Once the NDA is in effect, schedule periodic reviews and updates. This ensures the agreement adapts to any new process improvements or changes in the operational landscape. -

Implement Internal Security Measures:

An NDA is effective only when combined with internal measures such as restricted access to design files, secure communication channels, and vendor training on confidentiality protocols.

Integrating these best practices into your procurement process helps you to stay ahead of potential risks and ensure smooth production cycles:

Avoid generic, cookie-cutter contracts. Tailor your NDA to address the specifics of pickleball equipment manufacturing. Consider the unique risks associated with novel materials or unconventional production methods.

Given that legal language can be dense and subject to misinterpretation, employ in-house or third-party legal counsel specialized in OEM procurement contracts5. Their expertise can help bridge the gap between technical requirements and legal safeguards.

Study industry standards and best practices. For example, leading manufacturers like NEX Pickleball have stringent quality control measures and material selection criteria. Understanding these benchmarks allows you to set higher standards for confidentiality and IP protection in your agreements.

Comprehensive documentation of all exchanged materials helps in case a legal dispute arises. Ensure every meeting, email, and shared design is archived per the NDA's requirements. This audit trail adds an extra layer of protection.

Consider if a mutual NDA (where both parties agree to confidentiality) or a one-sided agreement (where only one party discloses sensitive information) best suits your needs. In many OEM partnerships, mutual NDAs are preferred to foster collaborative innovation while ensuring that each party’s trade secrets remain secure.

While NDAs are invaluable, several challenges might arise during their implementation:

Ambiguity can lead to disputes; therefore, clauses defining the scope of confidential information must be explicit. Ensure your agreement covers both tangible elements (e.g., design blueprints) and intangible aspects (e.g., production know-how).

When collaborating with international partners, determining the jurisdiction for legal disputes can be complex. Choose a mutually acceptable jurisdiction in the NDA to minimize future conflict. A choice of law clause can help clarify which country’s laws apply.

Even with a robust NDA in place, enforcement can be challenging in cross-border scenarios. Maintain a balance between legal strictness and practical enforcement by regularly evaluating your partner’s adherence to the agreement.

Negotiating an NDA involves legal fees and time investments. However, these costs are generally minimal compared to potential losses incurred through breaches. Always compare the cost of negotiation with the potential cost of intellectual property loss.

Below is an example table summarizing key aspects of NDA considerations:

| Aspect | Benefit | Risk if Not Applied |

|---|---|---|

| Confidential Scope | Clear boundaries on protected data | Ambiguity leading to potential leaks |

| Duration of Agreement | Long-term protection of sensitive info | Immediate vulnerabilities with new ideas |

| Jurisdiction Clause | Clear dispute resolution mechanism | Cross-border legal confusion |

| Mutual vs. One-Sided | Balanced protection for both parties | Unfair advantages, resulting disputes |

Consider a sports retail company that decided to source paddles directly from an OEM manufacturer. Without a robust NDA, initial discussions were promising; however, as design details were shared, the manufacturer inadvertently revealed technical details to a third party. This incident led to a market scenario where similar products appeared at lower prices, eroding the competitive edge of the original company.

After this experience, the company revised its procurement strategy by implementing a detailed NDA, which included:

- Clearly defined proprietary designs and production methods.

- Strict penalties for any breach of confidentiality.

- A mutual confidentiality clause ensuring reciprocal protection.

Following these changes, the company not only secured its intellectual property but also established stronger, trust-based relationships with its partners. This allowed for smoother negotiations, timely production, and overall enhanced market performance.

In summary, an NDA is not just a formality—it is an essential part of any OEM procurement strategy for pickleball equipment. Here are the key takeaways:

- An NDA legally safeguards your proprietary information during negotiations and production.

- Clearly define the scope, duration, and jurisdiction within the NDA.

- Combine the agreement with robust internal documentation and security measures.

- Tailor the NDA to the specific needs of pickleball OEM manufacturing, considering advanced materials and production processes.

- Regularly review and update the agreement to adapt to evolving industry practices.

By taking these steps, you will significantly reduce the risk of unintended information leakage and fortify your competitive position within the sports equipment market. For procurement and business development managers, understanding and implementing these legal measures early can make all the difference between a successful OEM partnership and costly intellectual property disputes.

Are licensed products available for pickleball?

Manufacturers work diligently to ensure pickleball equipment meets industry standards. While approvals by bodies such as USA Pickleball are common for competitive products, the licensing of technology or designs is typically negotiated separately between OEM partners.

Are there regulations for pickleball paddles?

Yes, there are established guidelines. For example, many regulations specify that the paddle length should not exceed 17 inches, and most paddles maintain a thickness between 0.4 to 0.6 inches. These rules help ensure competitive fairness while allowing manufacturers some flexibility in design.

Do pickleball paddles need to be approved?

For competitive play, particularly in sanctioned tournaments, using a USA Pickleball-approved paddle is essential. Approval ensures that the equipment adheres to the standards required for fair play and safety in high-level competition.

-

NDA: Click to read more about non-disclosure agreements and how they serve as a legally binding framework to protect sensitive business information. ^Return ↩

-

OEM: Click to understand the concept of Original Equipment Manufacturers and their role in product sourcing and production in B2B settings. ^Return ↩

-

thermoforming: Click to explore the thermoforming process, its applications in manufacturing, and why it is critical in the production of specialized equipment. ^Return ↩

-

carbon fiber: Click to learn about carbon fiber, its properties, and its significance in advanced manufacturing and material science. ^Return ↩

-

OEM procurement contracts: Click to delve into the details of OEM procurement contracts, including key clauses and legal considerations specific to B2B procurement. ^Return ↩