High-performance pickleball paddles are crafted through advanced manufacturing techniques that balance quality, performance, and cost, enabling B2B partners to confidently source equipment that meets market demands.

For sports equipment distributors, procurement managers, and retail decision makers, selecting a manufacturer that offers reliable production technology is essential. In today’s competitive market, understanding the nuances of advanced production techniques1—from raw material selection to final quality control—is key to sourcing paddles that meet both performance and durability standards. B2B buyers look for detailed technical explanations, a robust comparison of manufacturing processes, and clear data-driven insights.

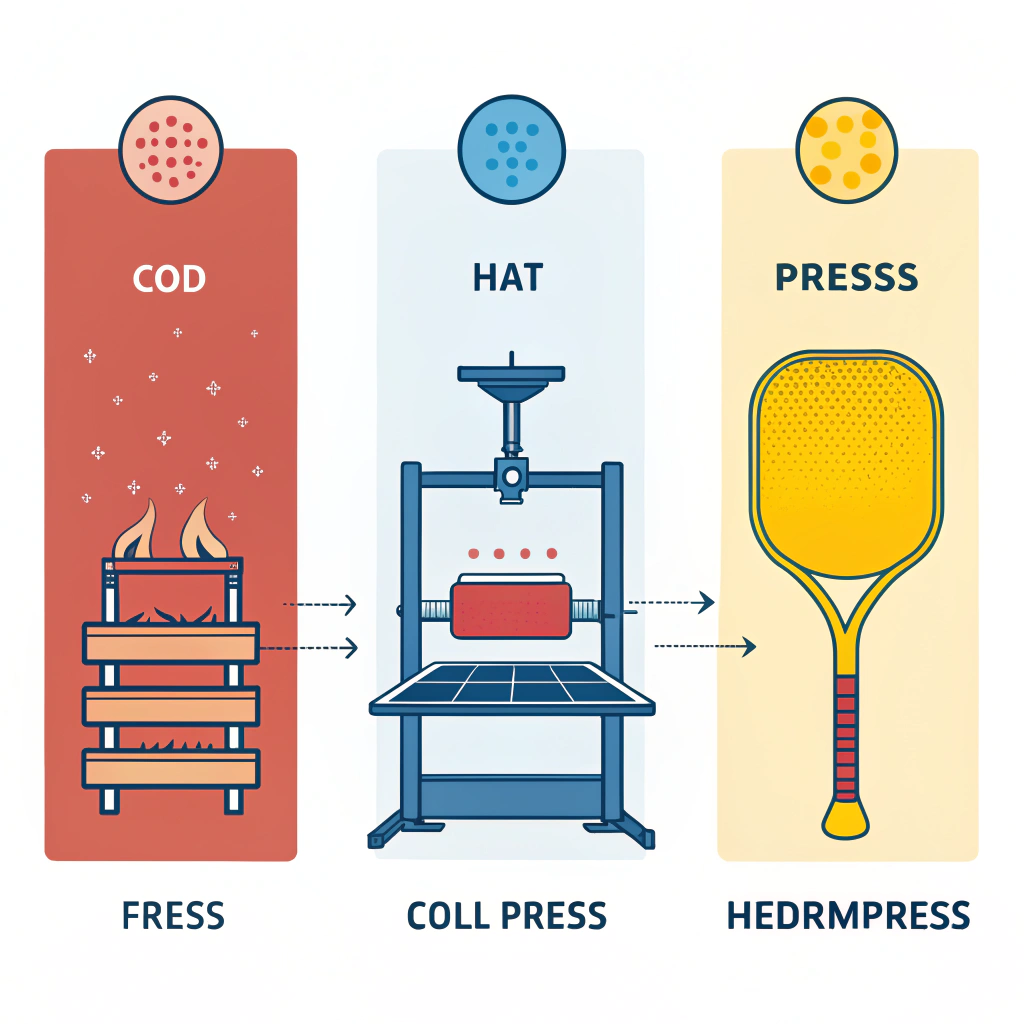

The primary challenge lies in balancing innovation with cost efficiency while ensuring the paddles are built to withstand the demands of high-intensity play. With diverse production methods available, including hot pressing2, cold pressing3, and thermoforming4, each has its strengths and limitations that must be weighed against specific market and performance needs.

