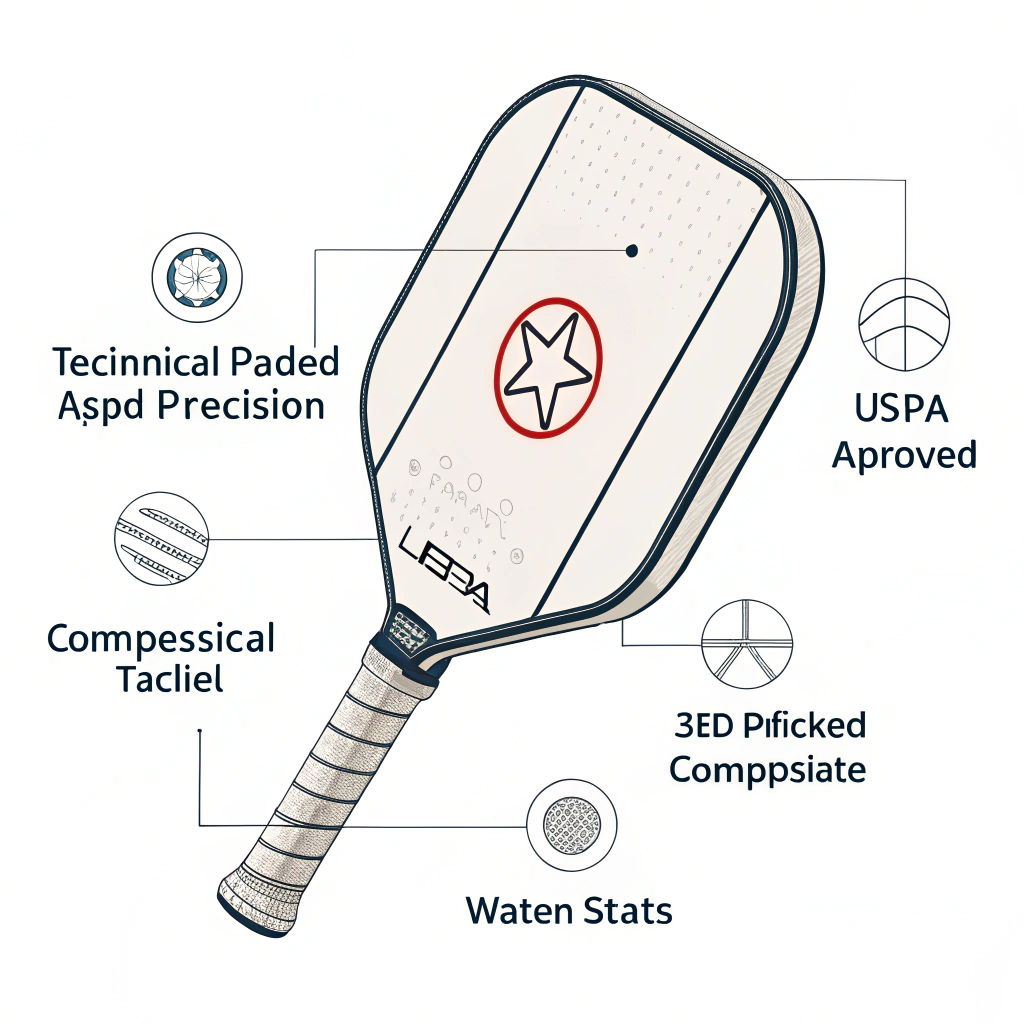

USAPA approval1 is a critical benchmark for high-performance pickleball paddles, ensuring that the equipment meets strict standards for competitive play. In this article, we compare various manufacturing techniques and materials with an emphasis on UPASA compliance and performance optimization, helping procurement and product managers make informed decisions.

USAPA (USA Pickleball Association) approval signifies that a pickleball paddle complies with standardized criteria regarding size, weight, material composition, and overall performance. This certification is essential for inclusion in competitive play and provides assurance that the paddle delivers consistent performance in terms of power, control, and durability. For B2B partners and sports equipment distributors, choosing USAPA-approved paddles not only aligns with regulatory standards but also enhances market credibility.

Key Factors Influencing USAPA Compliance:

- Material Quality: High-quality carbon fiber, fiberglass, and composite materials that meet performance standards.

