Digital twin technology integrates real-time data with simulation models to optimize pickleball paddle design and production—bringing enhanced performance, reduced development cycles, and operational efficiency to advanced manufacturing processes.

In today’s fast-paced manufacturing landscape, companies face constant pressure to innovate while maintaining quality and efficiency. Digital twin technology1 has emerged as a transformative tool in product development. For the pickleball paddle industry, integrating digital twins means accelerating R&D, improving design accuracy, and streamlining production. This article explores how digital twin technology, alongside traditional simulation methods, can revolutionize paddle manufacturing, focusing on design optimization, material performance, and process efficiency. We will detail the challenges, underlying causes, and the concrete solutions for these high-performance sports products.

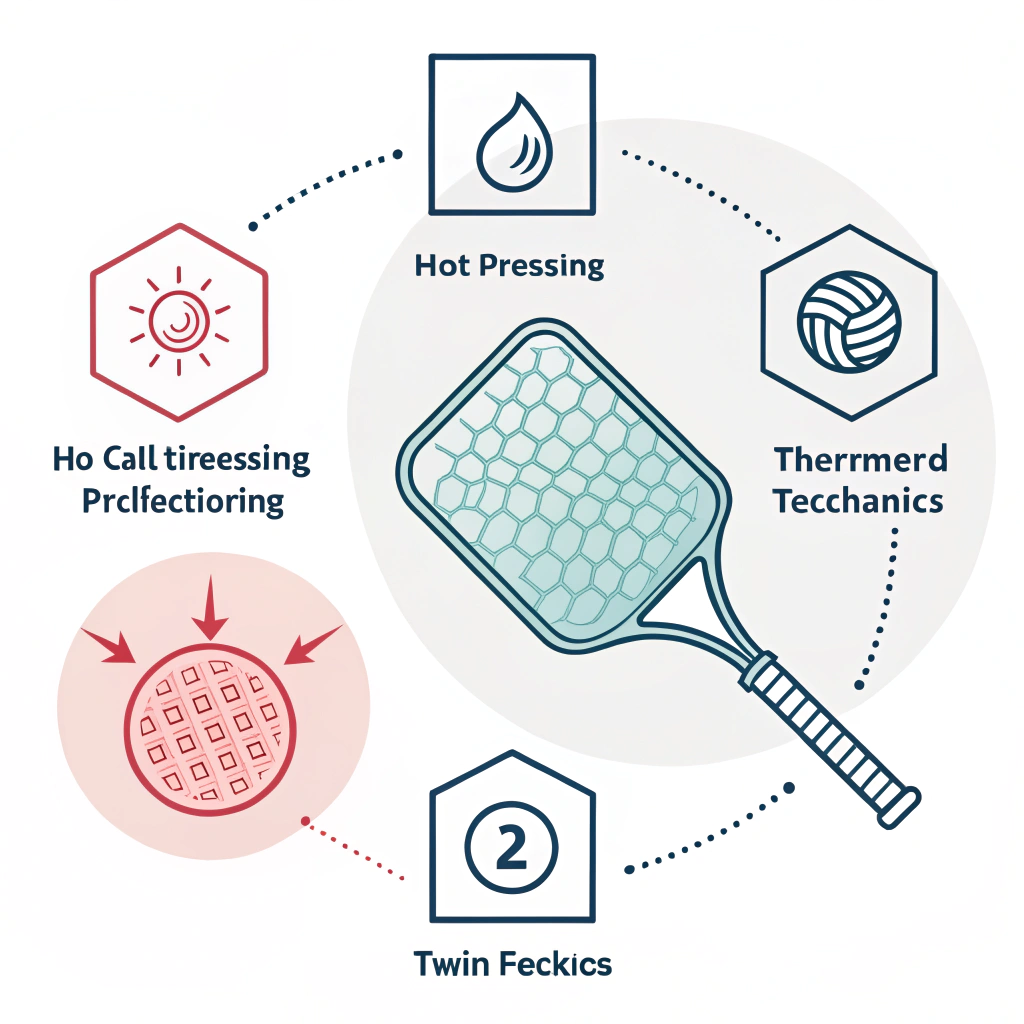

Manufacturing high-performance pickleball paddles involves balancing multiple factors such as weight distribution, impact resistance, and player comfort. Traditional simulation methods sometimes fall short in predicting real-world performance under varying stresses. Key challenges include:

• Achieving the optimal mix of carbon fiber2, fiberglass, and composite materials while maintaining durability and control.