Hot pressing involves heating materials and applying pressure simultaneously to form the paddle structure. This method creates paddles with robust structural integrity and excellent impact resistance.

Advantages:

- High production efficiency suitable for large-scale manufacturing

- Produces hard-hitting paddles with exceptional shock absorption

- Ensures structural strength and durability ideal for competitive play

Disadvantages:

- Potential alteration of certain material properties, which can affect the feel of the paddle

- Requires significant capital investment in high-temperature equipment

Cold pressing applies mechanical pressure at room temperature, thereby preserving the natural properties of the raw material. This process offers a precise control over the paddle’s structural characteristics and thickness.

Advantages:

- Excellent ball feel due to unchanged material properties

- Greater control over paddle thickness and structural integrity

- Enhances overall control and flexibility, important for players needing precision

Disadvantages:

- Longer production cycles compared to hot pressing

- Demands high-quality equipment for precise pressure management

Thermoforming uses controlled heating to soften the material before molding it into the paddle shape. This method is essential when intricate designs or variable thicknesses are required.

Advantages:

- Allows for the creation of complex paddle designs ensuring even material distribution

- Maintains paddle stability, which is crucial for performance

- Suitable for premium or custom-made paddles requiring refined aesthetics

Disadvantages:

- Higher equipment costs and longer production cycles

- Best utilized for low-volume, premium product lines

Below is a comparative table summarizing these processes:

| Production Process | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, structural integrity | Alters material properties, high equipment investment | High-volume competitive products |

| Cold Pressing | Maintains material properties, precise control, excellent ball feel | Longer production cycles, precision equipment required | Products needing precision and feel |

| Thermoforming | Intricate designs, even material distribution, product stability | Longer production time, higher costs | Premium/custom-designed paddles |

The choice of materials in paddle construction significantly affects the performance, particularly regarding weight, rebound, and vibration absorption. NEX Pickleball utilizes a diverse array of premium materials to accommodate different play styles and performance needs.

Carbon Fiber5: A Mark of Excellence

Customers seeking high-performance paddles often lean towards carbon fiber variants. Our production process involves multiple options:

- 3K Carbon Fiber: Known for its resilience and moderate flexibility. It provides excellent durability while reducing vibration, making it ideal for paddles needing high rebound force.

- 12K Carbon Fiber: Offers a higher thread density and smoother surface. This type is perfect for competitive scenarios requiring extreme strength and precision.

- T300 Carbon Fiber: Well-regarded for its balance of strength and lightweight properties, making it suitable for players who demand both power and control.

Carbon fiber paddles are typically chosen by professional players who require precision, repeatable control, and minimal energy loss during impact.

Beyond carbon fiber, fiberglass and composite materials offer a balanced blend of control and power.

- E-Glass Fiberglass: Provides elasticity and excellent ball control due to its inherent material flexibility.

- Carbon Fiber and Fiberglass Composite: Merges the technical advantages of both materials, delivering a paddle that caters to players needing a versatile tool.

- Bamboo Core Composite and Honeycomb Core: The core of the paddle is equally critical. Options like Nomex Honeycomb, Aluminum Honeycomb, and Polymer Honeycomb offer varied impacts on paddle weight, elasticity, and vibration absorption. This ensures that whether the demand is for a lightweight feel or an ultra-responsive touch, there is a suitable option available.

Manufacturers like NEX Pickleball provide customized paddle designs, a feature that is particularly valuable in B2B transactions. Clients can specify:

- Design Elements: Custom patterns, colors, and branding to align with team or retail aesthetics.

- Weight Distribution: Tailoring the paddle’s center of gravity to meet specific playing styles.

- Grip Size: Offering a range of grip sizes, which is a significant factor in ensuring comfort during prolonged play.

This level of customization—a blend of material innovation and advanced production techniques—enables businesses to provide unique, market-differentiated products that offer both aesthetic appeal and superior performance.