- Manufacturing Precision: Techniques like hot pressing2, cold pressing3, and thermoforming4 contribute significantly to the paddle's overall quality.

- Customization: The ability to tailor paddles for specific player requirements while maintaining USAPA standards.

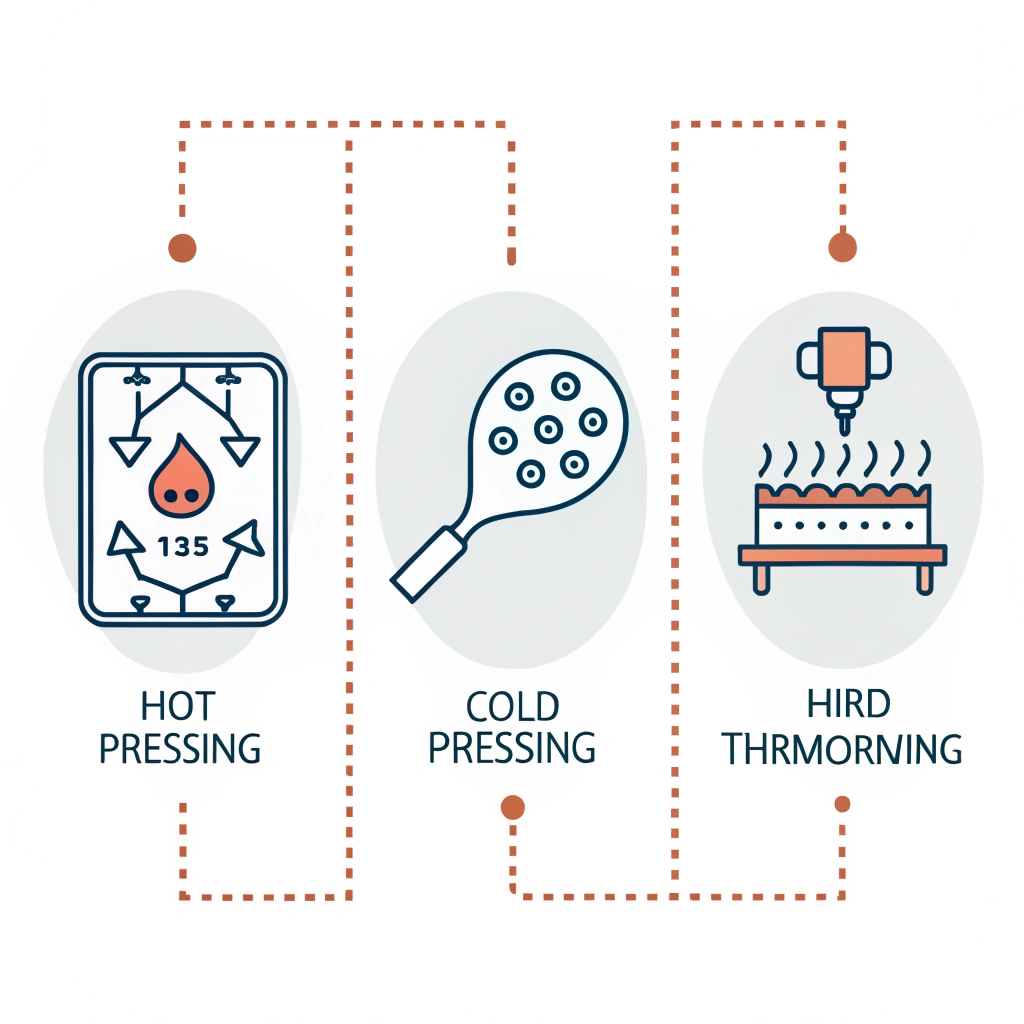

Procurement teams often face the challenge of selecting a manufacturing process that offers both performance and regulatory compliance. The three primary production processes used in our industry are hot pressing, cold pressing, and thermoforming. Each method has its unique benefits and limitations.

Hot pressing2 involves applying heat and pressure to shape and bond materials together. This process is ideal for creating paddles with exceptional strength and impact resistance.

-

Advantages:

- High production efficiency for large-scale manufacturing.

- Excellent impact resistance and durable construction.

- Maintains structural integrity, ensuring the paddle performs under high stress.