• Ensuring precise quality control in processes such as hot pressing, cold pressing, and thermoforming.

• Managing production cycles while adapting to custom design specifications, such as varied grip sizes and complex surface textures.

Often, static simulations cannot capture the dynamic interplay of materials and loads during actual play, leading to potential mismatches in expected performance and field results.

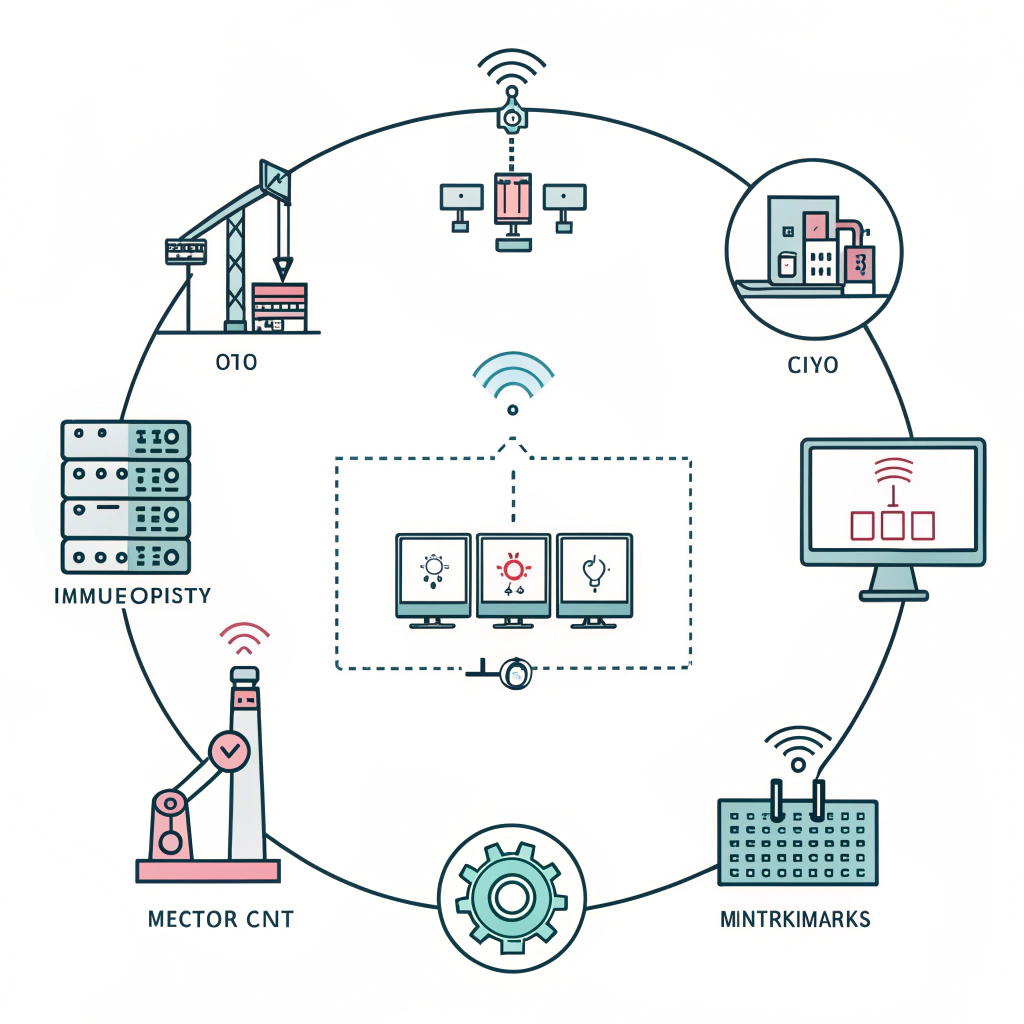

A digital twin is a virtual replica of a physical asset that continuously receives data from sensors and production feedback. This technology allows manufacturers to simulate numerous scenarios, optimize designs in real time, and predict material behavior under different conditions. When applied to pickleball paddle production, digital twins create opportunities to:

• Validate design changes quickly, reducing trial-and-error cycles.

• Forecast performance issues before they appear on the production line.

• Integrate real-time quality control, ensuring each paddle meets high precision standards.

By bridging the gap between digital models and physical tests, digital twin technology becomes a critical asset for competitive sports equipment manufacturing.

Successful digital twin integration revolves around three core areas:

-

Data Acquisition:

Gathering real-time data from production lines, material sensors, and testing facilities. -

Simulation and Modeling:

Using advanced algorithms to represent the physical behavior of paddle materials such as T300 Carbon Fiber, 3K Carbon Fiber, and composite mixes. -

Feedback Mechanism:

Continuous updates based on in-production performance data allow for iterative design enhancements.

Digital twins are particularly beneficial in optimizing traditional manufacturing methods:

• Hot Pressing:

Simulations clarify how heat and pressure influence the microstructure of carbon fiber composites. Although this method offers high efficiency and impact resistance, digital twins help balance the trade-offs between material property alterations and performance outcomes. Hot pressing3

• Cold Pressing:

By replicating the room-temperature press processes, digital twins offer insights into precision control over paddle thickness and structural stability. Better simulation of these processes means paddles with enhanced ball feel and responsiveness.