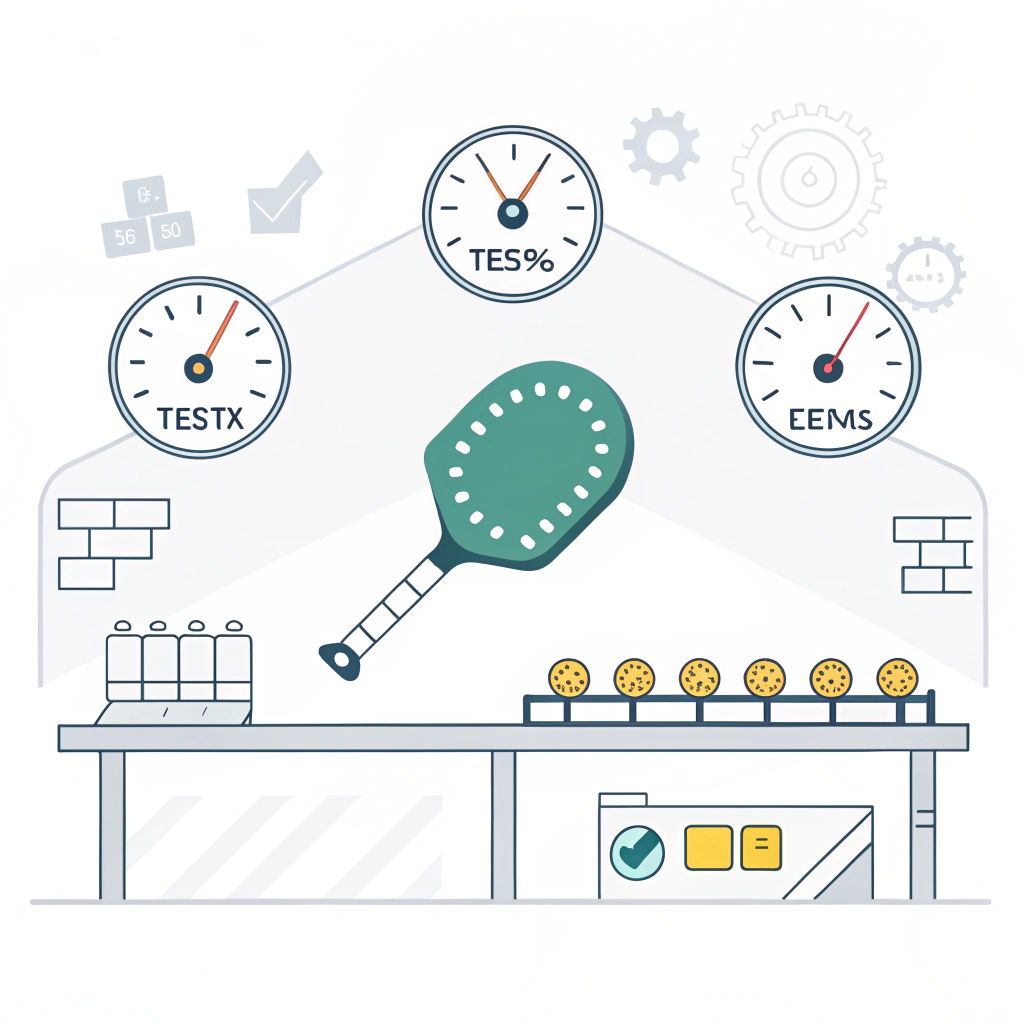

For B2B buyers, consistent quality is non-negotiable. Each paddle produced undergoes rigorous testing to ensure that every unit meets high standards of strength, flexibility, and reliability. Quality control is embedded in every production phase, starting from raw material inspection, through the manufacturing processes, to post-production testing.

Key quality control measures include:

- Material Integrity Assessments: Verifying that carbon fibers, fiberglass, and composites are within the required performance specifications.

- Process Monitoring: Continuous monitoring of pressures, temperatures, and cycle times in hot pressing, cold pressing, and thermoforming.

- Final Product Testing: Vibration, impact, and durability testing ensure that the final product consistently performs at the highest levels.