-

Disadvantages:

- Some alteration to material properties may occur, which can affect paddle feel.

- Requires significant investment in specialized equipment.

Cold pressing3 shapes paddle materials at room temperature, using mechanical pressure for precise control over the final product’s characteristics.

-

Advantages:

- Maintains the natural properties of materials, providing better control and elasticity.

- Ideal for producing paddles with enhanced ball feel and responsiveness.

- Allows for precise control over thickness and structural uniformity.

-

Disadvantages:

- Longer production cycles can reduce overall manufacturing efficiency.

- High-quality pressure control systems are essential, leading to potential cost increases.

Thermoforming4 uses heat to soften materials before forming them into precise shapes via molds. This method supports the creation of paddles with intricate designs and complex material distributions.

-

Advantages:

- Enables exact shape replication and intricate design elements.

- Helps maintain a uniform material distribution essential for batch consistency.

- Suitable for premium, custom-made products.

-

Disadvantages:

- Longer production times and higher equipment costs.

- Best suited for markets where high-quality, custom paddles are in demand.

| Process | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Hot Pressing | Efficient production; strong impact resistance; reliable durability | Altered material properties; high equipment cost | Mass production and high-performance use |

| Cold Pressing | Superior control; excellent ball feel; preserves material texture | Longer cycle times; requires precise equipment | Tailored paddle feel and control |

| Thermoforming | Detailed design capability; precision forming; good stability | Longer production time; premium pricing | Custom, premium paddles |

Each process’s impact on product durability, performance optimization, and USAPA compliance must be carefully evaluated. Procurement managers should consider the targeted market and specific performance requirements when choosing a manufacturing method for their B2B partnerships.

The construction of a pickleball paddle is more than just the process—it is also about the quality of materials used. At companies like NEX Pickleball, materials are chosen meticulously to enhance paddle performance and ensure compliance with USAPA standards. Here's a closer look at some of the premium materials commonly used:

Carbon fiber is a cornerstone in high-performance pickleball paddles. Different types of carbon fiber contribute unique characteristics to the paddle:

- 3K Carbon Fiber: Known for its strength and flexibility, it is ideal for paddles requiring quick rebound force and excellent vibration reduction.

- 12K Carbon Fiber: With a higher thread density, this fiber offers a smoother surface, enhanced hardness, and superior impact resistance for competitive play.

- T300 Carbon Fiber: Balanced for both strength and light weight, providing exceptional tensile strength and performance consistency.

Using these materials in a paddle guarantees not only enhanced power but also precise control and responsiveness—key to meeting and exceeding USAPA approval standards.

Fiberglass provides a distinct balance between power and control. It offers a broader sweet spot and improved elasticity compared to carbon fiber. E-Glass Fiberglass is particularly noted for its tensile strength and excellent elasticity, making it a popular choice for paddles where ball control is paramount.

Composite Materials5 and Core Options

Composite materials, which combine different elements like carbon fiber, fiberglass, or even natural materials such as bamboo, allow for a harmonious blend of strength, flexibility, and light weight. For example:

- Carbon Fiber and Fiberglass Composite: Merges the power of carbon fiber with the flexibility of fiberglass, yielding an ideal balance for competitive performance.

- Bamboo Core Composite and Honeycomb Core Materials: These cores provide a lightweight structure with excellent impact resistance and shock absorption, ensuring a firm yet responsive hitting experience.

The choice of core material (Nomex, Aluminum, or Polymer honeycomb cores) further influences paddle characteristics. Each core offers different levels of vibration reduction and control, aiding in compliance with USAPA regulations by delivering consistent performance.

In a competitive market, the ability to deliver custom solutions can significantly differentiate your product offer. Companies like NEX Pickleball provide on-demand print services and customizable paddle options, allowing clients to specify design, weight, balance, and grip sizes.

- Market Differentiation: Custom paddles enable brands to stand out in the marketplace, appealing directly to unique player preferences.

- Enhanced Performance: Tailoring the production process—be it altering the layering of carbon fiber or choosing a different core material—ensures that each paddle can be optimized for specific performance demands.

- Regulatory Compliance: Custom models can be designed with the strict USAPA standards in mind, ensuring that every paddle not only performs well but also meets the necessary regulatory criteria.