• Thermoforming:

This method benefits from digital twins by enabling simulations that account for complex shapes and intricate material distributions. Although thermoforming can extend production time and equipment investment, advanced modeling ensures premium quality for high-end paddle lines. Thermoforming4

To help you understand the distinct advantages of digital twin technology, consider the following table that highlights key performance metrics between traditional simulation methods and digital twin integration:

| Aspect | Traditional Simulation | Digital Twin Technology |

|---|---|---|

| Data Update Frequency | Static or periodic snapshots | Continuous real-time updates |

| Predictive Accuracy | Limited to pre-defined scenarios | Dynamic response to variables |

| Design Validation Time | Lengthy iterative cycles | Rapid adjustments and fast feedback |

| Production Process Integration | Siloed from live production | Integrated with real-time quality control |

| Customization Flexibility | Less adaptive to changes | High adaptability to design specifications |

This table underlines that digital twin applications drastically improve the accuracy of design validation and the speed at which prototypes can evolve into full-scale production, reducing both cost and risk while ensuring a superior final product.

A sports equipment manufacturer utilizing digital twins saw a significant reduction in production defects. By simulating the performance of paddles built with a Nomex Honeycomb Core5 and integrating real-time feedback on vibration dampening, they optimized the weight distribution and control feedback. This approach reduced material wastage and shortened the design cycle by 30%.

The case study revealed:

- Early detection of structural issues through real-time simulation feedback.

- Enhanced design iterations enabled by precise digital models.

- Better alignment with customer expectations, particularly in custom paddle orders.

These results not only improved the product’s performance but also increased market competitiveness, especially when catering to professional athletes.