This comprehensive quality control system not only minimizes the risk of production errors but also reinforces the reliability of each batch, ensuring that B2B partners receive paddles that deliver performance as promised.

Understanding production data is integral to making informed purchasing decisions in the sports equipment market. Comparative data, along with technical specifications of the production methods discussed, guides procurement managers in evaluating:

- Production Efficiency: How fast paddles can be built while maintaining quality.

- Cost Efficiency: The balance between production volume, customization, and final product price.

- Product Performance: The comparative performance metrics (such as rebound capabilities and vibration handling) that directly impact on-court performance.

Data and case studies from high-performance players provide additional credibility. For instance, many professional teams and competitive players have reported enhanced control and game longevity when using paddles built through a combination of cold pressing and carbon fiber materials. These reports not only substantiate the production approach but also highlight the direct correlation between advanced manufacturing techniques and overall product performance.

For procurement managers and distributors, selecting a partner with robust manufacturing processes is critical. When evaluating potential suppliers, consider:

- The compatibility of the manufacturing process with your target market's needs.

- The range of customization options available.

- The consistency and reliability of quality control measures.

- The production capacity and its alignment with your order volume requirements.

By using advanced techniques like hot pressing, cold pressing, and thermoforming, NEX Pickleball delivers paddles that combine engineered precision with practical performance. Leveraging state-of-the-art production technology and extensive customization capabilities, our paddles are engineered to meet the rigors of competitive play while offering superior durability and comfort.

The decision-making process should consider not only current market trends but also future growth. An investment in high-quality, customizable paddles might yield better long-term performance, reduced maintenance costs, and an enhanced brand reputation among competitive players and sports retailers.

In summary, high-performance pickleball paddles manufactured with cutting-edge production processes and premium materials are a smart investment for B2B buyers in the sports equipment market. By understanding the differences between hot pressing, cold pressing, and thermoforming—and by appreciating the technical nuances of materials like carbon fiber and fiberglass—procurement managers can make more informed, confident decisions.

Key action takeaways:

- Evaluate the production method that best meets your quality and performance requirements.

- Consider the benefits of customization to differentiate your product offerings.

- Rely on data-driven insights and quality control records when selecting your manufacturing partner.

- Engage with suppliers like NEX Pickleball, which bring technical expertise, cutting-edge processes, and proven industry performance to the table.

By ensuring that your product offerings are built on a foundation of technical excellence and innovative manufacturing, you guarantee a competitive edge in the dynamic sports equipment market.

What paddle do most professional pickleball players use?

Professional players typically favor paddles built with advanced materials such as carbon fiber and fiberglass. These paddles, including high-end models engineered with techniques like cold pressing and thermoforming, offer enhanced control, power, and minimal vibration. This ensures that they meet the rigorous demands of competitive play.

What is the best inexpensive pickleball paddle?

Inexpensive paddles often utilize materials like basic composites or lower-grade carbon fibers and may lack advanced production techniques. While they are affordable, their performance may not match premium paddles. It is essential to balance budget constraints with performance needs; you may opt for entry-level models for recreational play rather than professional competition.

Do more expensive pickleball paddles make a difference?

Yes, higher-end paddles, which incorporate premium materials and sophisticated manufacturing techniques, typically provide better control, power, and durability. However, the choice should depend on the player's skill level and intended use, as many mid-range paddles also offer excellent performance for most recreational or competitive settings.

-

advanced production techniques: Click to explore comprehensive methodologies in modern manufacturing that enhance efficiency, quality, and cost-effectiveness for B2B operations. ↩ ↩

-

Hot Pressing: Click to delve into the process of applying simultaneous heat and pressure to produce robust and high-impact products. ↩ ↩ ↩2

-

Cold Pressing: Click to learn about a room-temperature process that preserves material properties for precision manufacturing. ↩ ↩ ↩2

-

Thermoforming: Click to understand how controlled heating is used to mold and shape materials, allowing intricate designs and varied thicknesses. ↩ ↩ ↩2

-

Carbon Fiber: Click to read about this premium material’s properties—its balance of strength, lightweight nature, and performance benefits for high-end products. ↩ ↩