- Branding Opportunities: For B2B partners, personalized paddle designs can become a powerful marketing tool, augmenting team branding and customer loyalty.

For sports equipment procurement managers, this means acquiring paddles that not only match regulatory standards but also are optimized for regional market demands and distinctive player experiences.

Quality control is non-negotiable in the production of USAPA Approved pickleball paddles. At NEX Pickleball, rigorous testing protocols are in place to ensure that each paddle reflects the highest standard of performance and durability. Quality control measures include:

- Material Inspection: Each batch of carbon fiber, fiberglass, or composite is thoroughly inspected to verify consistency.

- Process Validation: Whether using hot pressing, cold pressing, or thermoforming, the production process is continuously monitored for deviations that might affect paddle performance.

- Performance Testing: Paddles are tested under varying conditions to measure factors such as vibration damping, impact resistance, and overall playability.

These controlled measures are crucial for upholding USAPA standards and ensuring that B2B partners receive products that meet the highest quality benchmarks.

When selecting your high-performance pickleball paddles, consider the following steps to ensure that your decision aligns with both performance needs and market expectations:

- Understand Manufacturing Techniques: Compare the strengths and limitations of hot pressing, cold pressing, and thermoforming to determine which process best matches your performance criteria and production scale.

- Evaluate Material Quality: Assess the benefits of carbon fiber variants, fiberglass, and composite materials. Consider how each material contributes to paddle durability, ball control, and overall performance.

- Consider Customization Options: Identify manufacturers offering customization. This flexibility can offer a competitive advantage by meeting specific player needs while ensuring compliance with regulatory standards.

- Review Quality Control Protocols: A robust quality control system is essential. Partner with manufacturers who adhere strictly to USAPA guidelines and who utilize rigorous testing methods.

- Make an Informed Choice: Use data from performance tests, production efficiency analysis, and quality inspections to guide your procurement strategy.

By following these steps, you can secure a supplier who not only delivers USAPA-approved paddles but also provides the technological and customization benefits needed in today’s competitive sports equipment market.

In summary, USAPA approval is a vital certification that ensures pickleball paddles meet essential performance and quality standards. By comparing the manufacturing processes—hot pressing, cold pressing, and thermoforming—and carefully selecting premium materials such as various forms of carbon fiber and fiberglass, businesses can make informed decisions in their B2B partnerships.

Customizable options and stringent quality control further enhance product performance, making it easier for procurement and product managers to meet customer expectations while staying compliant with regulatory requirements. The right selection of materials and techniques not only ensures excellence on the court but also strengthens your brand’s market position.

For sports equipment distributors and B2B buyers, investing in quality, USAPA-approved paddles is an investment in performance, durability, and market credibility. Consider these factors and proactively engage in a dialogue with your suppliers to ensure that every paddle delivers the expected competitive edge.

People Also Ask

Q: What does USAPA approved mean for pickleball paddles?

A: USAPA approval verifies that a pickleball paddle meets strict regulatory standards for size, weight, material composition, and performance, ensuring it is approved for competitive play.

Q: How do hot pressing, cold pressing, and thermoforming differ in manufacturing pickleball paddles?

A: Hot pressing creates durable, impact-resistant paddles efficiently; cold pressing preserves material properties for enhanced control; and thermoforming allows for intricate designs and consistent material distribution, with each technique influencing performance differently.

Q: Can custom manufacturing meet USAPA standards?

A: Yes, custom manufacturing can be designed to comply with USAPA standards. By selecting premium materials and applying precise production processes, custom paddles can deliver both regulatory compliance and optimized performance.

-

USAPA approval: Click to read more about the standards and benefits of achieving USAPA approval, including insights on regulatory compliance and market credibility. Back to top ↩

-

Hot pressing: Click to explore how hot pressing uses heat and pressure to create durable, high-performance pickleball paddles. Back to top ↩ ↩2

-

Cold pressing: Click to understand the cold pressing process, which preserves material properties for improved paddle control and responsiveness. Back to top ↩ ↩2

-

Thermoforming: Click to learn about the thermoforming process that enables precise shaping of paddles with intricate design details using heat. Back to top ↩ ↩2

-

Composite Materials: Click to discover how composite materials combine different fibers and natural elements to balance strength, flexibility, and performance in pickleball paddles. Back to top ↩