For companies considering the integration of digital twin technology into their manufacturing process, here’s a step-by-step guide:

-

Assessment of Current Processes:

Begin by mapping out existing simulation methods and production workflows. Identify areas where real-time data integration could provide the most benefit. -

Technology Selection:

Choose reliable digital twin platforms that support the specific manufacturing requirements of pickleball paddles. Ensure compatibility with materials like 12K Carbon Fiber and specialized composites. -

Data Infrastructure Setup:

Invest in advanced sensors and IoT devices to capture live production data. Proper data management is crucial for a successful digital twin ecosystem. -

Implementation and Testing:

Pilot the digital twin integration on a limited production line. Use the pilot phase to fine-tune simulation models and validate predictions against actual performance results. -

Scaling and Continuous Improvement:

Once the pilot shows promising results, scale the technology to all production lines. Continuously monitor, collect, and analyze data for sustained productivity gains and quality improvements.

A checklist for implementing digital twin integration:

| Step | Key Considerations |

|---|---|

| Process Mapping | Identify simulation gaps in current production workflows |

| Technology Integration | Ensure systems support real-time data analytics and model accuracy |

| Pilot Testing | Validate model predictions with live testing outcomes |

| System Scaling | Develop a roadmap for phased roll-out across production lines |

| Continuous Monitoring | Establish KPIs for quality control and performance improvement |

Digital twin technology represents a key step forward in modernizing the manufacturing process for high-performance pickleball paddles. By leveraging real-time data and dynamic simulation models, companies can enhance design accuracy, streamline production, and reduce operational costs. This integration not only addresses longstanding manufacturing challenges but also paves the way for innovative product developments—ensuring a competitive edge in the sports equipment market.

For technical product development managers focused on R&D innovation and process optimization, adopting digital twin technology is a strategic decision that brings together advanced materials like carbon fiber, fiberglass, and composite matrices with efficient production processes. The move toward digital twin integration ultimately supports improved product performance, lower defect rates, and faster time-to-market.

As the industry evolves, the combination of digital twin insights with established simulation and manufacturing processes will continue to redefine product development. Companies ready to embrace these new technologies will find themselves at the forefront of innovation, meeting the rigorous demands of modern athletes and recreational players alike.

The journey toward a digitalized, optimized production process begins with taking actionable steps—assessing current workflows, investing in robust digital platforms, and continuously iterating based on real-world performance feedback. For those ready to transform their manufacturing processes, now is the time to explore digital twin technology and unlock the next generation of pickleball paddle excellence.

Q1: How does digital twin technology improve pickleball paddle manufacturing?

A1: Digital twin technology improves manufacturing by creating a real-time virtual replica of the paddle production process, allowing for immediate adjustments and validations of design and material behavior, which enhances performance and reduces production defects.

Q2: What are the core benefits of using digital twins over traditional simulation methods?

A2: Digital twins offer continuous real-time data updates, higher predictive accuracy, faster design validation cycles, and seamless integration with actual manufacturing processes, leading to improved product quality and reduced development time.

Q3: What are the key production processes evaluated using digital twin simulations in paddle design?

A3: Digital twin simulations are used to evaluate key production processes such as hot pressing, cold pressing, and thermoforming, ensuring that each method meets the desired strength, durability, and control requirements in paddle production.

-

Digital twin technology: Click here to learn how digital twin technology creates virtual replicas of physical products, enabling real-time monitoring and simulation to optimize performance and maintenance in manufacturing environments. ^Return ↩

-

Carbon fiber: Click here to explore the properties and applications of carbon fiber, a high-strength, lightweight material commonly used in advanced manufacturing and composite construction. ^Return ↩

-

Hot pressing: Click here to understand the hot pressing process, a technique that uses heat and pressure to cure composite materials, enhance bonding, and achieve desired material properties in manufacturing. ^Return ↩

-

Thermoforming: Click here to delve into thermoforming, a manufacturing process where plastic sheets are heated to form specific shapes, ideal for complex designs and precision production in industrial applications. ^Return ↩

-

Nomex Honeycomb Core: Click here to discover the benefits of the Nomex honeycomb core, a lightweight and high-strength material used in composite structures, enhancing performance and impact resistance in advanced sports equipment. ^Return ↩